A kind of high toughness amorphous composite material and its preparation method and application

An amorphous composite material and high toughness technology, applied in the field of amorphous composite materials, can solve the problems of poor plasticity and toughness of amorphous alloys, complex process, brittle fracture of structural parts, etc., to achieve high toughness and impact resistance, preparation technology Simple and easy to implement, good effect of forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

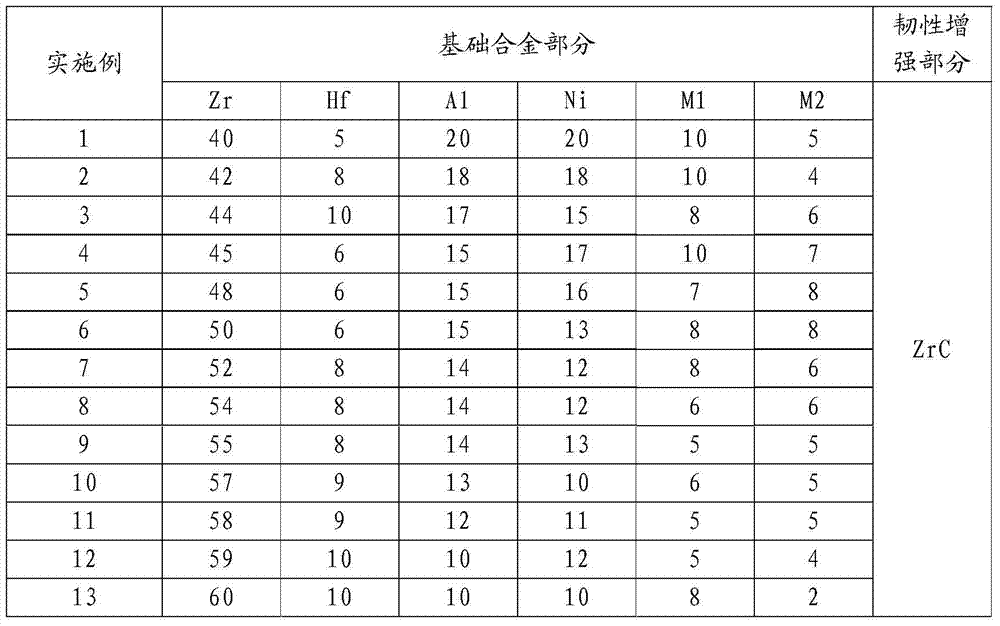

[0035] The amorphous composite materials of Examples 1-13 are obtained by weighing the corresponding raw materials according to the ratio in Table 1, and then preparing them according to the following steps. The raw material formulas of the base alloy part and the toughness enhancement part are shown in Table 1 below, and the values are corresponding The atomic mole percentage of:

[0036] Table 1 The formula of some raw materials of base alloy and some raw materials of toughness enhancement

[0037]

[0038] The purity of the alloy raw materials selected in the embodiment is greater than 99.9%, the reinforced part of the alloy is ZrC nano powder, the average particle size of the powder is 100 nm, and the addition amount of ZrC nano powder is 8% of the volume of the base alloy part. The raw materials used in the present invention can be purchased from the market.

[0039] Preparation method of high toughness amorphous alloy:

[0040] (1) The raw material of the base alloy part with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com