Rotary disc type switching tool magazine of horizontal combined machining center

A compound machining center and machining center technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of troublesome position adjustment, low control precision, poor stability, etc., and achieve convenient job replacement and high control precision , Adjust the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

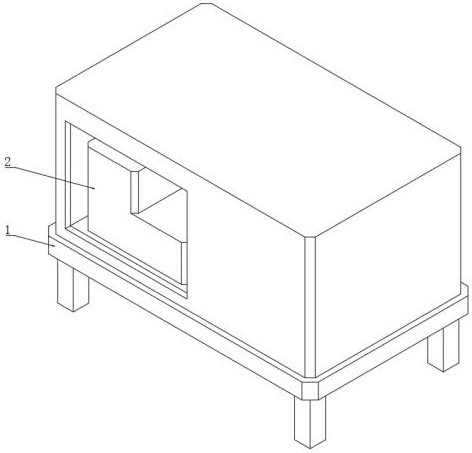

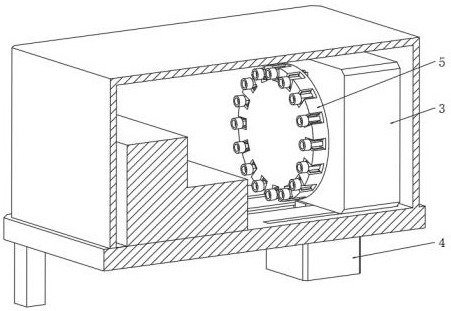

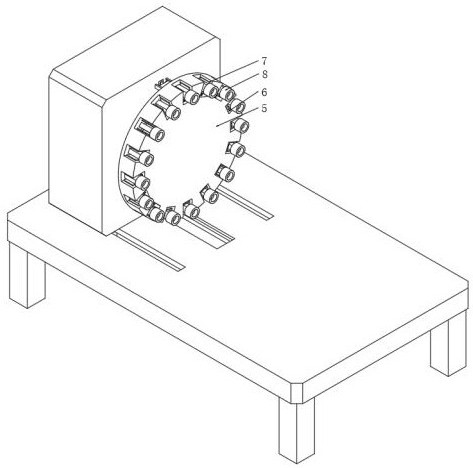

[0036] like Figure 1-15 As shown in the figure, a turntable switching tool magazine of a horizontal compound machining center includes a mounting base 1, a horizontal machining center body 2 is mounted on the upper surface of the mounting base 1, and a second mounting base 1 is fixedly mounted on one side of the lower surface of the mounting base 1 Box 4, a rotation control mechanism 3 is installed on the inner side of the main body 2 of the horizontal machining center, and an annular rotating plate 5 is installed on one side of the rotating control mechanism 3, and a number of tool installation grooves 6 are evenly distributed on the surface of the annular rotating plate 5. , a limit mounting frame 7 is movably installed inside each tool mounting groove 6 , and a tool mounting frame 8 is movably installed in each limit mounting frame 7 .

[0037] In this embodiment, a sliding installation groove 101 is opened on one side of the upper surface of the installation base 1 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com