Carbon fiber composite material for new energy automobile chassis structure and battery pack tray

A technology for new energy vehicles and composite materials, applied in the field of carbon fiber composite materials, can solve problems such as inability to meet the requirements and the battery pack cover does not have thermal insulation, and achieve the effect of reducing the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

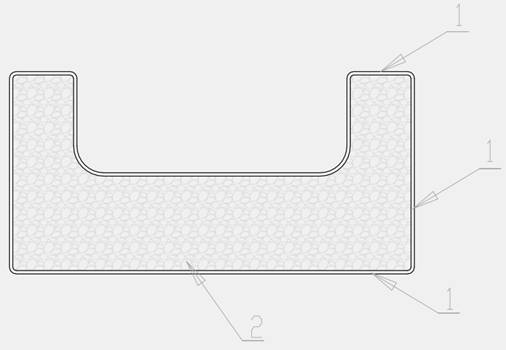

Image

Examples

preparation example Construction

[0036] The present invention also relates to a method for preparing the carbon fiber composite material, comprising the following steps:

[0037] (1) Preparation of carbon fiber and first resin material to obtain thermoplastic carbon fiber unidirectional tape;

[0038] In one embodiment of the present invention, in parts by weight, the carbon fiber is 50-65 parts, and the first resin material is 35-50 parts.

[0039] In one embodiment of the present invention, the first resin material is PET or PPO. The aforementioned resin material and the underlying inner core material are preferably the same material, which facilitates subsequent thermoforming. This step is carried out using a continuous compound press line.

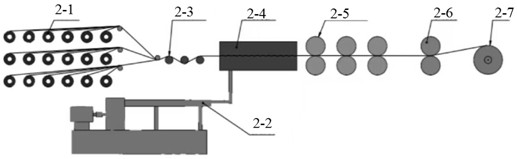

[0040] Such as figure 2 As shown, this process is carried out by the continuous compound press production line known in the art, and this production line comprises the yarn rack 2-1, extruder 2-2, yarn spreading device 2-3, dipping die head 2- 4. Cooling and sett...

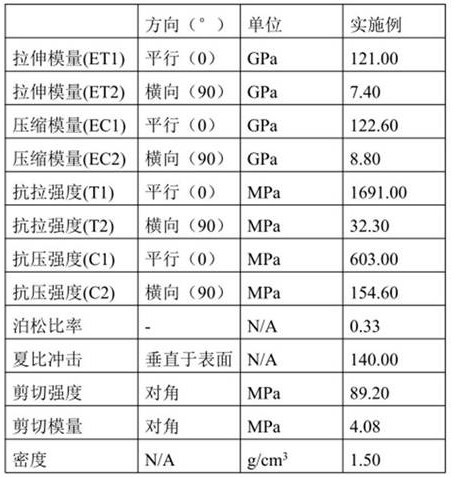

Embodiment 1

[0057] A carbon fiber composite material used for a chassis structure of a new energy vehicle and a battery pack tray, the preparation method of which comprises the following steps:

[0058] (1) A continuous composite press production line is used to prepare a thermoplastic carbon fiber unidirectional tape from carbon fiber and the first resin material PET, wherein the carbon fiber is 65 parts and the first resin material is 35 parts.

[0059] (2) Adding a chain extender to the second resin material PET for modification, the chain extender is 1,4-butanediol (BDO), and the added amount is 5% by mass of the second resin material. Then pelletizing and carbon dioxide supercritical physical foaming are carried out to obtain beads. EPET beads are added to the beads, the mass ratio of the second resin material to the EPET beads is 5:3, and a structural part of any shape is formed by a fully automatic molding machine to obtain the inner carbon fiber composite material. core. Compres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com