Satiety enhancing food compositions

A composition and biopolymer technology, applied in the field of water-containing or spoonable compositions, can solve the problems of complexity, suboptimal satiety effect, and insufficient satiety, so as to increase satiety and low production cost , the effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

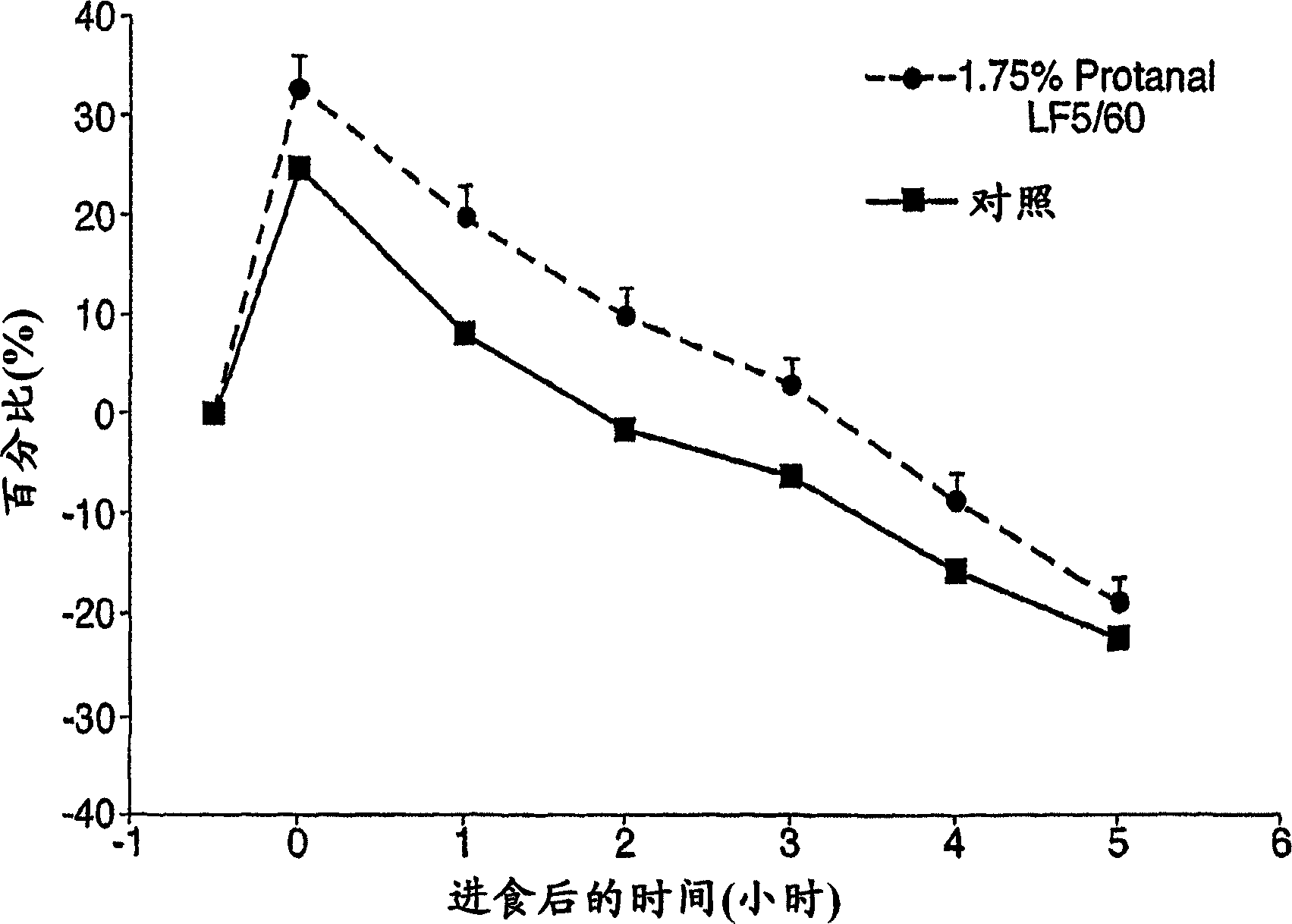

Embodiment 1

[0177] Commercially available meal replacement beverages (US Slim*Fast TM Chocolate Royale ready-to-drink beverage, multiple cans of the same batch) added 1.75% Protanal LF5 / 60 TM (The content of L-guluronic acid is 69%, and the weight average molecular weight is 1.0-1.2×10 5 Alginate from FMC Biopolymer), so that 325ml beverage contains 5.69g alginate. This meal replacement drink contains approximately 6.6g of protein.

[0178] Shake beverage cans, open, weigh and pour into Wolff food processor. Alginate, lactulose (5 g, added for calculation of intestinal transit time) and tricalcium phosphate (10% by weight of alginate) were mixed at 1500 rpm for 2 minutes at room temperature. The mixture was then evacuated and mixed for an additional 5 minutes. Steam was passed through the Wolff jacket until the contents warmed to 60°C and mixed at 1500 rpm for 15 minutes at this temperature. This mixture was then poured into the premix tank of the UHT plant and stirred slowly during ...

