Satiety enhancing food compositions

A technology of composition and biopolymer, which is applied in the direction of drug combination, food science, food preparation, etc., can solve the problems of insufficient satiety and suboptimal satiety effect, and achieve increased satiety, low production cost, The effect of disease prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

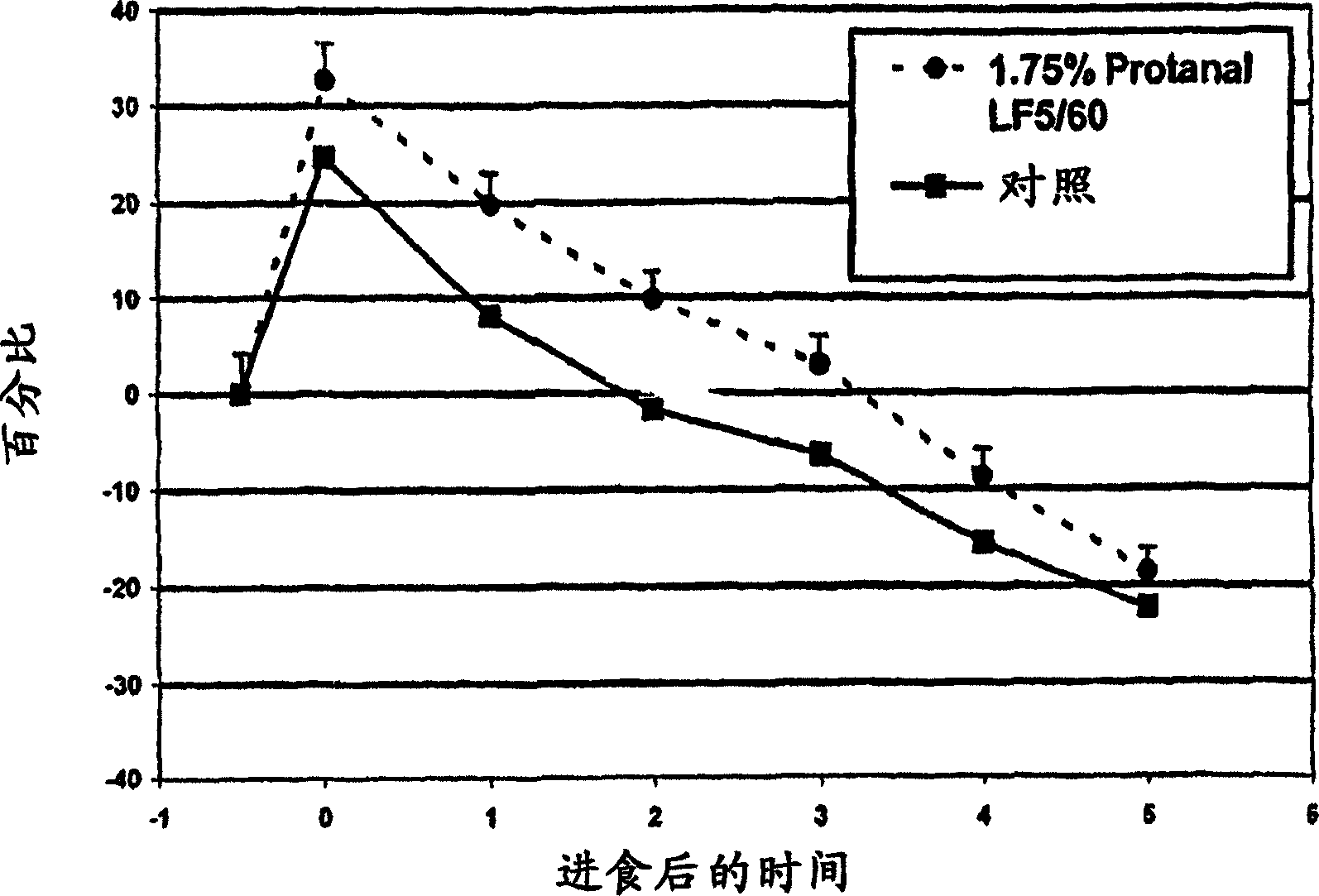

Embodiment 1

[0177] Commercially available meal replacement beverages (US Slim*Fast TM Chocolate Royale ready-to-drink beverage, multiple cans of the same batch) added 1.75% Protanal LF5 / 60 TM (The content of L-guluronic acid is 69%, and the weight average molecular weight is 1.0-1.2×10 5 Alginate from FMC Biopolymer), so that 325ml of beverage contains 5.69g of alginate. This meal replacement drink contains approximately 6.6g of protein.

[0178] Shake beverage cans, open, weigh and pour into Wolff food processor. Alginate, lactulose (5 g, added for calculation of intestinal transit time) and tricalcium phosphate (10% by weight of alginate) were mixed at 1500 rpm for 2 minutes at room temperature. The mixture was then evacuated and mixed for an additional 5 minutes. Steam was passed through the Wolff jacket until the contents warmed to 60°C and mixed at 1500 rpm for 15 minutes at this temperature. This mixture was then poured into the premix tank of the UHT plant and stirred slowly d...

