Desulfurization, denitration and dust removal integrated equipment for industrial waste gas

A technology for desulfurization, denitrification, and industrial waste gas, which is applied in gas treatment, chemical instruments and methods, and the use of liquid separation agents. loss, the effect of ensuring filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

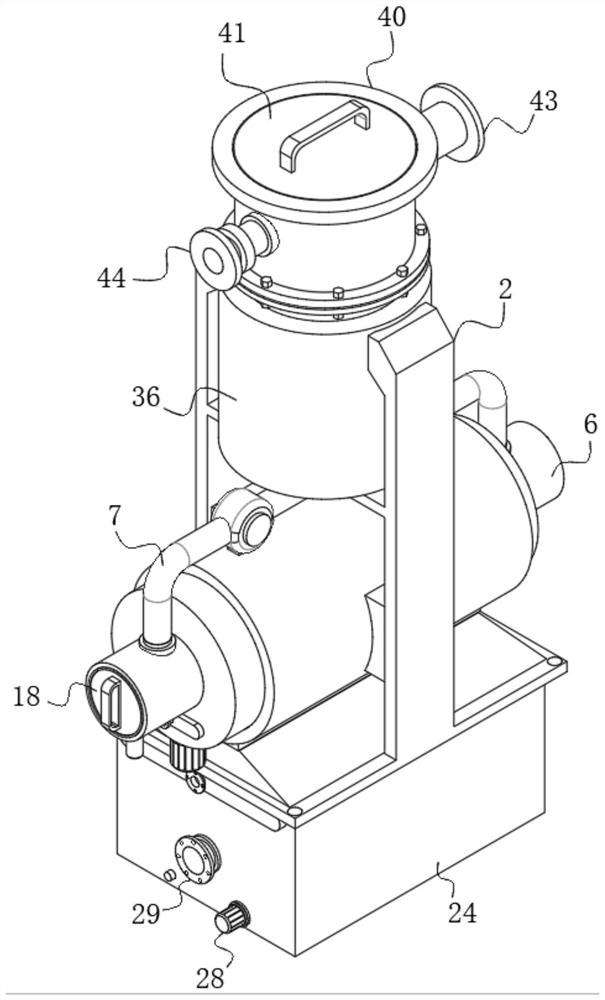

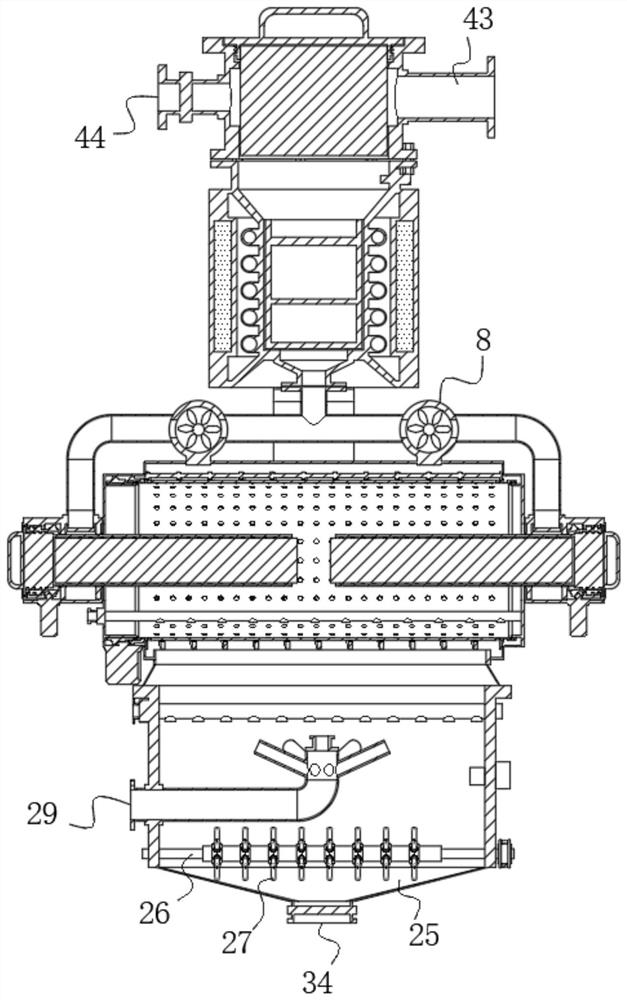

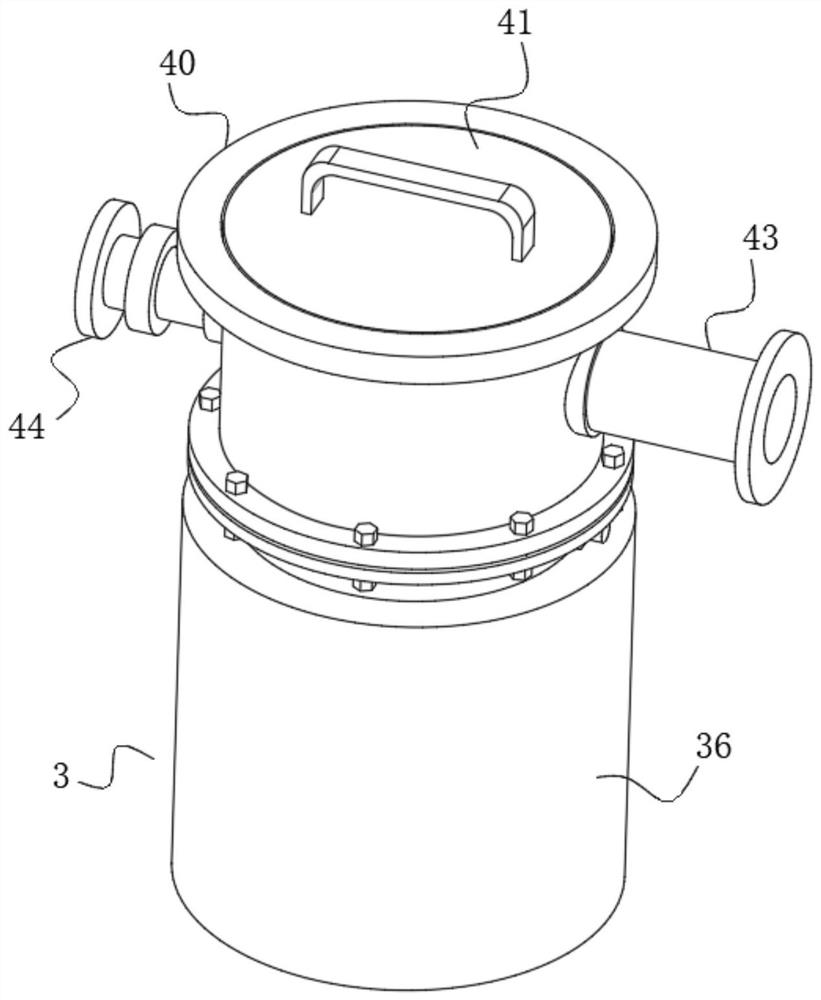

[0032] Such as Figure 1 to Figure 11 As shown, an integrated equipment for desulfurization, denitrification and dust removal of industrial waste gas includes an air intake mechanism 1, a filter mechanism 4 and an exhaust mechanism 3 arranged sequentially from bottom to top. The air intake mechanism 1 includes a water storage tank 24 and The air intake device and spray device in 24, the spray device is located above the air intake device; the filter mechanism 4 includes a filter housing 5, an air extraction device installed on the filter housing 5, and an air pump installed in the filter housing 5 Primary filtering device and secondary filtering device, filter housing 5 is installed on the top of water storage tank 24, and communicates with water storage tank 24, secondary filtering device is installed in the inside of primary filtering device, air extractor and secondary filtering device connection; the exhaust mechanism 3 is installed on the top of the filter mechanism 4, an...

Embodiment 2

[0055] On the basis of the first embodiment above, as figure 2 , Figure 8 and Figure 9 As shown, the packing assembly 9 is a rotating assembly, and the uniform loss of the filter element 20 can be realized by rotating the filter element 20, so as to prolong the service life, improve the utilization rate of the filter element 20, and facilitate the replacement of the filter element 20 at the same time.

