Filter mounting structure of glass panel transferring device

A flat glass and conveying device technology, which is applied in the direction of glass transportation equipment, glass manufacturing equipment, conveyor objects, etc., can solve the problems of inconvenient operation and shorten the time, and achieve the effect of easy setting and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings.

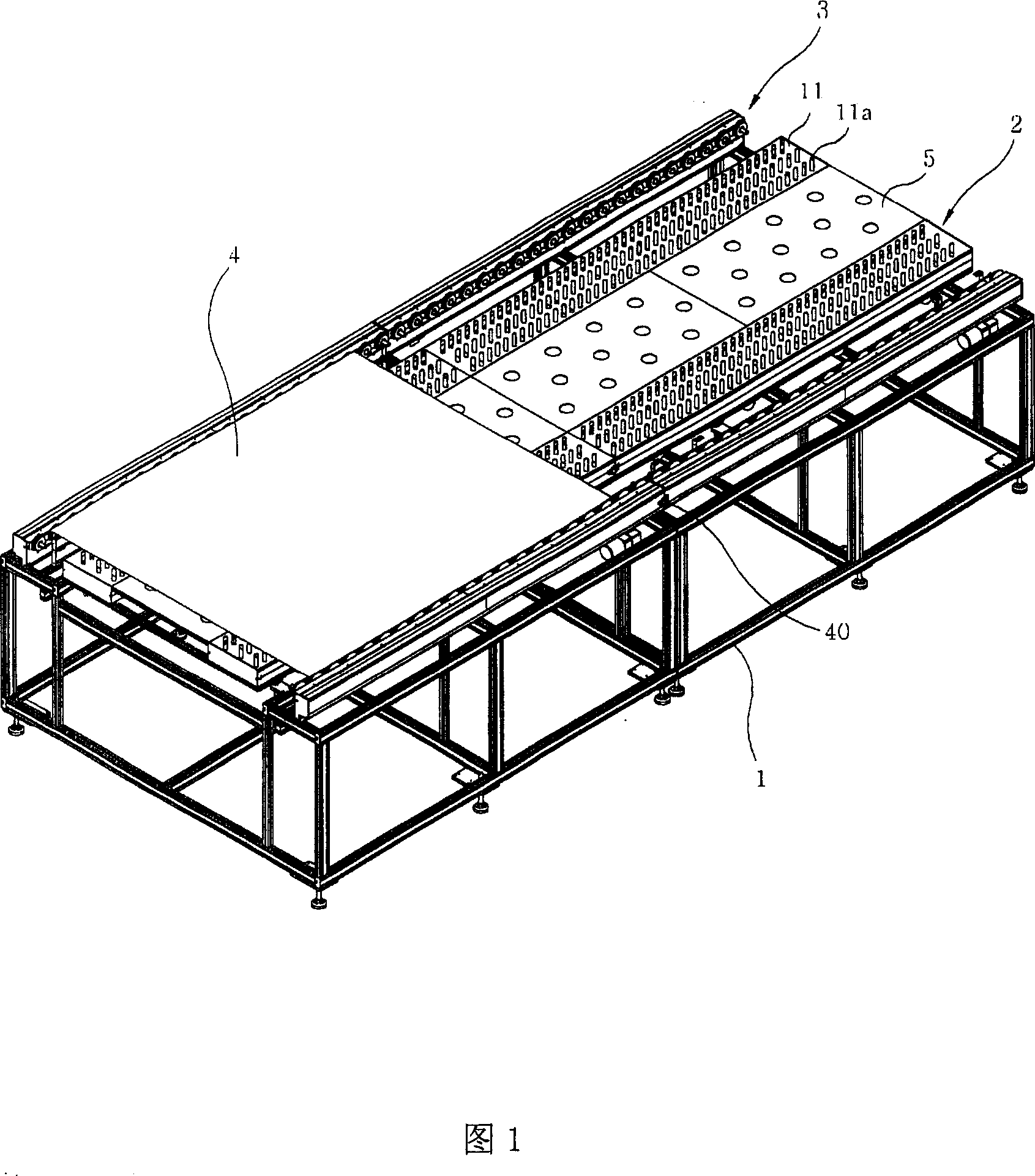

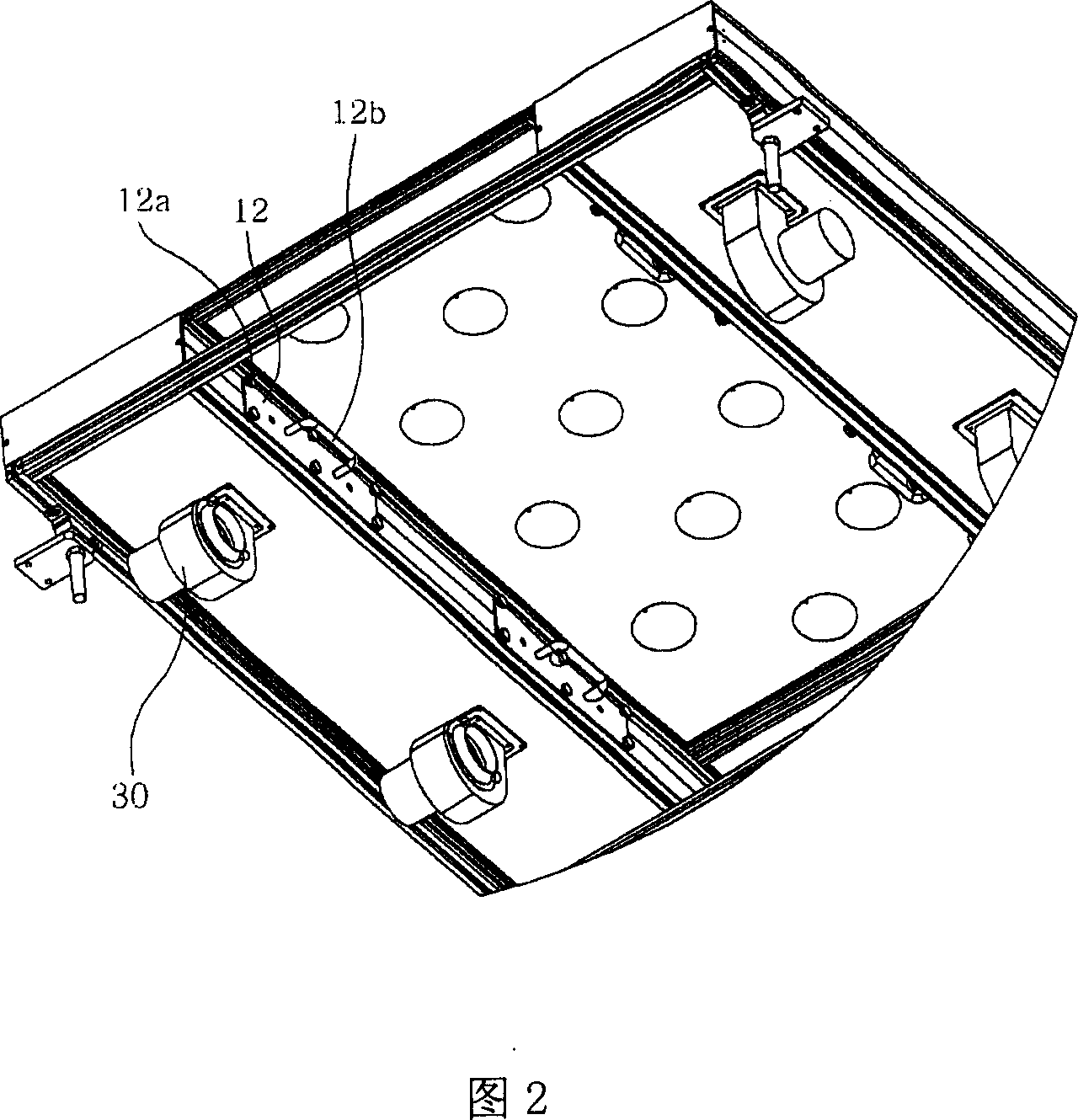

