Outer wall thermal insulation decoration integrated quick-equipping plate

A technology for external wall insulation and thermal insulation boards, which is applied in the direction of covering/lining, construction, building construction, etc. It can solve the problems of affecting the adhesion force, long interval time, affecting the adhesion of the board and the wall, and achieves wind pressure resistance. Improvement, no cold and heat bridges, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

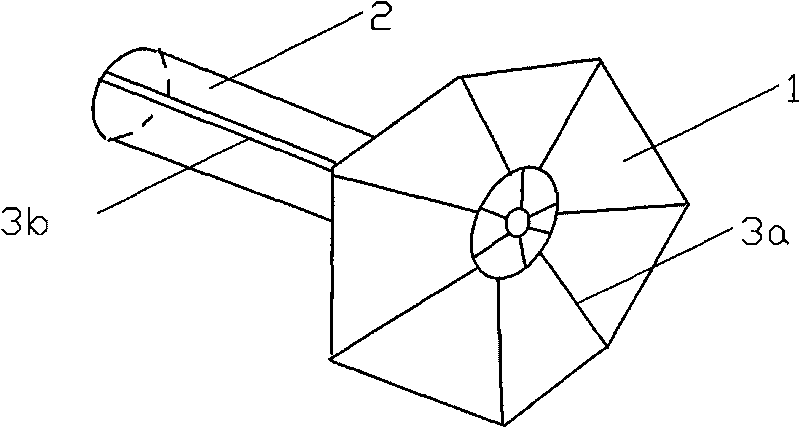

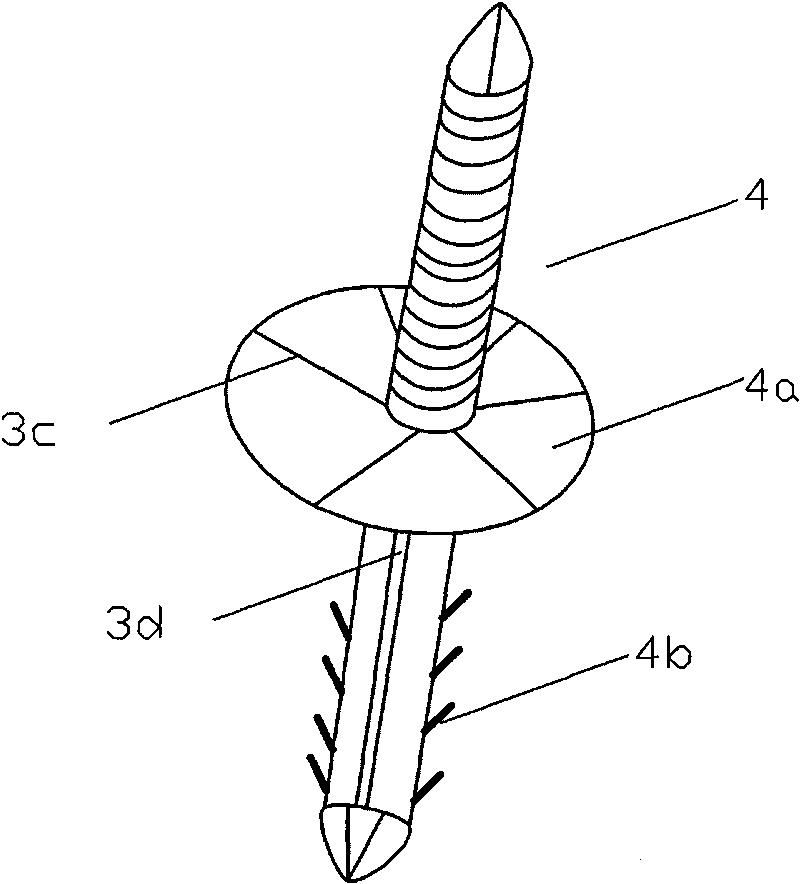

[0024] Example 1: see figure 1 , figure 2 , the invisible anchor bolt of the exterior wall thermal insulation decorative panel of the present embodiment is made of the inner pressure sheet 1 with the cylindrical presser foot and the fastener 4 embedded in the thermal insulation board 7, (the thermal insulation board 7 adopts conventional expanded polystyrene Foam board (EPS board or extruded polystyrene board (XPS board), presser foot 2 and inner pressure sheet 1 are integral components. In order to enhance its hardness, the surface of the inner pressure sheet is provided with reinforcing ribs 3a along the radial direction. The outer wall of the foot is also provided with axial reinforcing ribs 3b, and the presser foot and the fastener are connected by threads, and the connection method is that the presser foot is an internal thread, and the end connected to the presser foot on the fastener is an external thread; or the presser foot It is an external thread, and the end conn...

Embodiment 2

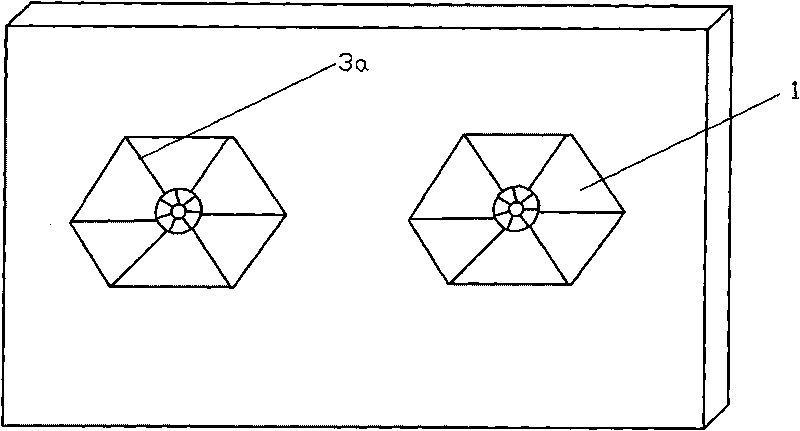

[0025] Example 2: see Figure 1-Figure 6 , the integrated quick-release board for exterior wall insulation and decoration in this embodiment includes the insulation board 7 whose inner surface is attached to the wall 5, and the interface agent layer attached to the outer surface of the insulation board one by one, and the alkali-resistant fiber-breaking grid Cloth or steel mesh layer, anti-cracking plastering layer 9, facing layer 10, embedded in the insulation board is an inner pressure sheet with a cylindrical presser foot, and the presser foot is provided with a screw thread connected with a fastener outside the board. The fastener is generally cylindrical, one end is screwed to the presser foot, and the other end is inserted into the mounting hole of the wall. The waist of the fastener is provided with an outer pressure piece perpendicular to the body itself. The inner pressure sheet can be designed in any shape other than circle, such as triangle, quadrilateral, pentagon,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com