Environment-friendly carbon nanotube/sodium alginate heavy metal ion sorbing material and preparation method thereof

A technology of heavy metal ions and carbon nanotubes, which is applied in the field of nano-materials and environmental protection, can solve the problems of carbon nanotubes, secondary micro-pollution of water environment, etc., and achieve good adsorption capacity, easy control of conditions, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] After cleaning and drying 2.0 g of carbon nanotubes treated with a mixed solution of concentrated nitric acid and sulfuric acid, put them into 50 ml of deionized water, use an ultrasonic cell pulverizer to fully disperse the carbon nanotubes, and then place them in a magnetic heating stirrer Stir on. Put 0.1-1.0g of sodium alginate into 50ml of deionized water respectively. After fully dissolving, slowly drop the sodium alginate solution into the stirring carbon nanotube solution to make it evenly mixed. Evenly inject the carbon nanotube / sodium alginate mixed solution into 2L aqueous solution containing 1wt% calcium chloride with a syringe to prepare uniform carbon nanotube / sodium alginate particles, and wait until the carbon nanotube / sodium alginate particles are fully solidified Afterwards, the carbon nanotube / sodium alginate granular composite material is obtained by filtration. Add 0.05g of this material to 100ml of solutions with lead ion concentrations of 5, 20, ...

Embodiment 2

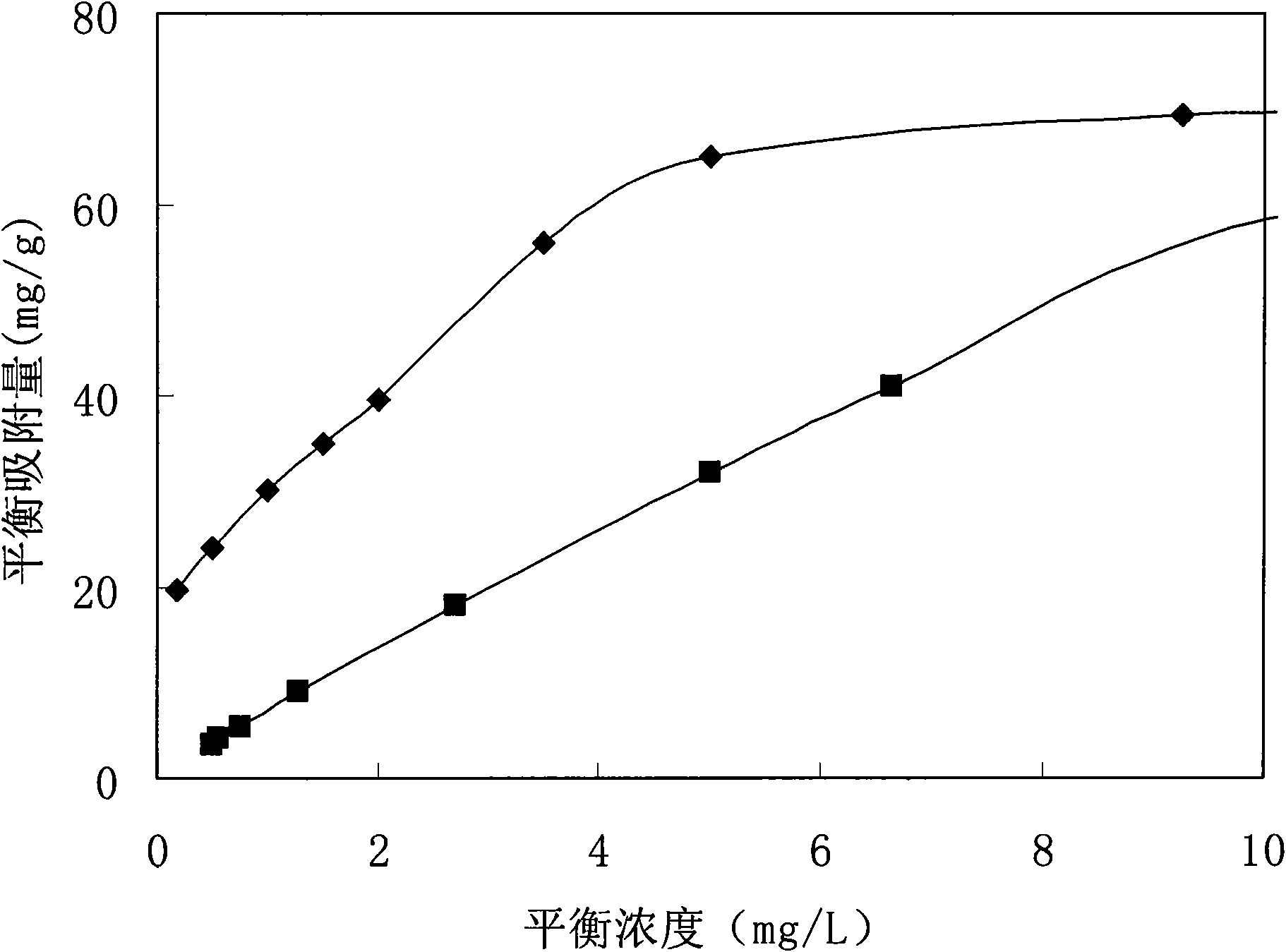

[0021] Weigh 2.0g of carbon nanotubes treated with a mixed solution of concentrated nitric acid and sulfuric acid, put them into 50ml of a solution containing 0.5g of potassium permanganate, heat to 100°C on a magnetic heating stirrer and stir for 2 hours, then vacuum repeatedly After filtering and washing, put the carbon nanotubes into an oven at 50°C for drying. The preparation method of the carbon nanotube / sodium alginate granular composite material and the lead ion adsorption experiment are the same as in Example 1. Adsorption experiments found that the carbon nanotube / sodium alginate composite material with potassium permanganate oxidation treatment of carbon nanotubes had better lead ion adsorption performance than the composite material prepared with mixed acid oxidation treatment of carbon nanotubes.

