Mechanical spraying plastering construction method

A technology of mechanical spraying and construction methods, applied in chemical instruments and methods, cement mixing devices, clay preparation devices, etc., can solve problems such as cracking and hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0057] The invention proposes a construction method for mechanical spraying and plastering.

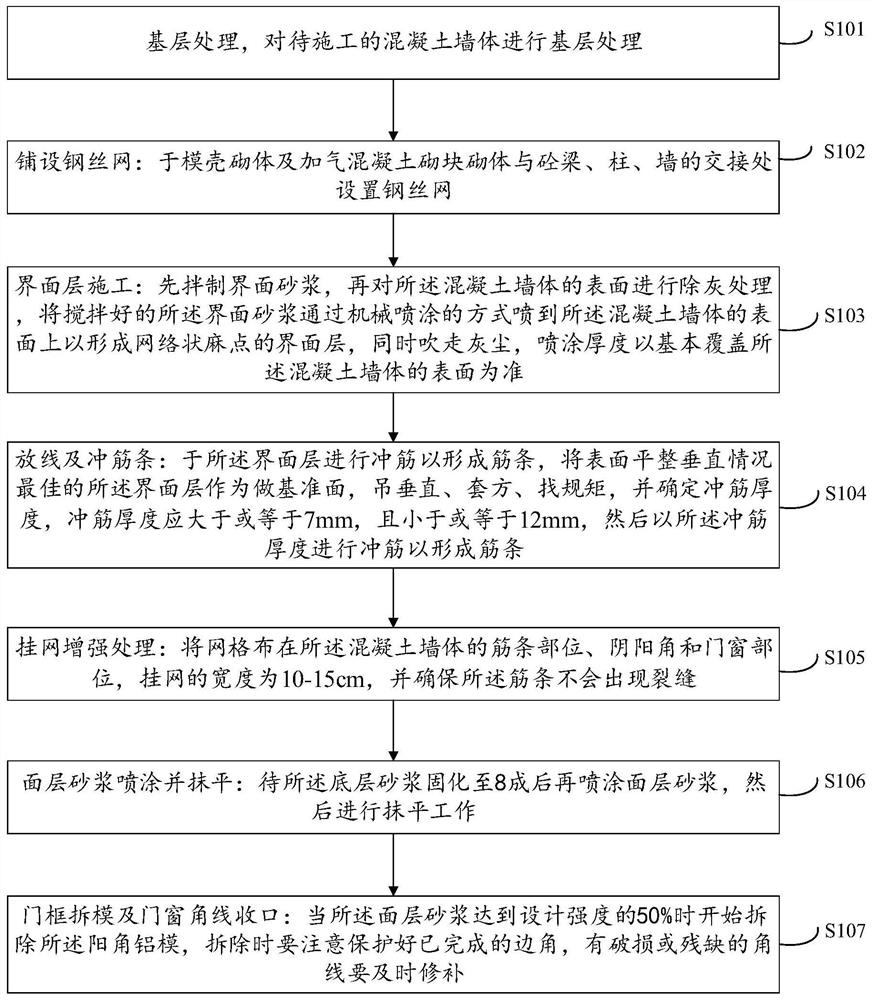

[0058] as attached figure 1 Shown, in the first embodiment that the present invention proposes a kind of mechanical spraying plaster construction method, this embodiment comprises the following steps:

[0059]Step S101: Base treatment: perform base treatment on the concrete wall to be constructed, specifically: remove protrusions, hollows and loose parts on the concrete wall to be constructed, and cover the screw holes on the concrete wall with polyurethane The styrofoam is sealed on both sides, so that the concrete wall is free from oil, dirt, soil and other attachments that hinder the bonding with the facing layer.

[0060] Step S102: Laying steel wire mesh: Install steel wire mesh at the joints of formwork masonry and ae...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com