Air brick masonry device

A hollow brick and hole filling technology, which is applied in construction, building structure, and building material processing, can solve problems such as insufficient masonry mortar, and achieve the effects of reducing construction costs, facilitating production, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

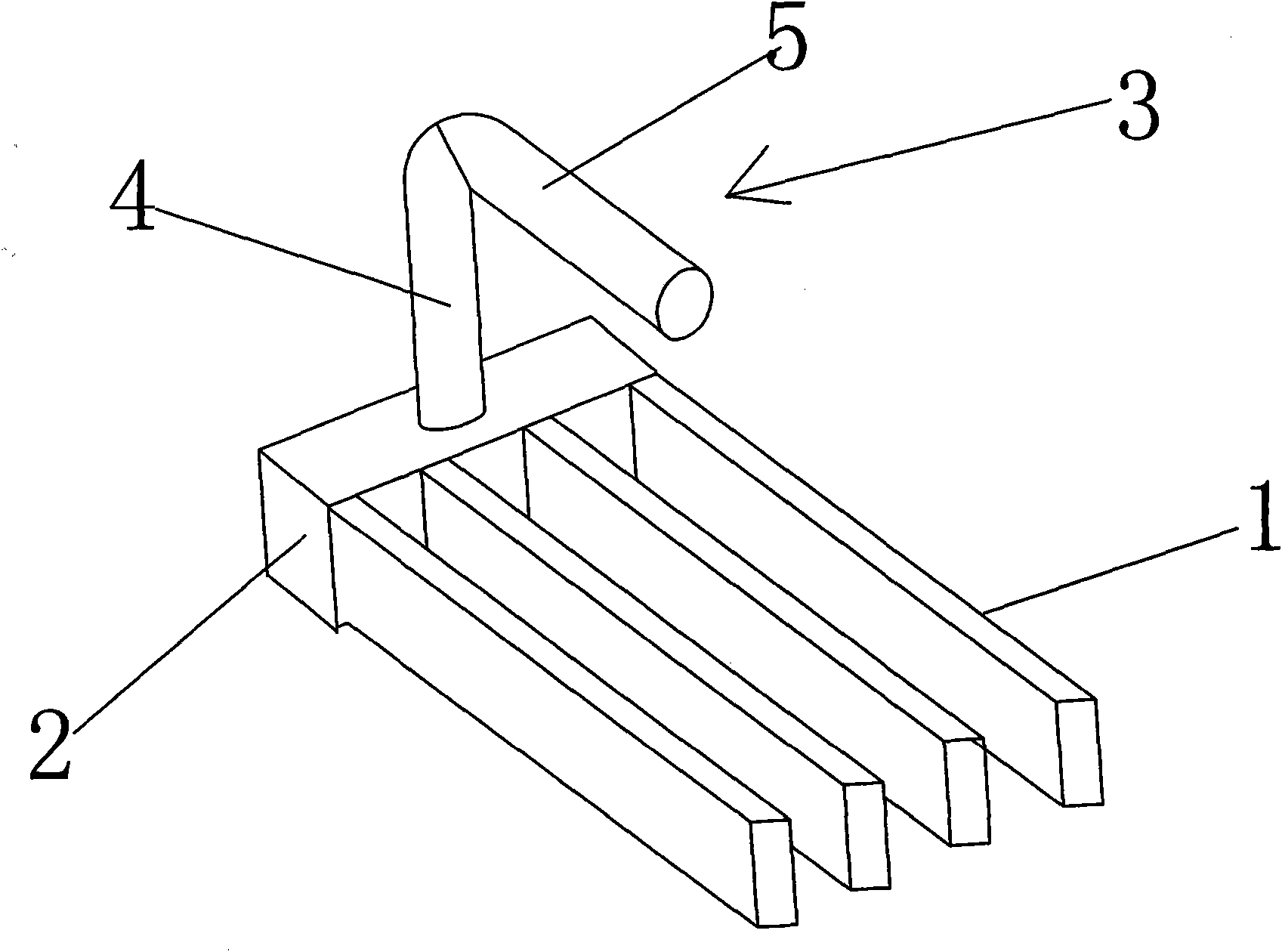

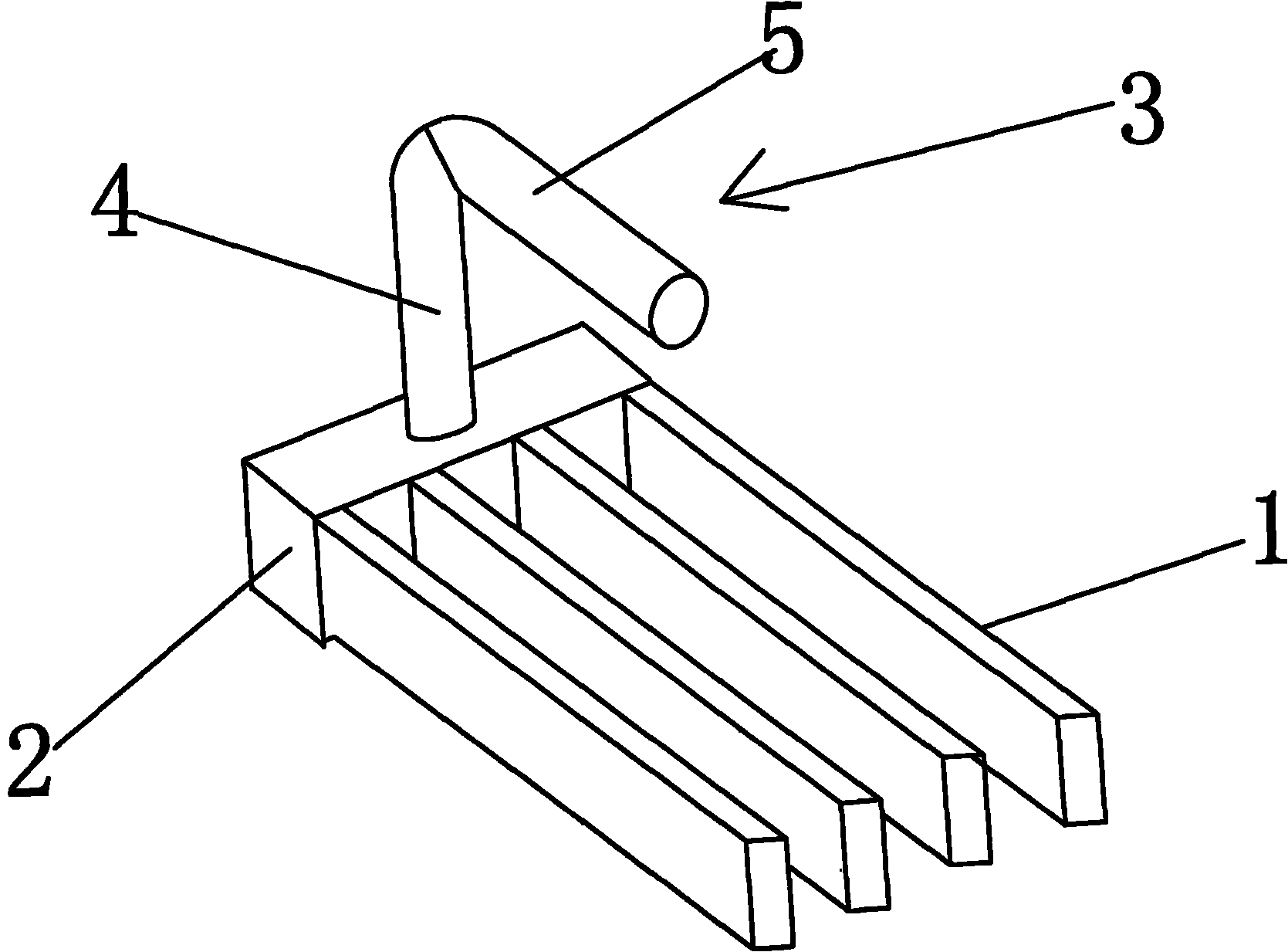

[0014] Hollow brick masonry, including four hole filling teeth 1, connecting plate 2 and handle 3. Each hole filling tooth 1 has a length of 190mm, a height of 50mm, and a width of 20mm. The four hole filling teeth 1 are arranged equidistantly, and their rear ends are respectively welded and firmly connected with the connecting plate 2. The handle 3 is composed of a riser 4 and a handle 5. The upper end of the riser 4 and the handle 5 are welded and firmly connected at a right angle, and the lower end of the riser 4 is welded and firmly connected with the middle of the connecting plate 2.

[0015] The hole filling teeth 1, the connecting plate 2 and the handle 3 are all hollow aluminum profiles.

[0016] This embodiment is suitable for the use of four-hole coal gangue (shale) sintered hollow bricks. The specifications of the four-hole coal gangue sintered hollow brick are: 190×190×90mm; the wall thickness of the hollow brick is 10mm, and the size of each hole is 70×35×190mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com