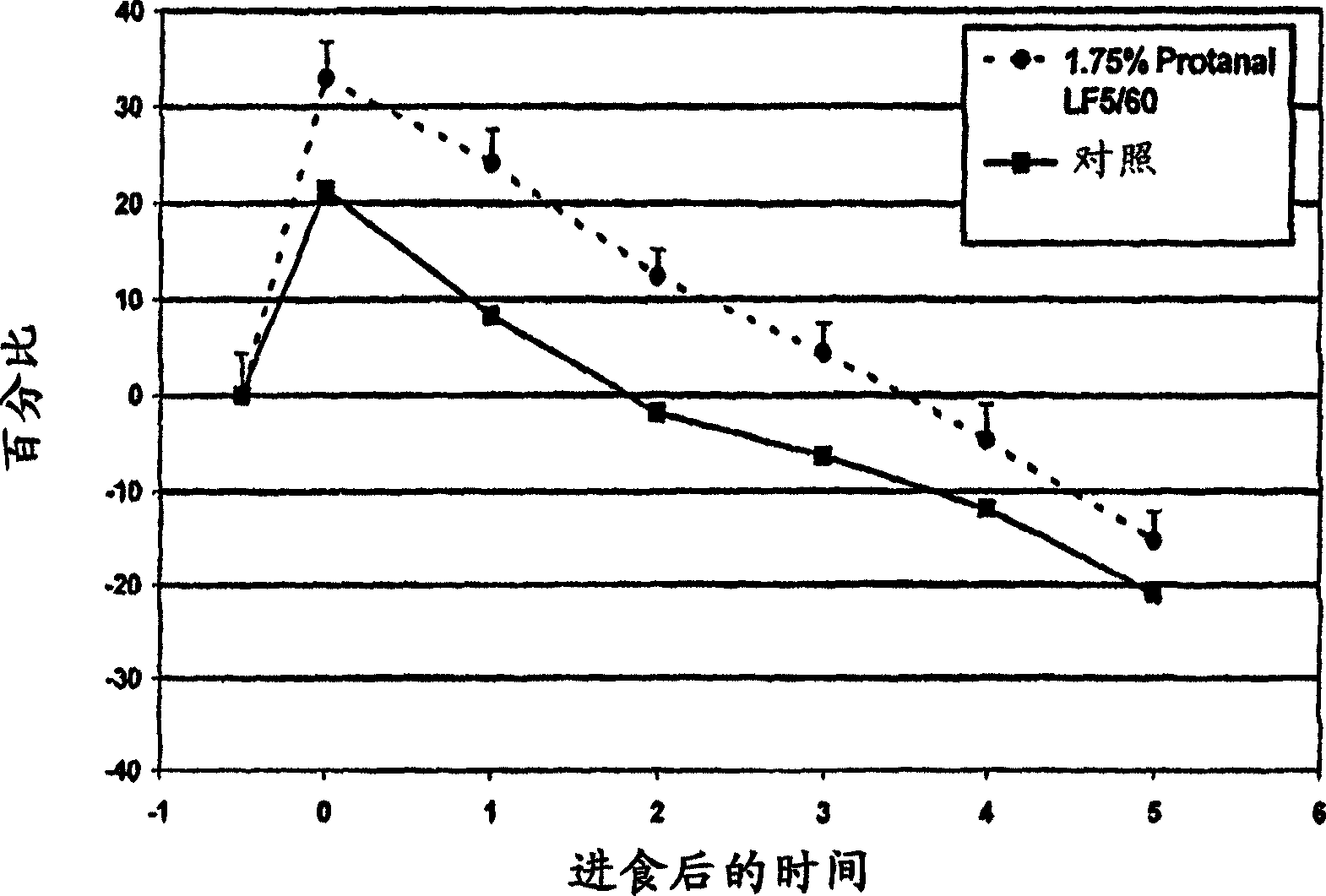

Embodiment 2

[0192] A control composition was prepared according to the formulation given in Table 1 below. All weights are given as percentages of the total weight of the control composition.

[0193] %weight

water

86.60

Skimmed Milk Powder (SMP)

6.50

4.05

calcium caseinate

1.60

Spices (French Herbs)

0.54

canola oil

0.33

0.10

Emulsifier

0.09

Total 100%

[0194]A control composition was prepared as follows: water was heated to 50°C, premixed skim milk powder (SMP), caseinate and sucrose were added and mixed. The mixture was heated to 55°C and mixed with an Ultra-Turrax for 15 minutes. Add the preheated (>60°C) fatty phase (oil, lecithin and emulsifier) and mix for 2 minutes. The mixture was homogenized in two stages; 100 / 40 bar (Niro homogenizer: throughput ~14 kg / hour, back pressure 4 bar), followed by a small UHT line (heating / holding p...

