Car body installation device

A mounting device, the technology of the side mounting part of the body, applied in the connection between the body and the frame, vehicle parts, transportation and packaging, etc., can solve the problem of increasing the number of parts, achieve the reduction of the number of parts, efficient setting operations, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0029] Hereinafter, a vehicle body mounting device according to a first embodiment of the present invention will be described with reference to FIGS. 1 to 3 .

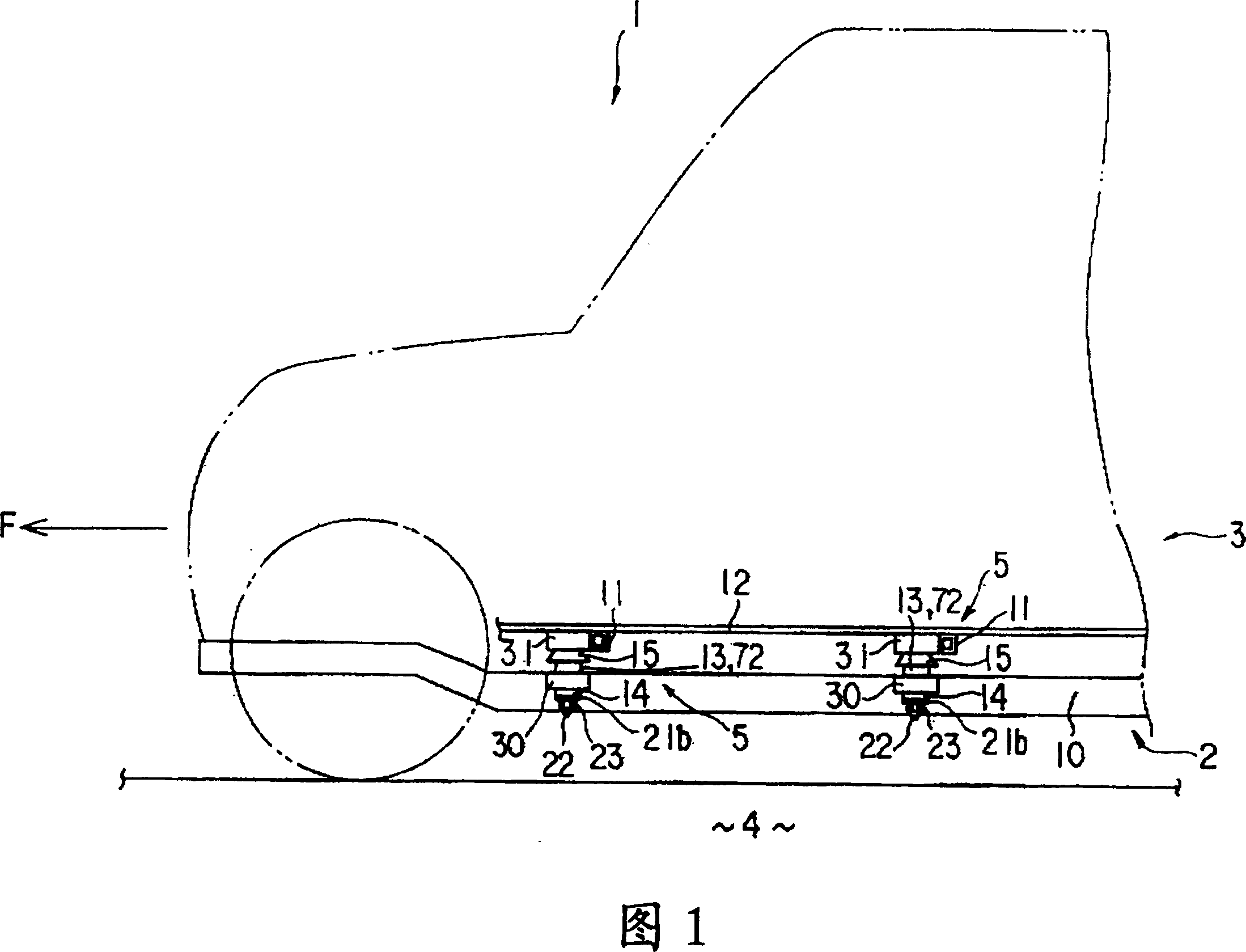

[0030] The body 1 of an automobile is provided with a chassis frame 2 and a vehicle body 3 respectively. As shown in FIG. Further, front, rear, left, and right are defined on the basis of the traveling direction F of the automobile, and up and down are defined with respect to the chassis frame 2 by taking the direction in which the vehicle body 3 is located as the upward direction. In addition, FIG. 1 shows the left sides of the chassis frame 2 and the vehicle body 3 .

