Ultralow-temperature moulding device and method for aluminum and lithium alloy complex curved-surface thin-walled components

A technology for complex curved surface and thin-walled components, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven deformation and local stress concentration, difficulty in controlling shape and size, increase material strength, etc., and achieve refrigeration temperature Wide range, reduced thinning and local wrinkling, and improved formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

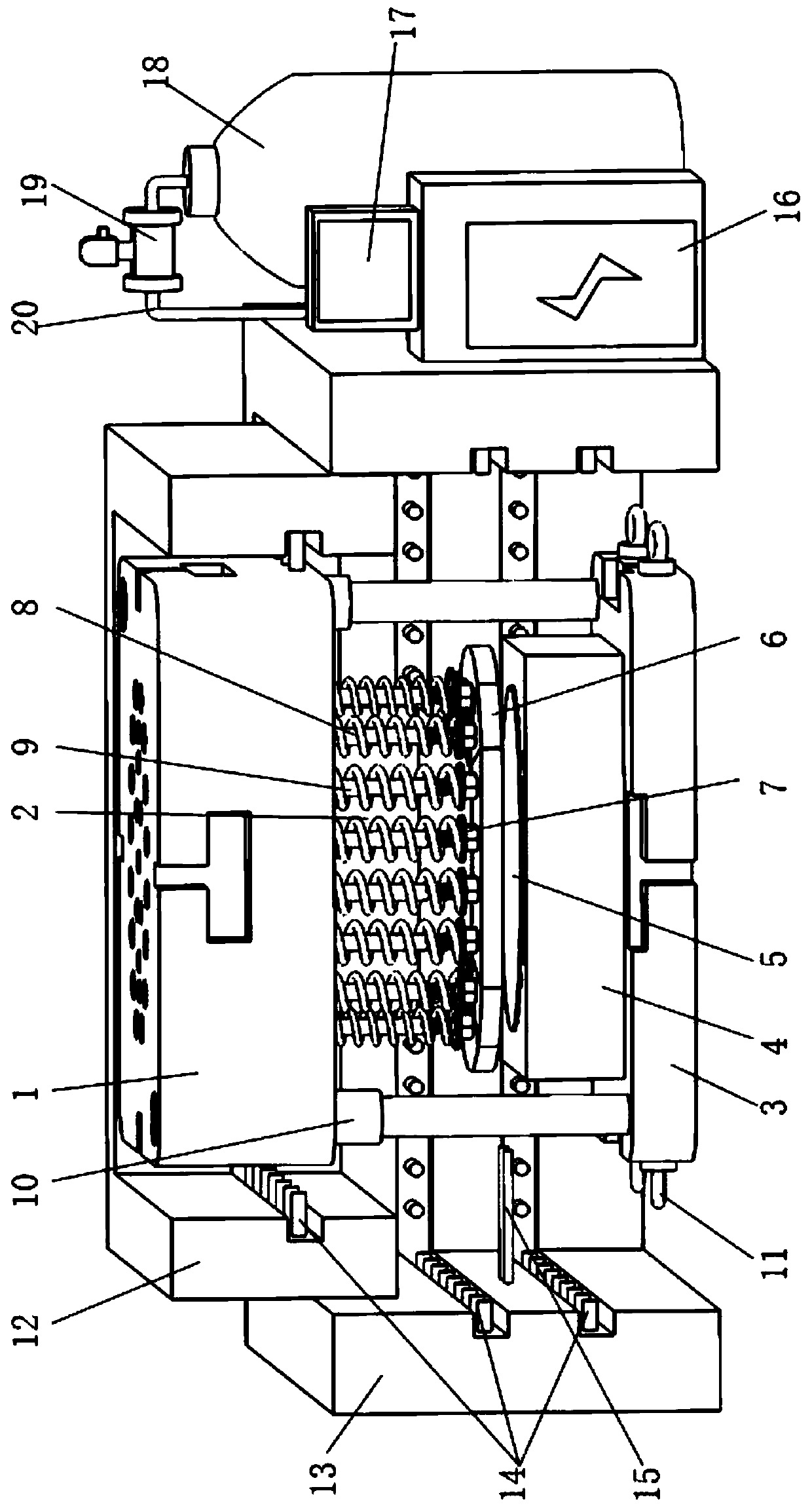

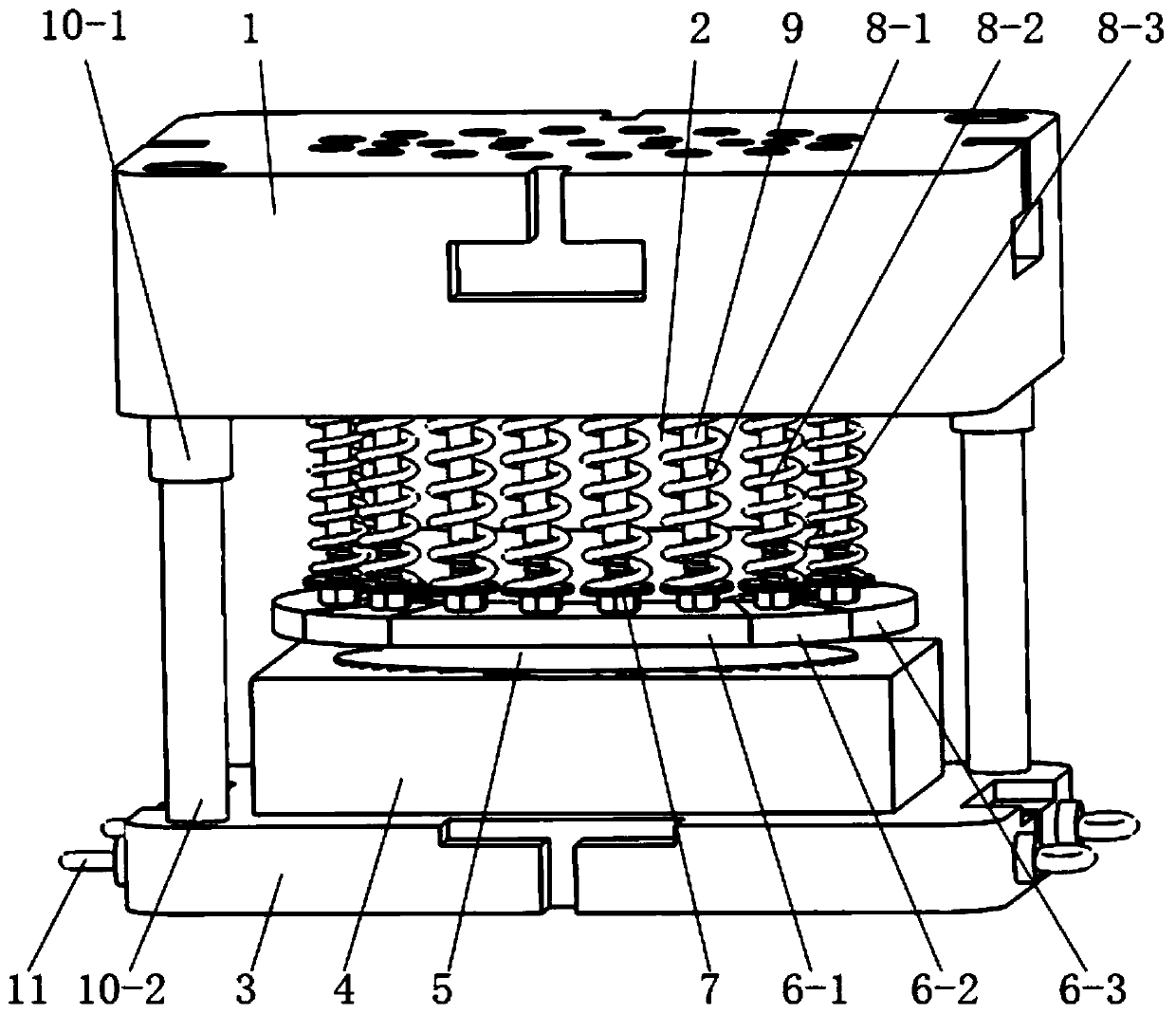

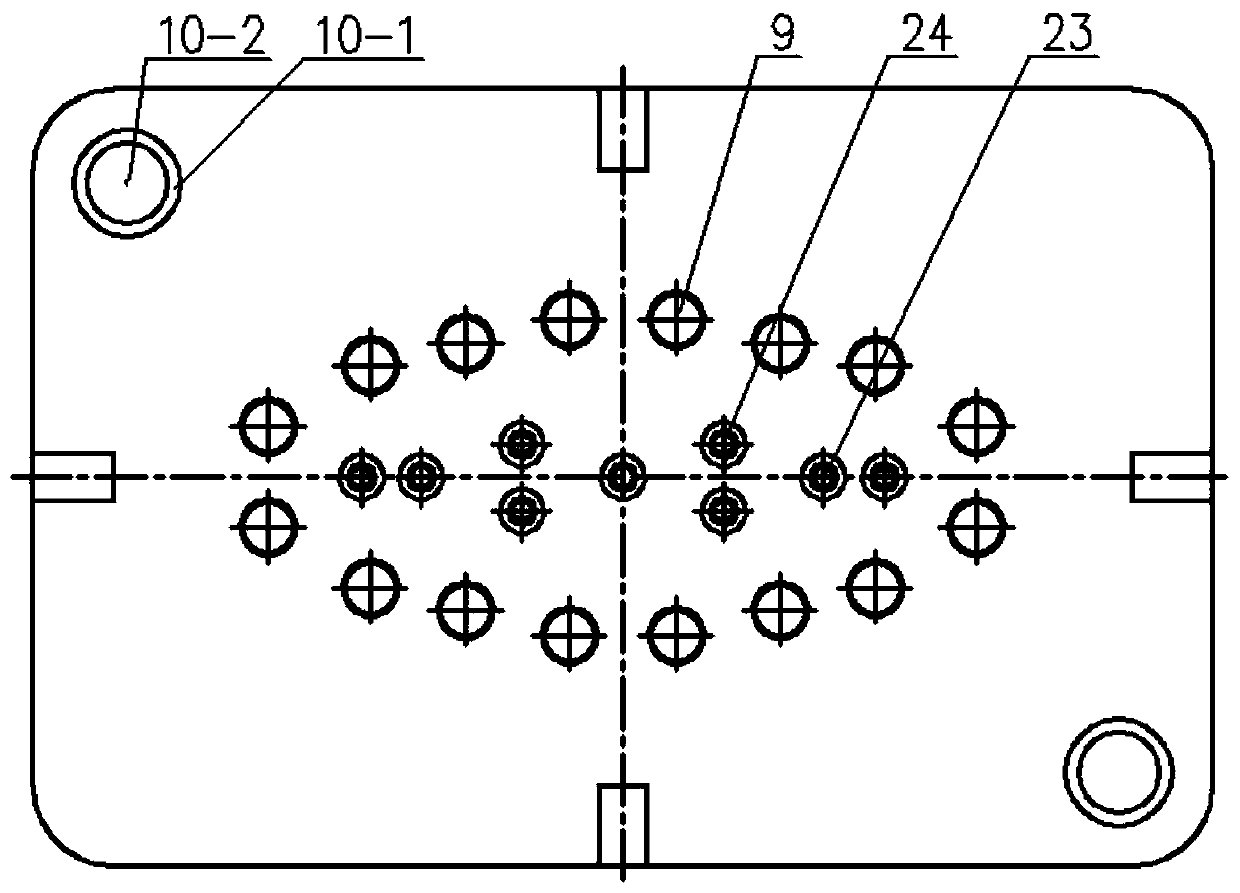

[0035] Such as Figure 1-5 As shown, the present invention discloses an ultra-low temperature forming device for aluminum-lithium alloy complex curved surface thin-walled components, including an upper template 1, a lower template 3, a punch 2, a concave mold 4, a guide mechanism 10, lifting lugs 11, and adjustable parts. Blankholder structure and cooling device with variable blankholder force. Among them, the upper template 1 and the lower template 3 are respectively connected to the upper and lower working planes of the press (not shown) with bolts through T-shaped slots, and the punch 2 is installed on the upper and lower working planes through the upper positioning pin 23 and the upper hexagon socket head cap screw 24. On the template 1, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com