Vacuum die-casting die and method for amorphous alloy flexible gear of harmonic reducer

A harmonic reducer and amorphous alloy technology, applied in the field of vacuum die-casting molds, can solve the problems that the quality and performance of the flexible wheel cannot be guaranteed, the welding seam area is prone to crystallization, and the material utilization rate is low, so as to improve the material utilization rate. And comprehensive mechanical properties, shorten the production cycle, high elasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

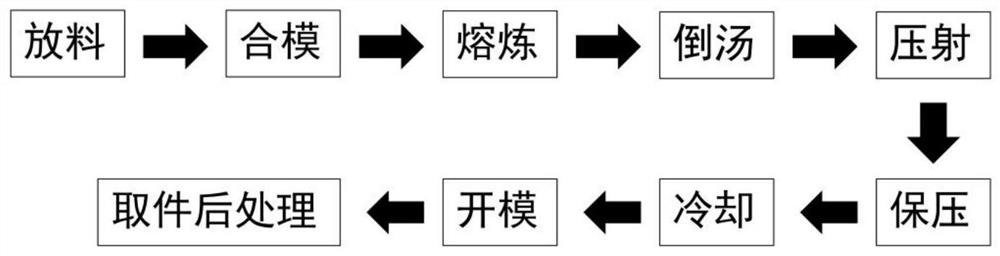

[0029] Example: see figure 1 and figure 2 , a vacuum die-casting method for an amorphous alloy flexible wheel of a harmonic reducer provided in this embodiment, which includes the following steps:

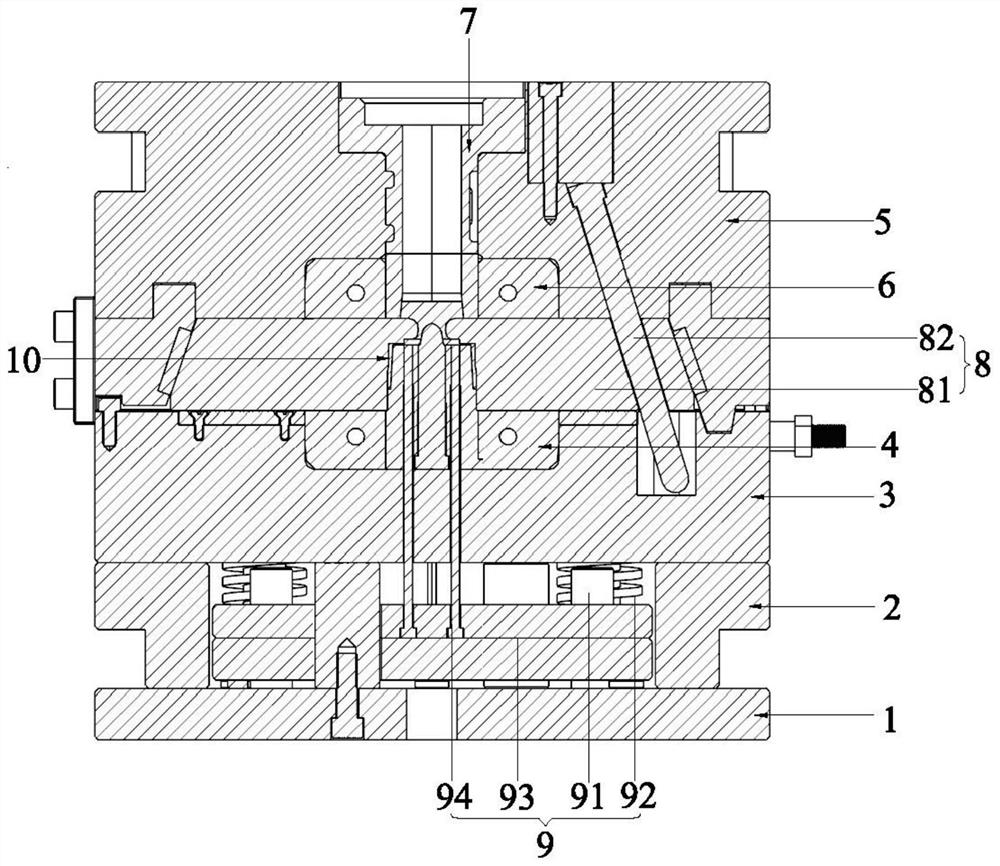

[0030](1) Prepare the amorphous alloy flexible wheel mold: the amorphous alloy flexible wheel mold includes a vacuum box (not shown in the figure) and a bottom plate 1, a square iron 2, a male template 3, and a male mold arranged in the vacuum box. core 4, female template 5, female mold core 6, sprue sleeve 7, core pulling assembly 8 and ejection mechanism 9, the male template 3 is set on the bottom plate 1 through square iron 2, and the male mold core 4 is set on On the male template 3, the position of the female mold core 6 corresponding to the male mold core 4 is set on the female template 5, and the position of the core pulling assembly 8 corresponding to the female mold core 6 is set on the male template 3, and the male mold core 6 is arranged on the male template 3. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com