Aerogel heat preservation and insulation system and construction process thereof

It is a technology of heat preservation and heat insulation and construction technology, which is applied in the direction of heat preservation, building components, coatings, etc. It can solve the problems of high labor intensity for operators, easy hollowing of the plastering layer, and heavy structure, etc., and achieves simple and easy operation in the construction process. Ensure thermal insulation performance and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

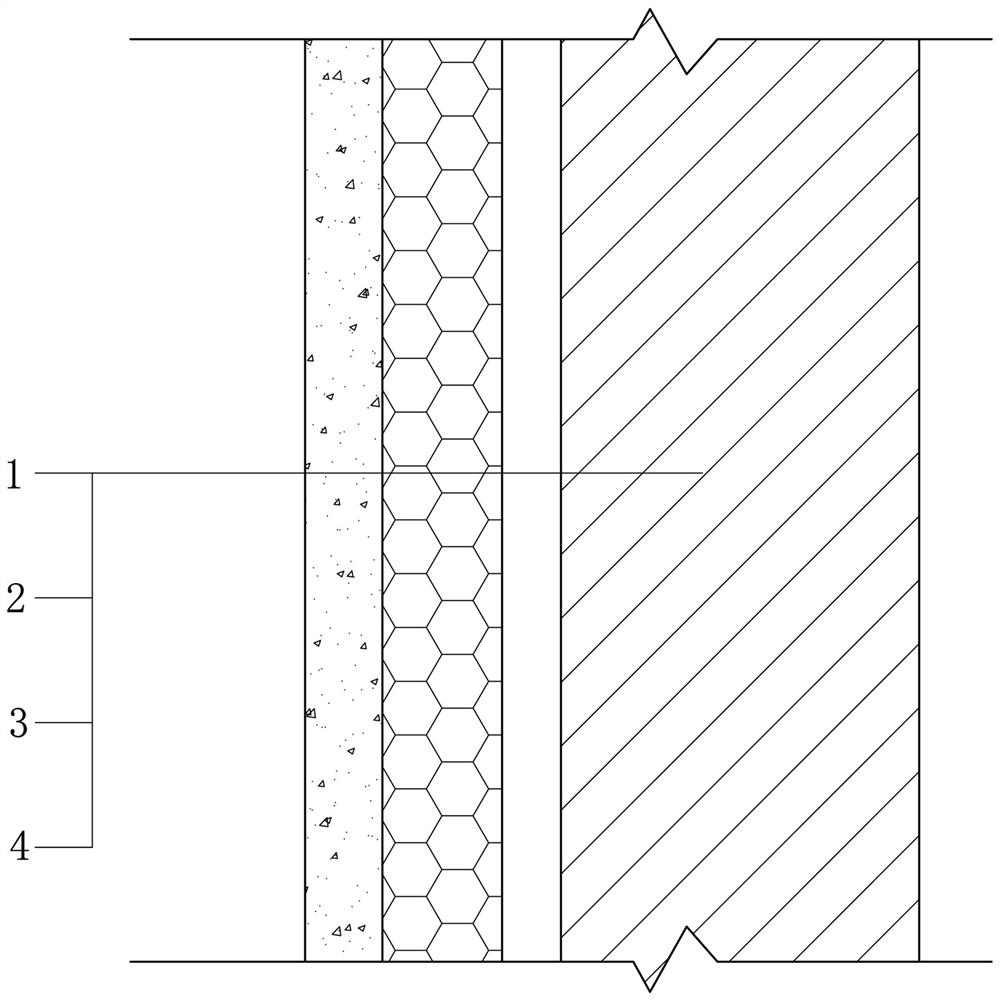

[0029] An airgel thermal insulation system, comprising a water-based multifunctional primer coating 2, an airgel thermal insulation middle coating 3, an airgel reflective thermal insulation surface coating 4, and a water-based multifunctional primer coating The coating used in layer 2 includes 30 parts of epoxy resin emulsion, 10 parts of additives, and 50 parts of deionized water; the coating used in airgel thermal insulation coating 3 includes 5 parts of resin emulsion, 35 parts of airgel slurry, hollow 5 parts of glass microspheres, 40 parts of deionized water; the paint used in the airgel reflective heat insulation surface coating 4 includes 10 parts of pure acrylic emulsion, 20 parts of airgel slurry, 20 parts of hollow glass microspheres, rutile titanium dioxide 5 parts, 40 parts of deionized water.

Embodiment 2

[0031] An airgel thermal insulation system, comprising a water-based multifunctional primer coating 2, an airgel thermal insulation middle coating 3, an airgel reflective thermal insulation surface coating 4, and a water-based multifunctional primer coating The coating used in layer 2 includes 40 parts of epoxy resin emulsion, 5 parts of additives, and 20 parts of deionized water; the coating used in airgel thermal insulation coating 3 includes 20 parts of resin emulsion, 40 parts of airgel slurry, hollow 12 parts of glass microspheres, 20 parts of deionized water; the paint used for airgel reflective heat insulation top coat 4 includes 5 parts of pure acrylic emulsion, 25 parts of airgel slurry, 12 parts of hollow glass microspheres, rutile titanium dioxide 10 parts, 30 parts of deionized water.

Embodiment 3

[0033] An airgel thermal insulation system, comprising a water-based multifunctional primer coating 2, an airgel thermal insulation middle coating 3, an airgel reflective thermal insulation surface coating 4, and a water-based multifunctional primer coating The coating used in layer 2 includes 35 parts of epoxy resin emulsion, 0.2 parts of additives, and 35 parts of deionized water; the coating used in airgel thermal insulation coating 3 includes 10 parts of resin emulsion, 30 parts of airgel slurry, hollow 20 parts of glass microspheres, 30 parts of deionized water; the paint used in airgel reflective heat insulation top coat 4 includes 7 parts of pure acrylic emulsion, 30 parts of airgel slurry, 5 parts of hollow glass microspheres, rutile titanium dioxide 7 parts, 20 parts of deionized water.

[0034] In actual application, after three layers of paint with the above-mentioned specific component formula are applied on the wall, the thermal insulation effect can meet the requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com