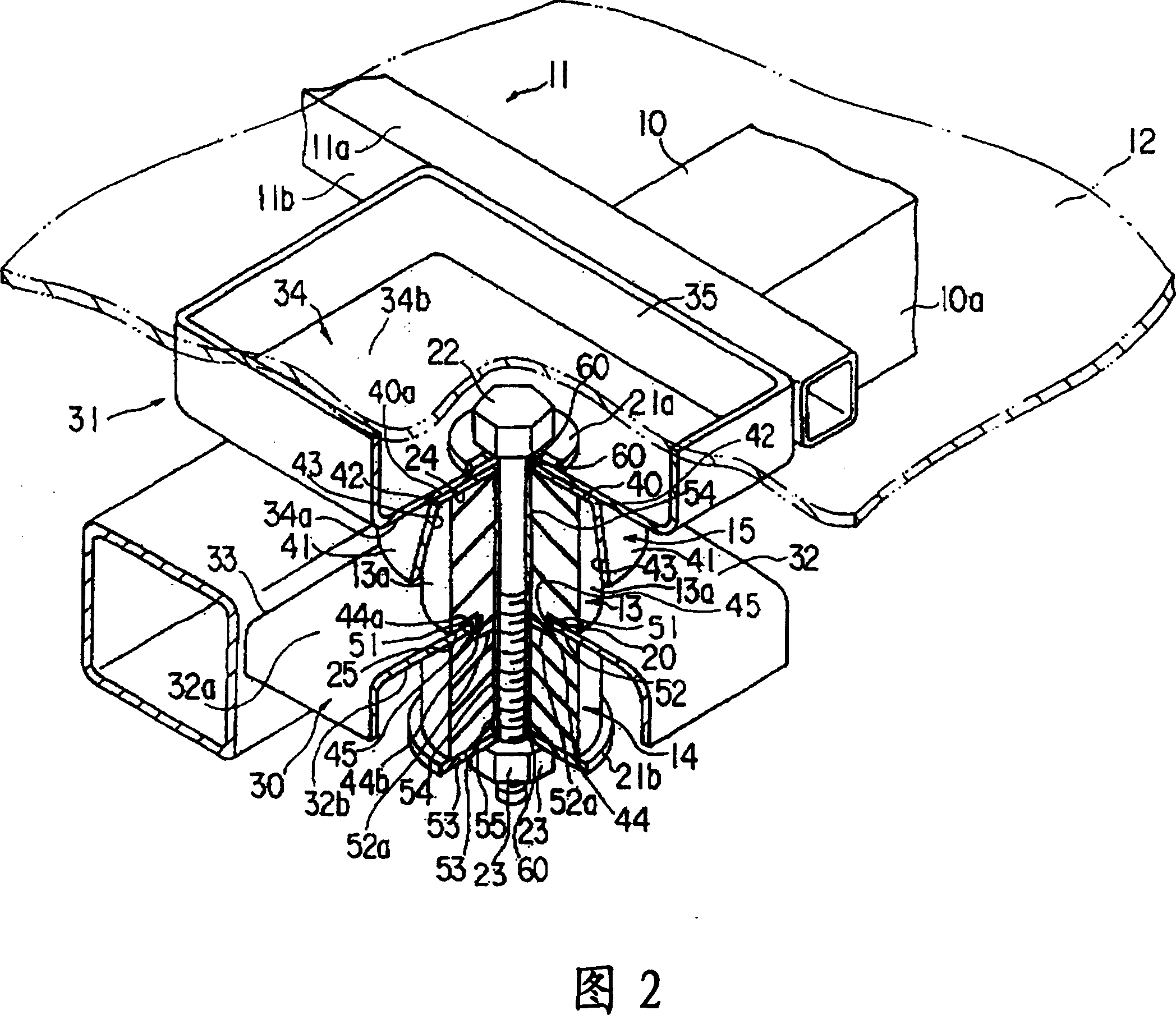

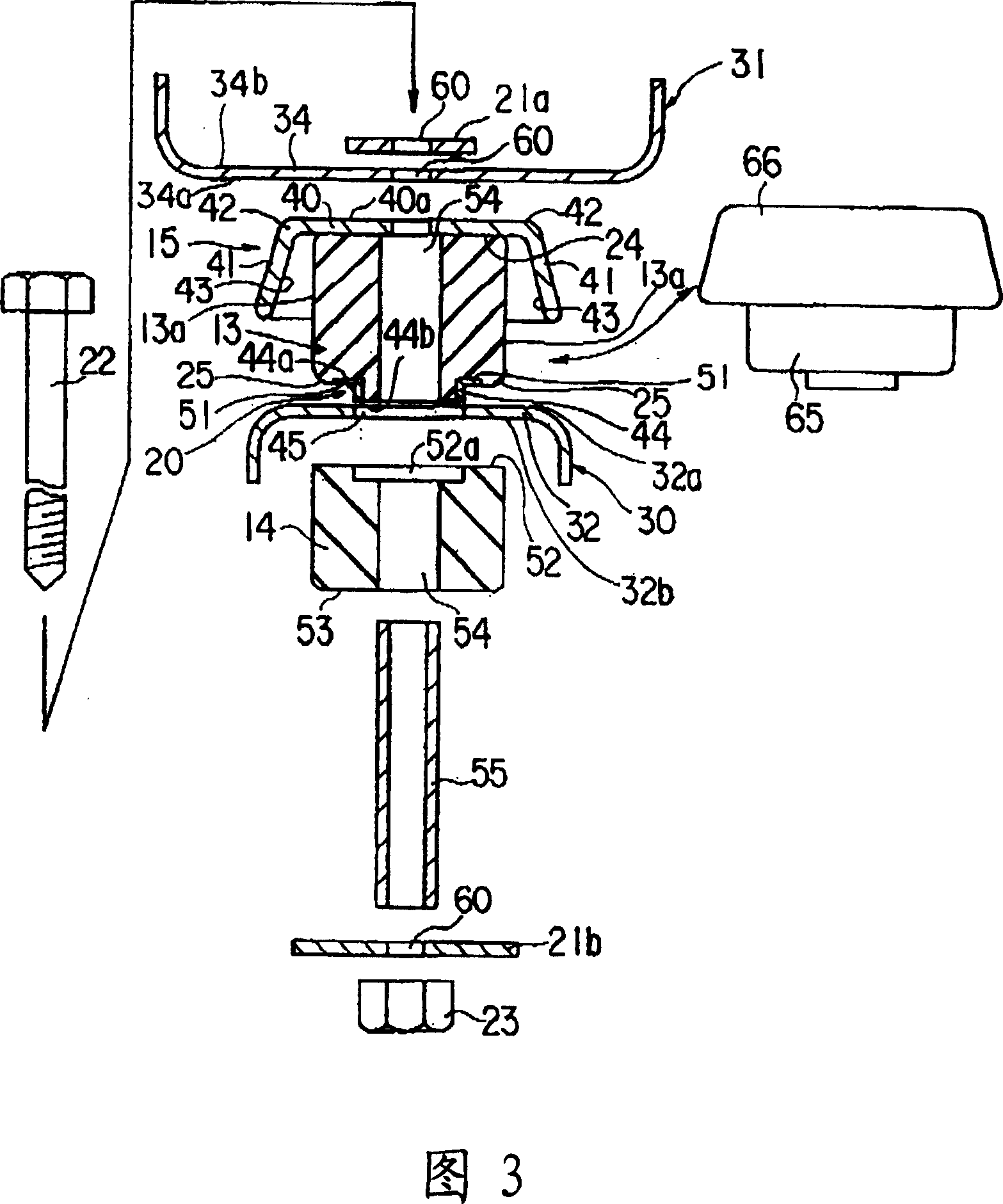

[0031] FIG. 2 shows a state in which a vehicle body 3 is fixed to a chassis frame 2 using a vehicle body mounting device 5 on the left side of the vehicle body 1 . The chassis frame 2 has side members 10 with a rectangular closed section extending in the front-rear direction. The vehicle body 3 has: a beam 11 extending in the left-right direction wit...

no. 2 approach

[0063] A second embodiment will be described with reference to FIG. 4 . The second embodiment does not use the body-side elastic body 13 described in the first embodiment, but uses a body-side elastic body 72 composed of a main body portion 70 and an extension portion 71 .

[0064] The main body portion 70 has, for example, a cylindrical shape, and its upper surface 73 is integrally fixed to the base portion 40 of the protective member 15 . The extension portion 71 extends from the outer peripheral edge 74 of the upper surface 73 of the main body portion 70 along the inner surface 43 of the receiving portion 41 away from the outer surface 75 of the main body portion 70 to cover the front edge 80 of the receiving portion 41 .

[0065] The body side elastic body 72 is formed integrally by vulcanization molding using rubber, for example, as in the first embodiment. In addition, the body side elastic body 72 is installed between the chassis bracket 30 and the body bracket 31 like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com