Patents

Literature

38results about How to "Diffusion evenly distributed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

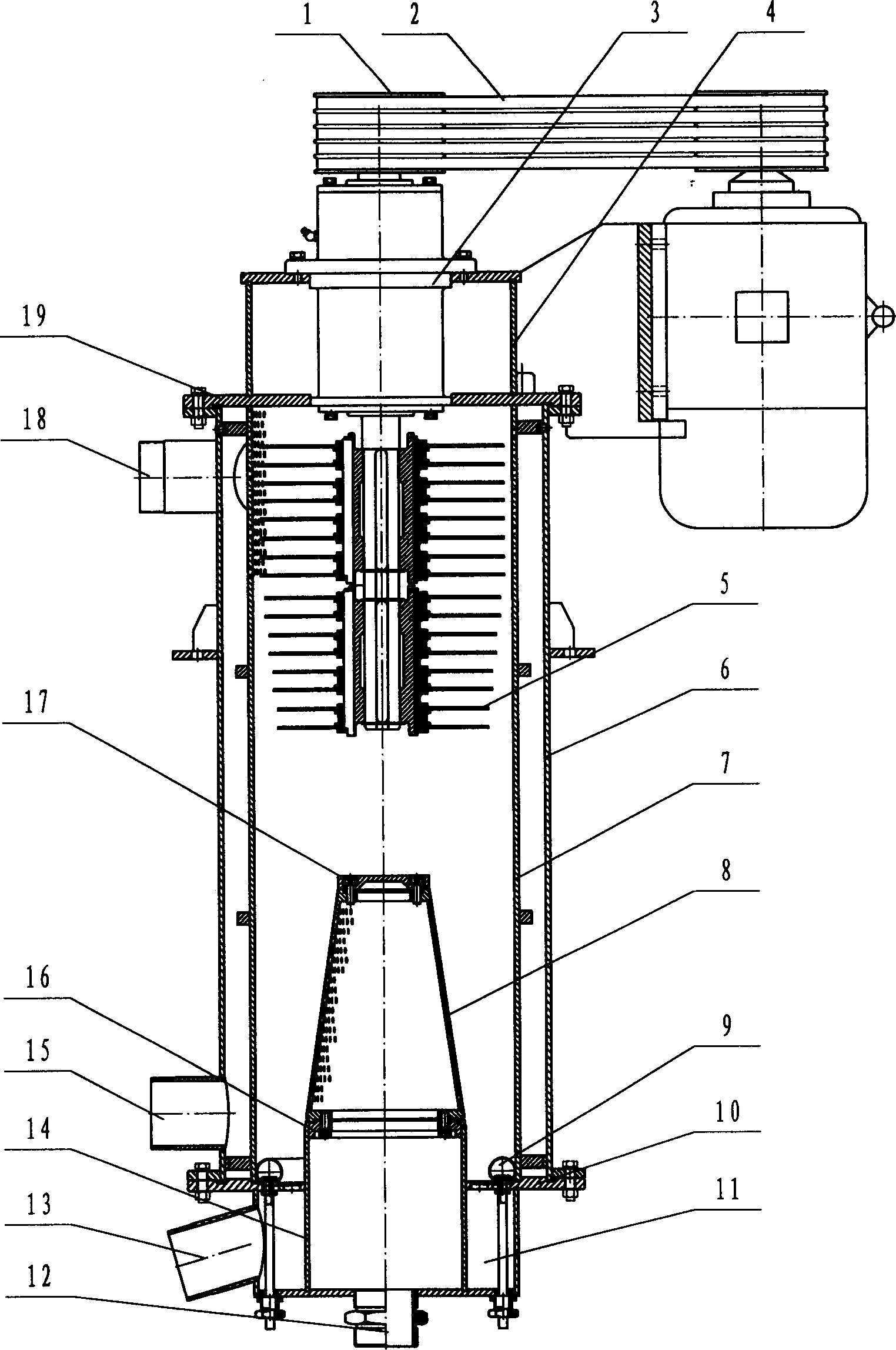

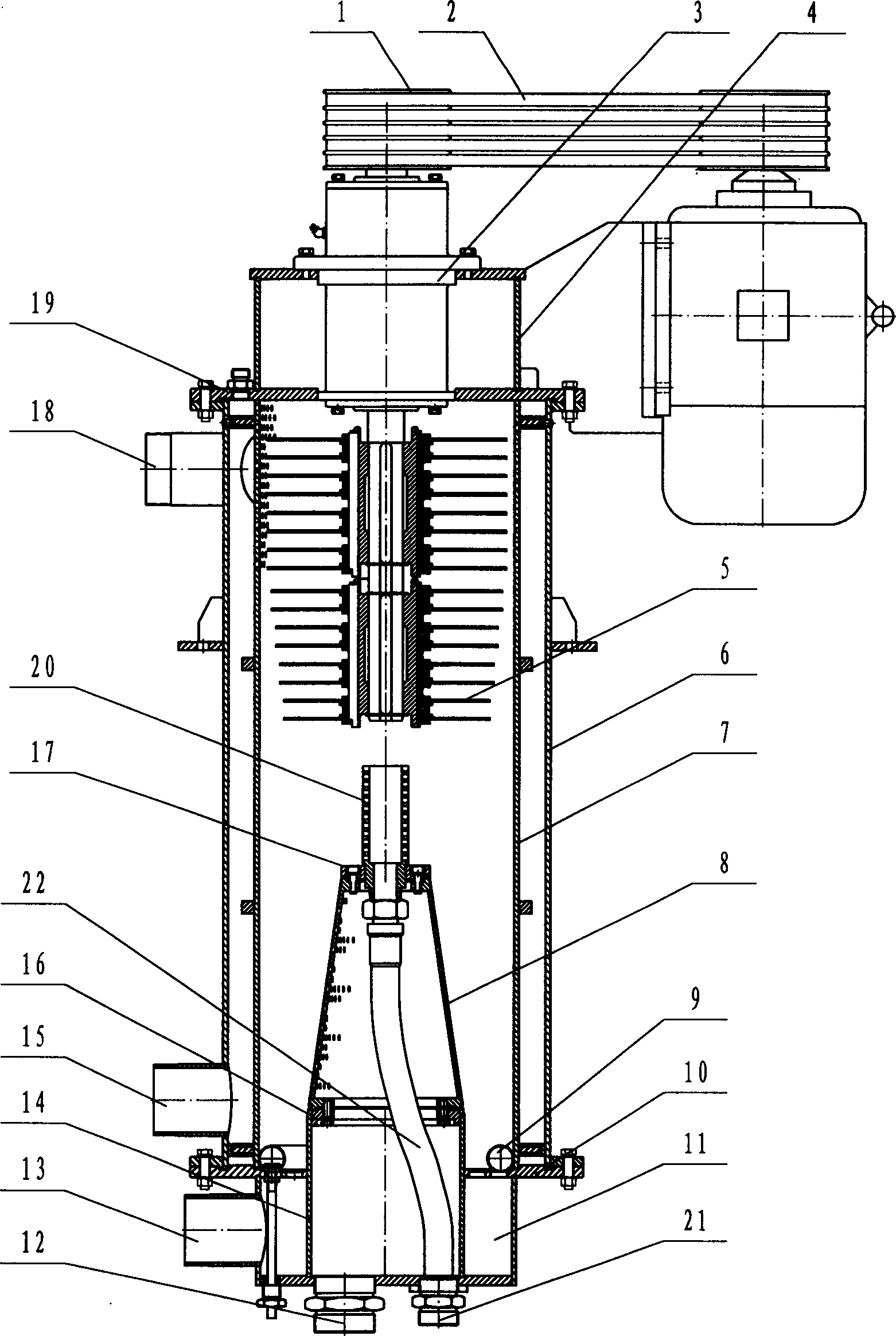

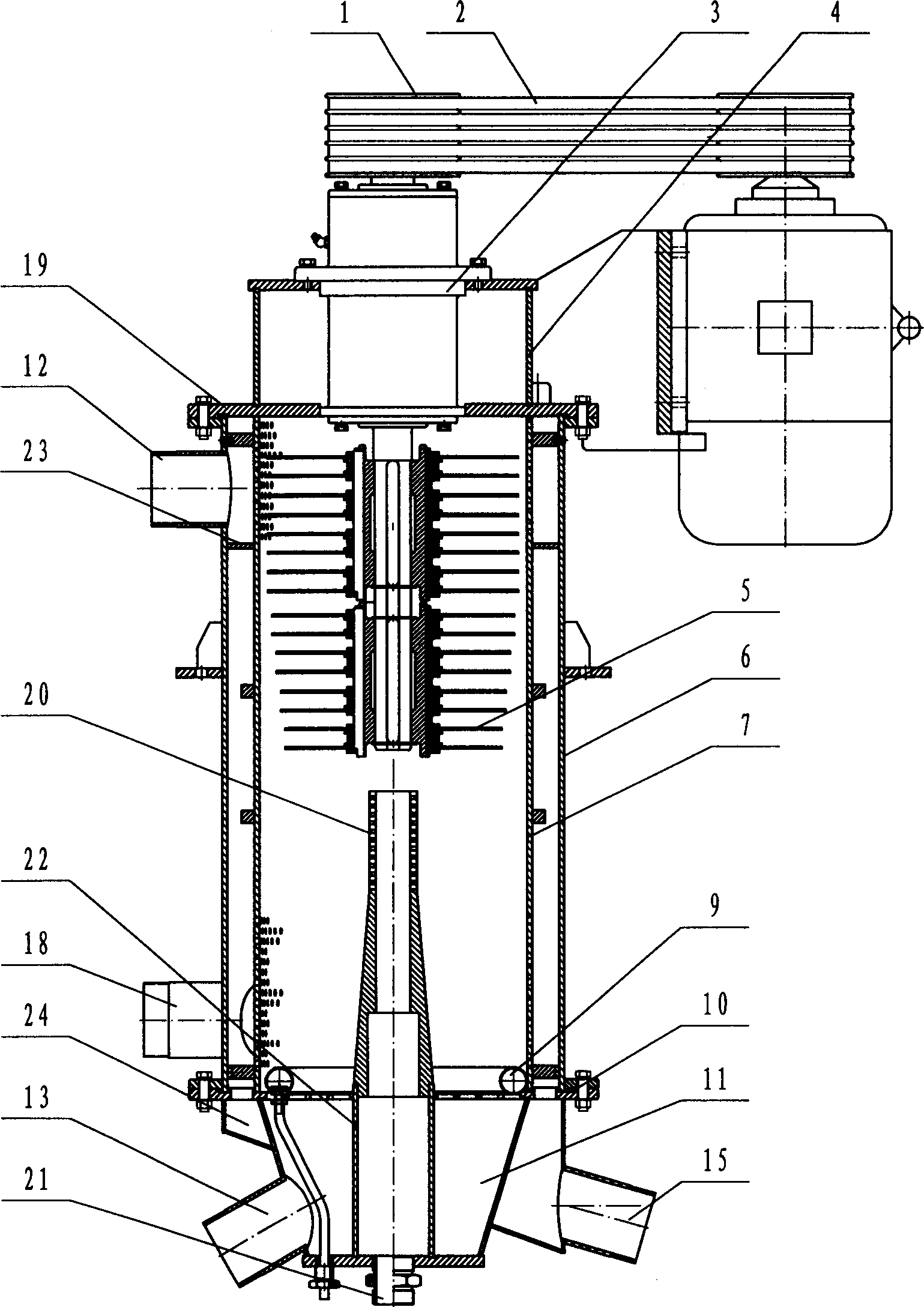

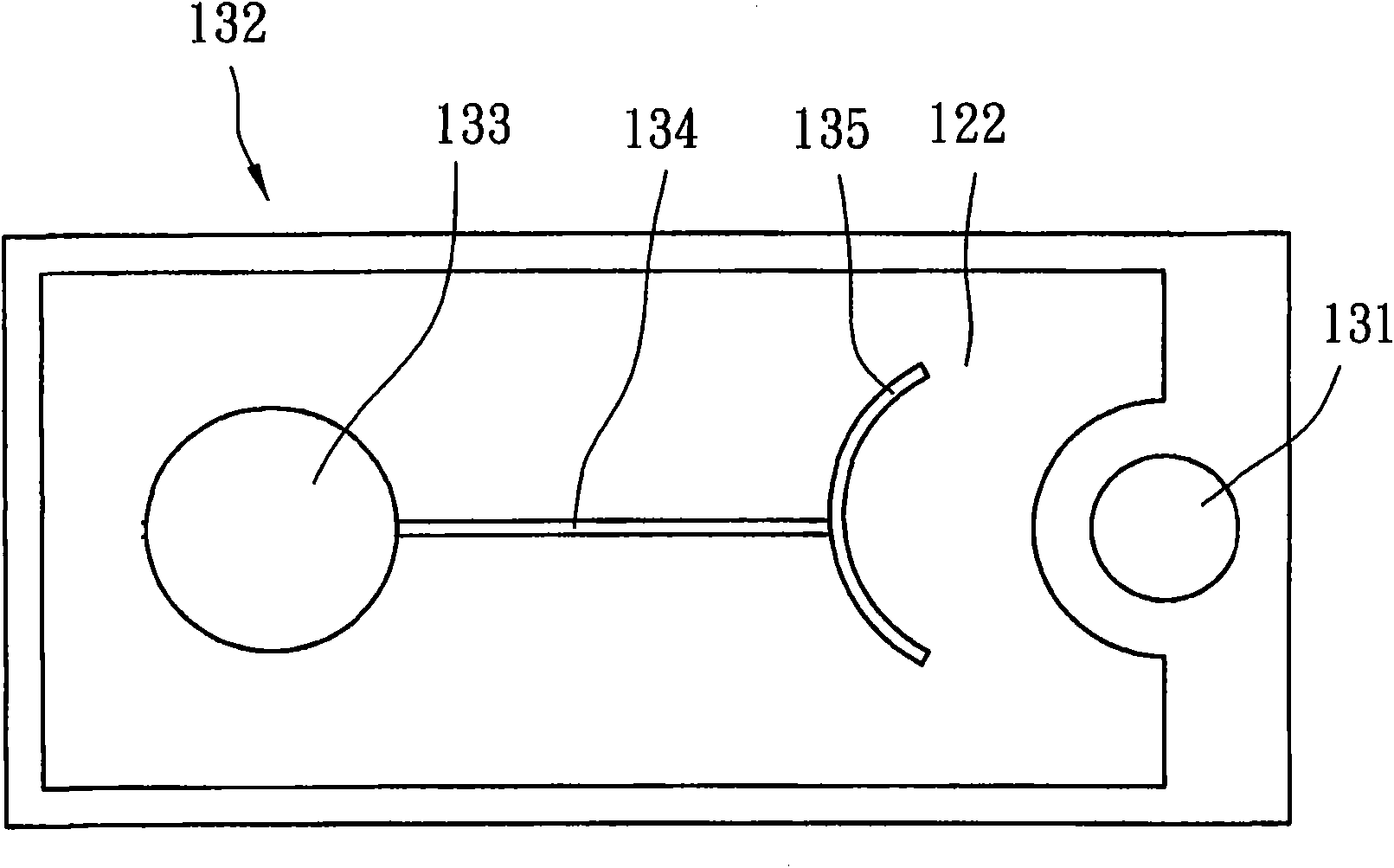

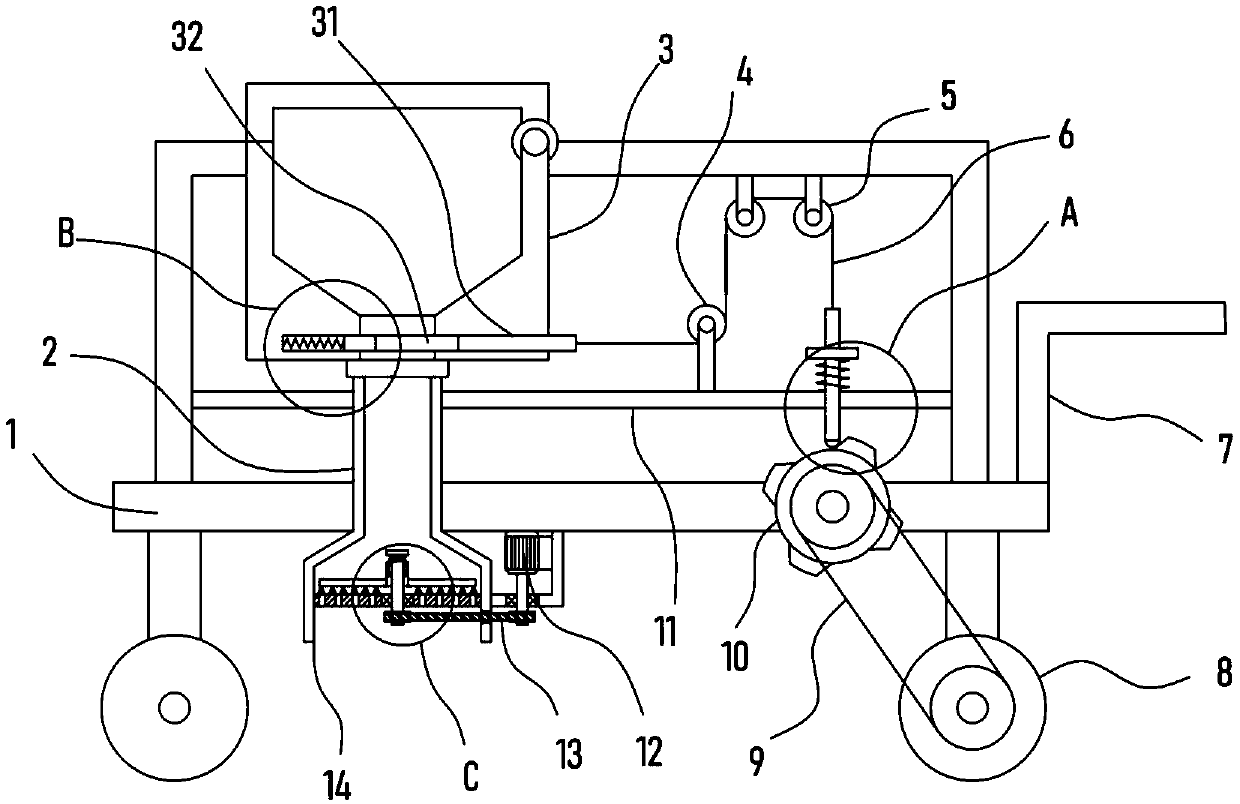

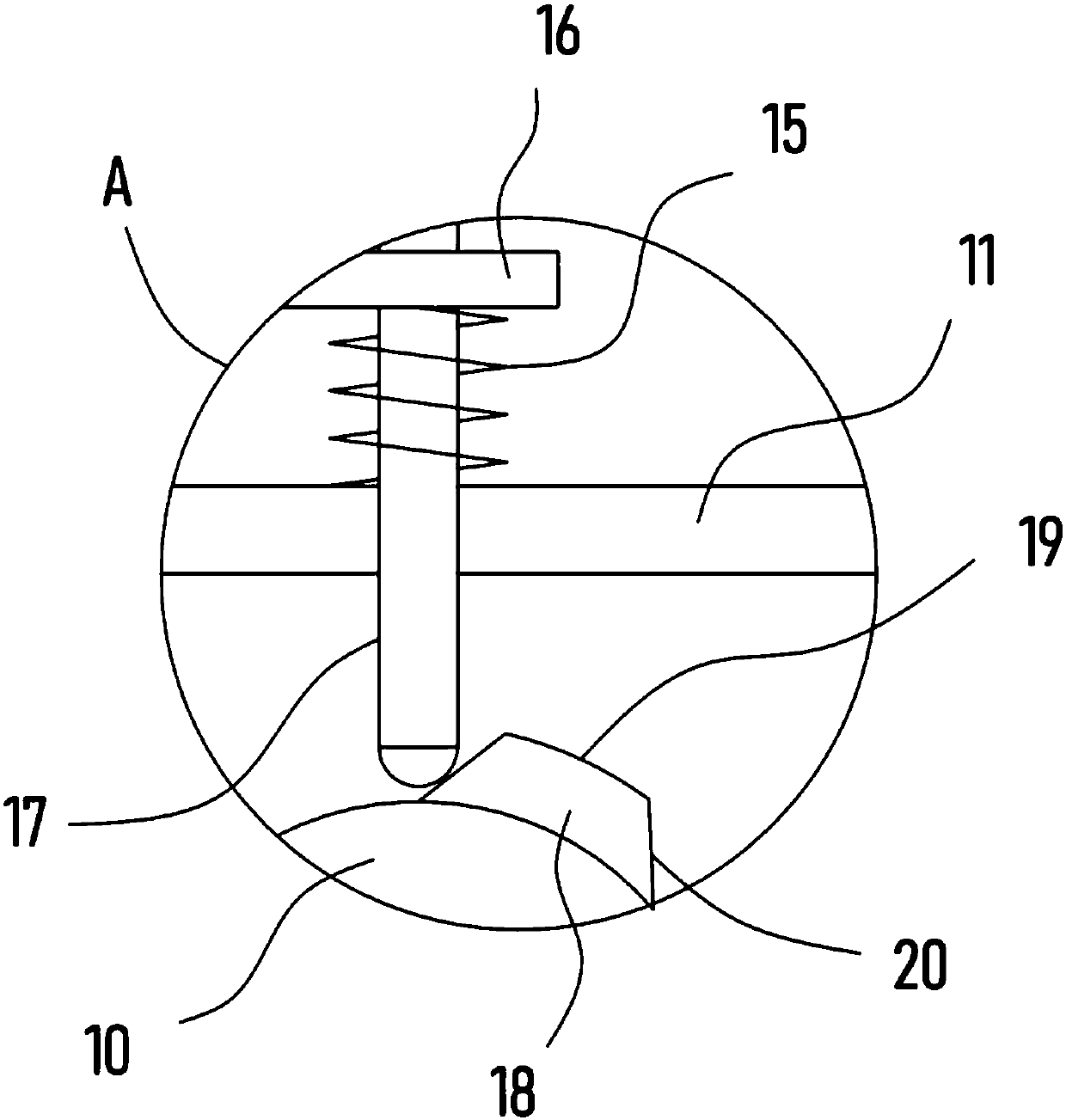

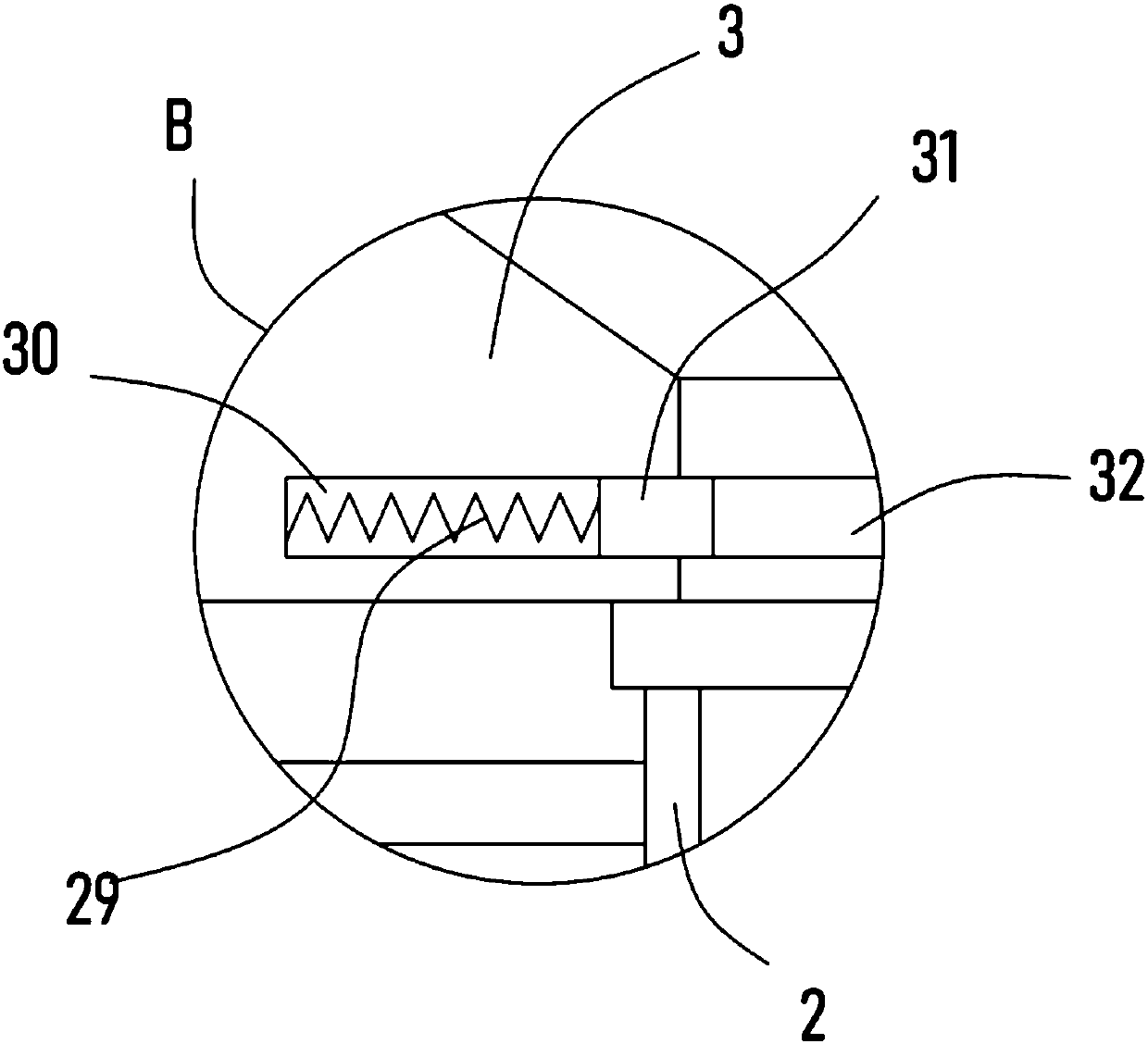

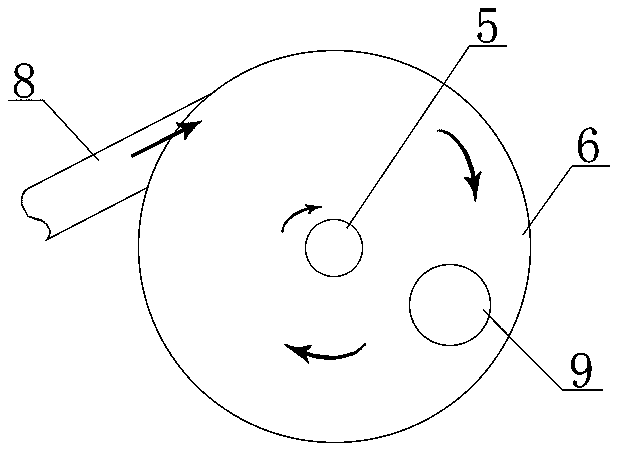

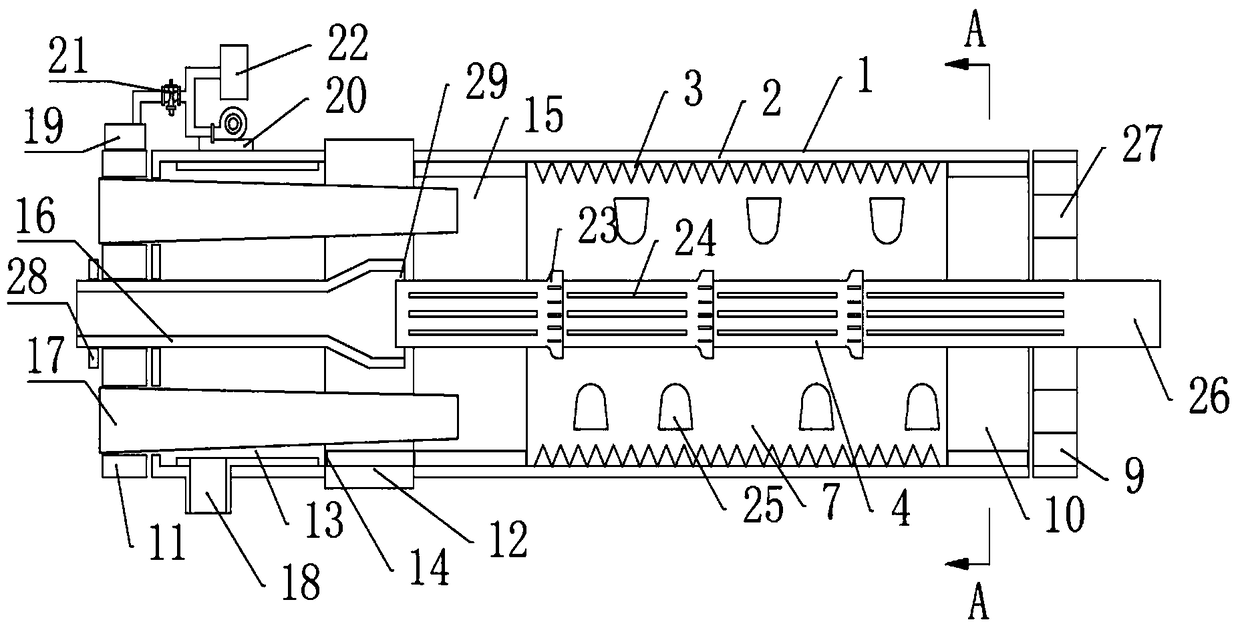

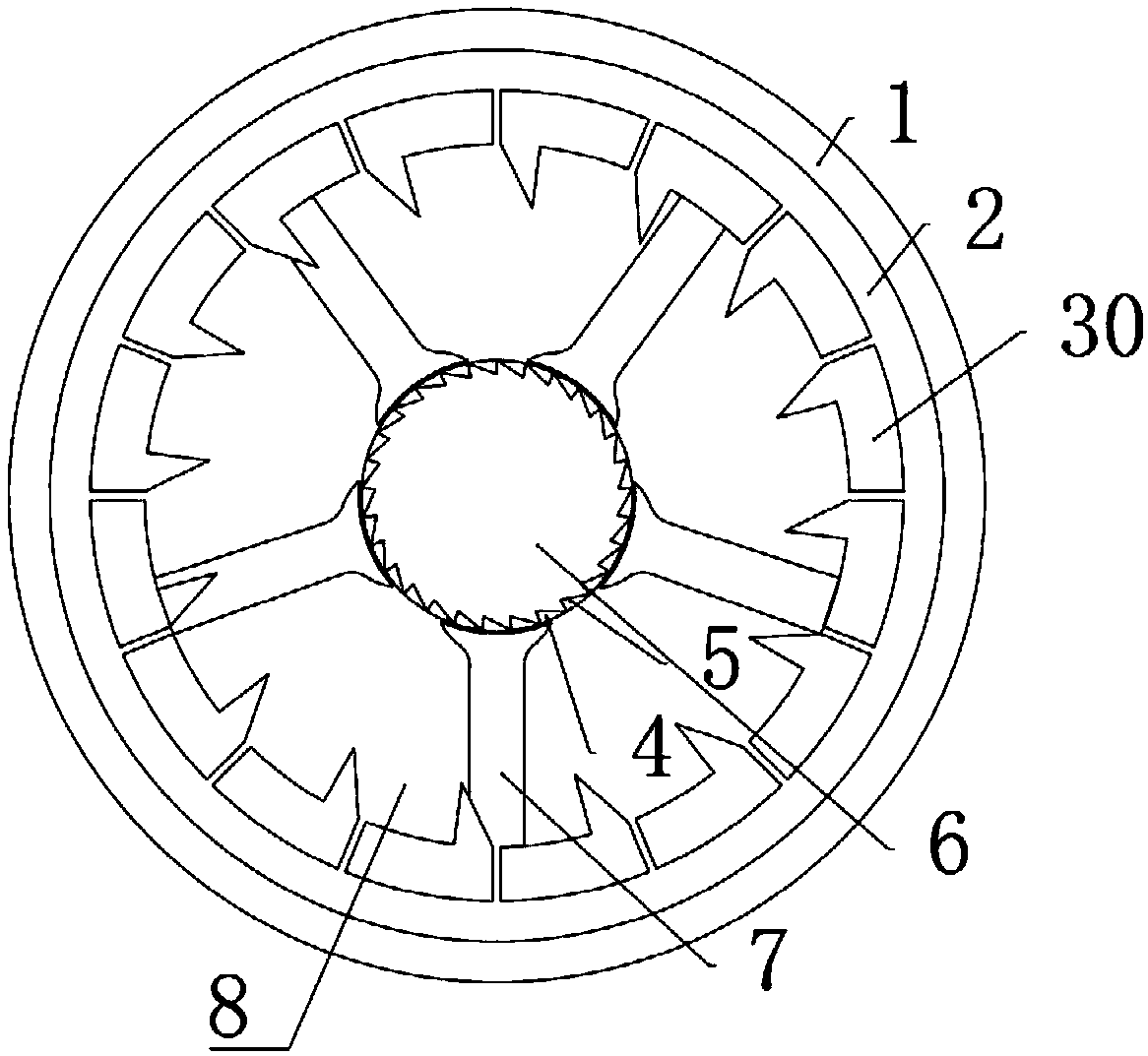

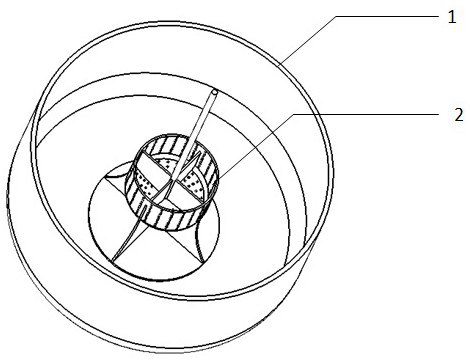

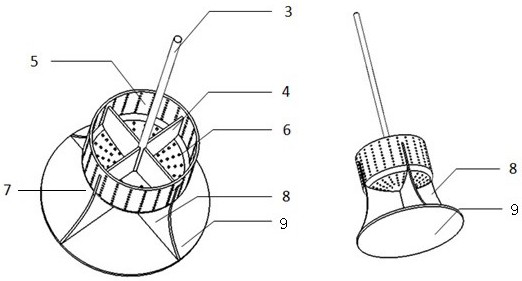

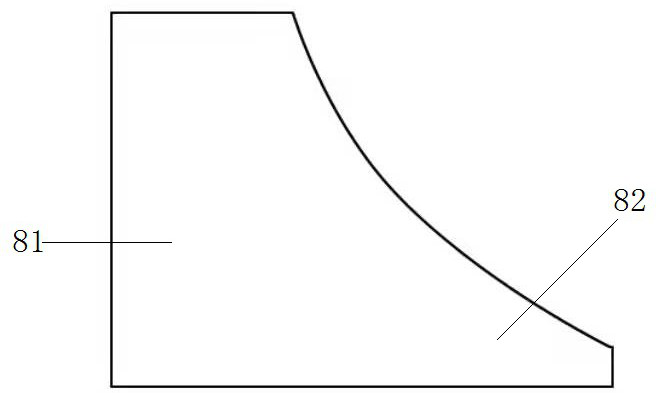

Settling centrifuger with internal rotor

InactiveCN1383926ADiffusion evenly distributedEasy to separateWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSlurrySewage treatment

The present invention relates to the technology of centrifugal separation of mixed liquid. The centrifuge incldues transmission mechanism, pin wheel rotor with extending area covering at least partial centrifugal cavity space, slurry intake, casing and filtering cylinder assembly, aerator, slurry outlet filter and light phase skimming out device. The centrifugal cavity has several modes and several slurry and material discharge combinations. The material in slurry discharge filter is eliminated by centrifugal vortex and gravity. The present invention is used in solid-solid, liquid-liquid and solid-liquid-liquid separation, mass-transferring reaction and sewage treatment.

Owner:高根树

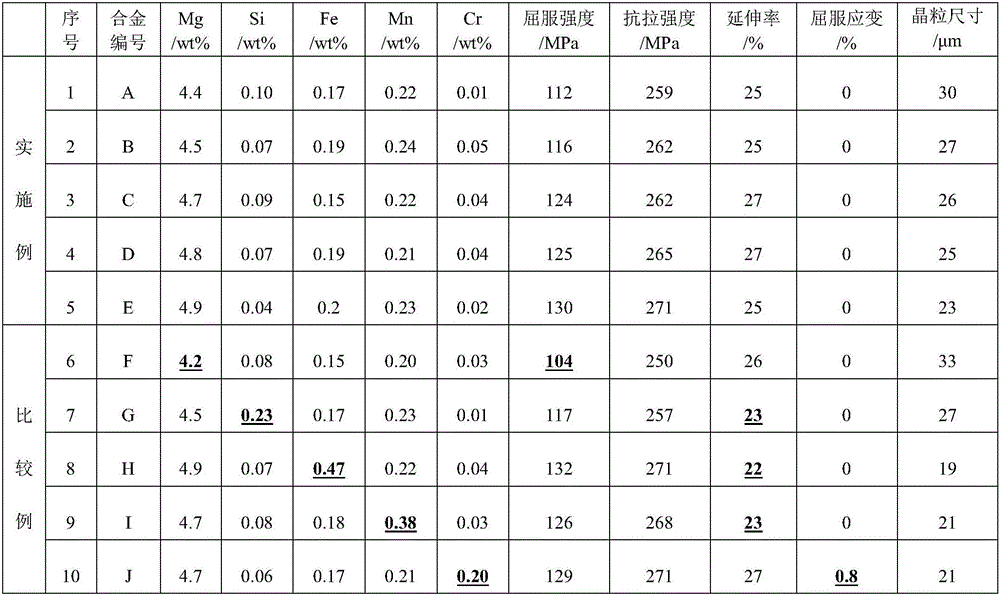

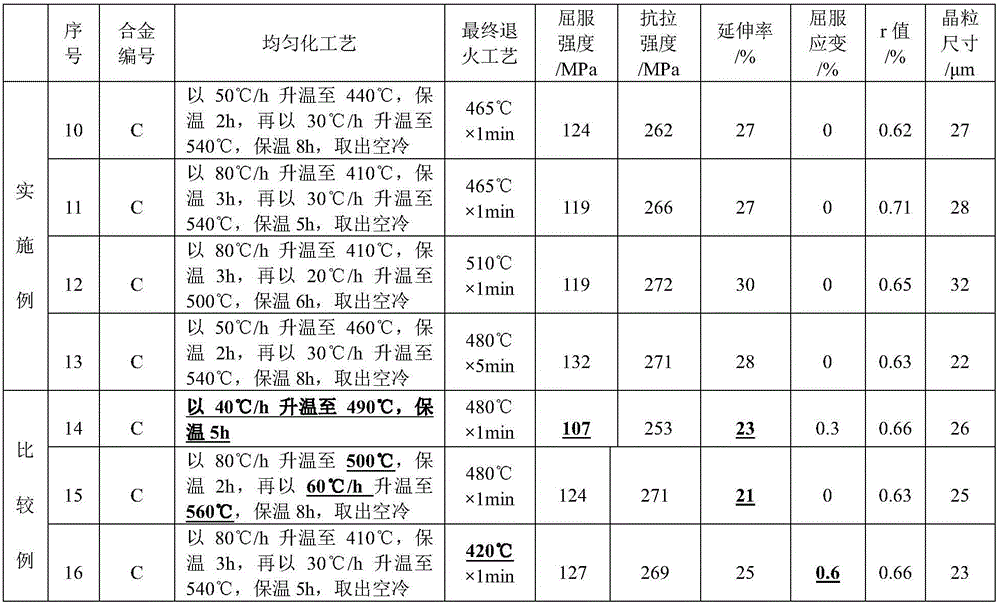

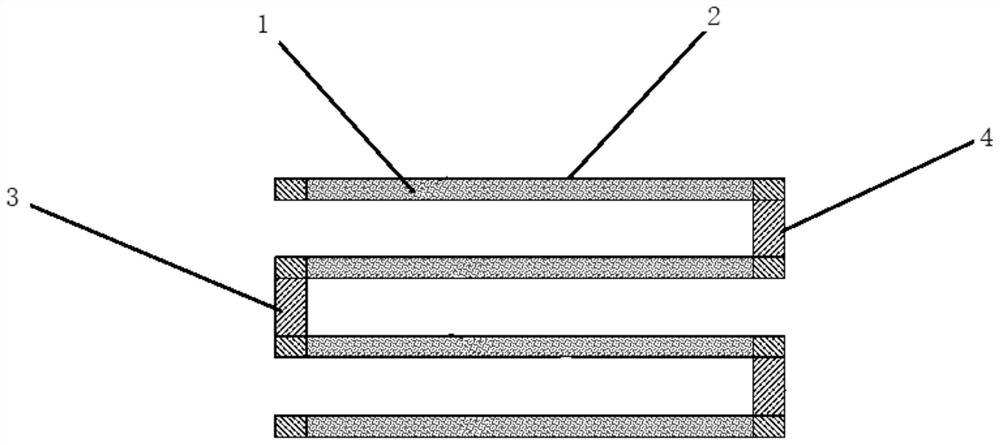

5xxx aluminum alloy board for automobile body and manufacturing method thereof

The invention provides a 5xxx aluminum alloy board for an automobile body and a manufacturing method thereof. The board comprises the following components: 4.4 to 5.0wt% of Mg, not greater than 0.1wt% of Si, not greater than 0.25wt% of Fe, not greater than 0.25wt% of Mn, not greater than 0.05wt% of Cr, not greater than 0.3wt% of Cu, and the balance Al and inevitable impurity elements. The manufacturing method comprises the following steps: melting and casting aluminum alloy into an ingot; performing double-stage homogenizing treatment, namely, heating at a speed of being not less than 50 DEG C per hour until the temperature is 400 to 440 DEG C, maintaining the temperature for more than 2 hours, then heating at the