Scribing device and scribing method

A scribing device and moving direction technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as damage to the substrate, difficulty in maintaining the flatness of the conveying substrate, and difficulty in maintaining the orderly arrangement of the glass, so as to prevent sliding, The effect of increased flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Hereinafter, the configuration of the scribing device will be described with reference to the drawings, and the scribing method of the present invention will be described with reference to the above configuration.

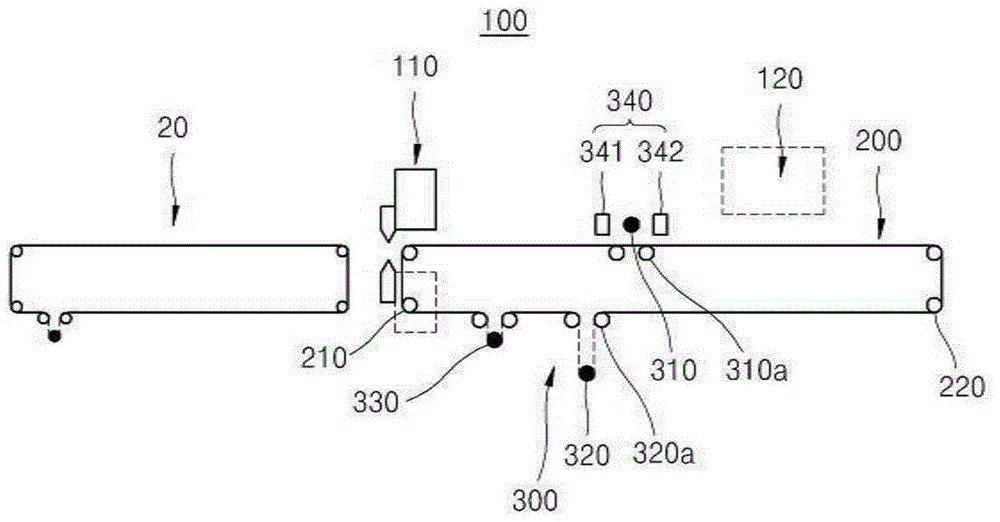

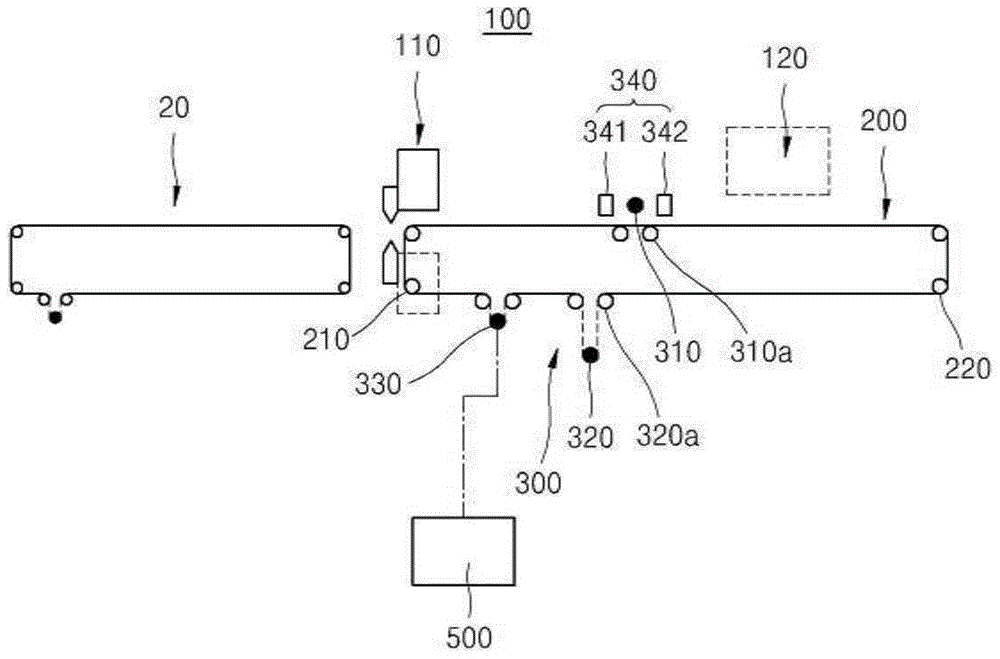

[0079] figure 1 is a schematic diagram of the scribing device of the present invention.