[0056] The packing assembly 9 includes a cylinder rotary seat 17, a cylinder cover plate 18, a purification cylinder 19, and a filter element 20; the cylinder rotary seat 17 is installed on the end of the filter gas exhaust cylinder 6 through a bearing, and is located on one side of the through hole; The cylinder cover plate 18, the exhaust cylinder cover plate 18 is installed on the exhaust cylinder rotary seat 17 by threads; the purification cylinder 19, the purification cylinder 19 is provided with several air holes 22, and the purification cylinder 19 is fixed on the ex...

Embodiment 3

[0060] On the basis of any of the above-mentioned embodiments, such as Figure 1 to Figure 4 As shown, a return air device is also included, and the return air device includes a return air pipe 44, a return air valve and an air intake valve, and the return air pipe 44 is fixed on the air outlet tube 40, and is communicated with the waste gas inlet pipe 29 of the air intake device; The return air valve is installed on the return air pipe 44 for controlling the switch of the return air pipe 44 ; the air outlet valve is installed on the clean air exhaust pipe 43 for controlling the switch of the clean air exhaust pipe 43 .

[0061] In normal mode, the air outlet valve is open, the clean air exhaust pipe 43 is open, the return air valve is closed, and the return air pipe 44 is in a closed state. When repeated filtration is required, the air outlet valve is closed, the clean air exhaust pipe 43 is closed, and the return air valve is opened , the air return pipe 44 is opened, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com