speed of being not greater than 30 DEG C per hour until the temperature is 500 to 540 DEG C, and maintaining the temperature for more than 5 hours; performing hot rolling, cold rolling, intermediate annealing and final cold rolling; performing final annealing at the temperature of 450 to 530 DEG C in a continuous annealing manner. According to the 5xxx aluminum alloy board for the automobile body and the manufacturing method thereof, the components of the alloy and the preparation process of the aluminum alloy board are controlled, so that the yield strength and elongation percentage of the aluminum board can be improved, and as a result, the grain size can be increased within a certain range, and the surface of the formed board is free of luders bands.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Gasoline engine tailing gas particle filtering device catalyst and preparation method thereof

ActiveCN109621952ADiffusion evenly distributedReduce exhaust back pressureDispersed particle separationCatalyst activation/preparationCeriumRare earth

The invention relates to a gasoline engine tailing gas particle filtering device catalyst and a preparation method thereof. The catalyst comprises a carrier, the inner wall of a hole of the carrier iscoated with a catalytic coating layer, the coating mount of the catalytic coating layer is 50-120 g / L, the height of the catalytic coating layer in the axial direction is 100% of the height f the carrier, the catalytic coating layer comprises cerium-zirconium rare-earth oxides, gamma-aluminum oxides and precious metal active components, the precious metal active components comprise Pd and Rh, wherein the loading amount of Pd is 0.1-1.5 g / L, and the loading amount of Rh is 0.05-0.5 g / h. the catalyst has the advantages that through the improvement of a catalytic coating layer coating technology, the uniform dispersing distribution on the inner wall structure of the hole of the catalytic coating layer is achieved to significantly reduce the gas discharging back pressure of a particle filtering device catalyst, the effects of intercepting particles and converting gaseous pollutants are well achieved by the uniformly distributed catalytic coating layer, and therefore gas discharging back pressure is reduced by the prepared filtering device catalyst while the particle capturing rate and catalytic performance are not impacted by negative influences.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