[0080] refer to figure 1 The scribing device of the present invention is roughly composed of a main body 100 with a conveyor belt 200 and a process control unit 300 .

[0081] Body 100

[0082] The body 100 according to the invention is provided with a conveyor belt 200 .

[0083] The conveyor belt 200 is installed on the main body 100 to be able to rotate on an infinite track.

[0084] The two ends of the conveyor belt 200 are respectively supported and rotated by a pair of guide rollers.

[0085] The pair of guide rolls is composed of the first and second guide rolls 210 on the left side and the first and second guide rolls 220 on the right side.

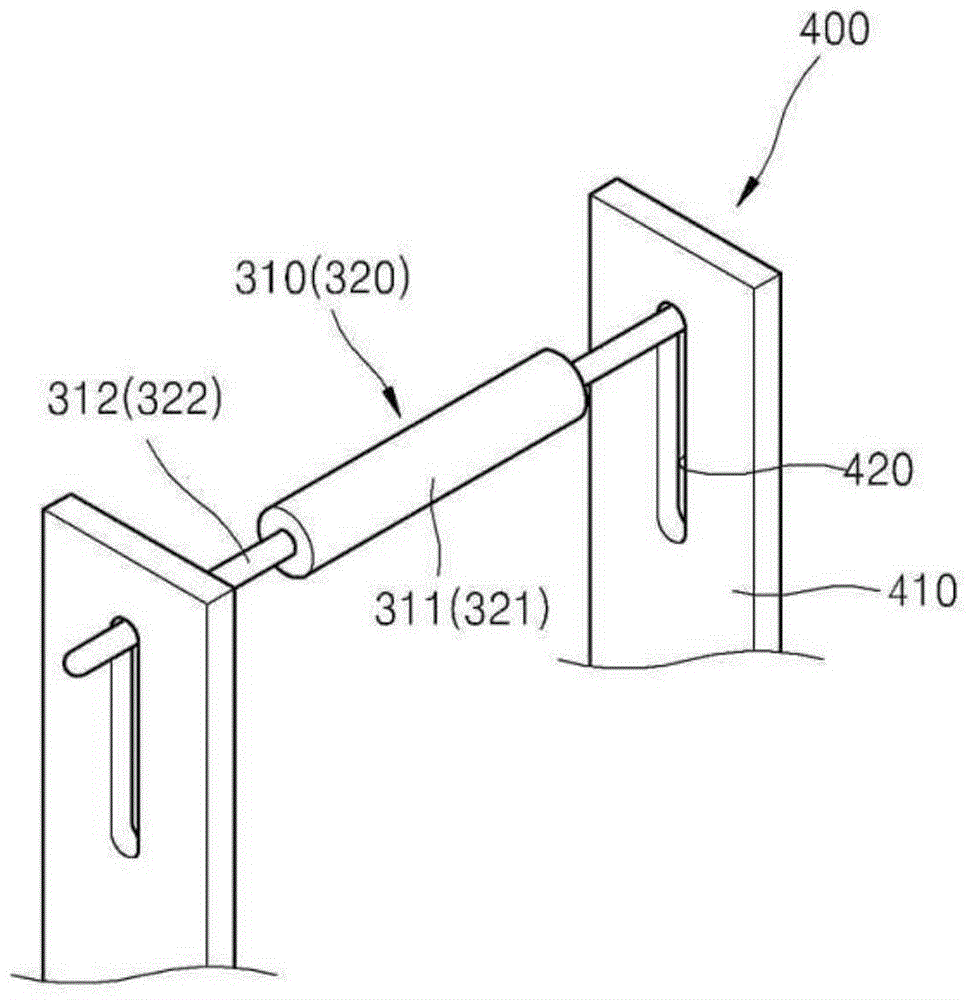

[0086] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com