Ti-Al-based alloy with good additive manufacturing forming property and application thereof

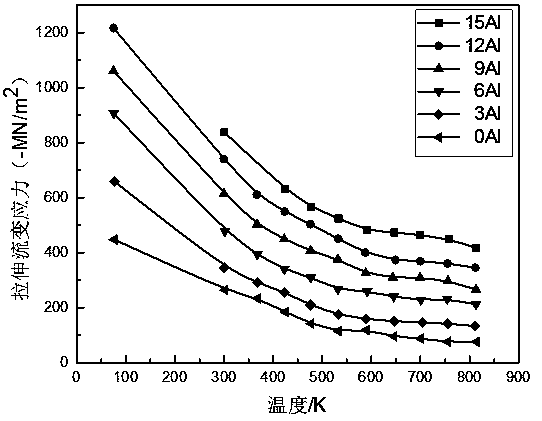

A technology for additive manufacturing and forming performance, applied in the field of Ti-Al-based alloys, can solve the problem of not being able to give full play to the mechanical properties of additively manufactured components, and achieve the effects of good mechanical properties, good forming ability, and small liquid-solid phase region.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following examples will further illustrate the present invention.

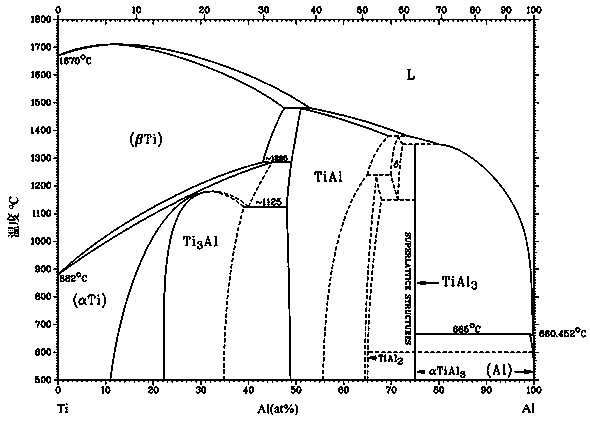

[0013] Based on the Ti-Al alloy system, the atomic integer substitution of alloying elements is carried out according to the double-cluster alloy design model. Among them, the total amount of (Ti, V, Nb, Ta, Zr, Hf, Mo) elements single or mixed is 2.9 0.5 at.%, the total amount of (Al, Sn) element single or its mixture is 11.8 1.0 at.%, the total amount of other elements is controlled within 1 at.%.

[0014] The specific embodiment of the present invention will be described below in conjunction with specific experimental steps.

[0015] 1. Alloy preparation: According to the double-cluster alloy design model [Al-Ti 14 +Al-Ti 14 ]Al 2 Ti 2 =Al 4 Ti 30 , to obtain a binary alloy composition of Al 11.8 Ti 88.2 (at.%), change the element from atomic percentage to mass percentage 7.0Al-93.0Ti (wt.%) for composition ratio; use vacuum electric arc furnace to melt the prepared alloy raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com