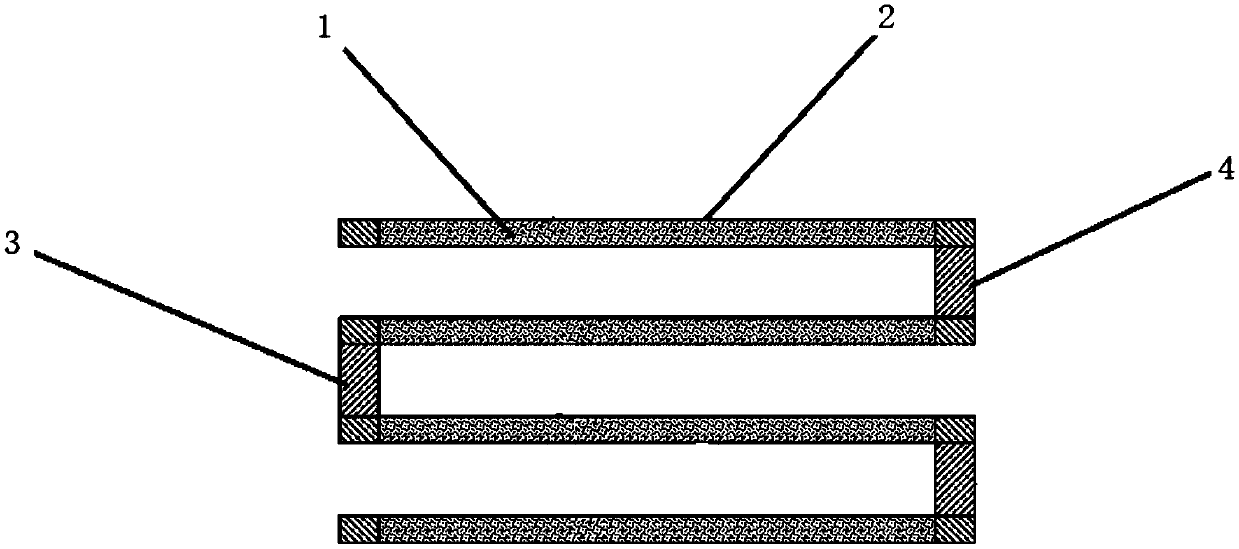

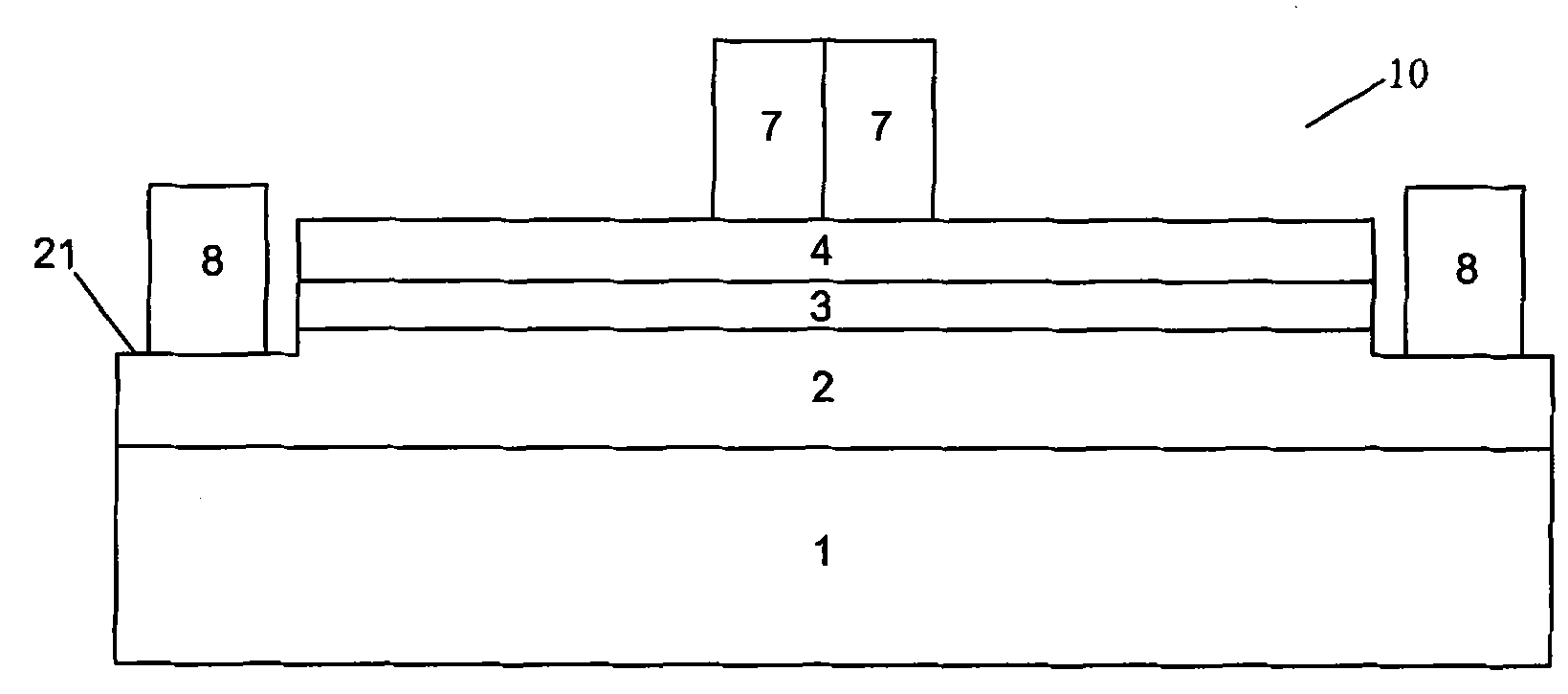

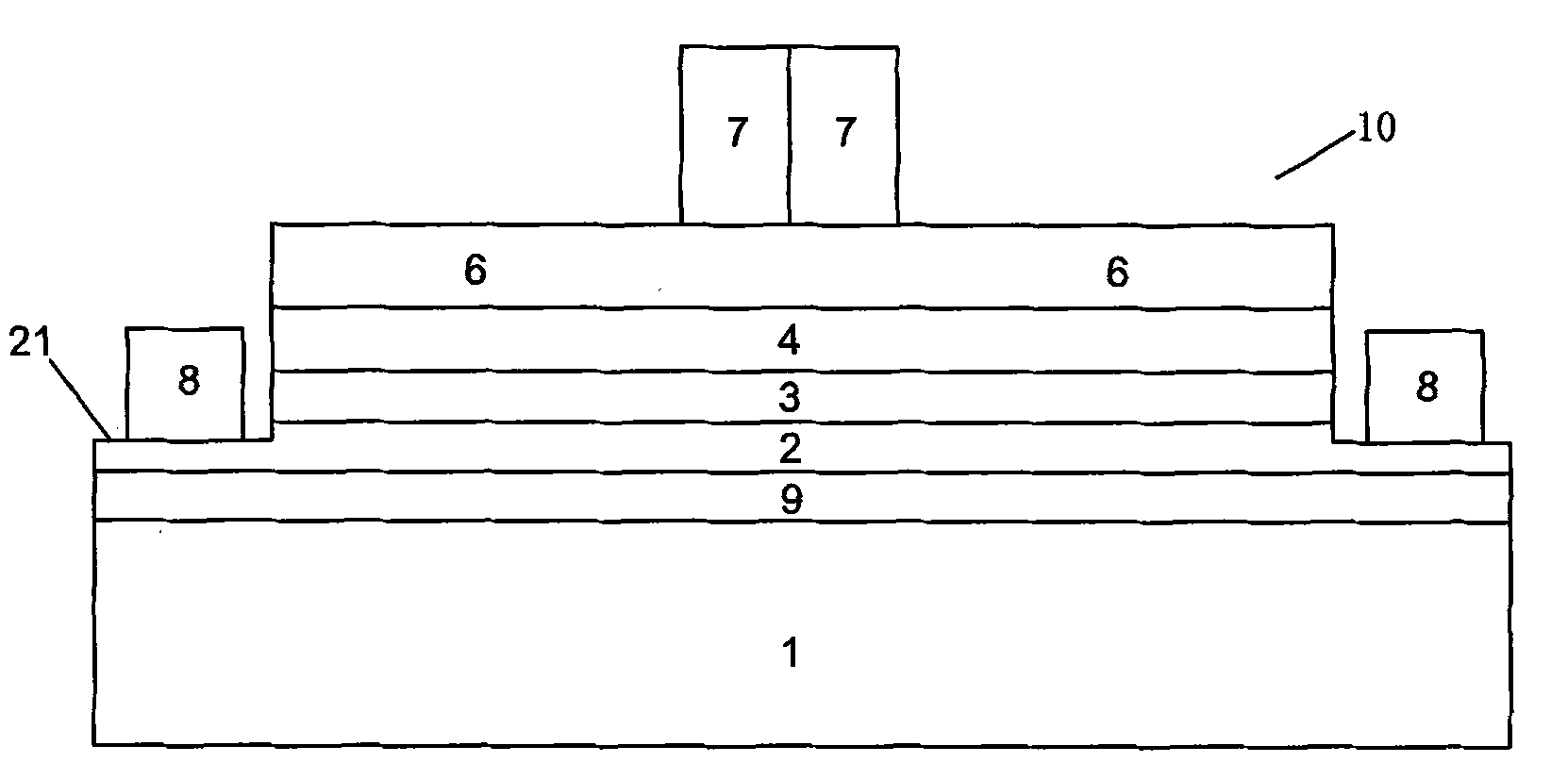

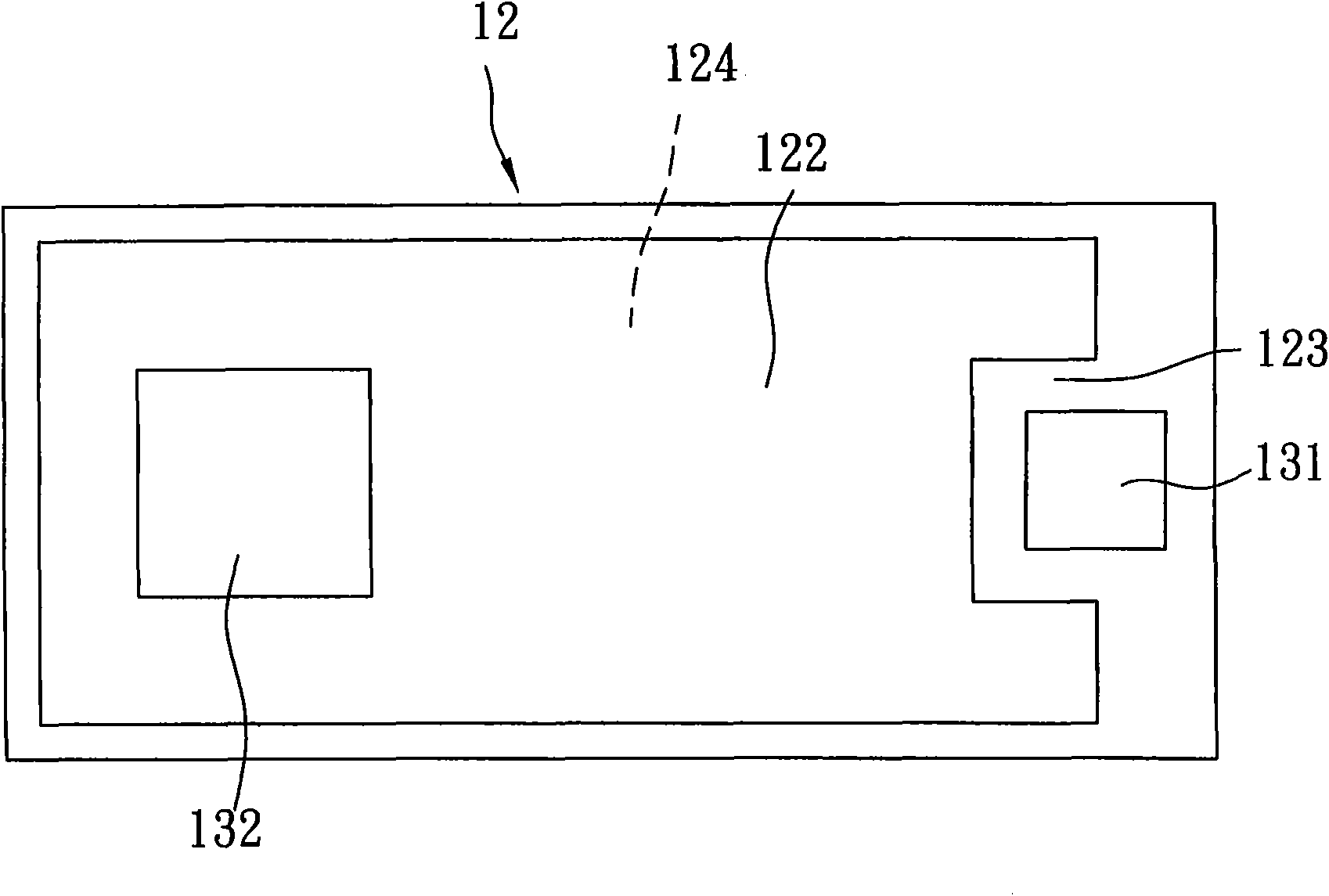

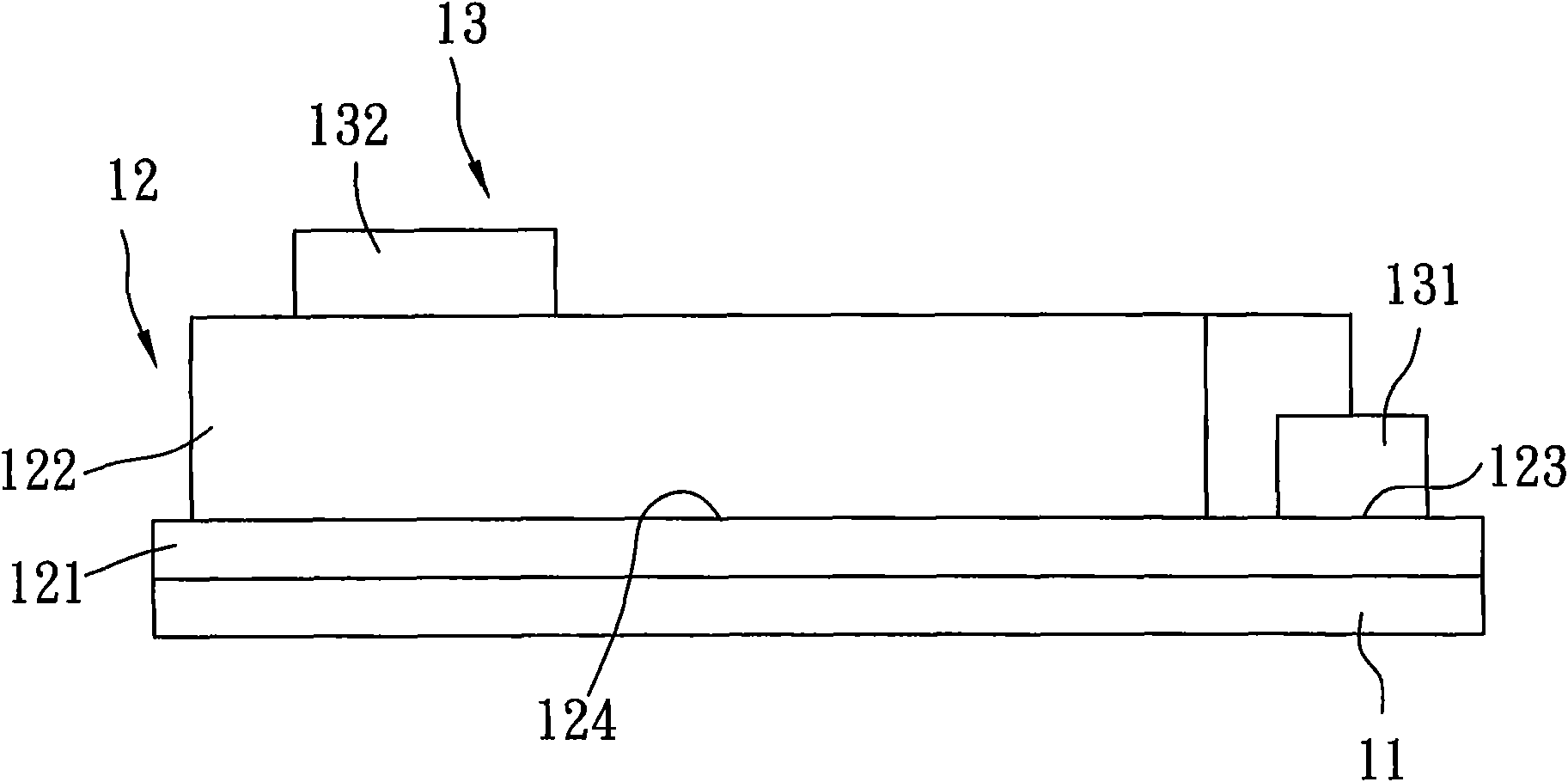

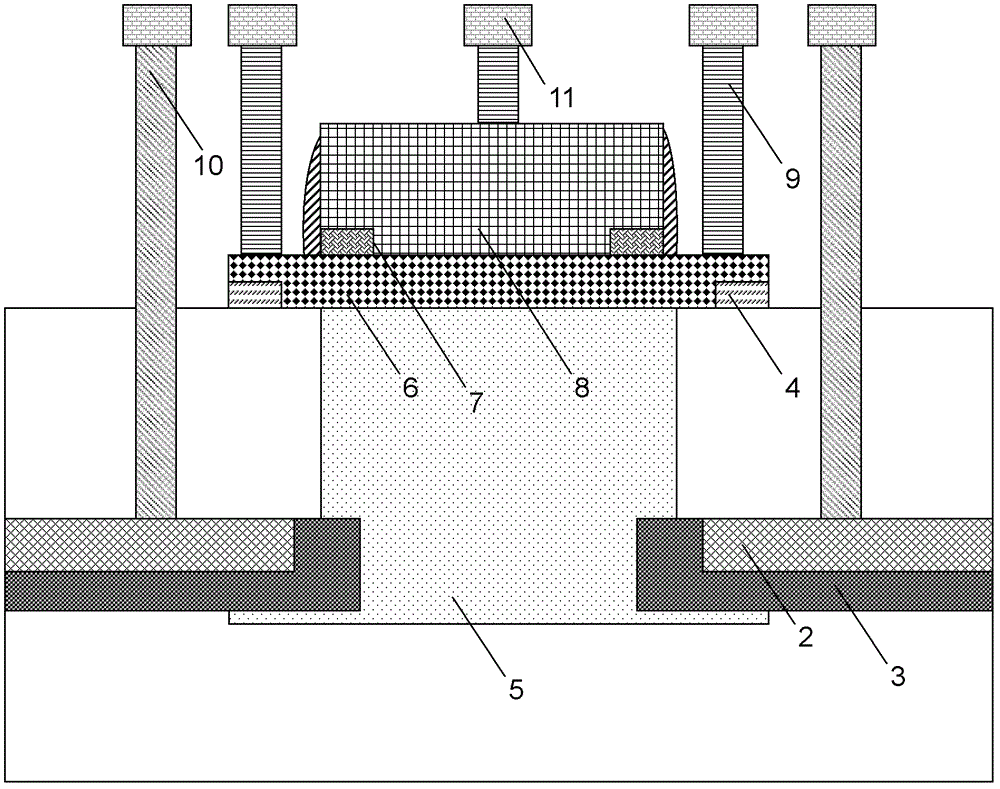

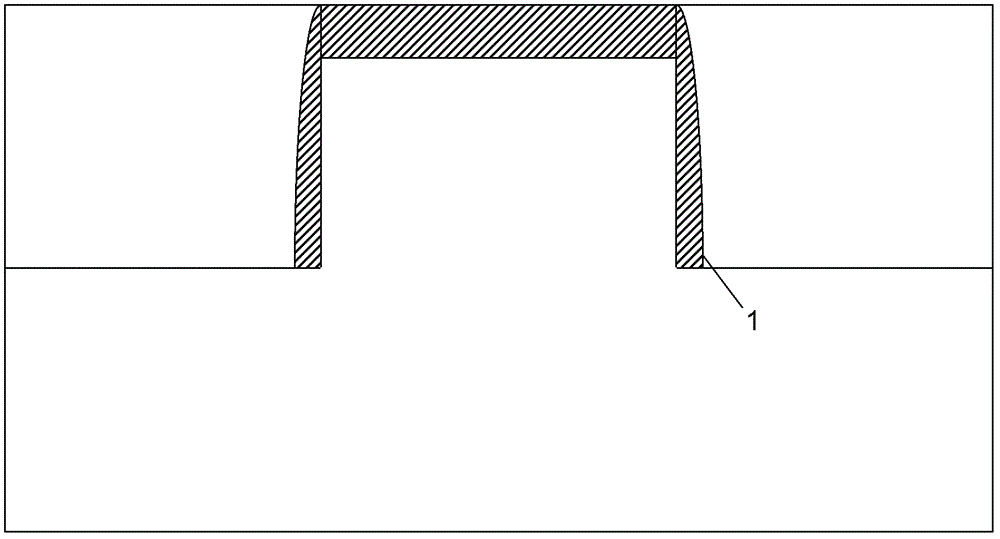

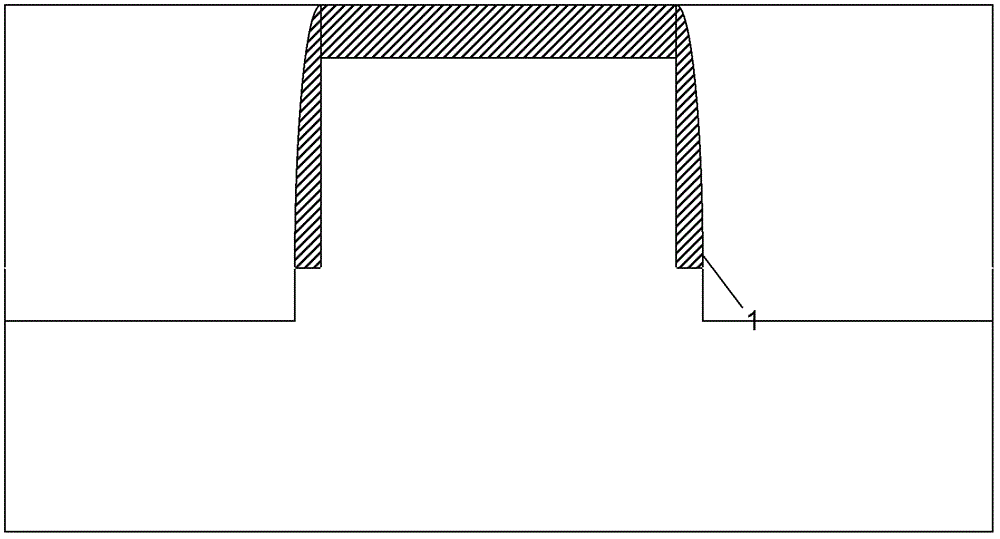

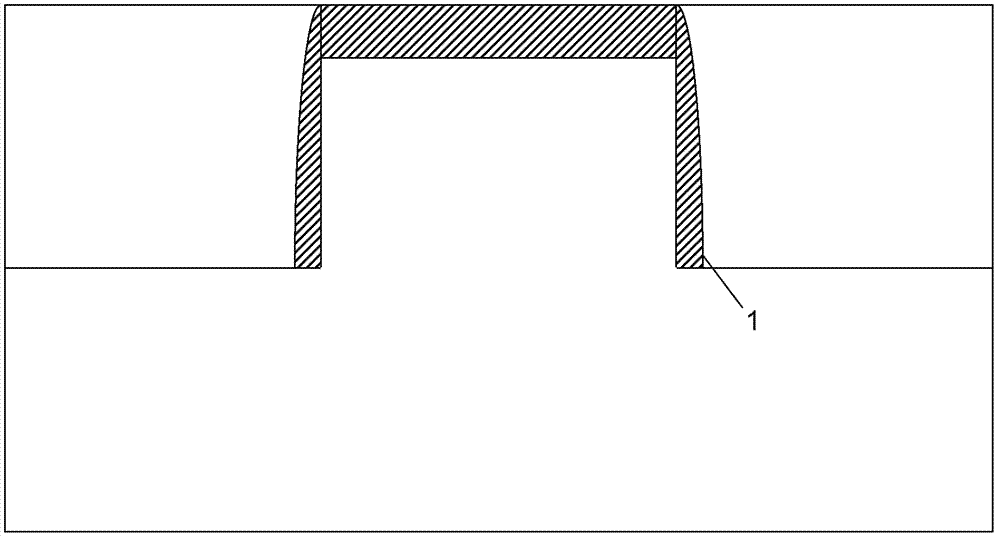

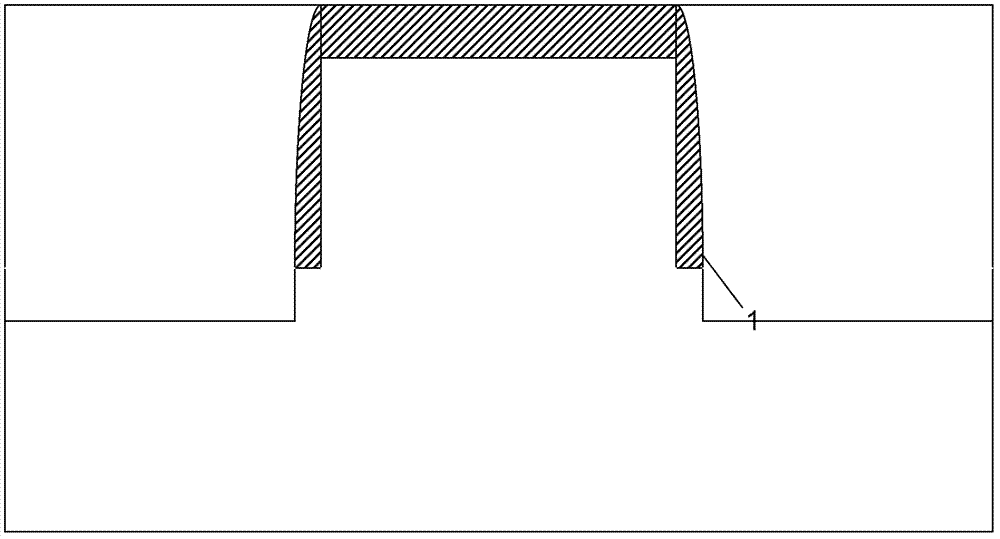

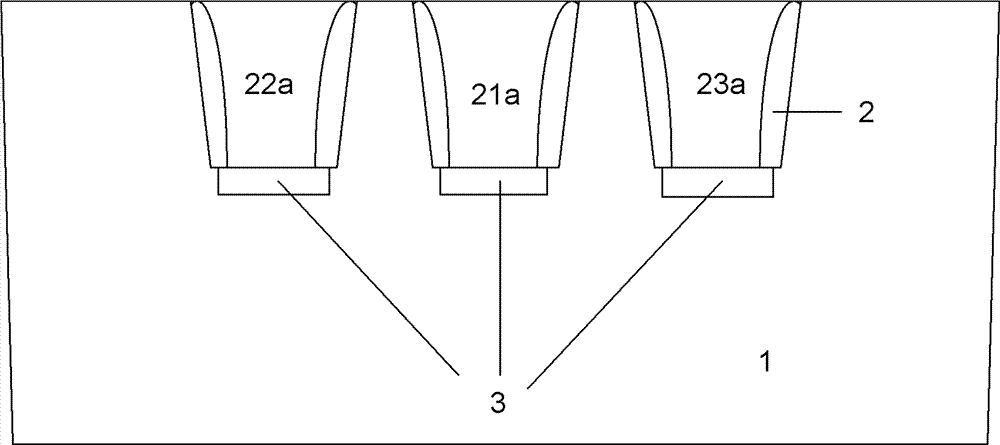

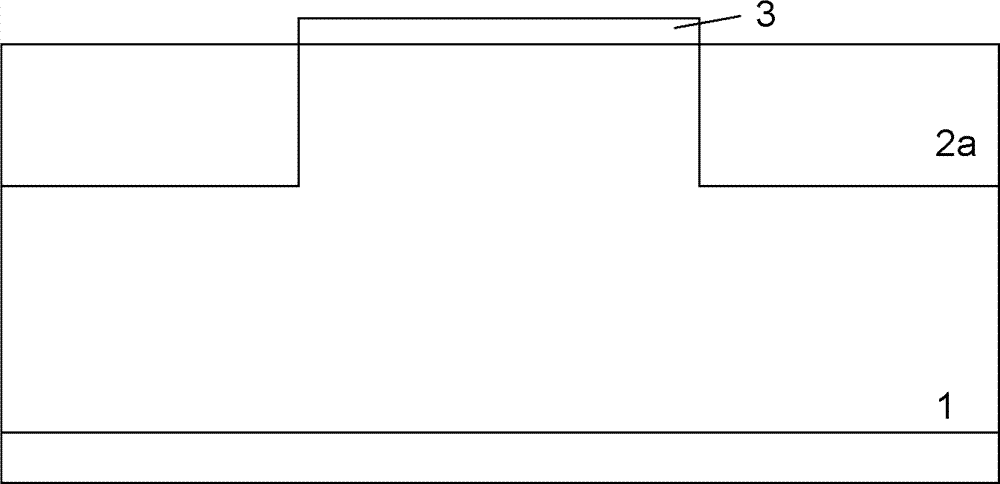

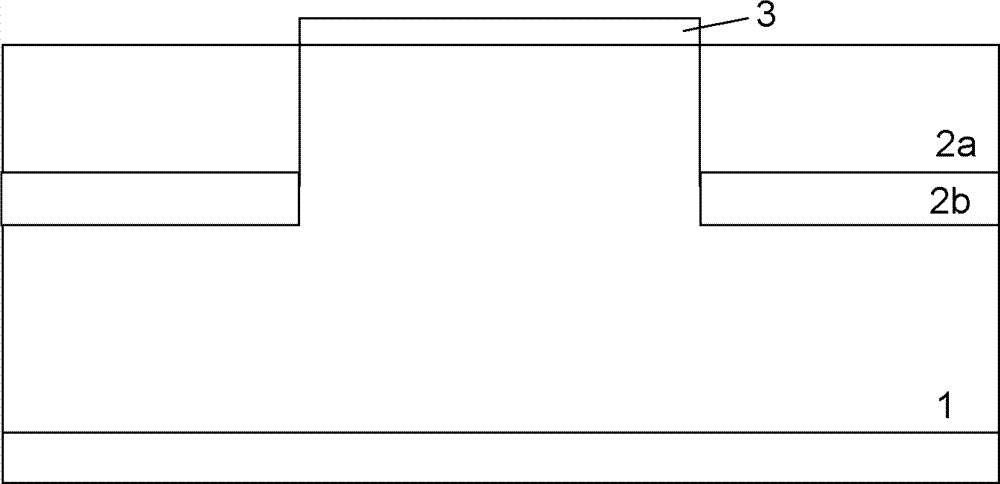

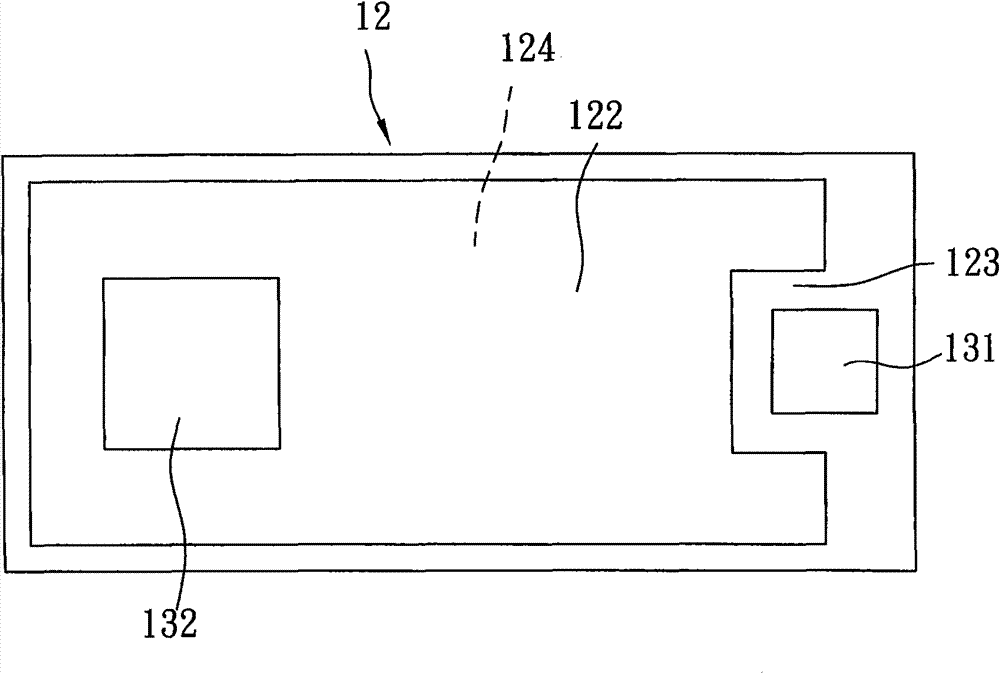

LED (light emitting diode) wafer with evenly distributed current

InactiveCN102142499AImprove light extraction efficiencyExtended service lifeSemiconductor devicesLight-emitting diodeLight emission

The invention discloses an LED (light emitting diode) wafer with evenly distributed current, comprising an N-type semiconductor layer, a luminescent layer, a P-type semiconductor layer, negative electrodes and positive electrodes, wherein the luminescent layer is formed on the N-type semiconductor layer; the P-type semiconductor layer is formed on the luminescent layer; the surface of the P-type semiconductor layer is provided with grooves communicated with the N-type semiconductor layer; the negative electrodes are formed on the grooves; and the positive electrodes are formed on the P-type semiconductor layer. The LED wafer is characterized in that the grooves are one pair of symmetrical E-shaped grooves; the symmetrical E-shaped grooves are distributed on the N-type semiconductor layer; the negative electrodes are formed on the grooves to correspondingly form symmetrical E-shaped negative electrodes; and the positive electrodes surround the symmetrical E-shaped negative electrodes. The LED wafer has the advantages of even heat dissipation, high light emission efficiency, long service life and the like.

Owner:GUANGDONG TONGFANG ILLUMINATIONS CO LTD

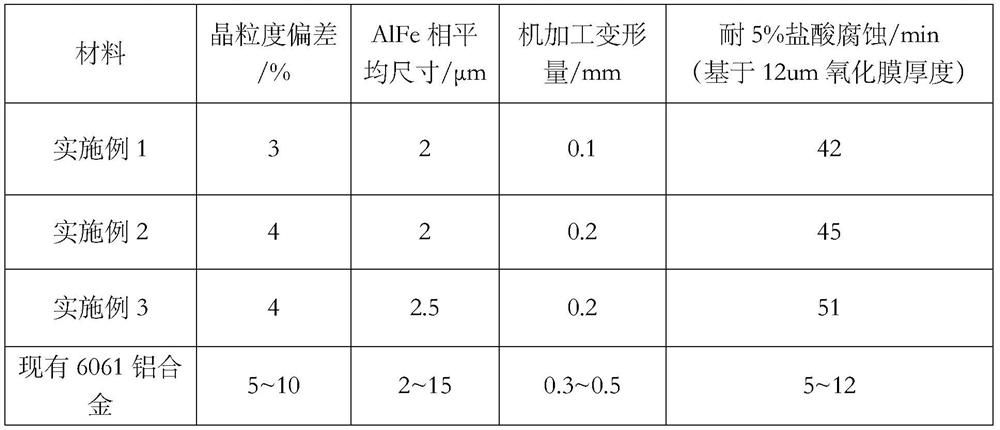

Preparation method of large-size 6061 aluminum alloy plate for semiconductor equipment

PendingCN112593100AImprove machining accuracyMeet the requirements of shape and position stabilityIngotStress relief

The invention discloses a preparation method of a large-size 6061 aluminum alloy plate for semiconductor equipment. The preparation method comprises the following steps of smelting and casting a proportioned aluminum alloy to obtain an aluminum alloy cast ingot; enabling the obtained aluminum alloy cast ingot to be subjected to homogenizing heat treatment, machining, preheating and hot rolling, and obtaining the large-specification aluminum alloy plate; and enabling the large-specification aluminum alloy plate obtained after the hot rolling to be pre-stretched, enabling the pre-stretched plateto be subjected to solution hardening, then conducting stretching and leveling, and conducting artificial aging. According to the preparation method, microstructure distortion energy segregation generated in the rolling process of the ultra-thick and ultra-wide 6061 plate can be eliminated or even, quenching internal stress generated by solid solution quenching is lower and more even, meanwhile,stress relief stretching after the quenching is combined, the residual internal stress is almost completely eliminated, the subsequent machining precision of the plate is remarkably improved, and therequirement of semiconductor equipment on high form and location stability of the aluminum plate is met.

