Alumina-carbon composite nanofiber aerogel material and preparation method thereof

A technology of alumina nanometer and nanofiber, which is applied to ceramic products, other household appliances, climate change adaptation, etc. It can solve the problems of airgel shrinkage, cracking, high temperature heat insulation performance, and high material density, and achieve overall strength improvement, Good heat insulation performance at high temperature and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

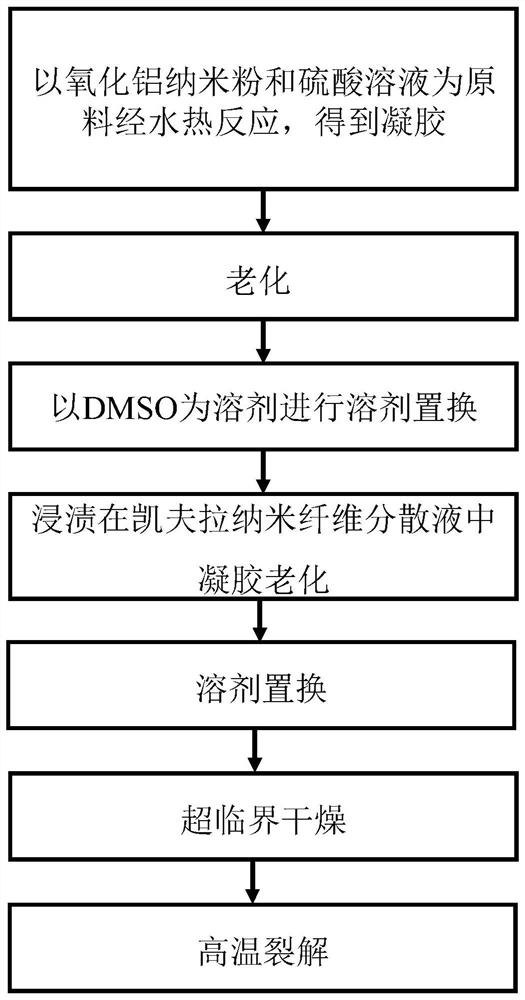

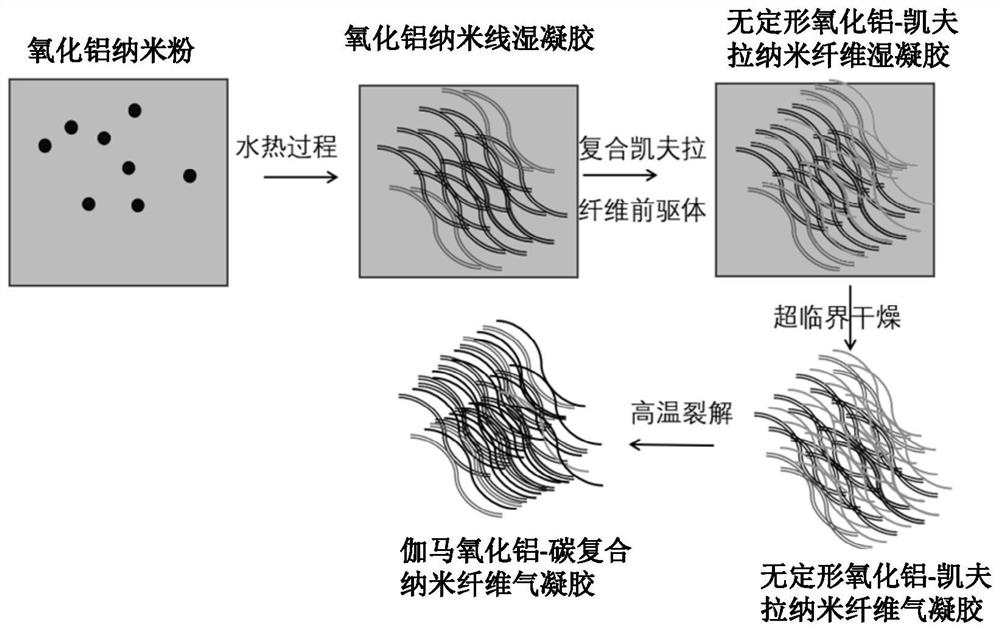

[0032] The present invention provides, in a first aspect, a method for preparing an alumina-carbon composite nanofiber aerogel material, the method comprising the following steps:

[0033] (1) Mix the alumina nano-powder and the sulfuric acid solution evenly with water to obtain a mixed solution, and then place the mixed solution at 150-300° C. for a hydrothermal reaction for 12-18 hours (for example, 12, 13, 14, 15, 16, 17 or 18h) to obtain a gel; in the present invention, the gel is a semi-solid gel; the present invention has no special restrictions on the source of the alumina nano-powder, and a product that can be directly purchased on the market can be used; In the invention, for example, the alumina nano-powder and the sulfuric acid solution are uniformly mixed with water by stirring (such as magnetic stirring) and / or ultrasonic. The sulfuric acid solution can be mixed evenly in water; specifically, for example, it can be magnetically stirred for 1 to 24 hours, and then ...

