Super-large thin-plate curved-surface part numerical-control hydro-mechanical deep-drawing forming method

A technology of liquid-filled deep drawing and curved surface parts, which is applied in the field of numerical control liquid-filled deep drawing forming of ultra-large thin plate curved surface parts. It can solve the problems such as difficulty in guaranteeing the forming quality of ultra-large thin plate materials, and achieve the effect of improving the forming ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, the method is applied to the bottom of the rocket storage tank In the overall forming optimization of , the material used for the bottom of the box is 2219 aluminum alloy, the diameter of the blank is 7728 mm, and the thickness is 2 mm. The mechanical properties of the sheet are shown in Table 1 below.

[0041] Table 1

[0042]

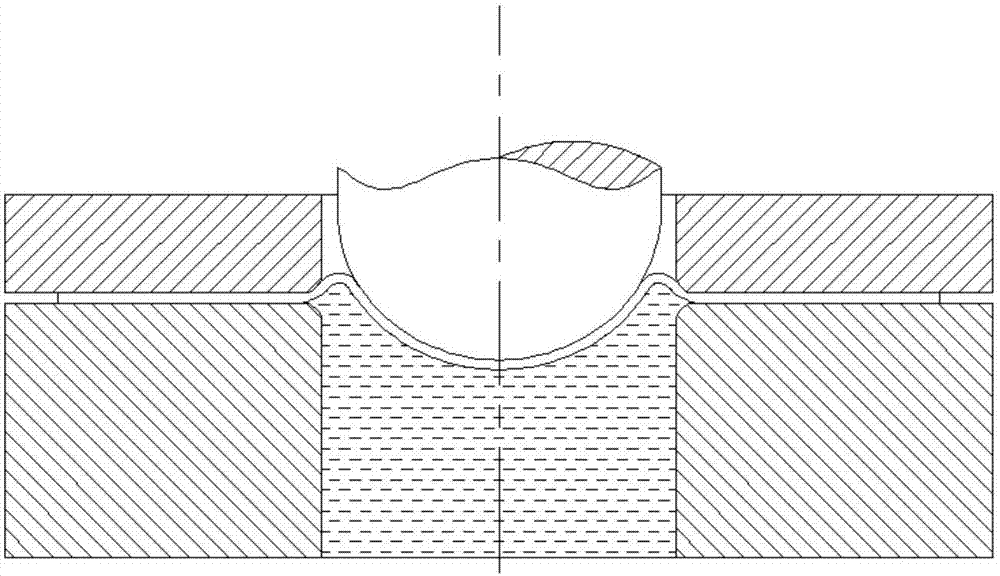

[0043] The assembly diagram of the mold and sheet size used for forming is as follows figure 1 As shown (the unit is 1mm), the major semi-axis of the punch is 2497mm, the minor semi-axis is 2280mm, the diameter of the die opening is 5000mm, and the fillet radius of the die is 198mm.