Owner:广西南南铝加工有限公司

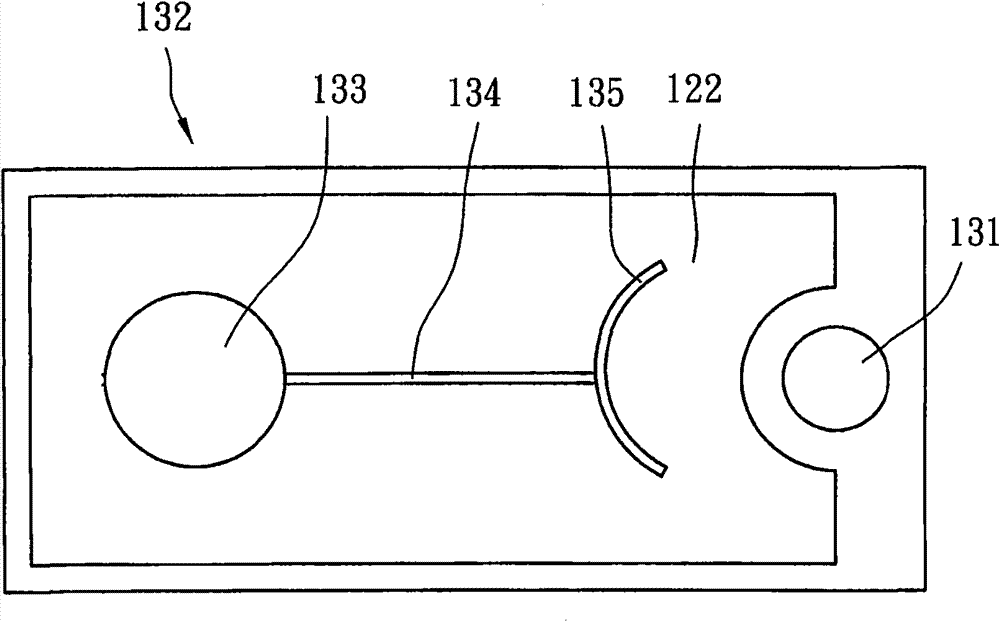

Light-emitting diode

InactiveCN101944559ADiffusion evenly distributedImprove luminous efficiencySemiconductor devicesLight-emitting diodeDiode

The invention provides a light-emitting diode comprising a base material, an action membrane and an electrode unit; particularly, the action membrane comprises a bottom connected with the base material and a platform part extending upwards from the bottom; the bottom comprises an opening region, a middle region, a first region and a second region, wherein, the middle region extends towards the first direction from the opening region; the first region and the second region are positioned at the two sides opposite to the opening region and the middle region; the electrode unit comprises a firstelectrode and a second electrode, wherein, the first electrode is arranged on the opening region; the second electrode is arranged on the top surface of the platform part; the width specific value ofthe first region and the second region which are vertical to the first direction is between 0.6 to 0.95; and the light-emitting efficiency of the light-emitting diode can be effectively promoted by utilizing the specific setting of the width specific value of the first region and the second region which are vertical to the first direction.

Owner:UBILUX OPTOELECTRONICS CORP

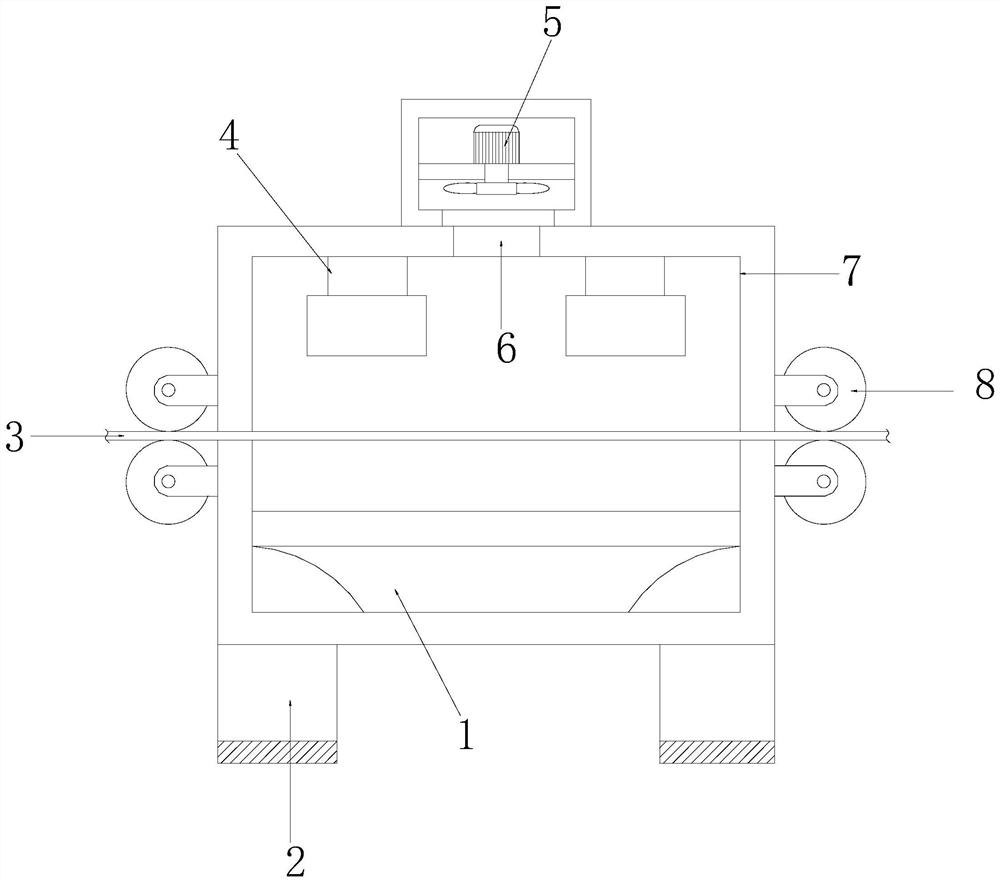

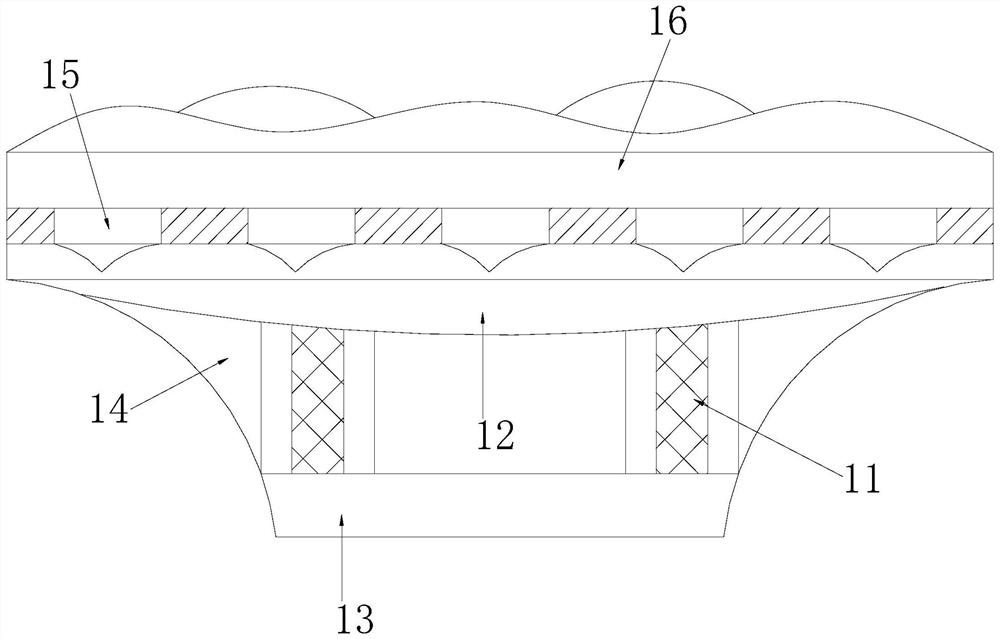

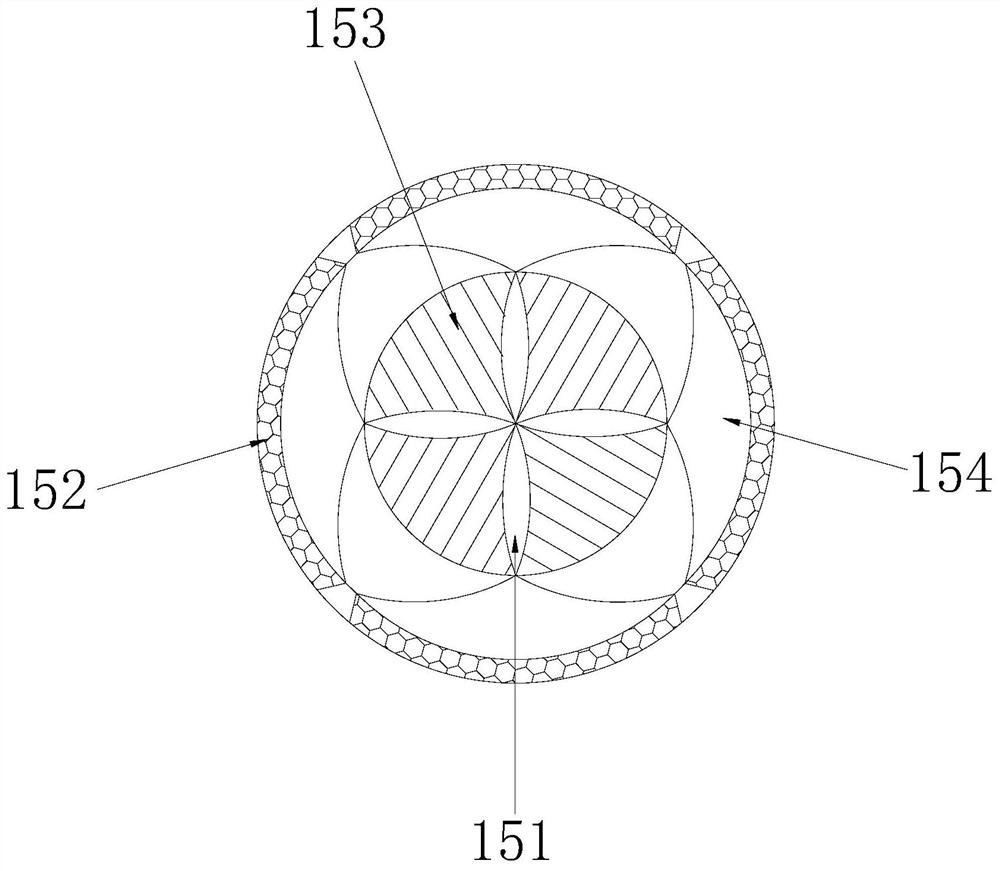

Seeding device for traditional Chinese medicinal material planting

InactiveCN109601074AHigh degree of automationGuaranteed sowing spacingBroadcast seedersDrive motorGermination

The invention discloses a seeding device for traditional Chinese medicinal material planting, and relates to the technical field of traditional Chinese medicinal material planting. The seeding devicefor the traditional Chinese medicinal material comprises a movable frame; travelling wheels which are driven to rotate through a motor are rotationally arranged at the bottom of the movable frame; a storage box which is used for storing seeds is mounted on the movable frame; a limiting spring of which the two ends are respectively fixed to a sliding baffle plate and the storage box is transverselyarranged in an inserting chamber; a driving motor is in transmission connection with an equally distributing mechanism which is positioned in equally distributing cover and is used for equally dividing seeds; the seeding device for traditional Chinese medicinal material planting is high in automation degree; the sliding plate is driven to perform transverse reciprocating motion through a transmission mechanism so as to realize intermittent falling seeding of the traditional Chinese medicine seeds in the storage box; the device seeds intermittently when moving, so that the seeding distance ofthe seeds is ensured; meanwhile, the equally distributing mechanism is arranged, which can uniformly disperse and distribute the seeds which fall from the equally distributing cover, so that the influence on the germination of the seeds caused by excessive accumulation of the traditional Chinese medicine seeds is avoided, and the seeding effect of the seeds in a traditional Chinese medicinal material planting process is greatly improved.