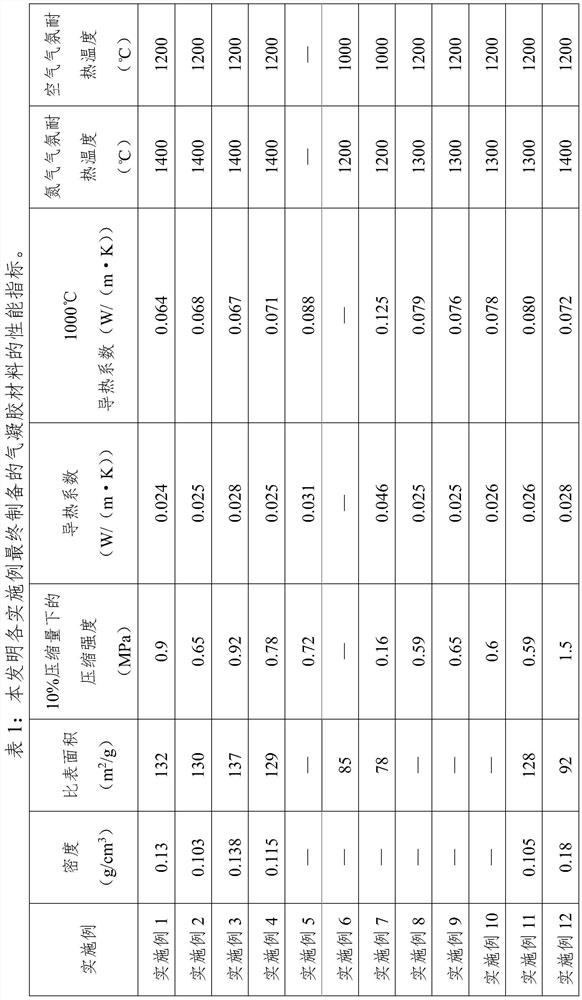

Embodiment 1

[0060] ①Mix alumina nanopowder with a particle size range of 10-15nm and a sulfuric acid solution with a concentration of 10mmol / L in deionized water, first magnetically stir for 1h, and then ultrasonicate for 1h to obtain a uniformly mixed mixture; in the mixture , the mass percentage of the alumina nano-powder is 8%, and the amount of the sulfuric acid solution accounts for 1% of the total weight of the mixed solution.

[0061] ② The above mixed solution was placed in a closed container and subjected to a hydrothermal reaction at 230° C. for 12 hours to obtain a semi-solid gel.

[0062] ③ The above gel was aged at 60° C. in an unsealed environment for 2 hours to obtain an aged gel.

[0063] ④ The above-mentioned aged gel was placed in DMSO for solvent replacement, and 10 times the volume of aged gel was replaced with DMSO once, and the replacement time was 24h.

[0064] ⑤ Soak the gel after solvent replacement in step ④ in a Kevlar nanofiber dispersion liquid with a concent...

Embodiment 2

[0071] Embodiment 2 is basically the same as Embodiment 1, except that:

[0072] ①Mix alumina nanopowder with a particle size range of 10-15nm and a sulfuric acid solution with a concentration of 10mmol / L in deionized water, first magnetically stir for 1h, and then ultrasonicate for 1h to obtain a uniformly mixed mixture; in the mixture , the mass percentage of the alumina nano-powder is 5%, and the amount of the sulfuric acid solution accounts for 0.8% of the total weight of the mixed solution.

[0073] ⑤ Soak the gel after solvent replacement in step ④ in a Kevlar nanofiber dispersion liquid with a concentration of 3% for 96 hours; the Kevlar nanofiber dispersion liquid uses DMSO as a solvent, and the Kevlar nanofiber dispersion liquid uses DMSO as a solvent. The volume dosage of 4 is 3 times the volume of the gel after solvent replacement in step ④.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com