Multi-way rotor control valve

A technology for controlling valves and rotors, applied in multi-port valves, valve details, valve devices, etc., can solve the problems of many control unit lines, high hardware investment cost, large size, etc., and achieve diversified functions, convenient control, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

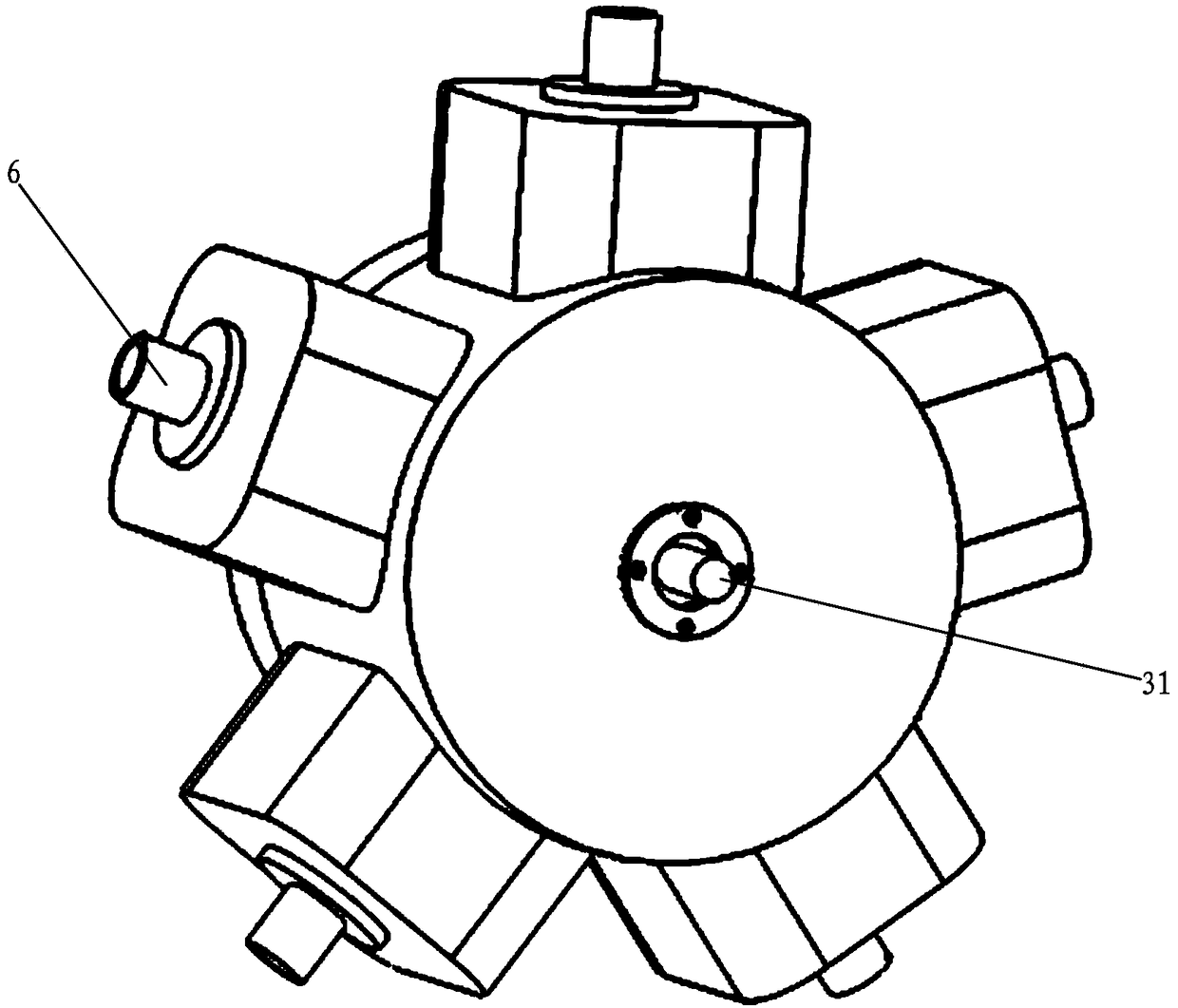

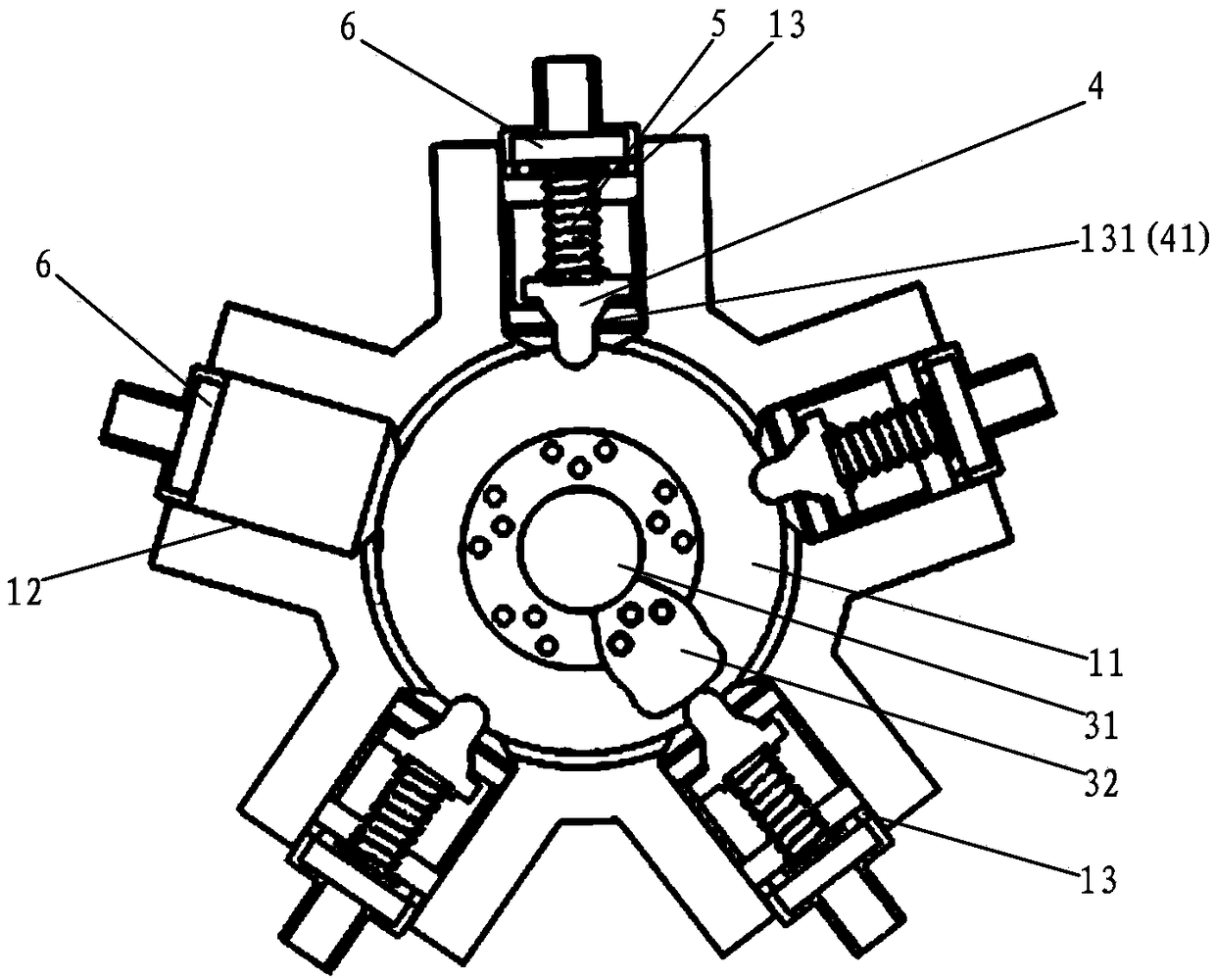

[0034] see Figure 1 to Figure 6 , this embodiment relates to a control valve, including a valve body 1, a valve cover 2, a rotating mechanism 3, a valve core 4, an elastic member 5 and a connecting seat 6, the rotating mechanism 3 is rotatably mounted on the valve body 1, and the valve A built-in cavity 11 is provided on the body 1, and a first through hole 12 and a plurality of second through holes 13 communicating with the built-in cavity 11 are opened on the circumferential direction of the valve body 1, and the valve cover 2 is sealed and closed. On the built-in cavity 11; the valve core 4 is slidably installed in the second through hole 13, the opening end of the second through hole 13 is provided with an internal thread, and the connecting seat 6 is connected by a thread Installed at the opening end of the second through hole 13, the two ends of the elastic member 5 respectively press the valve core 4 and the connecting seat 6 to press the valve core 4 to the inner cavi...

