Preparation method of new nanometer composite adsorption material

A nano-composite and adsorption material technology, applied in the field of nano-materials, can solve the problems of easy agglomeration of graphene oxide, secondary micro-pollution, etc., and achieve the effects of large adsorption capacity, easy control of conditions, and good desorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation of graphene oxide

[0023] Add 50mL of concentrated sulfuric acid into a 500mL beaker, slowly add 10g of potassium permanganate and 2g of sodium nitrate in an ice bath, and stir thoroughly. After the potassium permanganate and sodium nitrate are completely dissolved, slowly add 2g of expanded graphite, After the expanded graphite is completely stirred evenly, it is sealed and stored in a refrigerator at 273K for 24 hours. The beaker was heated to 308K in an oil bath, and kept stirring for 30 minutes. Start to slowly add deionized water dropwise, this process is a key step in the preparation of graphene oxide, the slower the dropwise addition of deionized water is, the more beneficial it is for the synthesis. While adding deionized water dropwise, keep stirring, when the temperature rises to 371K, just drop the 500mL beaker full of deionized water. Insulate and stir at 371K for 15 minutes, then add a few milliliters of hydrogen peroxide dr...

Embodiment 2

[0024] Embodiment 2: the preparation of coconut shell activated carbon

[0025] Put the coconut shell into a muffle furnace for 673K carbonization for 2 hours, use a QM all-round planetary ball mill to crush the carbonized coconut shell, and mix 5 grams of crushed coconut shell charcoal with potassium hydroxide in a weight ratio of 1:2 into the Soak in 200mL of deionized water for 24 hours, and put the sample into an oven to dry at 273K. Put the dried coconut shell charcoal and potassium hydroxide mixture into a tube furnace, heat and keep warm at 1173K for 1 hour under the protection of nitrogen to prepare activated carbon, rinse it repeatedly with deionized water after cooling, and when the pH of the solution reaches neutral, put The activated carbon was dried in an oven at 273K for later use.

Embodiment 3

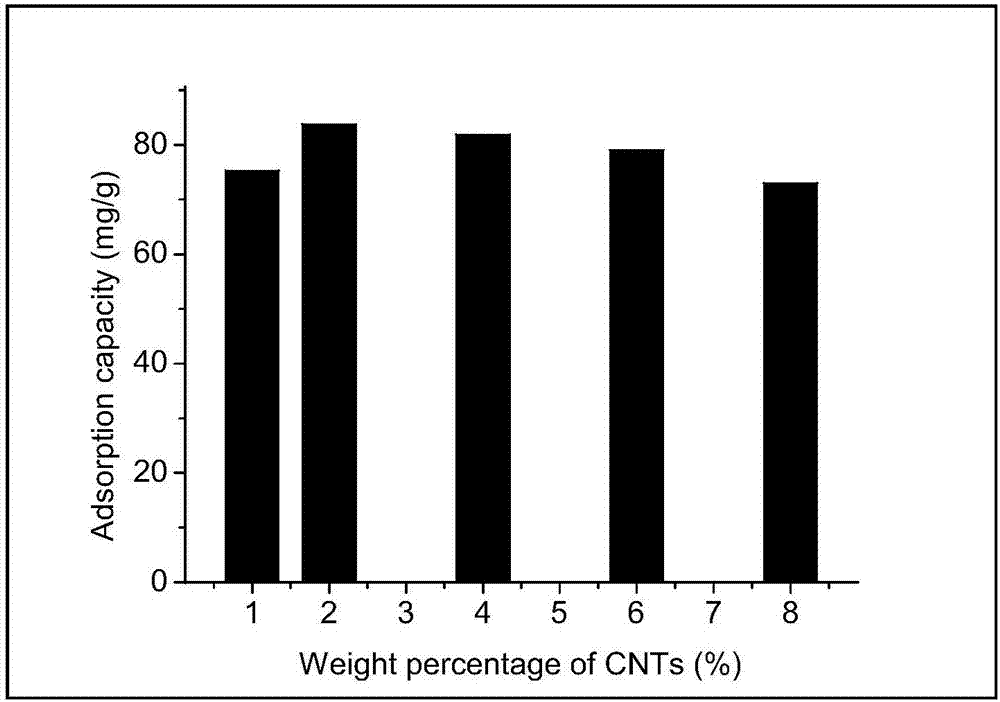

[0026] Embodiment 3: the preparation of the activated carbon / graphene oxide solution of different activated carbon contents

[0027] Mix the activated carbon and graphene oxide solution in a certain proportion, the content of activated carbon in the activated carbon / graphene oxide dry sample is 1%, 2%, 4%, 6% and 8%, respectively, and the activated carbon and graphene oxide solution are placed in a magnetic Stir on a stirrer for 5 hours until the activated carbon and graphene oxide are mixed evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com