Production method and application of pitchstone expansion vitrified micro-bead energy storage material

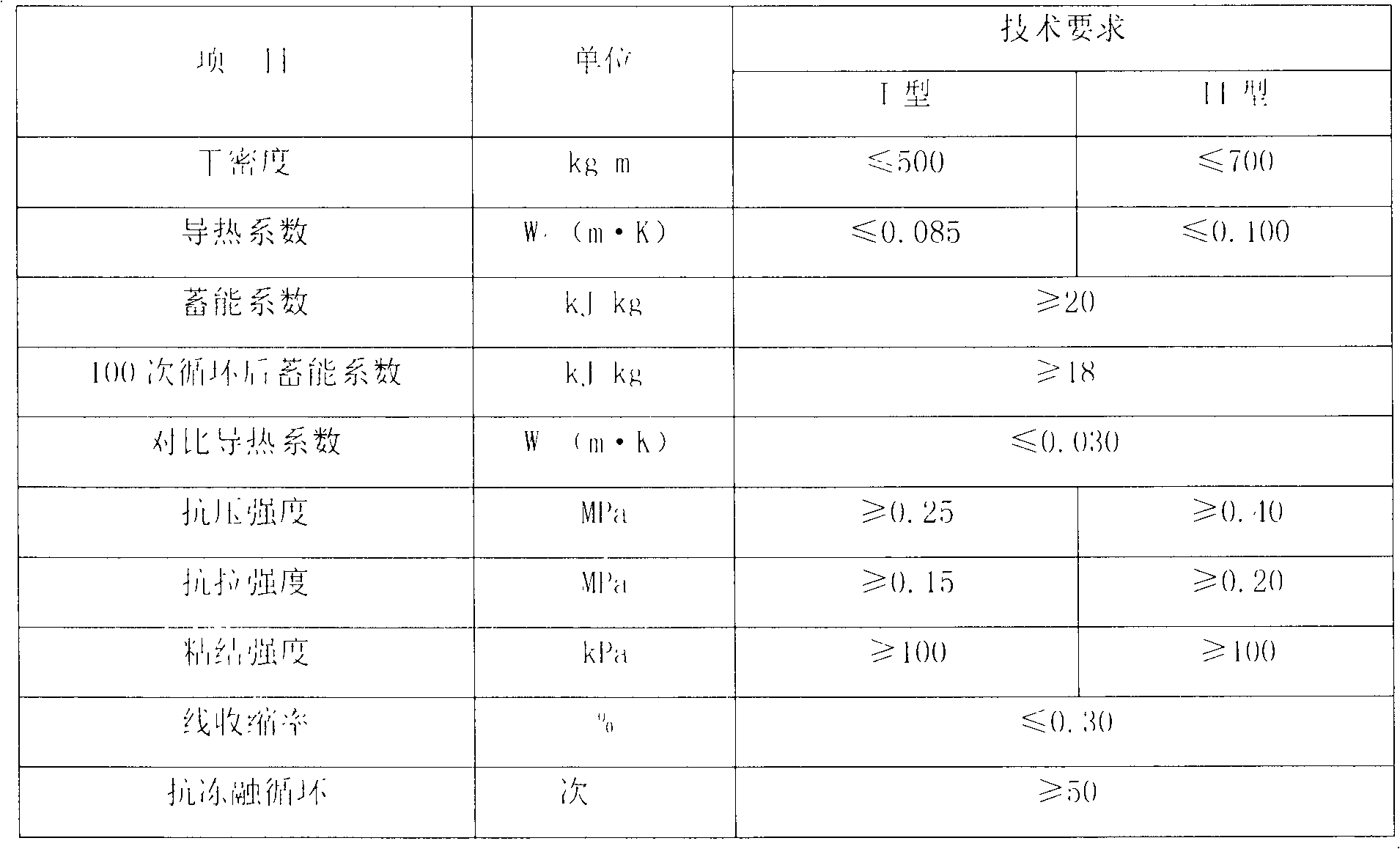

A technology of expanding vitrified microbeads and production methods, which is applied to building components and thermal insulation, can solve problems such as missed fire fighting opportunities, lack of durability of reinforced mesh, corrosion of glass fiber mesh cloth and steel wire mesh, etc., and achieves improved thermal insulation. Thermal and energy-saving effect, good thermal insulation and energy-saving effect, good effect of comfort and environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

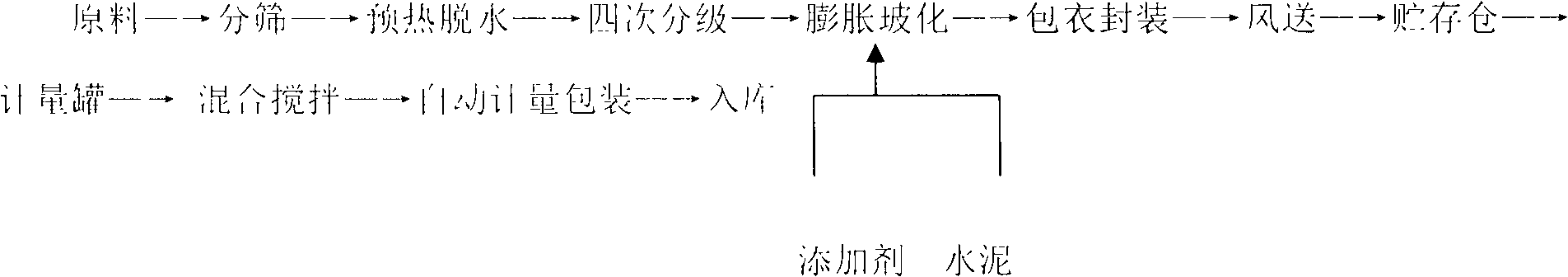

Method used

Image

Examples

Embodiment approach

[0073] (1) Apply turpentine expanded vitrified microbead energy storage material

[0074] 1. Mixing material: press turpentine swelling vitrified microsphere energy storage material

[0075] Dry-mixed mortar: water = 1:0.15 (mass), stir it evenly with a machine and wait for use.

[0076] 2. Apply in layers

[0077] ①The first layer is compacted and smoothed, thickness: inner wall 5mm, outer wall 11-22.5mm, and the surface is rough.

[0078] ②Apply a second time after the initial setting of the first layer, thickness: inner wall 5mm, outer wall 11~22.5mm, leveling treatment, smooth surface (paint decorative surface) or rough surface (tile decorative surface or dry row) .

[0079] 3. The technical essentials of applying turpentine expanded vitrified microsphere energy storage materials

[0080] ①Appropriate pressure should be used when applying to ensure effective bonding between layers.

[0081] ②The first application does not receive gloss to ensure that the surface is rough. The second a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com