Embodiment 3

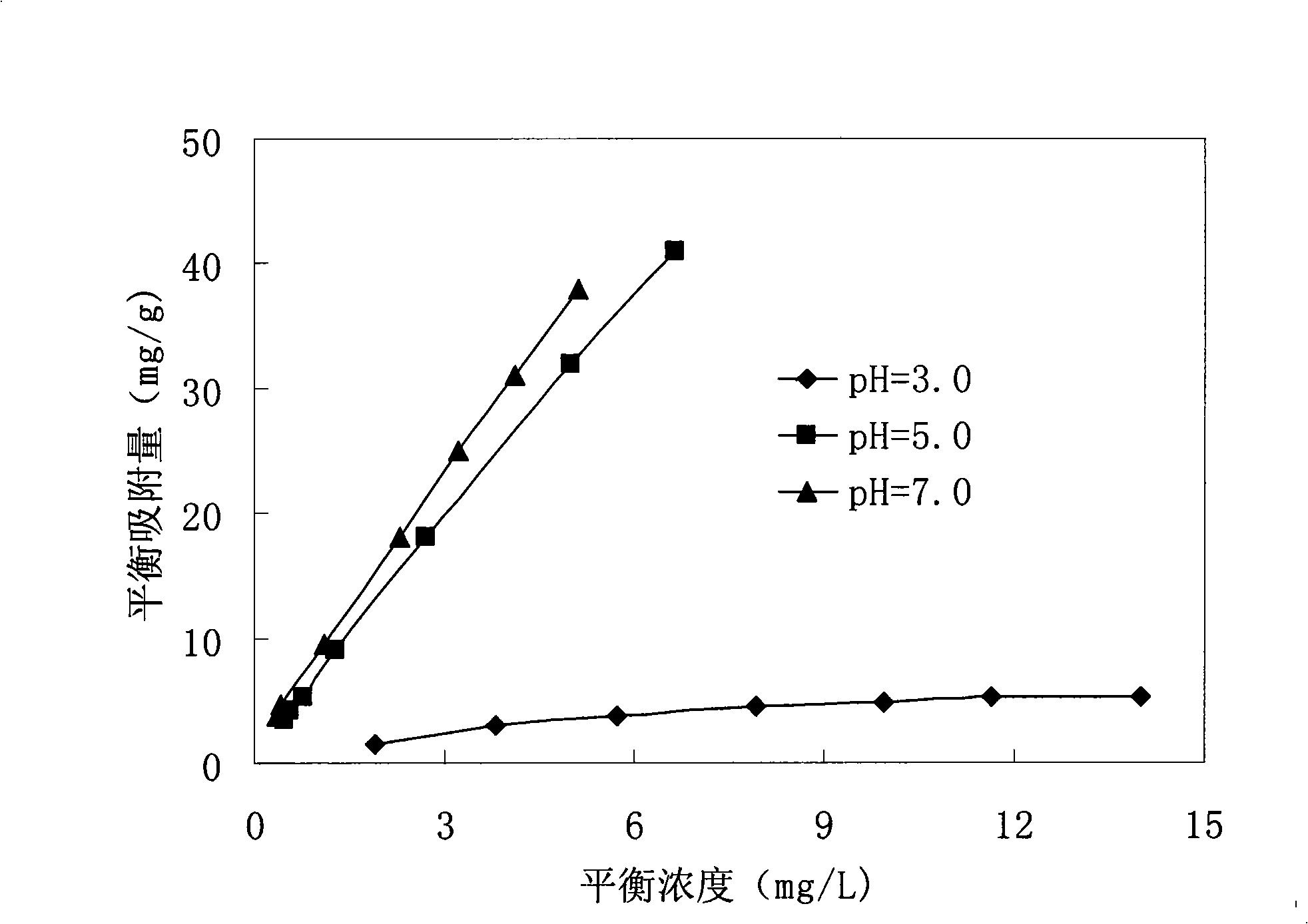

[0023] Put 0.05g carbon nanotube / sodium alginate composite into 100ml with different Pb 2+ concentration of the solution, adjust the pH of the solution from 3.0 to 7.0 under acidic conditions, at pH=3.0, due to H + and Pb 2+ The competition at the adsorption site makes the carbon nanotube / sodium alginate composite 2+ The adsorption effect is very weak; at pH = 5.0, the composite material for Pb 2+ The adsorption capacity is greatly increased; at pH = 7.0, the composite material for Pb 2+ The adsorption effect is more significantly increased, but at this time the lead ion will interact with OH - The reaction produces a white flocculent lead precipitate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com