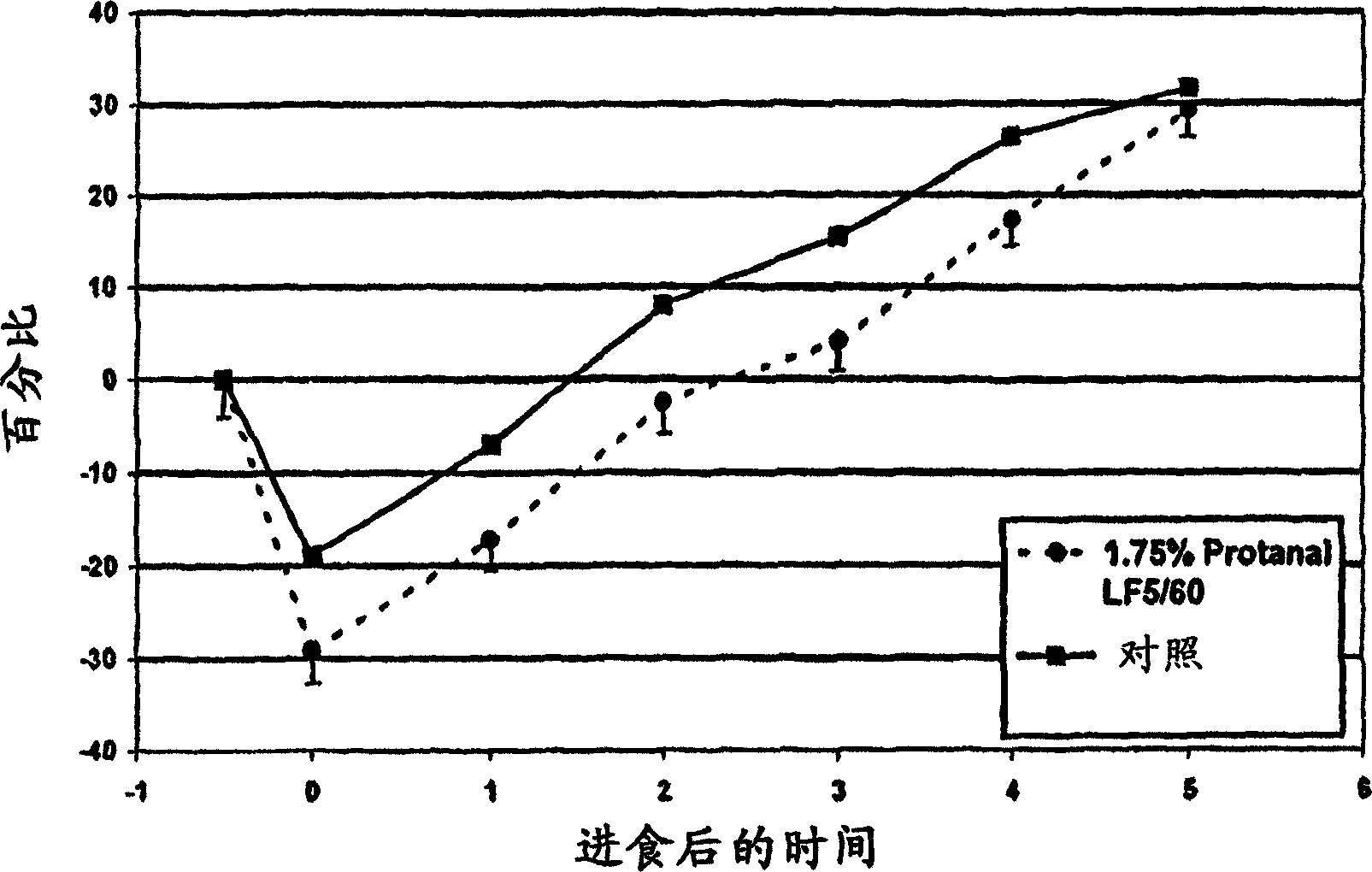

Embodiment 3

[0208] Commercially available meal replacement beverages (US Slim*Fast TM Chocolate Royale ready-to-drink beverage, multiple cans from the same batch) added 0.8% ManugelDMB TM (See Example 2) so that 325 ml of the drink contained 2.6 g of alginate. This meal replacement drink contains approximately 6.6g of protein.

[0209] Stir the drink with a magnetic stirrer at room temperature and mix the Manugel DMB TM Alginate is sprinkled in this solution. The composition was then heated at 80°C for 10 minutes, then the temperature was lowered to 37°C for 2 hours with continued stirring.

[0210] The gel strength of the composition comprising alginate was determined according to the gel strength determination method in the detailed description of the invention above. The gel strength at 37°C and pH 2 is 17.5 KPa, which is greater than the gel strength of the edible composition (about 370 Pa).

[0211] The presence of Manugel in the polysaccharide continuous phase of the compositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com