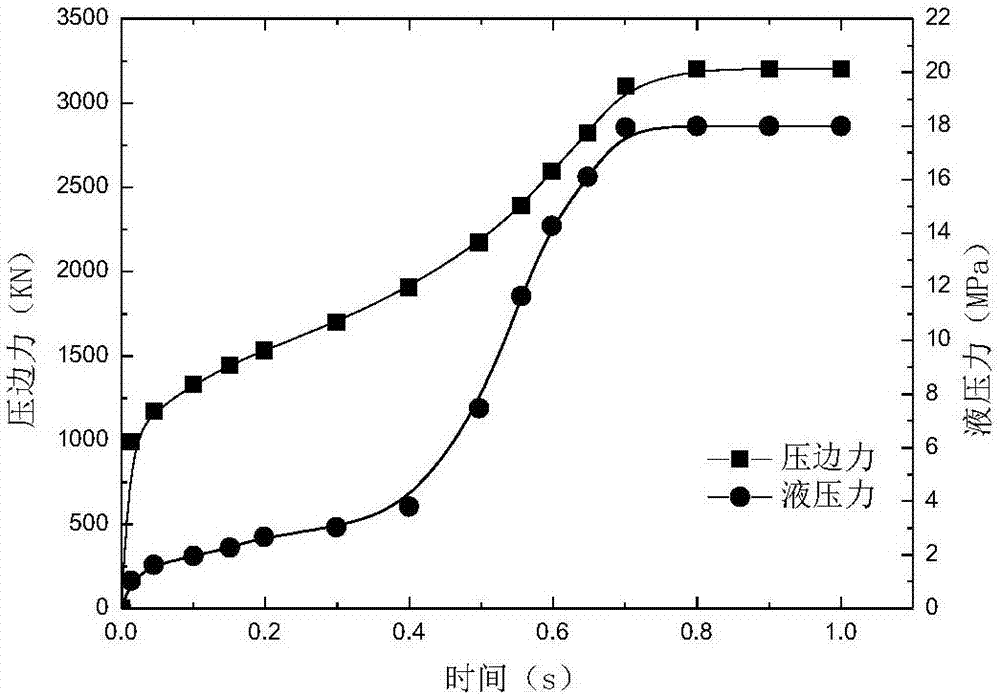

[0044] Through CATIA modeling, and then imported into the special stamping forming simulation software DYNAFORM, by analyzing the forming conditions of the parts, determine the growth of blank holder force and hydraulic pressure required in each forming stage.

[0045] Through the set parameters, the range of the blank holder force of the...

Embodiment 2

[0050] In this embodiment, the method is applied to the bottom of the rocket storage tank In the overall forming optimization of , the material used for the bottom of the box is 5A06 aluminum alloy, the diameter of the blank is 5510 mm, and the thickness is 2 mm. The mechanical properties of the sheet are shown in Table 2 below.

[0051] Table 2

[0052]

[0053] The semi-major axis of the punch used for forming is 1672 mm, the semi-minor axis is 1393 mm, the diameter of the die mouth is 3350 mm, and the fillet radius of the die is 198 mm.

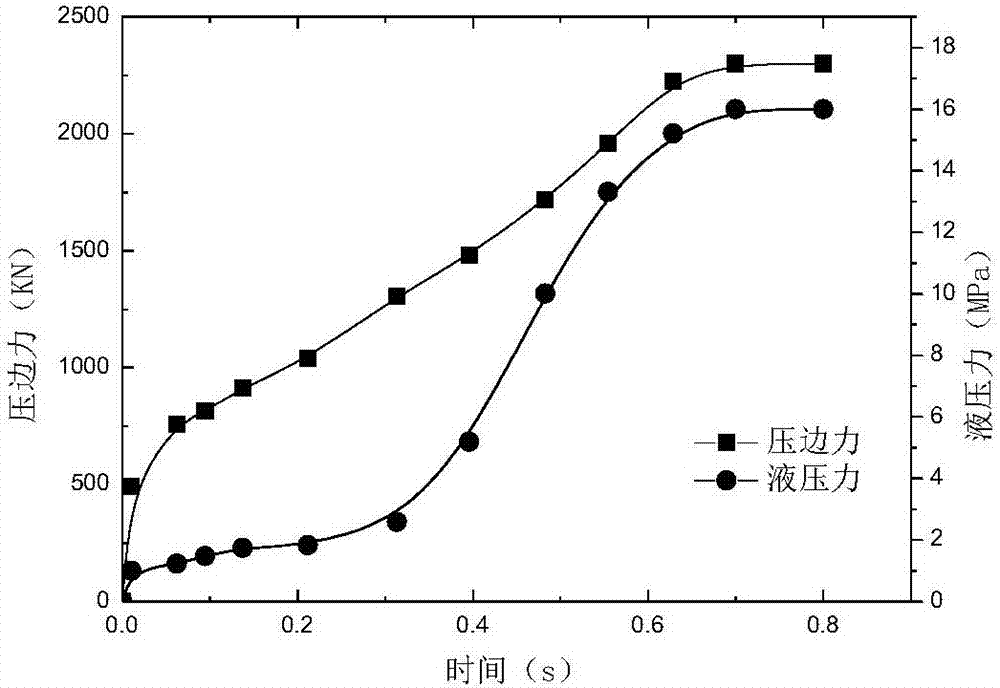

[0054] Through CATIA modeling, and then imported into the special stamping forming simulation software DYNAFORM, by analyzing the forming conditions of the parts, determine the growth of blank holder force and hydraulic pressure required in each forming stage.

[0055] Through the set parameters, the range of the blank holder force of the sheet is determined by the relevant formula: F b >2229kN.

[0056] According to the relationshi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Semi-major axis | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com