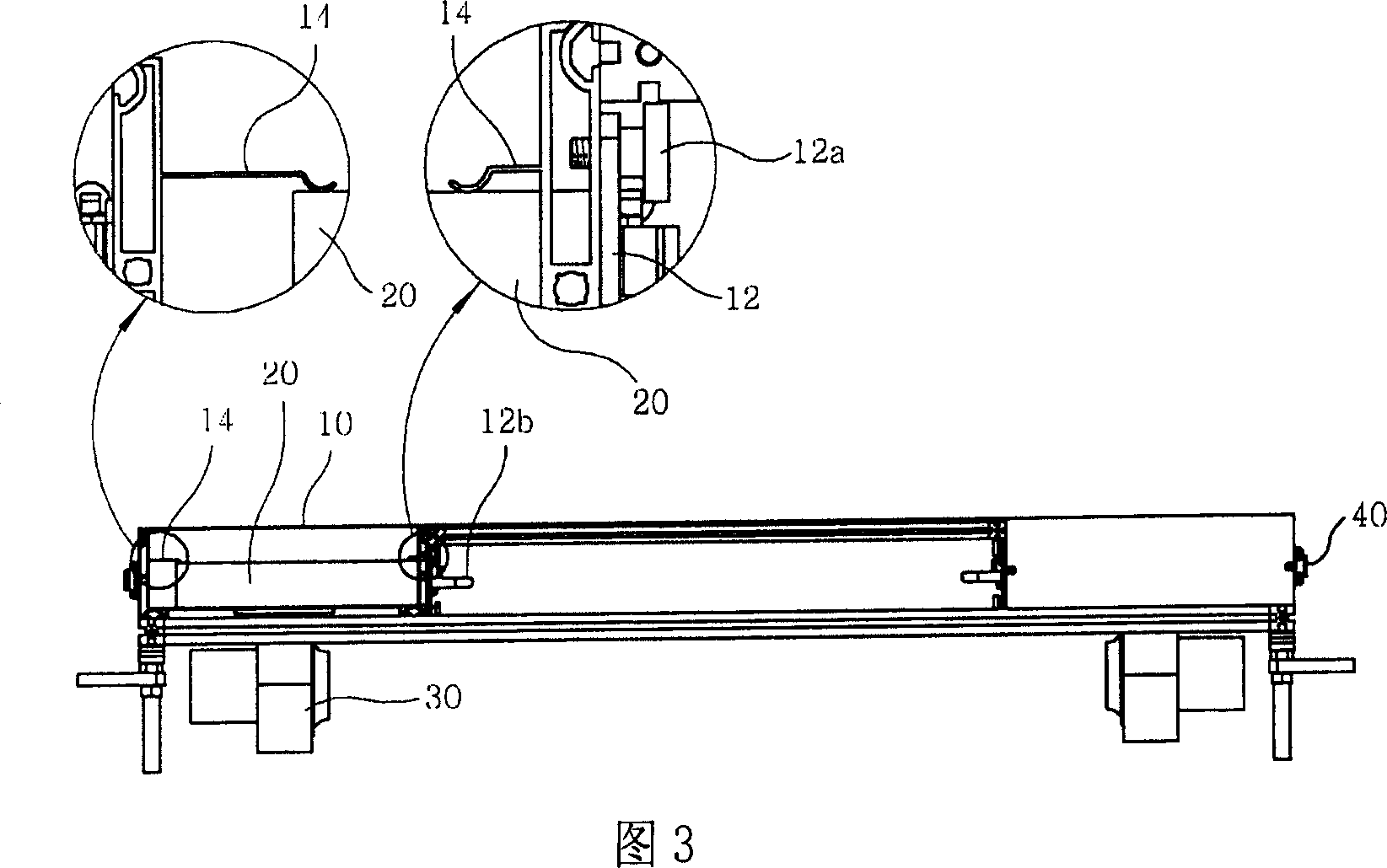

[0022] FIG. 1 is a schematic perspective view showing an example of a plate glass conveying device to which a filter installation structure according to an embodiment of the present invention is applied, and FIG. 2 shows a partial outline of the plate glass conveying device in FIG. 1 , to which a filter is installed. Fig. 3 is a front view showing a state in which a filter installation structure is applied by cutting away part of the plate glass conveying device in Fig. 1 .

[0023] The plate glass conveying device applicable to the filter setting structure according to the embodiment of the present invention includes: an air flotation device 2 arranged on the workbench 1; a conveyor 3 arranged on both sides of the above-mentioned air flotation device in the width direction, And the flat glass 4 conveyed on the upper part of the air flotation device is convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com