Construction process for replacement of large-tonnage bridge support

A technology of bridge bearings and construction techniques, applied in bridges, bridge parts, bridge maintenance, etc., can solve problems such as bearing capacity of temporary old bearings that have not been considered, and achieve the effect of solving construction problems and quickly replacing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will describe in detail with reference to the drawings in the embodiments of the present invention.

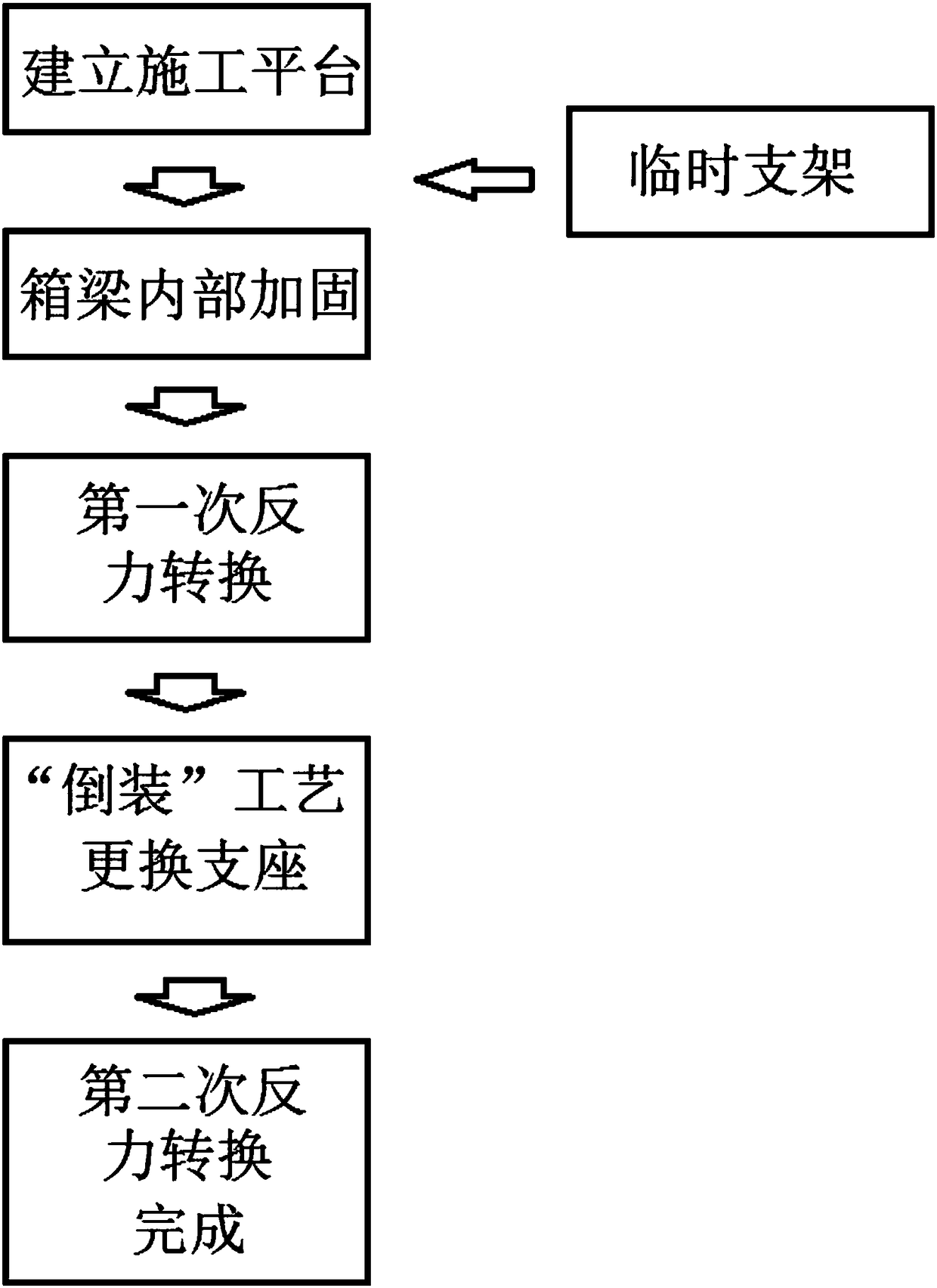

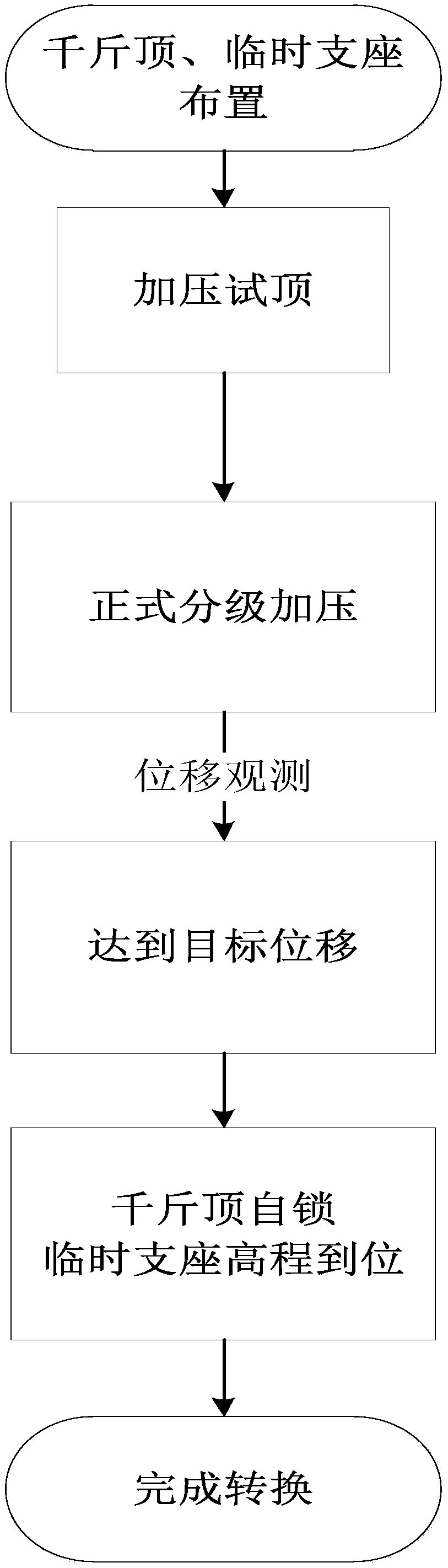

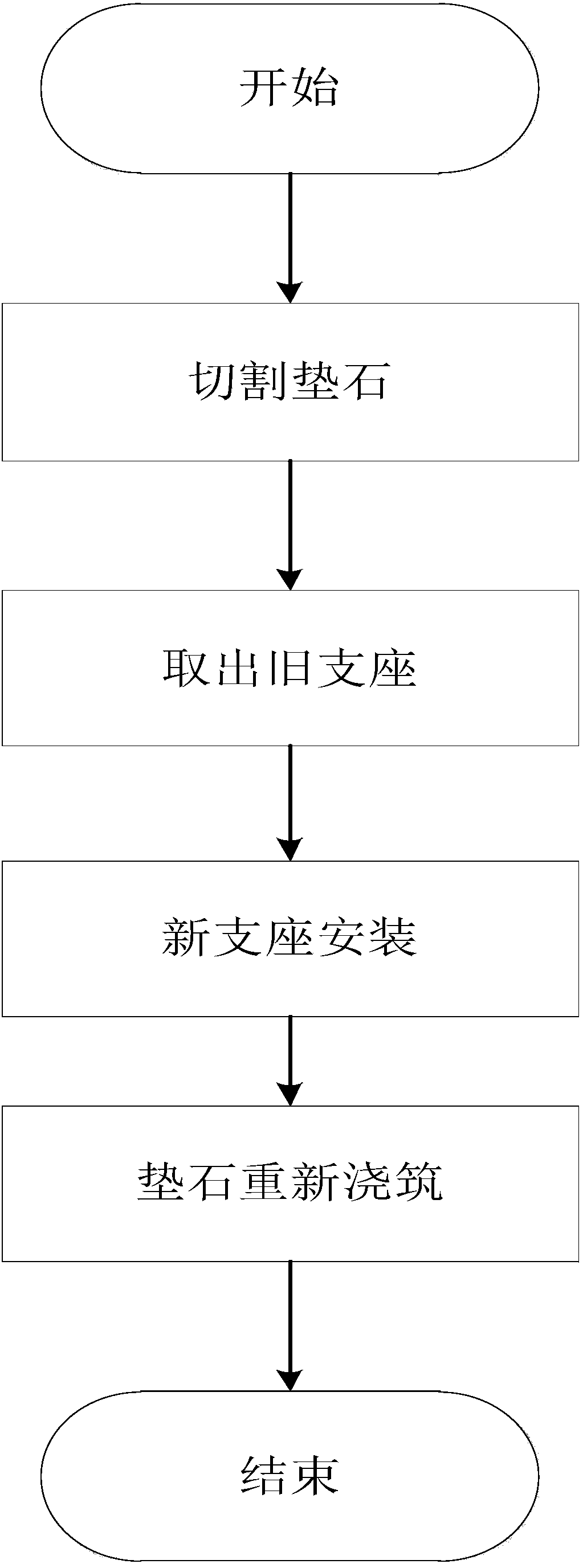

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , for the construction technology of large-tonnage bridge bearing replacement, the specific steps are as follows:

[0037] Build a construction platform 3 with sufficient strength, rigidity and stability, and bear vertical and horizontal thrust through scaffolding. The construction platform 3 has a construction load capacity of more than 20 tons and can withstand impact loads. The space between the construction platform 3 and the bottom of the box girder 1 is maintained at a height of 1.6m-2m to ensure the ease of operation for construction personnel. The construction platform 3 includes a translation track 4 arranged above, and the translation track 4 is flush with the bottom surface of the old support 2 of the box girder 1 .

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com