Printed facing artificial stone slab convenient to install

An artificial stone slab, a technology that is easy to install, is applied in the manufacture of tools, floors, building structures, etc., and can solve the problems of easy fracture and damage of the plate, easy oxidation, corrosion, and falling off of the metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

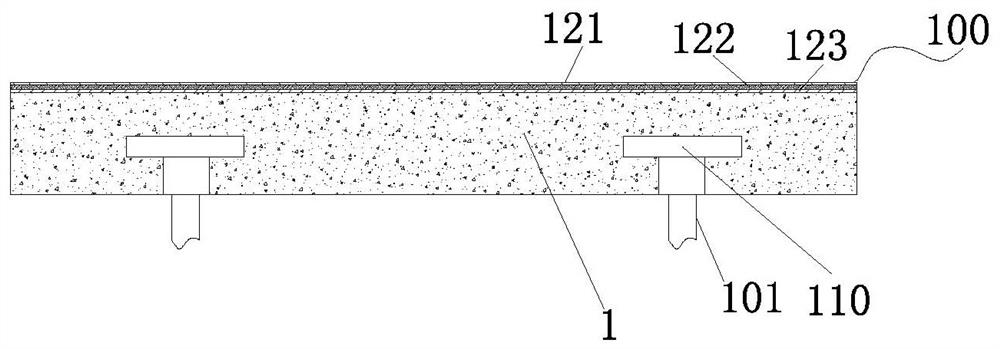

[0033] Material preparation: 600mm*900mm*8mm artificial stone substrate board; topaz stone effect

[0034] Equipment: automatic roller coater, shower coater, UV printer, laminating machine

[0035] The plate making method of the artificial stone substrate plate at least includes the following steps:

[0036]Step 1: Mix dry powder including high-grade cement and silica fume with high-efficiency water reducer and water at a water-binder ratio below 0.25 to make a slurry;

[0037] Step 2, put the slurry into the mold box, and after using vibration equipment to vibrate strongly, lay a mesh with nuts on the surface of the slurry, lay an isolation cloth on the upper part of the mesh in the mold box, turn on the hydraulic press and press it at the same time Vacuuming (plate making equipment needs to have high-frequency vibration, not less than 10kg / cm 2 pressure hydraulic press, vacuum equipment to a pressure below -0.08MPa);

[0038] Step 3, the pressure plate of the hydraulic pr...

Embodiment 2

[0049] Material preparation: 800mm*1200mm*10mm artificial stone substrate board; sandalwood grain effect

[0050] Equipment: automatic roller coater, shower coater, automatic thermal transfer machine, laminating machine

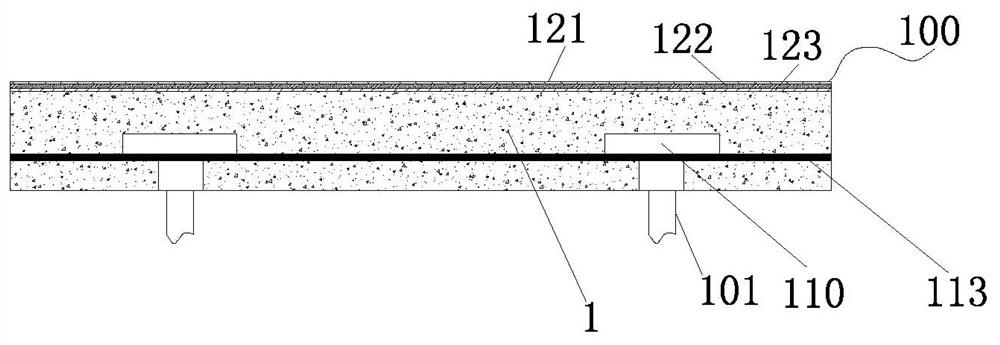

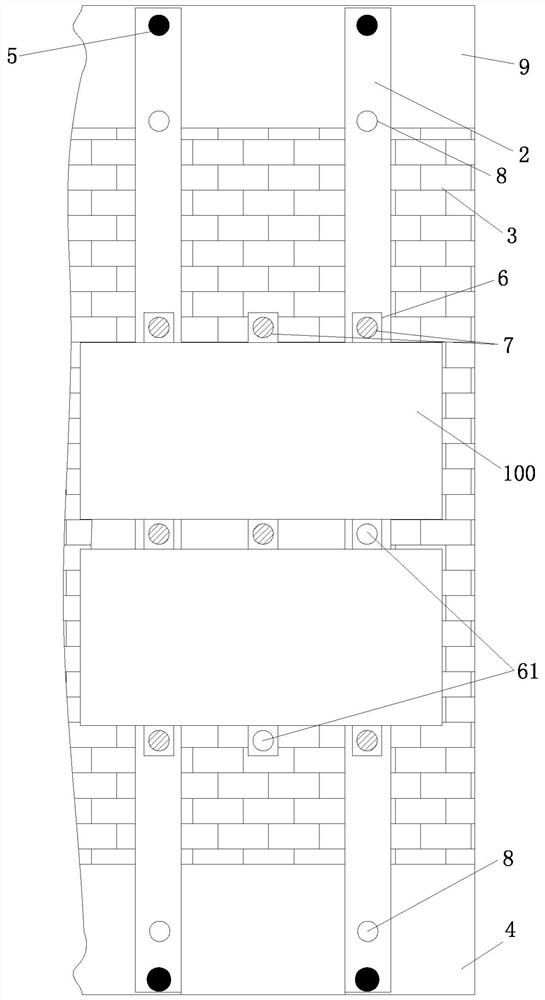

[0051] Such as figure 2 As shown, a mesh 113 is embedded in the artificial stone base plate 1 , and the nut 110 is arranged in the mesh 113 .

[0052] The surface of the artificial stone base plate 1 is spray-coated with UV primer by a roller coater to form a primer layer 123; and then the transfer paper with sandalwood pattern is transferred to the primer layer with a heat transfer machine to form a finish layer 122, and then spray PU topcoat or flow coat UV varnish on the decorative layer of the transferred artificial stone base plate 1 to form a protective layer 121. Finally, an automatic laminating machine is used to coat the surface of the processed board to prevent damage during transportation and use. Finally, the printed decorative artificial ston...

Embodiment 3

[0054] Material preparation: 900mm*1500mm*12mm artificial stone base plate; metal fluorocarbon finish effect.

[0055] Equipment: automatic spraying machine, shower coating machine, laminating machine.

[0056] First, the artificial stone base plate 1 is sealed with a two-component epoxy varnish, and then an epoxy resin primer is sprayed on the surface of the artificial stone base plate 1 by an automatic spraying machine to form a base coat 123; then a base coat is sprayed on the base coat. One layer of fluorocarbon paint, dry and polish and then spray a layer of fluorocarbon paint, dry and polish to form a finish layer 122, then spray UV varnish on the finish layer of the polished artificial stone substrate plate 1 to form a protective layer 121. Finally, an automatic laminating machine is used to coat the surface of the processed board to prevent damage during transportation and use. Finally, the printed decorative artificial stone plate 100 of the present invention is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com