Owner:赵月春

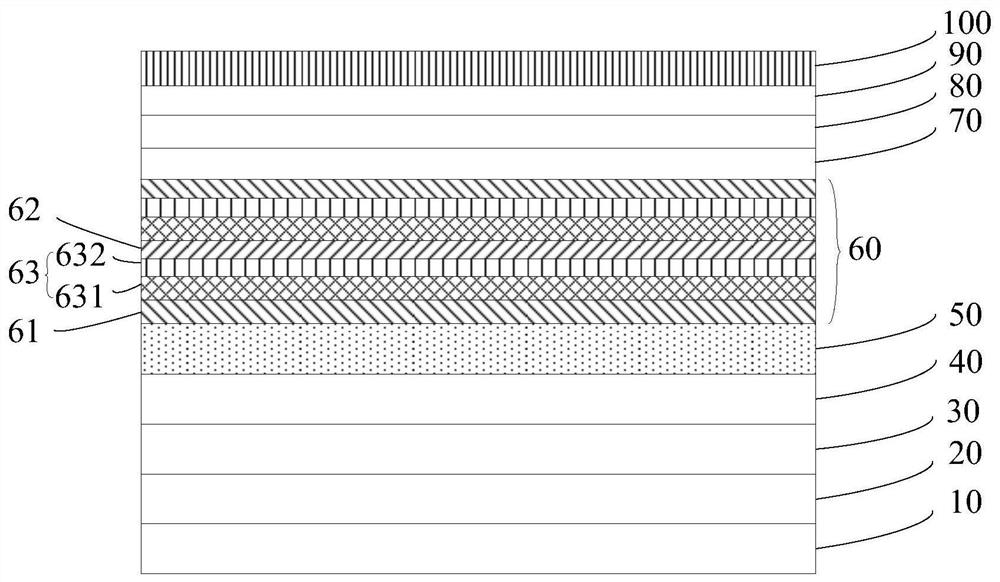

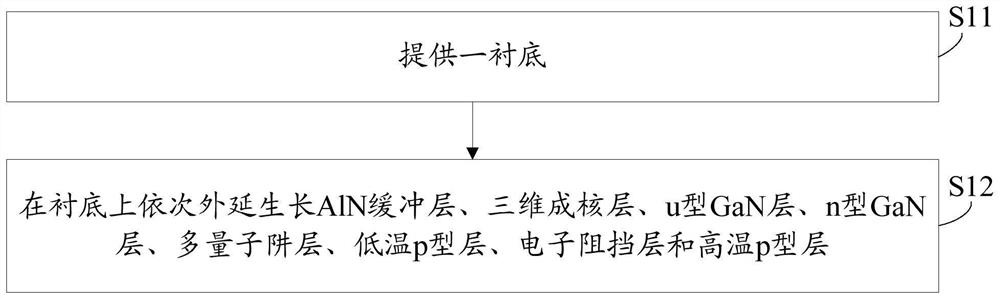

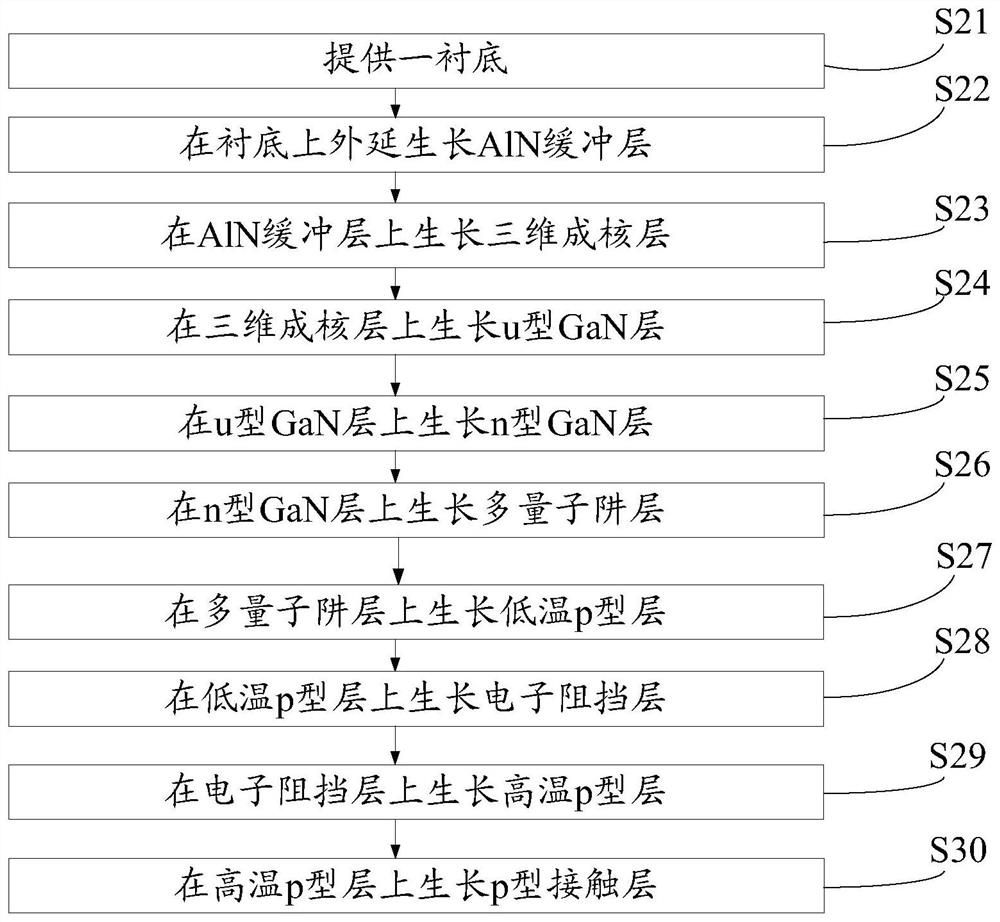

Epitaxial wafer of light-emitting diode and preparation method of epitaxial wafer

ActiveCN112582508AImprove luminous efficiencyPrevent extensionSemiconductor devicesElectron blocking layerBlocking layer

The invention provides an epitaxial wafer of a light emitting diode and a preparation method of epitaxial wafer, and belongs to the technical field of photoelectron manufacturing. The epitaxial wafercomprises a substrate, an AlN buffer layer, a three-dimensional nucleating layer, a u-type GaN layer, an n-type GaN layer, a multi-quantum well layer, a low-temperature p-type layer, an electron blocking layer and a high-temperature p-type layer, the multi-quantum well layer comprises a plurality of InxGa1-xN quantum well layers, a plurality of GaN quantum barrier layers and a composite structurelocated between the InxGa1-xN quantum well layers, and the composite structure comprises a n-InyGa1-yN layer and a SiN layer. Si atoms in the n-In-yGa1-yN layer can fill defect vacancies in the InGaNmaterial, the InGaN material with a low In component is beneficial to weakening a polarization electric field and improving energy band inclination, and the SiN layer is beneficial to uniform diffusion of carriers in the multi-quantum well layer, improving the carrier localization effect and improving the luminous efficiency of the LED.

Owner:HC SEMITEK ZHEJIANG CO LTD

Nickel-molybdenum-copper alloy and preparation method thereof

The invention discloses a nickel-molybdenum-copper alloy, which is an alloying agent used for smelting pipe line steel, stainless steel and special steel. The alloy comprises: 20 to 45 percent of nickel, 1 to 8 percent of molybdenum, 18 to 50 percent of copper, less than 0.5 percent of carbon, less than 0.05 percent of sulfur, less than 0.05 percent of phosphorus, less than 2.0 percent of silicon and the balance of ferrum. The alloy can be put at one time during the smelting of the pipe line steel and the like and reduce the labor intensity of smelters.

