Grinding device

A technology for grinding devices and grinding bodies, which is applied in the direction of grinding devices, grinding machine tools, and devices for fixing grinding wheels, etc., which can solve the problems of reduced replacement operation efficiency, great time and labor consumption, and small frictional resistance, so as to shorten maintenance time, Ease of replacement and excellent practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

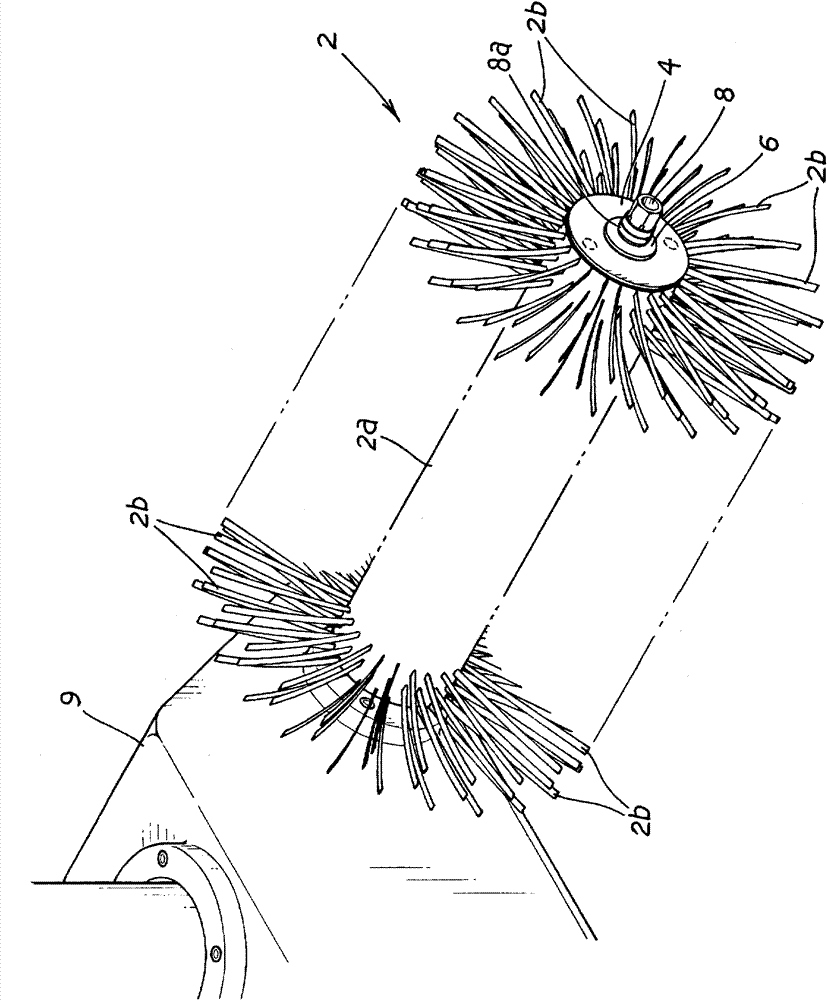

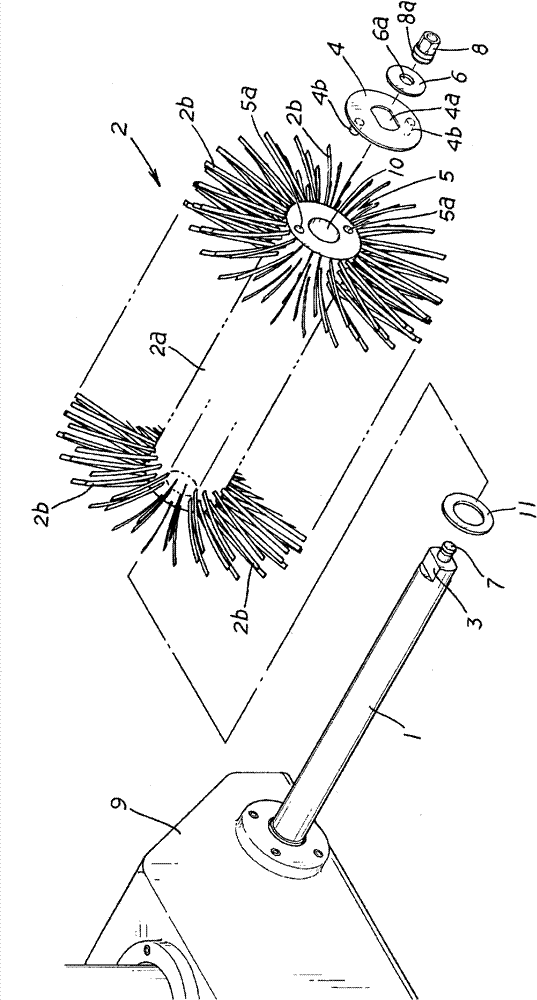

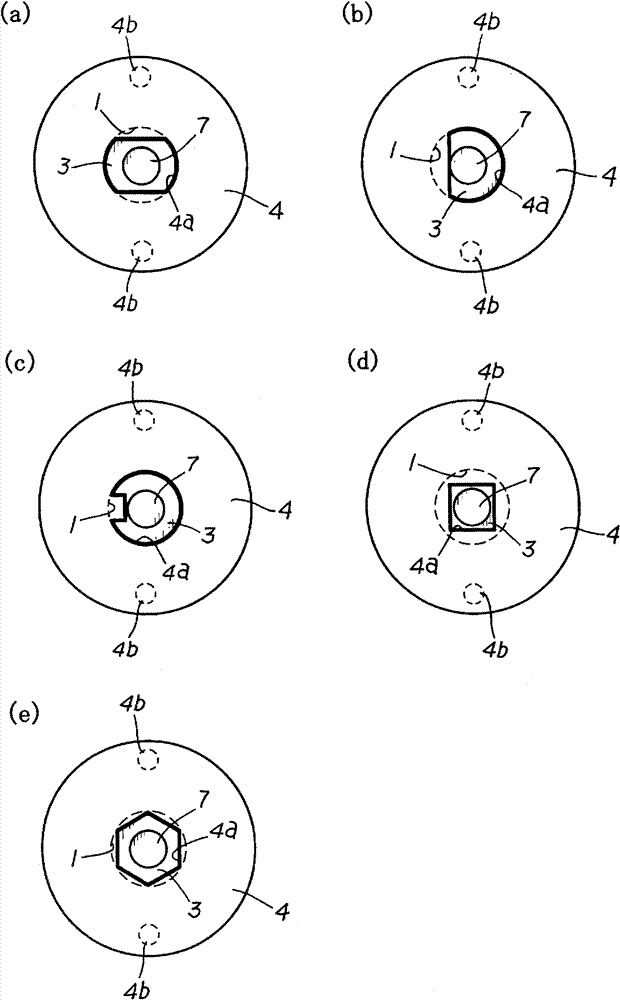

[0036] The action of the present invention is shown based on the drawings, and preferred embodiments of the present invention will be briefly described.

[0037] In the present invention, the anti-rotation fitting part 4 is anti-rotation fitting with the grinding body side fitting part 5 provided on the rotating grinding body 2. On the anti-rotation part 3 that is provided with, therefore do not constitute the structure that the rotating grinding body 2 itself is directly anti-rotation relative to the rotation shaft 1, but is indirectly arranged on the rotation shaft 1 in an anti-rotation state, which can be extremely simple The structure reliably sets the rotating grinding body 2 in a state of being locked relative to the rotating shaft 1 .

[0038] That is, in the case of a structure in which the rotating shaft 1 and the rotating grinding body 2 are directly locked, it is necessary to integrally form the rotating shaft 1 and the rotating grinding body 2, or to make the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com