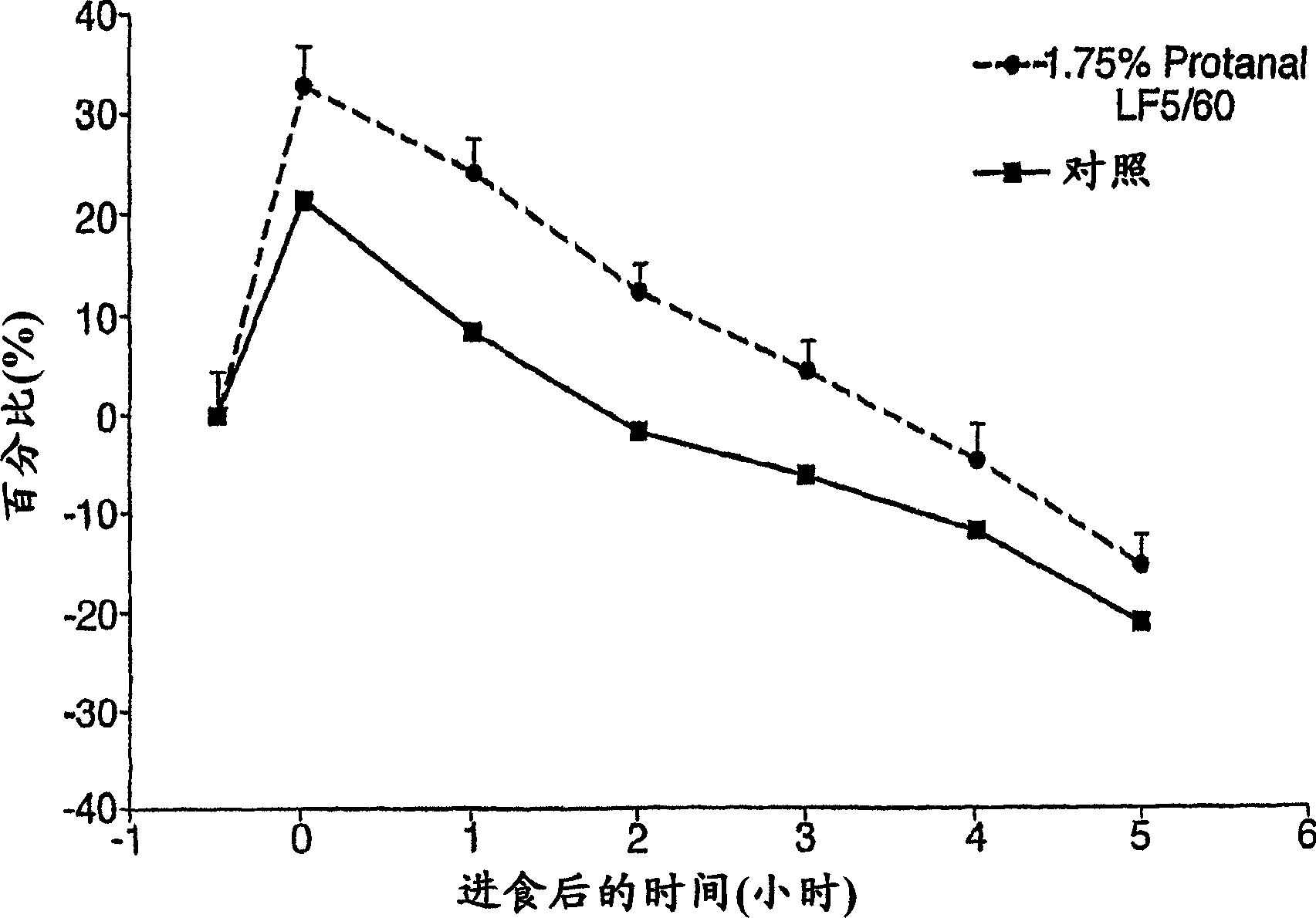

Embodiment 2

[0191] A control composition was prepared according to the formulation given in Table 1 below. All weights are given as percentages of the total weight of the control composition.

[0192] %weight

water

86.60

Skimmed Milk Powder (SMP)

6.50

4.05

calcium caseinate

1.60

Spices (French Herbs)

0.54

canola oil

0.33

0.10

Emulsifier

0.09

Total 100%

[0193] A control composition was prepared as follows: water was heated to 50°C, premixed skim milk powder (SMP), caseinate and sucrose were added and mixed. The mixture was heated to 55°C and mixed with an Ultra-Turrax for 15 minutes. Add the preheated (>60°C) fatty phase (oil, lecithin and emulsifier) and mix for 2 minutes. The mixture was homogenized in two stages; 100 / 40 bar (Niro homogenizer: throughput ~14 kg / hour, back pressure 4 bar), followed by a small UHT line (heating / holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com