Embodiment 2

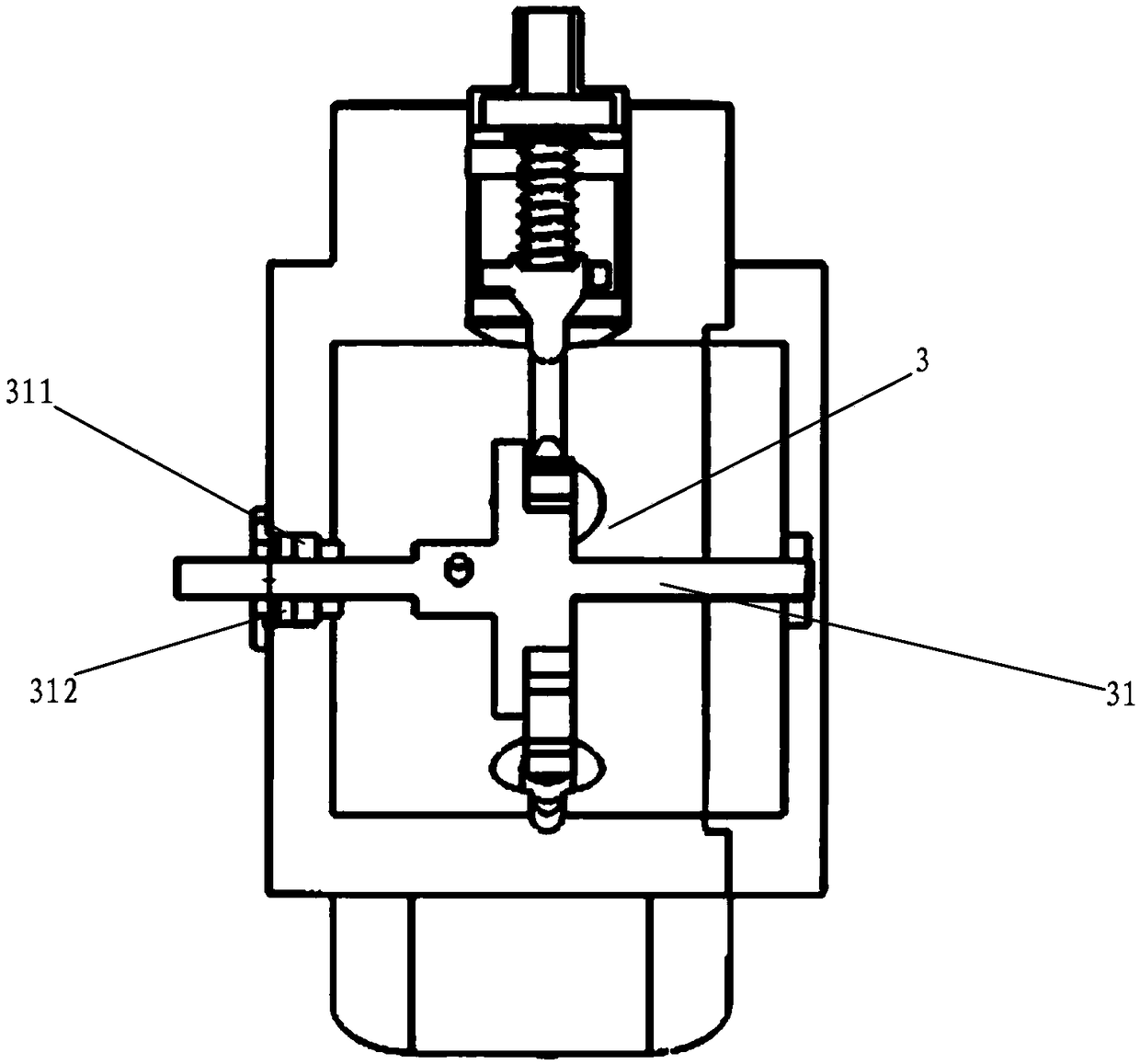

[0048] This embodiment is based on Embodiment 1, as an improvement to the structure of the rotating shaft and valve cover, such as Figure 8 to Figure 10 As shown, one end of the rotating shaft 31 is installed on the valve body 1 through a bearing 311 to form a cantilever support structure, and the rotating shaft 31 is sealed and connected with the valve body 1 through a seal 312; A third through hole 21 is opened, and the third through hole 21 is a water inlet or a water outlet. The control valve of this structure adds a third through hole 21 on the basis of Embodiment 1, so that figure 2 The control structure of one input and four outputs or four inputs and one output can realize the control structure of one input and five outputs or five inputs and one output without increasing the volume of the valve body, which increases the control range and is more convenient to use And flexible, it not only improves the number of control loops, but also prevents the increase of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com