High-strength hollow thermal-insulating building material and application thereof

A building material, high-strength technology, used in applications, building components, other household appliances, etc., can solve the problems of low heat, low thermal conductivity, and inability to achieve thermal insulation, and achieve the effect of high hardness and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

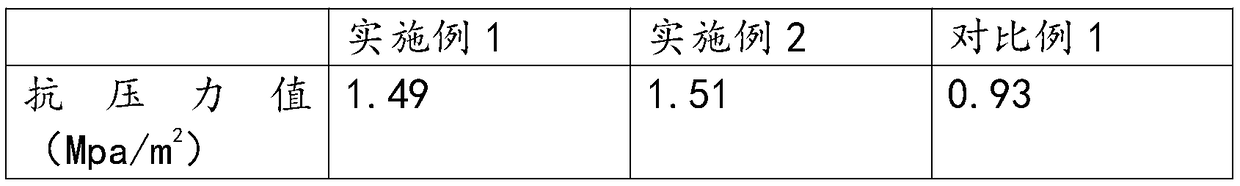

Examples

Embodiment 1

[0023] A high-strength hollow heat-insulating building material, the specific preparation process is as follows:

[0024] In the first step, pour the sodium hydroxide solution with a concentration of 17% into the reaction container, raise the temperature to 60°C, add a certain amount of polyvinyl chloride foam plastic microspheres, stir the hydrolysis reaction for 5-7h, remove it, and then After immersing in 1% hydrochloric acid solution for 30 minutes, then pour it into clean water and repeatedly squeeze and wash until neutral, and at the same time dry the hydrolyzed microspheres in an oven at 50°C to obtain hydrolyzed plastic microspheres;

[0025] In the second step, add 2.3kg of silicon dioxide and 2.9kg of aluminum oxide into 10kg of water and stir evenly, then add 0.3kg of bentonite, 0.7kg of liquid paraffin and 0.05kg of surfactant, stir evenly and add 1.2kg of phenolic resin Adhesive, stirring and mixing for 30-40 minutes to obtain a molding slurry;

[0026] The third...

Embodiment 2

[0032] A high-strength hollow heat-insulating building material, the specific preparation process is as follows:

[0033] In the first step, pour the sodium hydroxide solution with a concentration of 20% into the reaction container, raise the temperature to 60°C, add a certain amount of polyvinyl chloride foam plastic microspheres, stir the hydrolysis reaction for 5-7 hours, remove it, and then add After immersing in 1% hydrochloric acid solution for 30 minutes, then pour it into clean water and repeatedly squeeze and wash until neutral, and at the same time dry the hydrolyzed microspheres in an oven at 50°C to obtain hydrolyzed plastic microspheres;

[0034] In the second step, add 2.6kg of silicon dioxide and 3.3kg of aluminum oxide into water and stir evenly, then add 0.7kg of bentonite, 0.9kg of liquid paraffin and 0.09kg of surfactant, stir evenly, and then add 1.7kg of phenolic resin. Mixture, after stirring and mixing for 30-40min, forming slurry is obtained;

[0035] ...

Embodiment 3

[0052] The prepared high-strength porous hollow microspheres are used in the preparation of high-strength heat-insulating coatings in the construction field. The specific preparation process is as follows: In the first step, 2.1kg of acrylic emulsion, 0.8kg of nano-titanium dioxide, 0.3kg of talcum powder, and 0.5kg of disperse Add the agent and 10kg water into the reaction vessel, stir and mix for 10-15min;

[0053] In the second step, then add 6.1kg of porous hollow microspheres prepared in Example 1, 0.3kg of thickener, 0.4kg of defoamer and 3.1kg of curing agent, and stir to obtain the heat-insulating coating;

[0054] The third step is to apply a layer of primer on the surface of the wall and brush the heat-insulating paint on the surface of the primer through a roller to obtain a high-strength heat-insulating coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com