Owner:LIAONING JIUTONG FRICTION MATERIALS

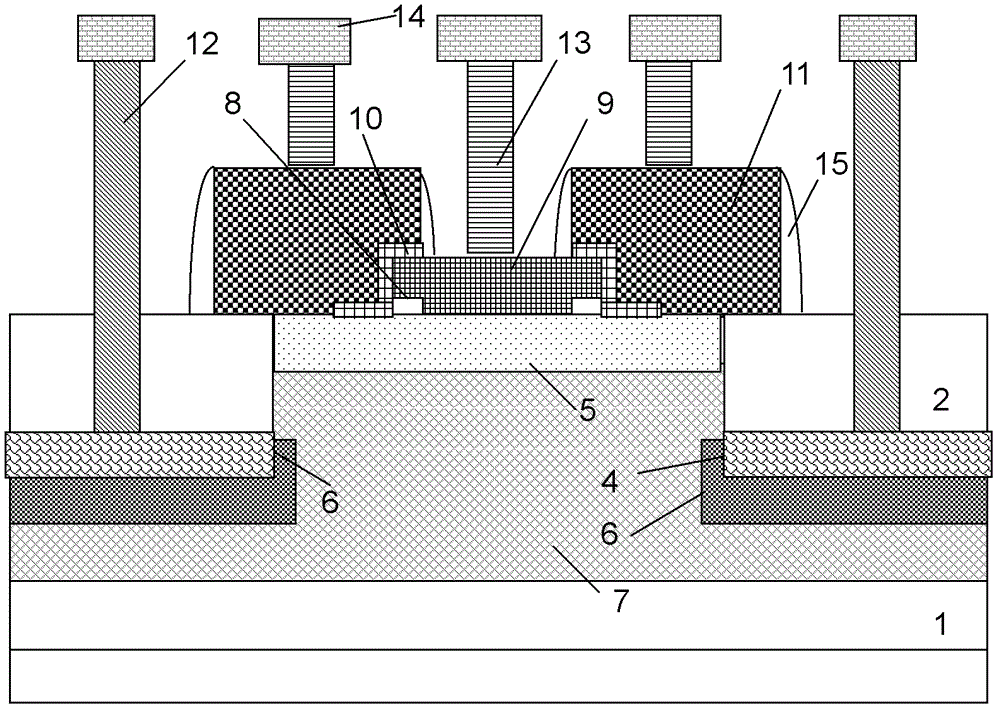

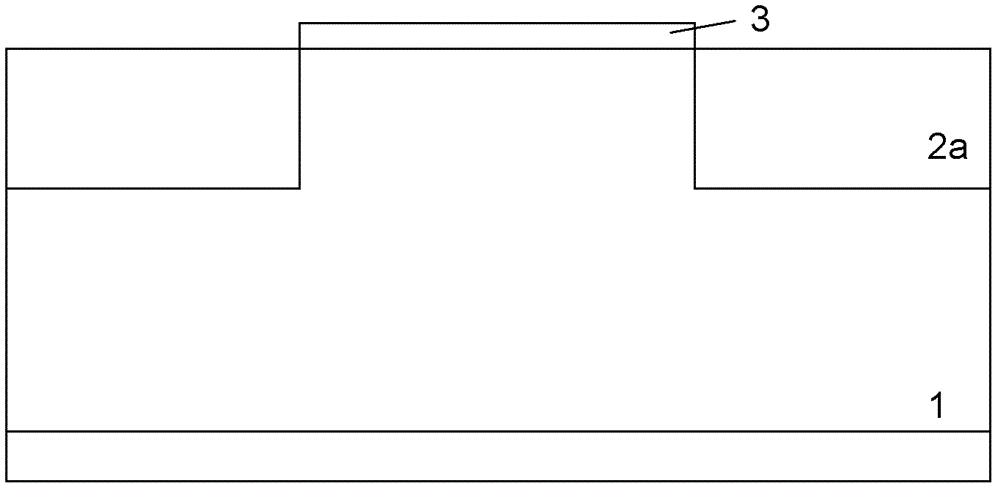

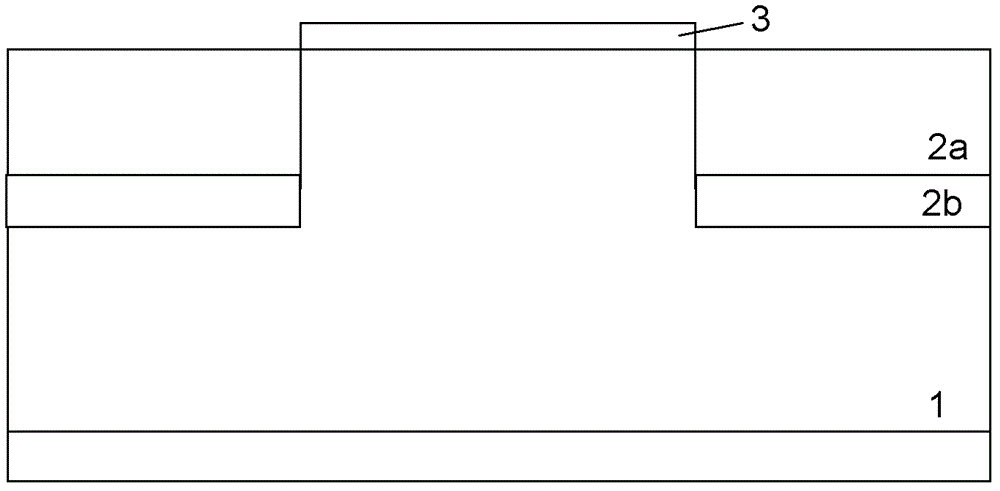

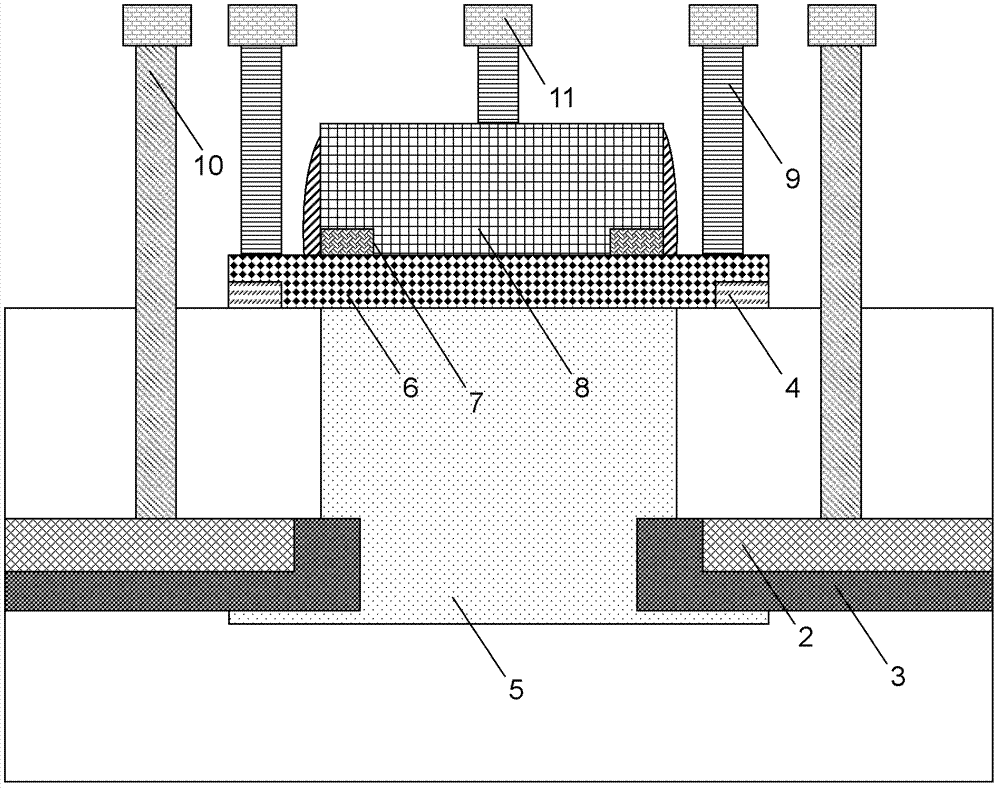

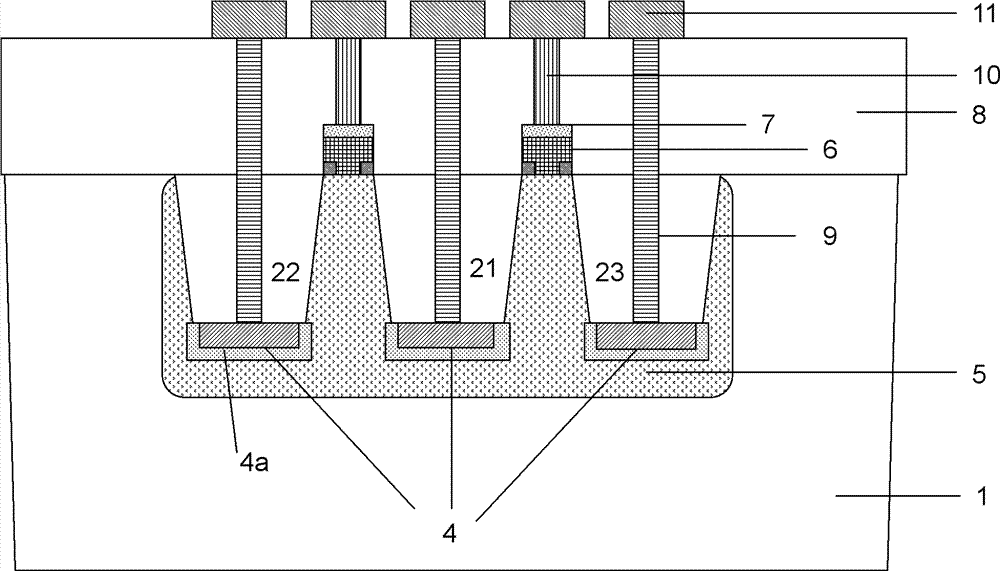

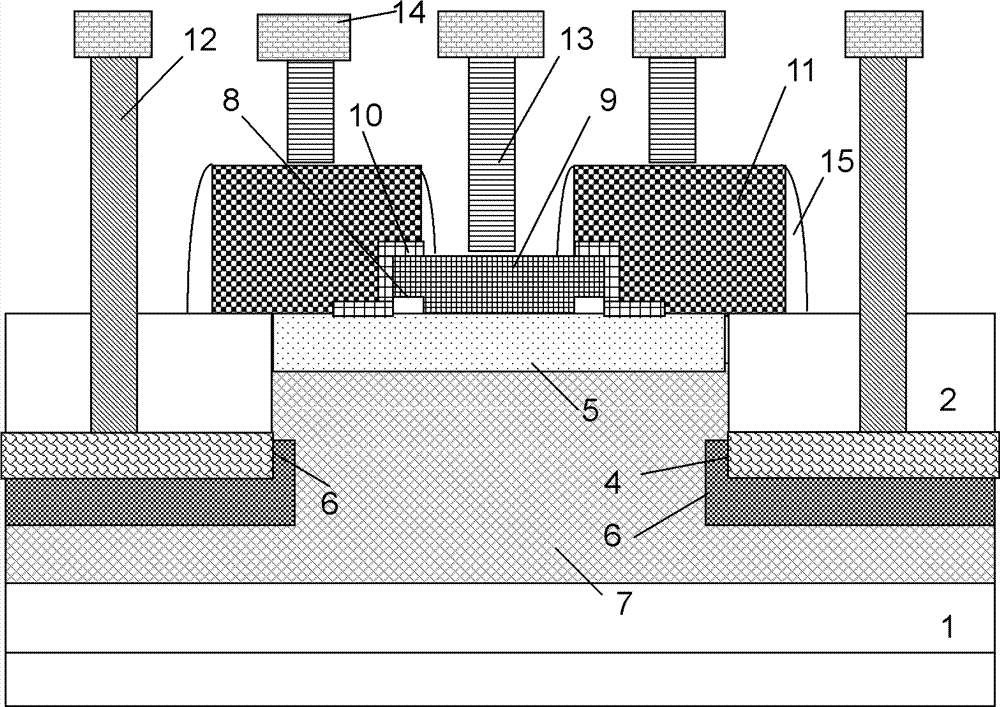

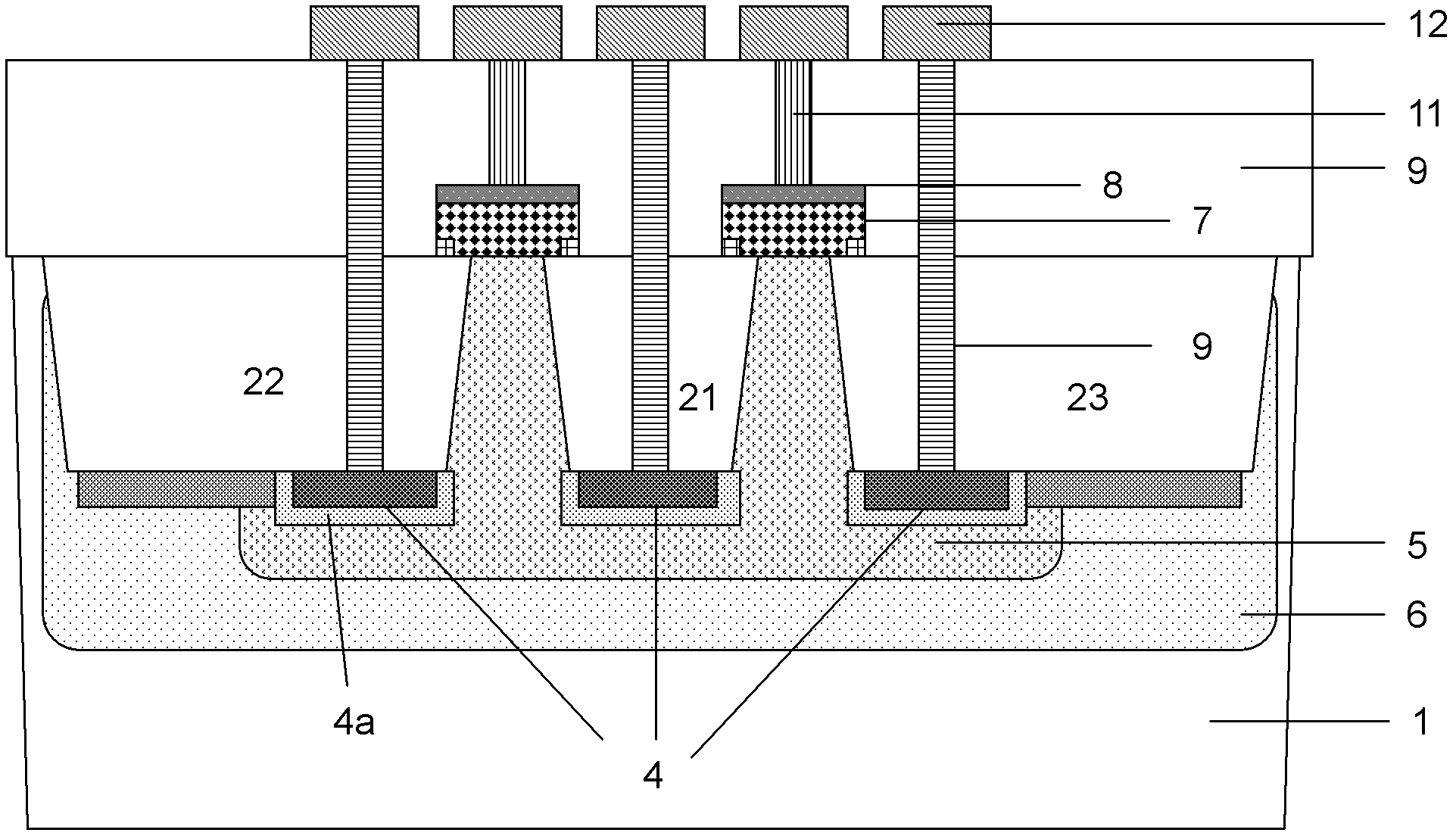

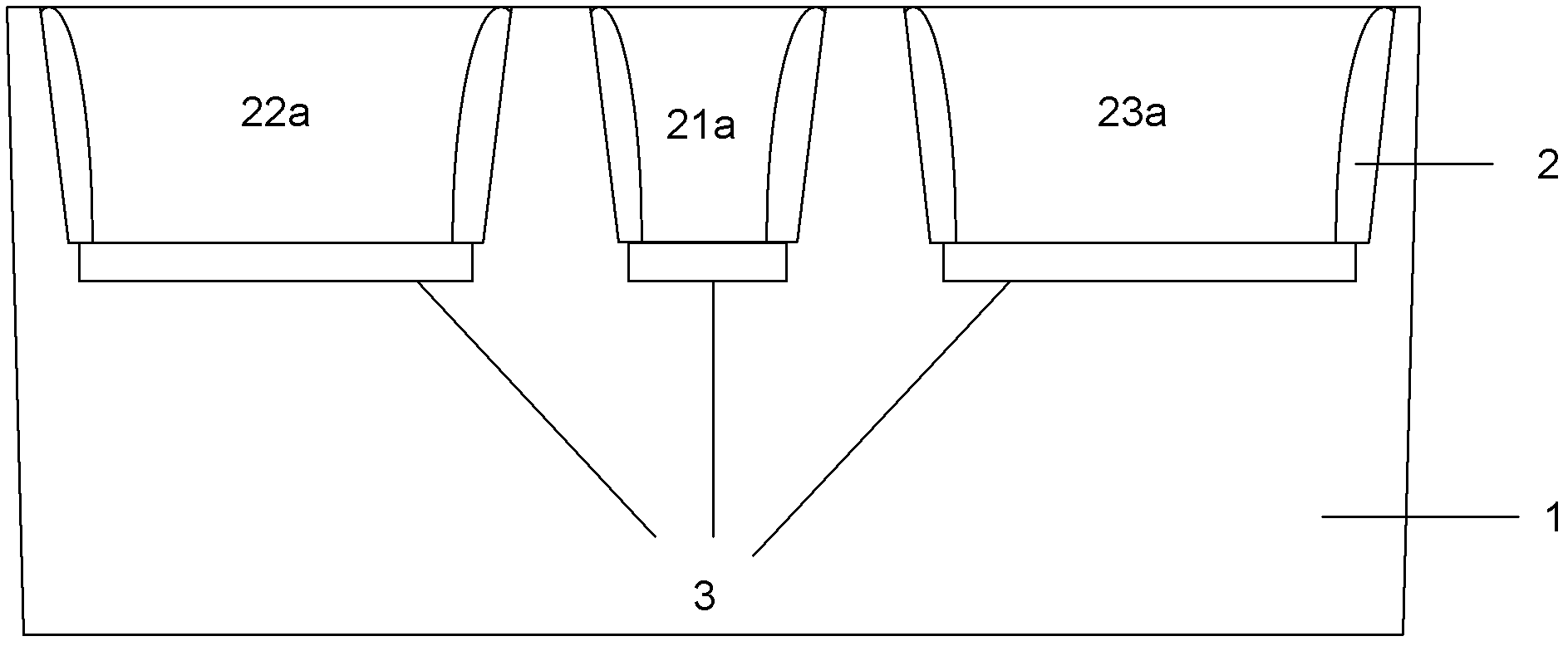

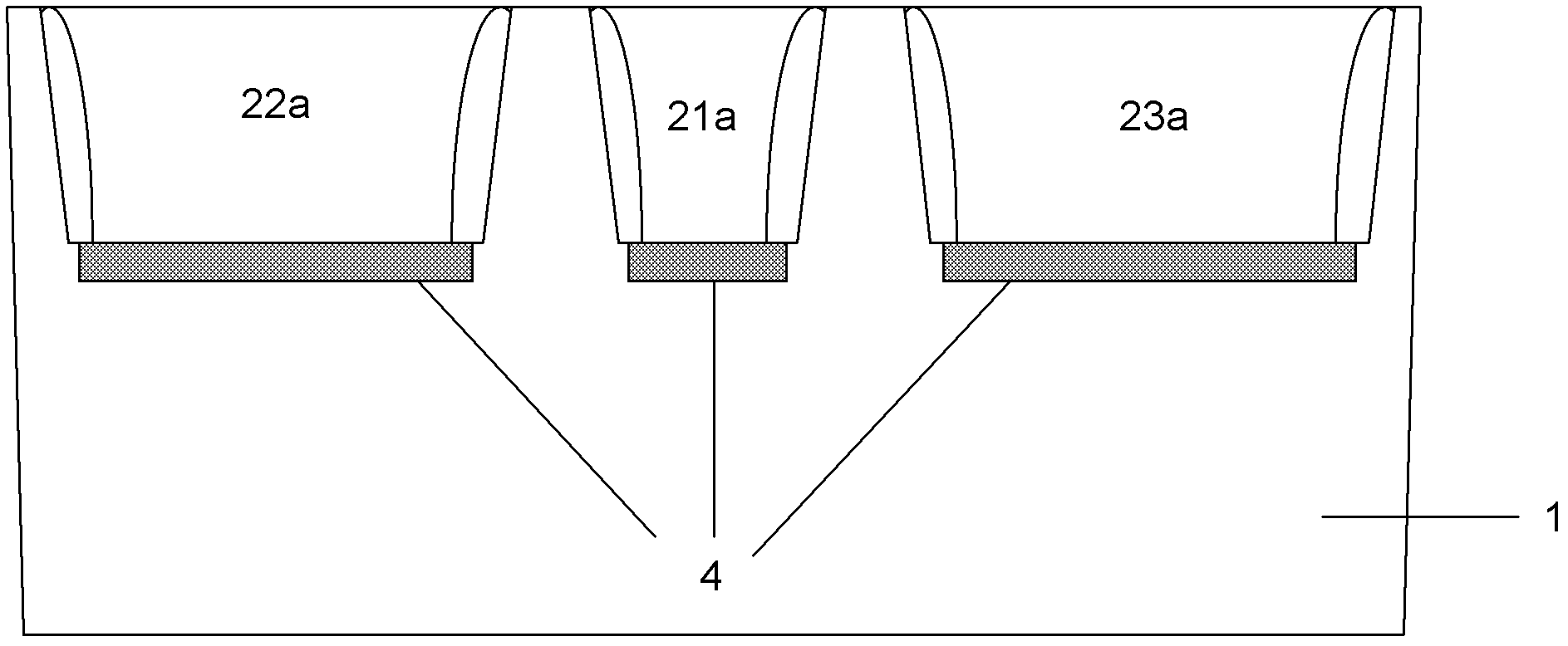

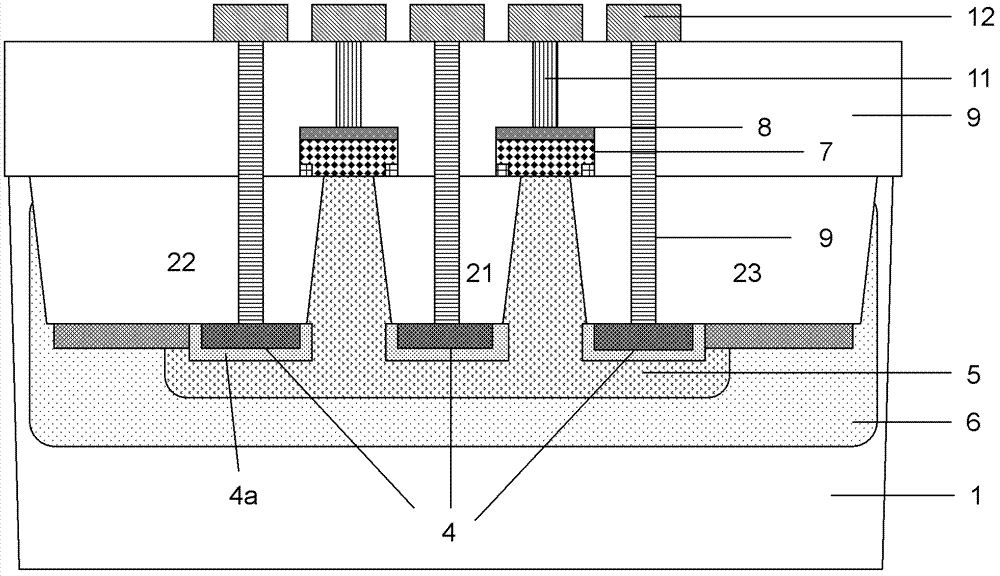

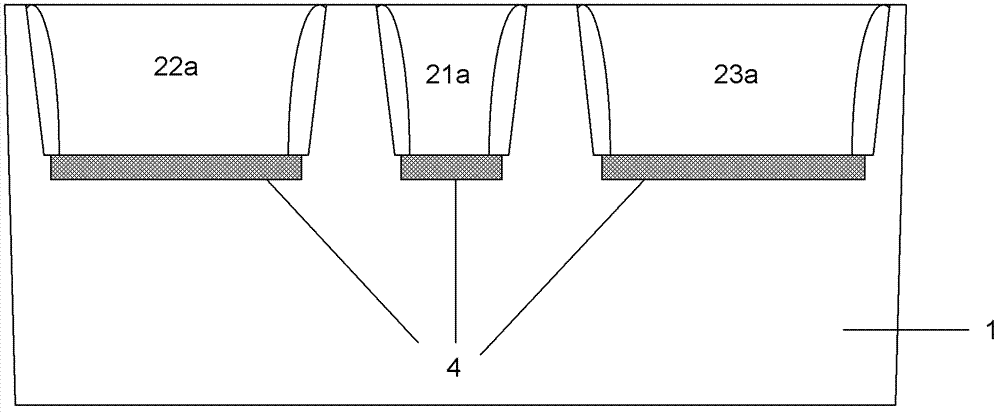

Germanium silicon heterojunction bipolar transistor and manufacturing method thereof

ActiveCN103066119AUniform resistanceRaise the cutoff frequencySemiconductor/solid-state device manufacturingSemiconductor devicesSilicon heterojunctionImpurity

The invention discloses a germanium silicon heterojunction bipolar transistor. A groove is formed in the bottom of shallow groove field oxygen in the circumstance of an active region, polycrystalline silicon is filled in the groove, a polycrystalline silicon burying layer is formed by the polycrystalline silicon filled in the groove, N type impurities are mixed with the polycrystalline silicon burying layer, the N type impurities further spread to a silicon substrate in the circumstance of the polycrystalline silicon burying layer to form a first N type impurities region, a collector connecting layer is formed by the polycrystalline silicon burying layer and the first N type impurities region, the collector connecting layer is contacted with a collector region at the bottom of the shallow groove field oxygen, and a deep hole contact area is formed in the shallow groove field oxygen on the top of the pseudo buried layer and leads a collector out. The invention further discloses a manufacturing method of the germanium silicon heterojunction bipolar transistor. According to the germanium silicon heterojunction bipolar transistor and the manufacturing method thereof, the thickness of the collector connecting layer can be increased to enable the distribution of impurities to be even, the resistance and the contact resistance of the collector connecting layer can be reduced and the value of the resistance and the contact resistance are enabled to be even, and thus the cut-off frequency of the germanium silicon HBT (SiGe HBT) can be improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

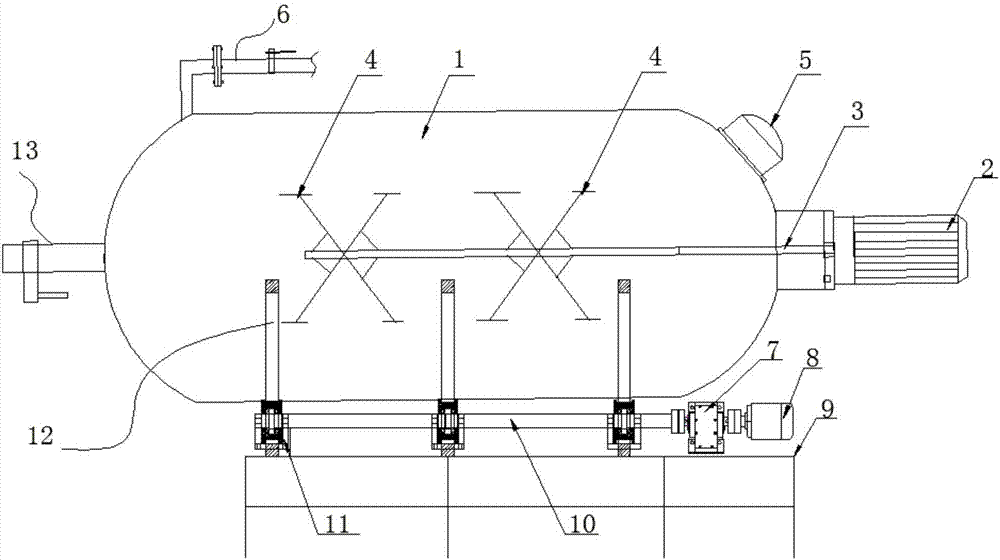

Desulfurizing method using desulfurizing tank

The invention discloses a desulfurizing method using a desulfurizing tank. The method comprises the following steps: grinding to-be-desulfurized rubber into rubber powder, and sieving with a sieve of5-200 meshes; removing iron chips and impurities in the rubber powder by an electromagnetic method; putting the rubber powder into the desulfurizing tank; adding a desulfurizing agent into the desulfurizing tank through a liquid inlet pipe; mixing the rubber powder and the desulfurizing agent according to a mass ratio of 100 to (15-25); starting two motors of the desulfurizing tank so that the desulfurizing tank rotates at a speed of 40r / min, enabling a stirring blade to stir the mixture in the desulfurizing tank at the same time; starting a microwave generator; introducing steam at 280-380 DEG C into the desulfurizing tank while ensuring that pressure in the tank is 14-18MPa; reacting for 120min and cooling the desulfurizing tank to 150 DEG C or below.

Owner:江苏华兴橡胶科技有限公司

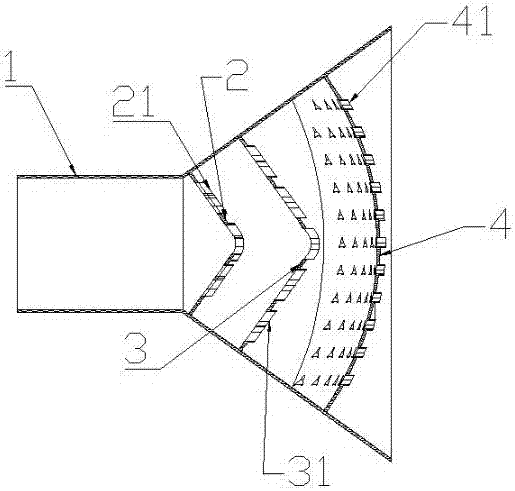

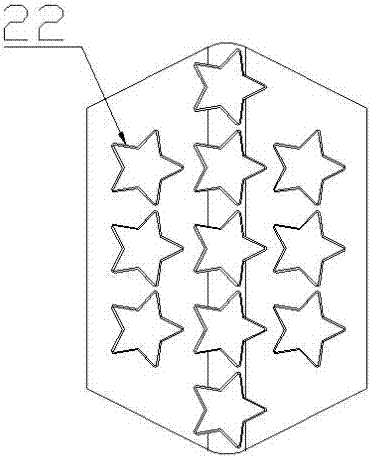

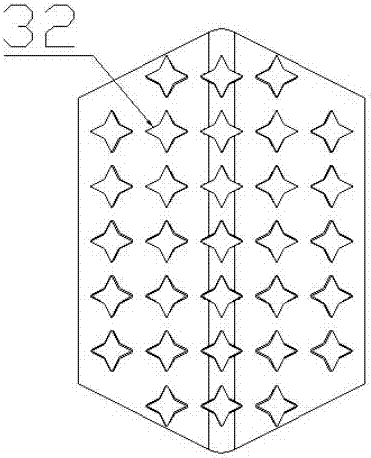

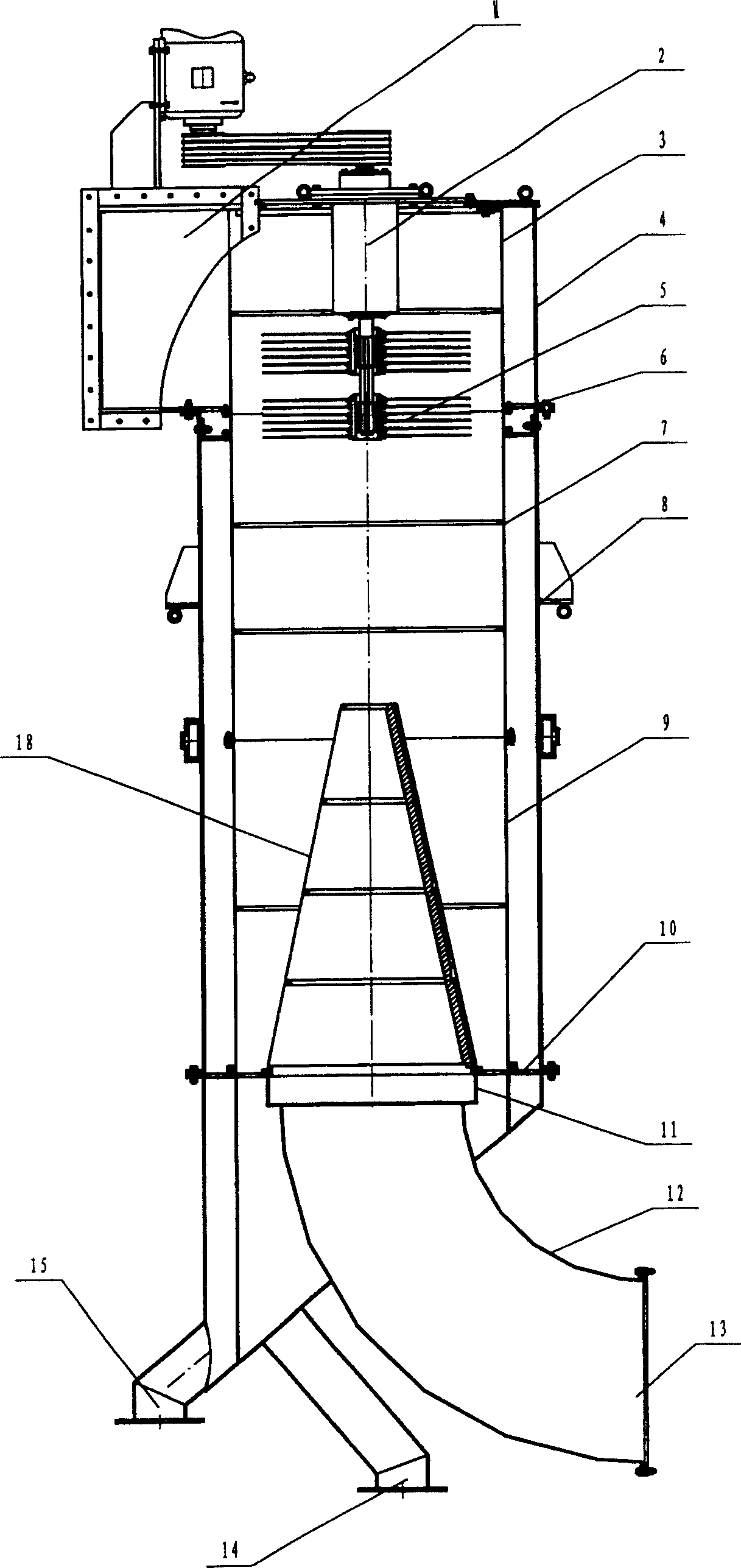

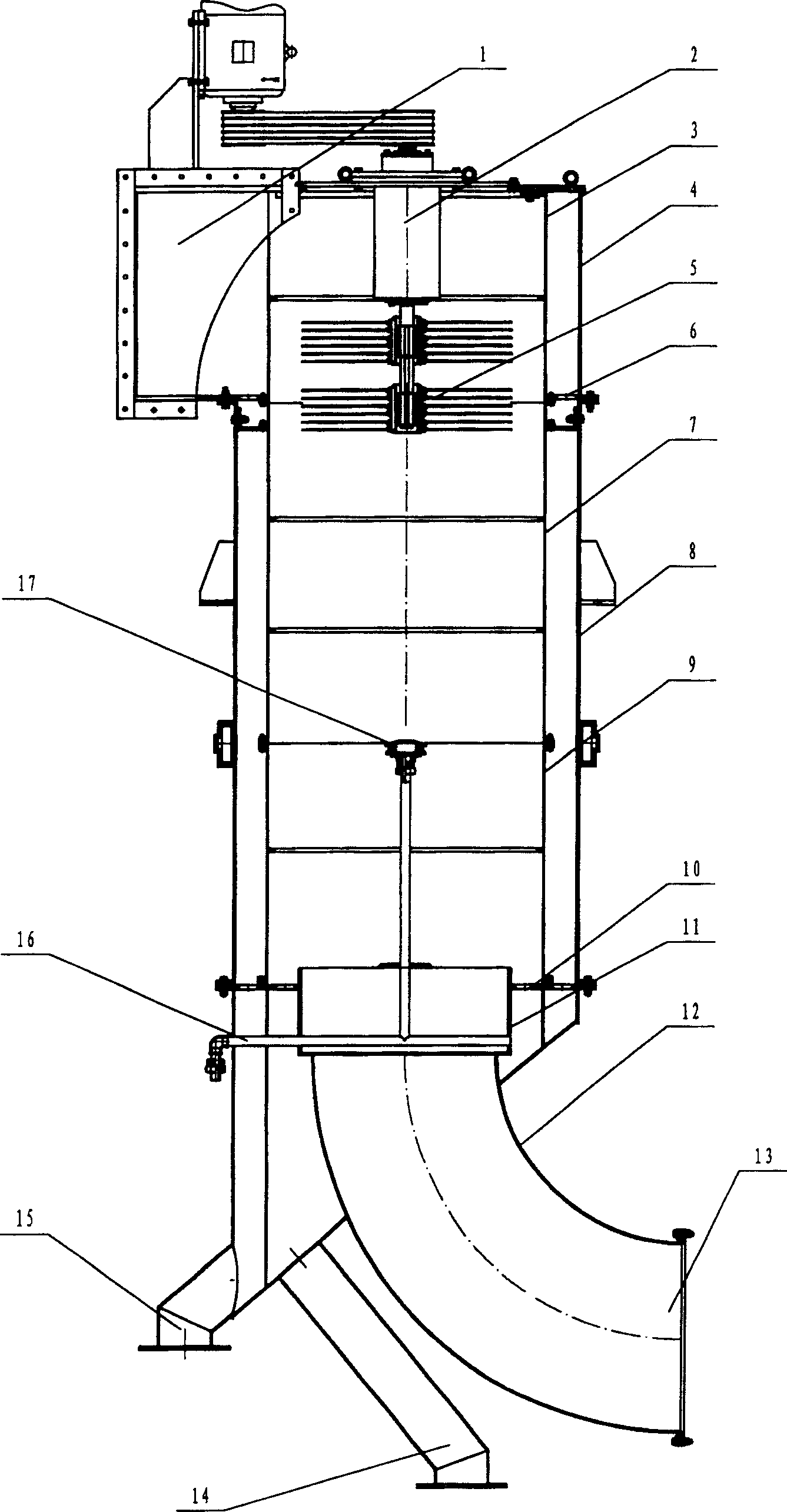

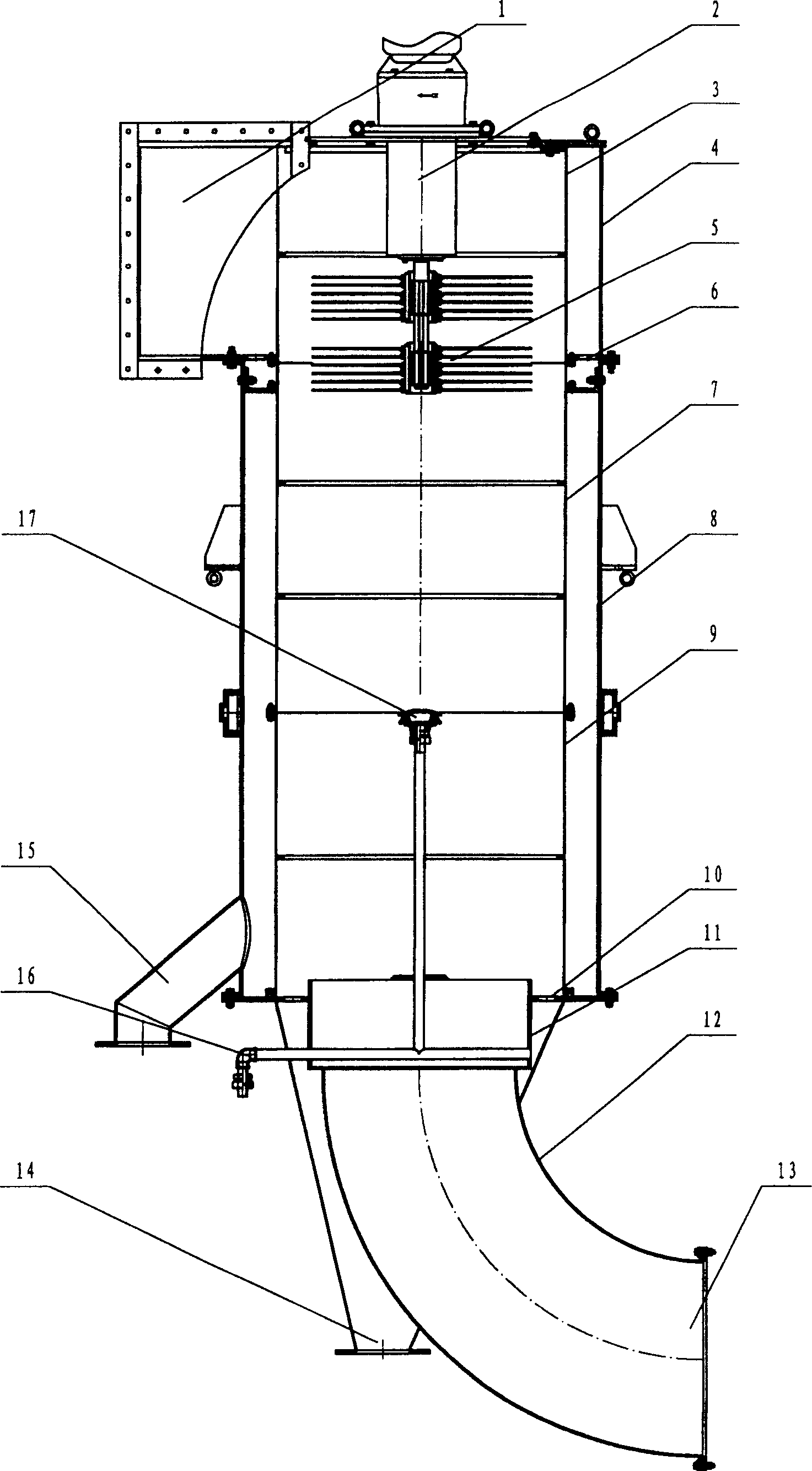

Airflow distribution device for electrostatic-bag precipitator

PendingCN107042046AImprove purification efficiencyReduce equipment failure rateCombination devicesDispersed particle filtrationAirflowEngineering

