Tile glue for ceramic thin plate

A ceramic thin plate and tile adhesive technology, applied in the field of tile adhesives, can solve problems such as cracking and falling off, safety hazards, inapplicability, etc., and achieve the effects of prolonging the operating time, improving construction performance, and increasing water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

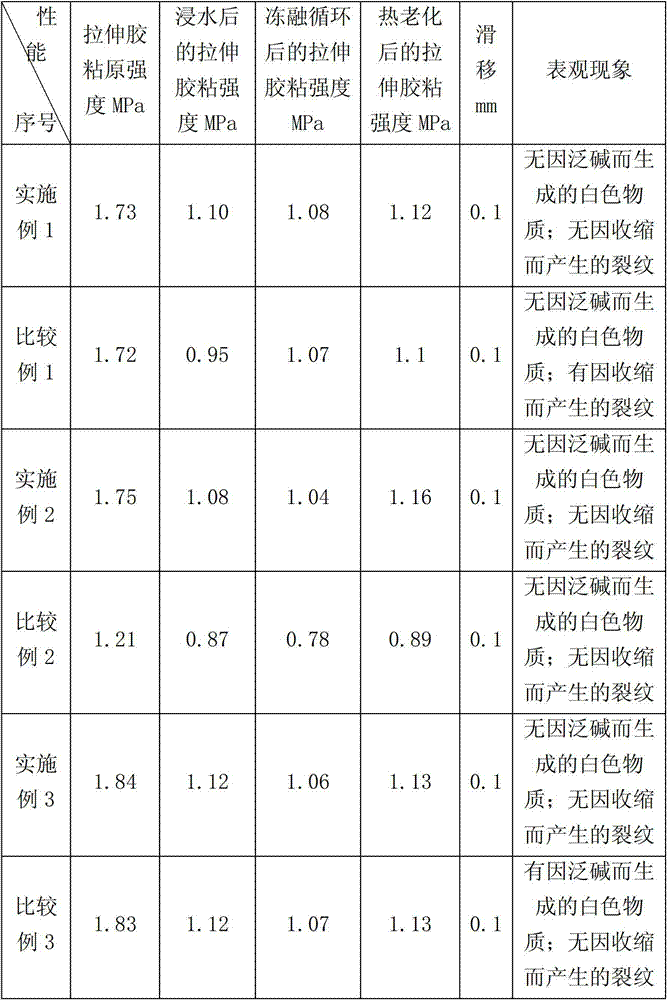

Embodiment 1

[0027] Weigh 18.8g of Portland cement and 44g of quartz sand, mix and stir for five minutes to obtain mixture A, and set aside; continue to weigh 10g of Portland cement, 0.4g of wood fiber, 3.2g of concrete expansion agent, and redispersible latex Powder 2.4g, cellulose ether 0.16g, early strength agent 0.64g, thixotropic lubricant 0.24g, water repellent 0.08g and anti-efflorescence agent 0.08g, stir for five minutes to get mixture B, pour B into A , stirred for five minutes, and then mixed and stirred with 20 g of the emulsion to obtain the adhesive for the ceramic sheet.

Embodiment 2

[0031] Weigh 17.2g of Portland cement and 45.6g of quartz sand, mix and stir for five minutes to obtain mixture A, and set aside; continue to weigh 10g of Portland cement, 0.24g of wood fiber, 2.4g of concrete expansion agent, and redispersible Latex powder 3.2g, cellulose ether 0.24g, early strength agent 0.56g, thixotropic lubricant 0.24g, water repellent 0.16g and anti-efflorescence agent 0.16g, stir for five minutes to get mixture B, pour B into A , stirred for five minutes, then mixed and stirred with 20 g of the emulsion to obtain the adhesive for ceramic thin plates.

Embodiment 3

[0035] Weigh 17.6g of Portland cement, 43.2g of quartz sand, mix and stir for five minutes to obtain mixture A, and set aside; continue to weigh 10g of Portland cement, 0.32g of wood fiber, 3.2g of concrete expansion agent, and redispersible Latex powder 2.4g, cellulose ether 0.24g, early strength agent 0.48g, thixotropic lubricant 0.32g, water repellent 0.16g, anti-efflorescence agent 0.08g, stir for five minutes to get mixture B, pour B into A , stirred for five minutes, and then mixed and stirred with 22g of the emulsion to obtain the adhesive for the ceramic sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com