The invention relates to an airflow distribution device for an electrostatic-bag precipitator. The airflow distribution device comprises a shell, a first distribution plate, a second distribution plate and a third distribution plate, wherein the first distribution plate, the second distribution plate and the third distribution plate are sequentially arranged in a shell of a reducer pipe from exterior to interior; an angle of 90 degrees is formed between an upper panel of the first and second distribution plates and an upper panel of the shell; an angle of 90 degrees is formed between a lower panel of the first and second distribution plates and a lower panel of the shell; the third distribution plate is spherical; the aperture ratios of airflow holes in the first, second and third distribution plates are respectively 40%, 60% and 80%; and shapes of the airflow holes in the first, second and third distribution plates are respectively pentagram, four-angle star and three-pointed star. According to the device disclosed by the invention, the flow velocity of inlet airflow in the reducer pipe is adjusted, so that the airflow is uniformly diffused and distributed, the purification efficiency is improved, and the equipment failure rate is reduced.

Owner:EQUIP MFG FACTORY HEBEI HONGDA ENVIRONMENT ENG CO LTD

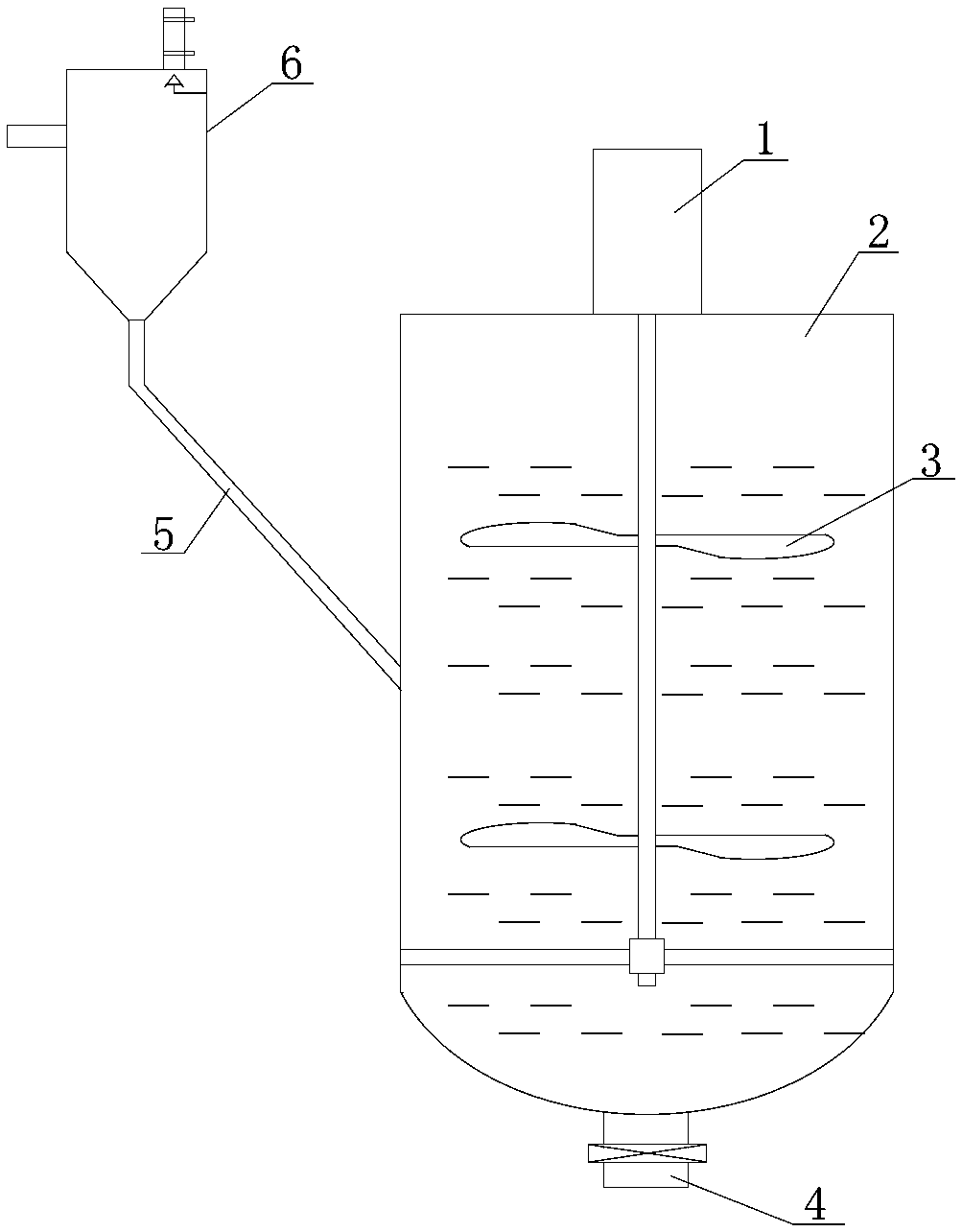

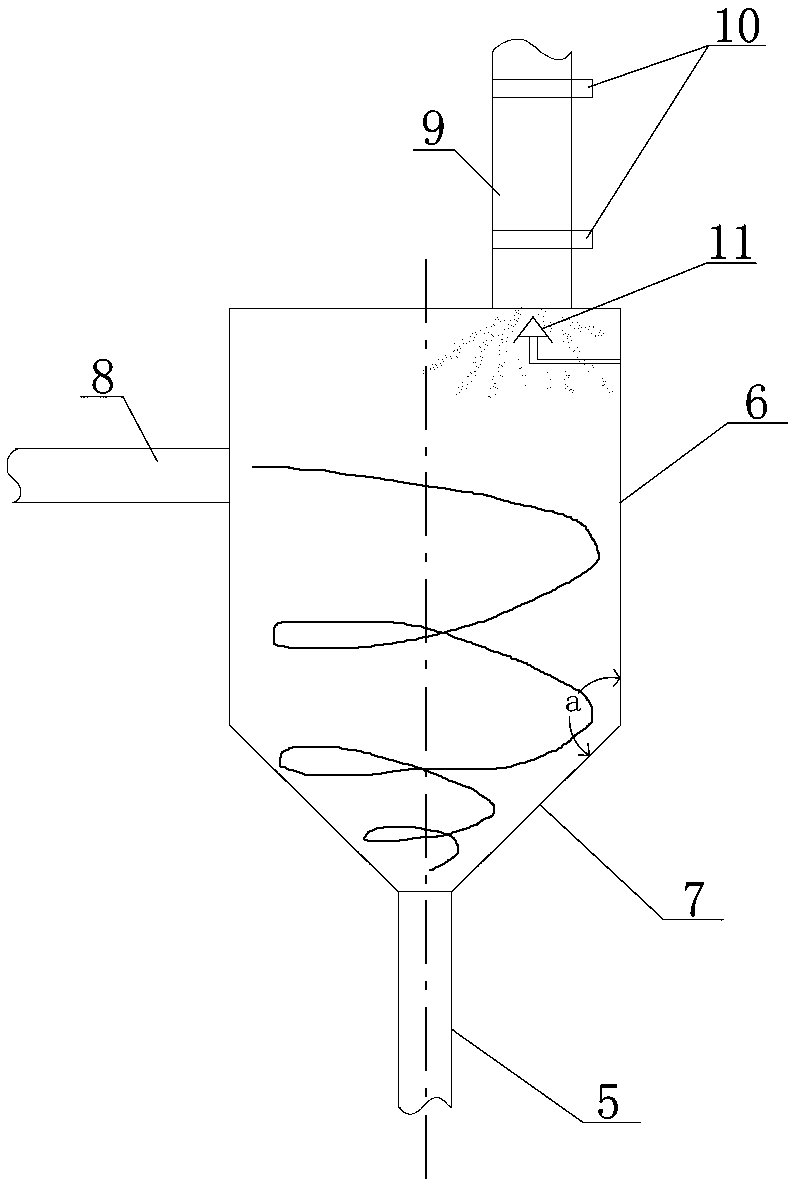

White clay mixing device for grease decolorization

PendingCN110257171AImprove the mixing effectIncrease contact areaRotary stirring mixersTransportation and packagingEddy currentEngineering

The invention discloses a white clay mixing device for grease decolorization. The device includes a stirring tank. One side of the stirring tank is provided with a premixing tank. The top end of the premixing tank is provided with a white clay metering cylinder. The top end of the bottom end of the white clay metering cylinder communicate with a white clay tank and the premixing tank. The communicating part of the white clay tank and the premixing tank is provided with a conical diffusion plate. The bottom end of the premixing tank is provided with a conical hopper. One side of the premixing tank is provided with an oil filling pipe. The oil filling pipe communicates with the premixing tank in a horizontal internally tangent manner. The oil filling pipe and the white clay metering cylinder are diagonally arranged. The premixing tank, the stirring tank, the conical diffusion plate and blades are all provided with anti-sticking coatings. White clay is changed to a current diffusion type and mixed and stirred in the premixing tank, and so the mixing and stirring effect is better and more thorough. Oil is injected into the premixing tank in a horizontal internally tangent manner by using the pressure of the oil, and the stirring effect is improved by using eddy currents. The anti-sticking coatings can prevent the adhesion of the oil and the white clay, and agglomerates are always in a state of stirring motion.

Owner:山东绿地食品有限公司

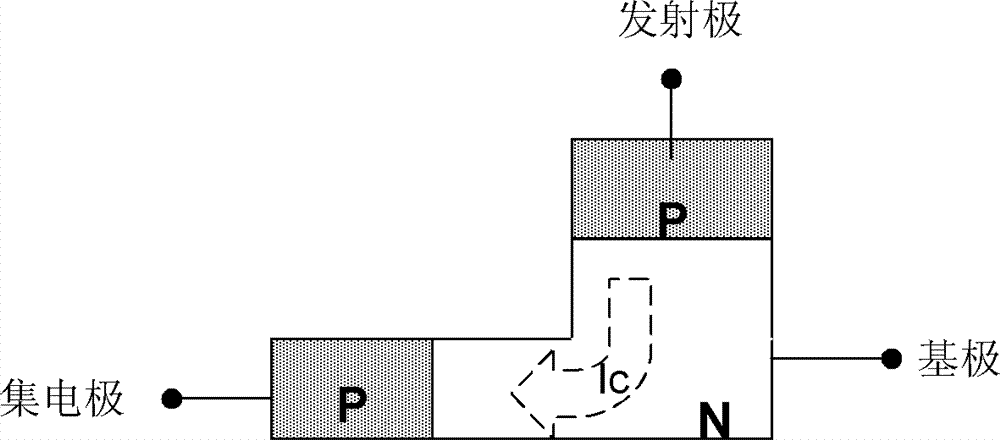

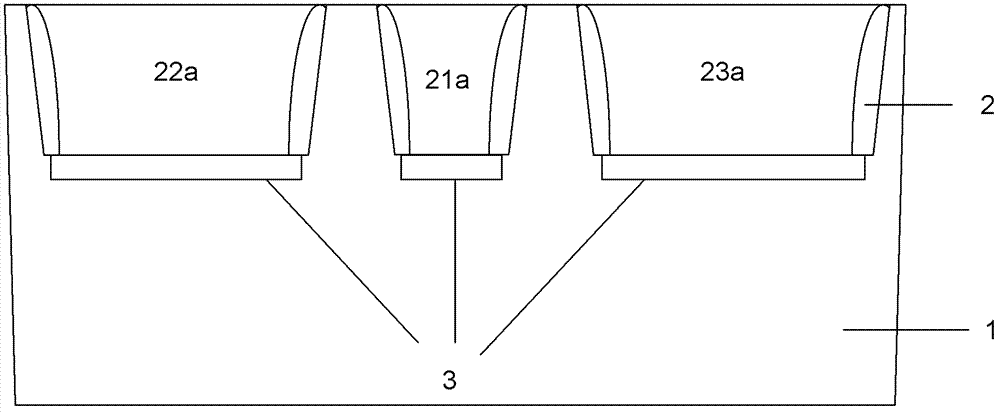

Vertical parasitic type PNP triode and manufacture method

ActiveCN103066115ARaise the cutoff frequencyReduce areaTransistorSemiconductor/solid-state device manufacturingOxygenP type doping

The invention discloses a vertical parasitic type PNP triode. A groove is formed in the bottom portion of shallow shot field oxygen on the circumferential side of an active region, and is filled with polycrystalline silicon, the polycrystalline silicon filling in the groove forms a polycrystalline silicon buried layer, P-type impurities are mixed in the polycrystalline silicon buried layer, and the P-type impurities further spread to silicon substrate on the circumferential side of the polycrystalline silicon buried layer to form a first P-type doped region. The polycrystalline silicon buried layer and the doped region form a collector connecting layer, and the collector connecting layer contacts with a collecting region on the bottom portion of the shallow slot field oxygen. Deep holes are formed in the shallow slot field oxygen on the upper portion of the polycrystalline silicon buried layer and contact with and lead out collectors. The invention further discloses a manufacture method of the vertical parasitic type PNP triode. The vertical parasitic type PNP triode and the manufacture method of the vertical parasitic type PNP triode can improve the thickness of the collector connecting layer, and enable the impurities to be distributed evenly, can reduce the resistance and the contact resistance of the collector collecting layer and enable resistance values to be even, and therefore can improve the cut-of frequency of a device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Industrial firing rotary kiln with kiln-in-kiln structure

PendingCN109186253AAvoid loops hanging on the wallFull drying effectRotary drum furnacesInsulation layerCombustor

The invention provides an industrial firing rotary kiln with a kiln-in-kiln structure. The industrial firing rotary kiln comprises a rotary kiln barrel body, the rotary kiln barrel body comprises a heat insulation layer and a toothed hook special-shaped flame retardant layer, an inner kiln circular pipe with the inner wall provided with inner kiln toothed hooks is arranged inside the rotary kiln barrel body, a plurality of supporting column walls are arranged in an outer kiln in a balanced mode, a heating space is formed between every two adjacent supporting column walls, the two ends of the rotary kiln barrel body are provided with a kiln tail cover and a kiln head cover correspondingly, an outer kiln centralized stock bin is formed between the kiln tail cover and the supporting column walls, the rotary kiln barrel body is provided with a transition cover, a cooling zone is formed between the transition cover and the kiln head cover, the bottom of the cooling zone is provided with a material feeding cooling zone channel port, a combustor placing chamber is formed between the transition cover and the supporting column walls, an inner kiln receiving pipe and a combustor are arrangedin the center inside the cooling zone, and the lower portion of the transition cover and the position leading to the cooling zone are each provided with a discharge outlet. The industrial firing rotary kiln has the advantages that the inner and outer filling rate is high, drying and combustion are sufficient, fuel energy consumption is low, combustion time is short, and energy conservation and emission reduction are achieved.

Owner:杨锡娟

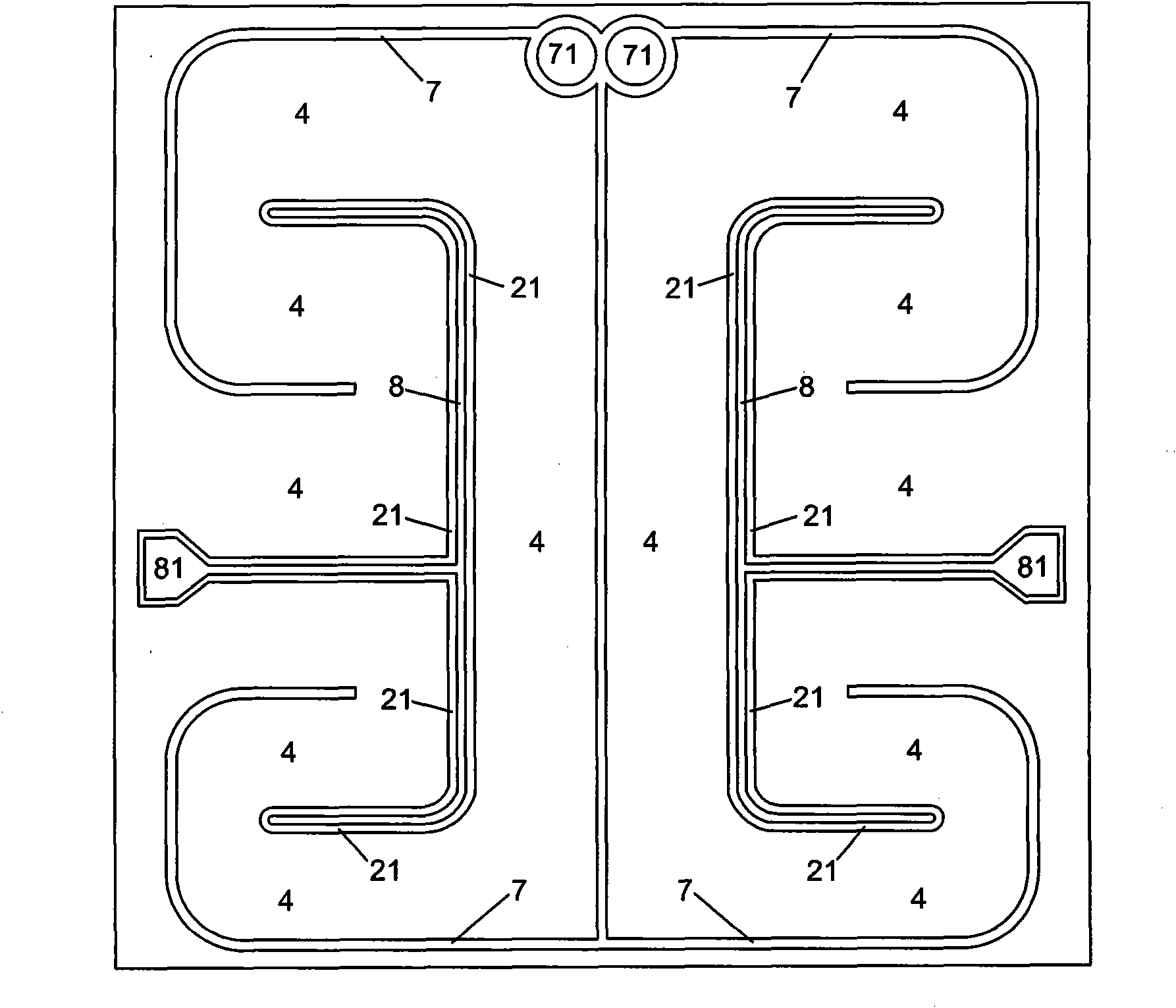

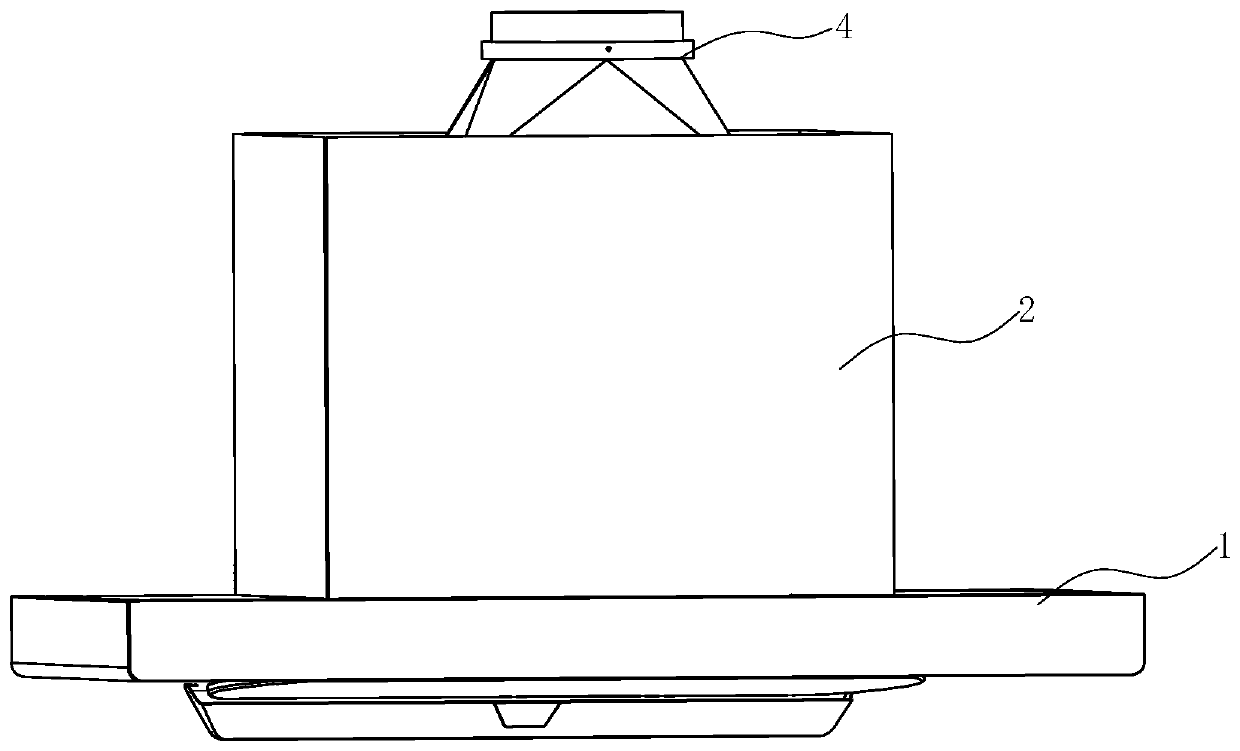

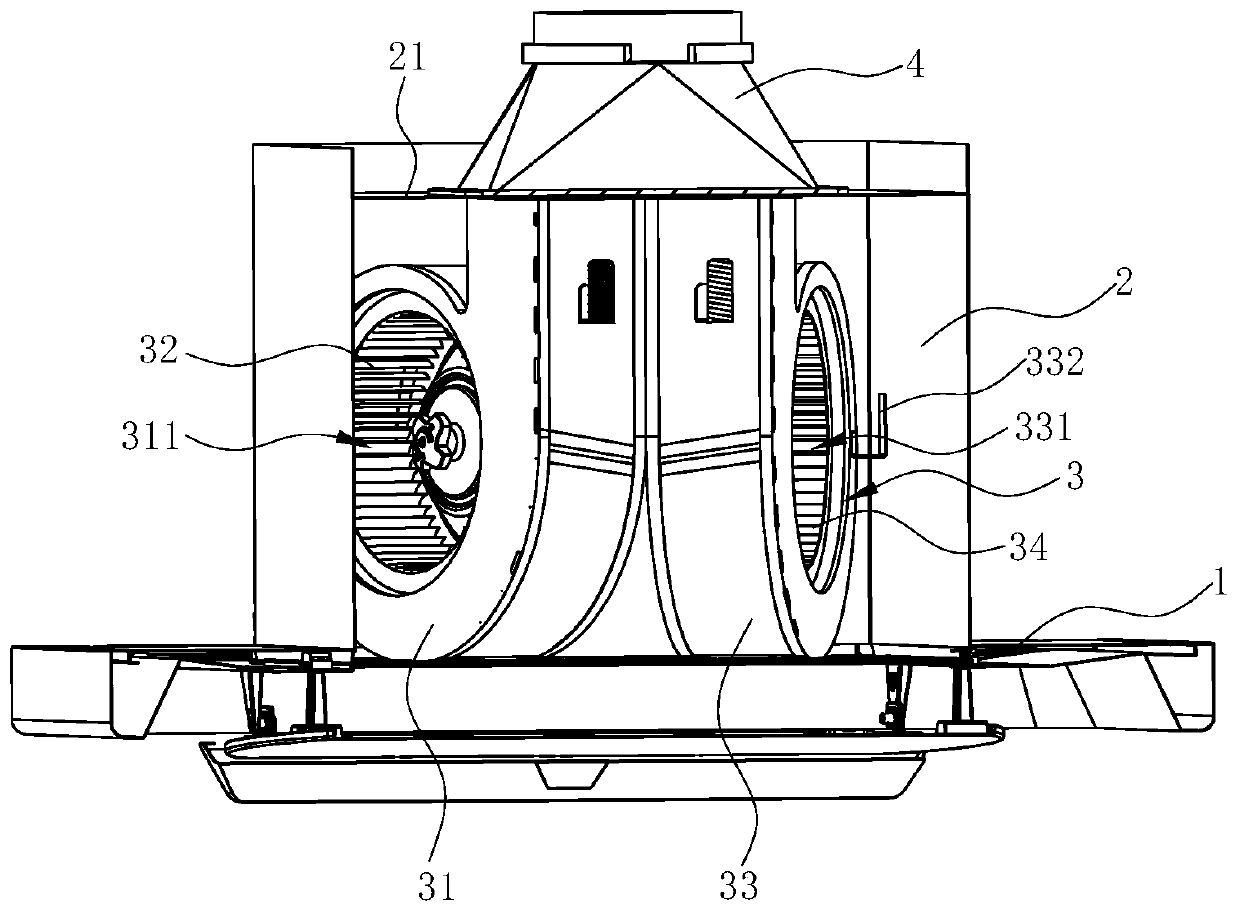

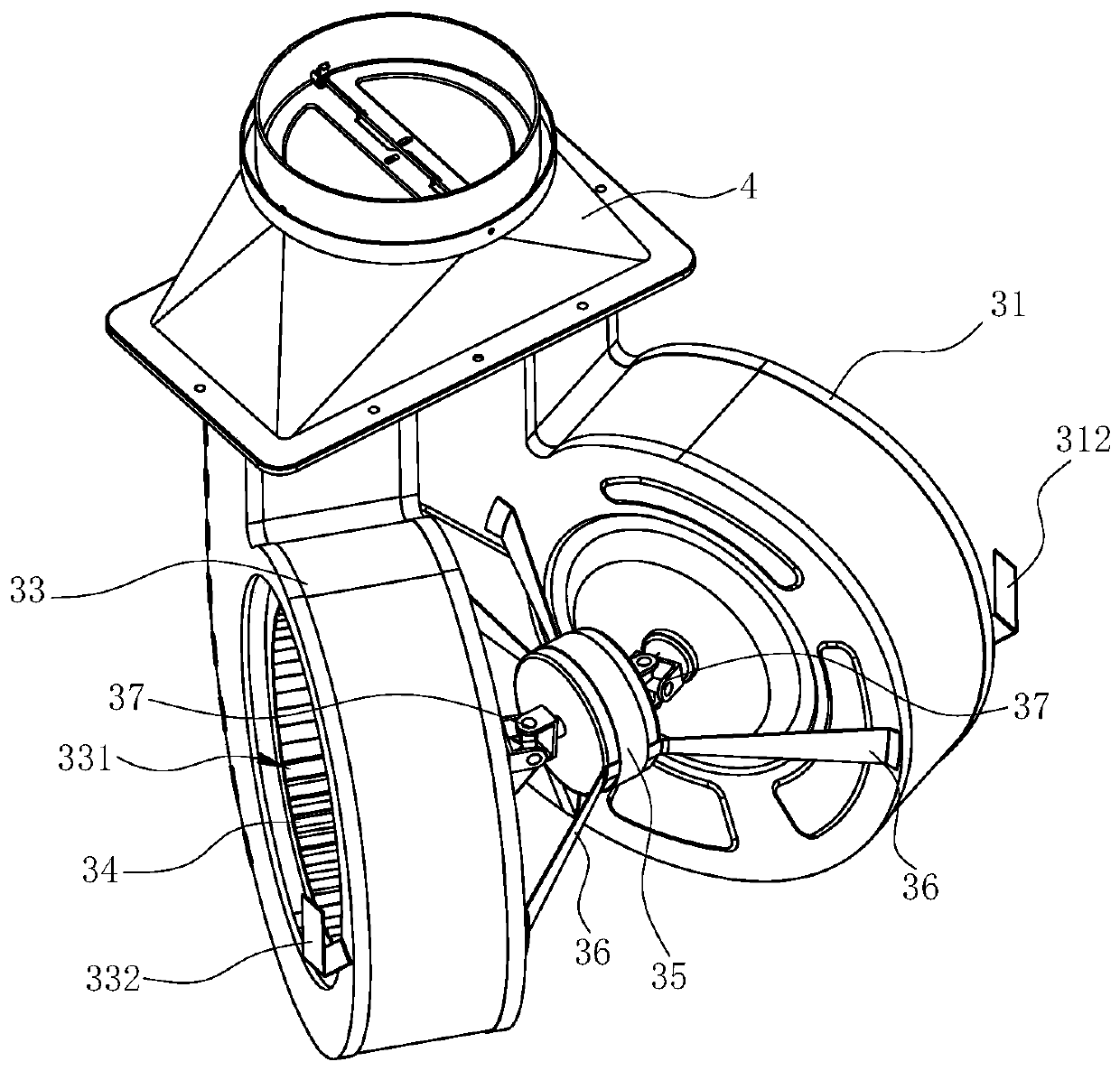

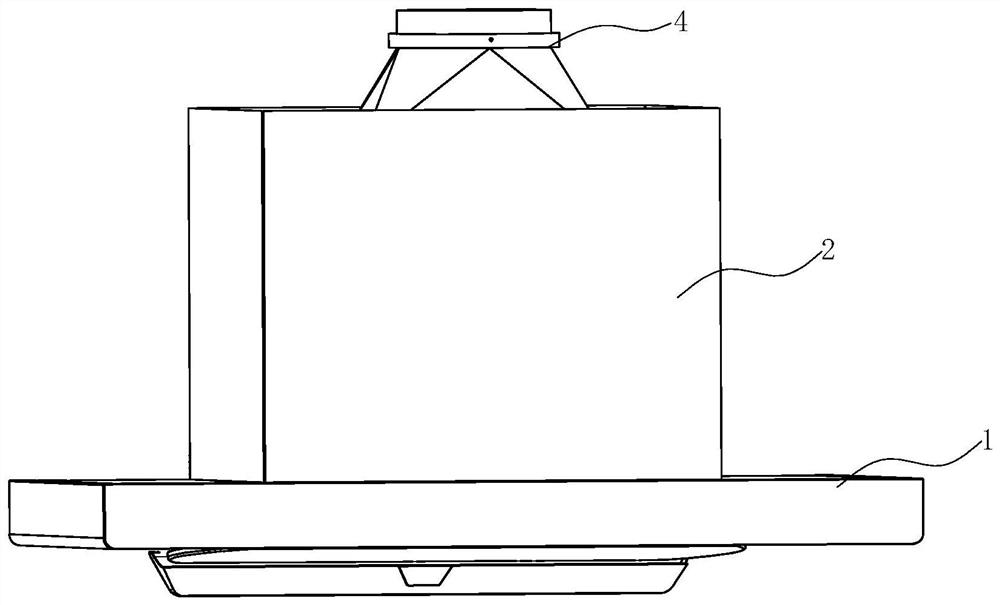

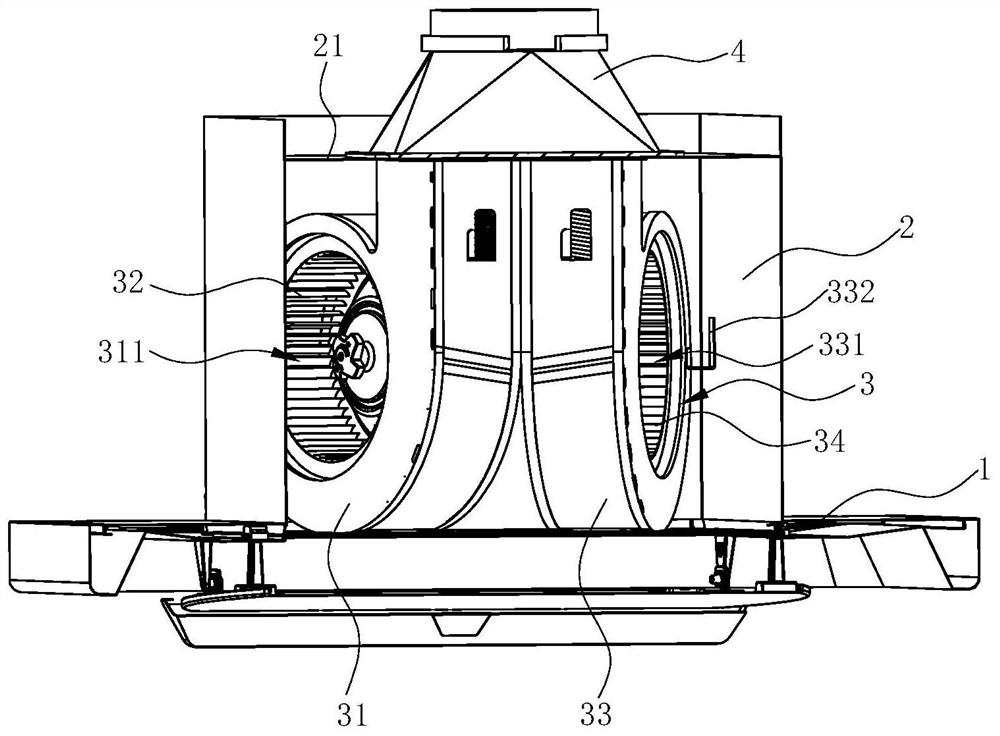

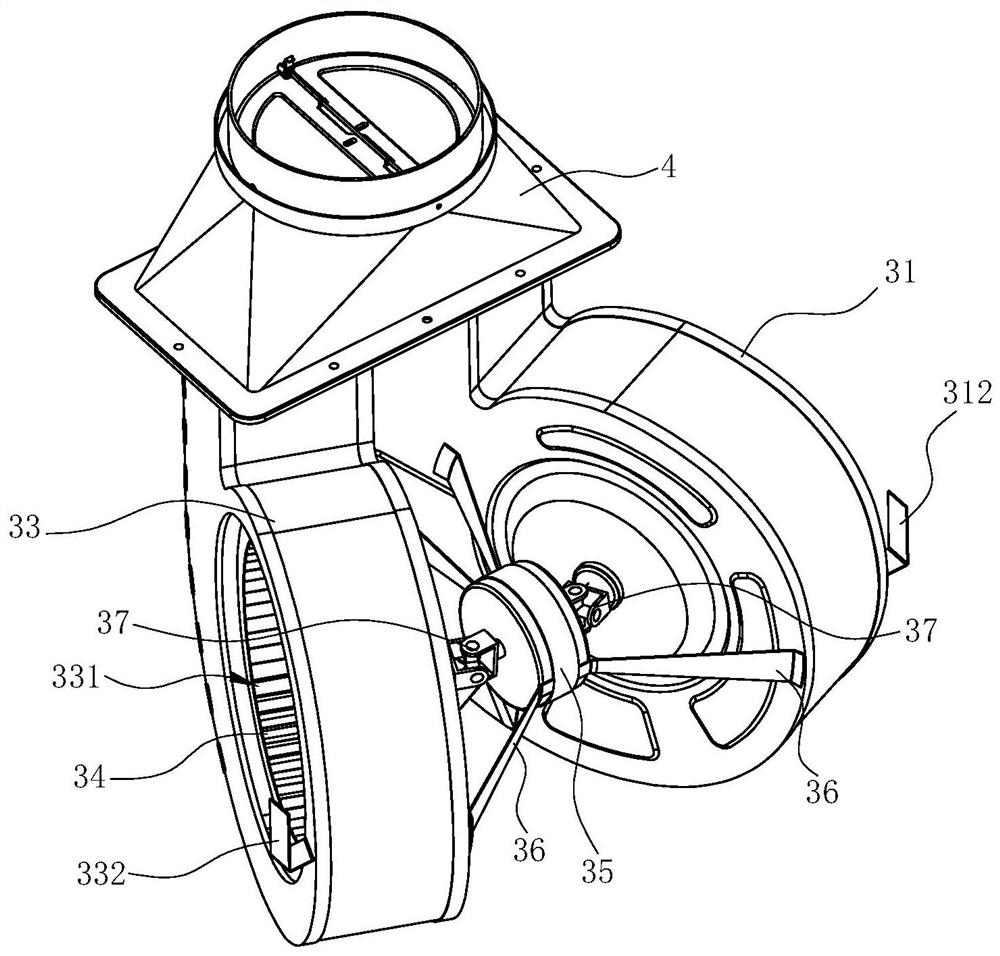

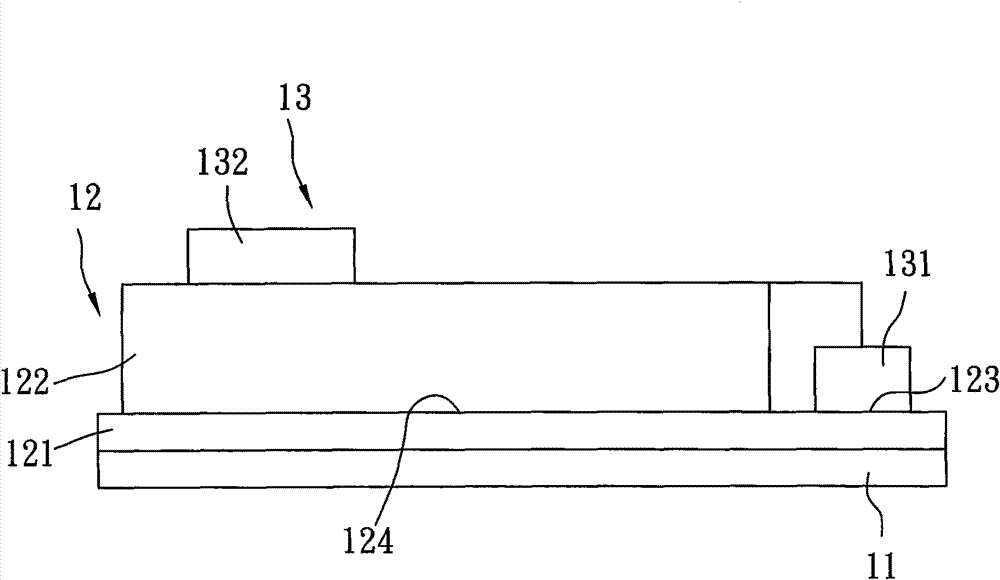

Range hood

ActiveCN111322649AShort processSlow flowDomestic stoves or rangesPump componentsAcoustic noise reductionMechanical engineering

The invention discloses a range hood. The range hood comprises a fan frame and a fan system arranged in the fan frame, wherein the fan system comprises a first volute and a second volute which are arranged in parallel; a first air inlet is formed in the first volute; a second air inlet is formed in the second volute; the first air inlet faces the left side; and the second air inlet faces the rightside. The range hood is characterized in that the first air inlet is gradually inclined leftwards from front to back, and the second air inlet is gradually inclined rightwards from front to back, sothat an included angle is formed between the first air inlet and the second air inlet. Compared with the prior art, the range hood has the advantages that oil smoke on the front side is pulled to therear side, so that flow fields on the front side and the rear side are uniformly distributed, and the flow speed of the oil smoke accumulated on the front side is lower than that of the oil smoke accumulated on the front side which is placed in parallel (so that noise and abnormal sound can be reduced); and the rear side is narrow, so that the capturing capacity of the rear side of each air inletis higher, the longitudinal balance is improved, the stress is more uniform, and vibration is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Catalyst for gasoline engine exhaust particulate matter filter and preparation method thereof

ActiveCN109621952BDiffusion evenly distributedReduce exhaust back pressureDispersed particle separationCatalyst activation/preparationPtru catalystGasoline

The invention relates to a gasoline engine exhaust particle filter catalyst and a preparation method thereof. The height of the direction is 100% of the height of the carrier. The catalytic coating contains cerium-zirconium rare earth composite oxide, γ-alumina and noble metal active components. The noble metal active components include Pd and Rh, and the loading of Pd is 0.1~1.5 g / L; the loading of Rh is 0.05~0.5 g / L. The invention realizes the uniform diffusion and distribution of the catalytic coating on the inner wall structure of the pore channel through the improvement of the coating process of the catalytic coating, thereby significantly reducing the exhaust back pressure of the particulate matter filter catalyst, and meanwhile the uniformly distributed catalytic coating is very good It plays the role of intercepting particulate matter and transforming gaseous pollutants, so that the filter catalyst prepared by the invention does not negatively affect the particle collection rate and catalytic performance while reducing the exhaust back pressure.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

Germanium silicon heterojunction bipolar transistor and manufacturing method thereof

ActiveCN103066119BUniform resistanceRaise the cutoff frequencySemiconductor/solid-state device manufacturingSemiconductor devicesSilicon heterojunctionImpurity

The invention discloses a germanium silicon heterojunction bipolar transistor. A groove is formed in the bottom of shallow groove field oxygen in the circumstance of an active region, polycrystalline silicon is filled in the groove, a polycrystalline silicon burying layer is formed by the polycrystalline silicon filled in the groove, N type impurities are mixed with the polycrystalline silicon burying layer, the N type impurities further spread to a silicon substrate in the circumstance of the polycrystalline silicon burying layer to form a first N type impurities region, a collector connecting layer is formed by the polycrystalline silicon burying layer and the first N type impurities region, the collector connecting layer is contacted with a collector region at the bottom of the shallow groove field oxygen, and a deep hole contact area is formed in the shallow groove field oxygen on the top of the pseudo buried layer and leads a collector out. The invention further discloses a manufacturing method of the germanium silicon heterojunction bipolar transistor. According to the germanium silicon heterojunction bipolar transistor and the manufacturing method thereof, the thickness of the collector connecting layer can be increased to enable the distribution of impurities to be even, the resistance and the contact resistance of the collector connecting layer can be reduced and the value of the resistance and the contact resistance are enabled to be even, and thus the cut-off frequency of the germanium silicon HBT (SiGe HBT) can be improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

a range hood

ActiveCN111322649BShort processSlow flowDomestic stoves or rangesPump componentsAcoustic noise reductionMechanical engineering

The invention discloses a range hood, which comprises a fan frame and a fan system arranged in the fan frame. The fan system includes a first volute and a second volute arranged side by side. A first air inlet is formed, and a second air inlet is formed on the second volute. The first air inlet faces to the left, and the second air inlet faces to the right. It is characterized in that: the first air inlet is formed by The front to the rear is gradually inclined to the left, and the second air inlet is gradually inclined to the right from the front to the rear, so that there is an included angle between the first air inlet and the second air inlet. Compared with the prior art, the present invention has the advantages of pulling the oil fume on the front side to the rear side to realize uniform distribution of the flow field on the front and rear sides, so that the oil fume accumulated on the front side has a slower flow rate than that placed in parallel (thus It can reduce noise and abnormal sound), and the narrow state of the rear makes the capture ability of the rear side of each air inlet stronger, improves the longitudinal balance, and the force is more uniform, reducing vibration.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Parasitically transversal type PNP device and manufacture method

ActiveCN103117300AIncreased current capabilityImprove featuresTransistorSemiconductor/solid-state device manufacturingHigh current densityElectrical resistance and conductance

The invention discloses a parasitically transversal type PNP device. A base region is composed of N-type injection layers which are formed in two adjacent active regions. An emitter region is composed of P-type doped polycrystalline silicon artifact buried layers which are formed on a shallow groove field oxide bottom between the two active regions of the base region. A collector region is composed of the P-type doped polycrystalline silicon artifact buried layers which are formed on shallow groove field oxide bottom on two sides of the two active regions of the base region. The final formed device is in a C-B-E-B-C structure. The structure can convert a current path of the base region of the device into a straight line type, improve current capacity of the device, and significantly improve the current gain and frequency features of the device. Meanwhile, areas of the device can be reduced and current density is improved. The polycrystalline silicon artifact buried layers can reduce the connecting resistance of the emitter region and the collector region, enable the resistance to be uniform, and improve cut-off frequency of the device greatly. The invention further discloses a manufacture method of the parasitically transversal type PNP device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

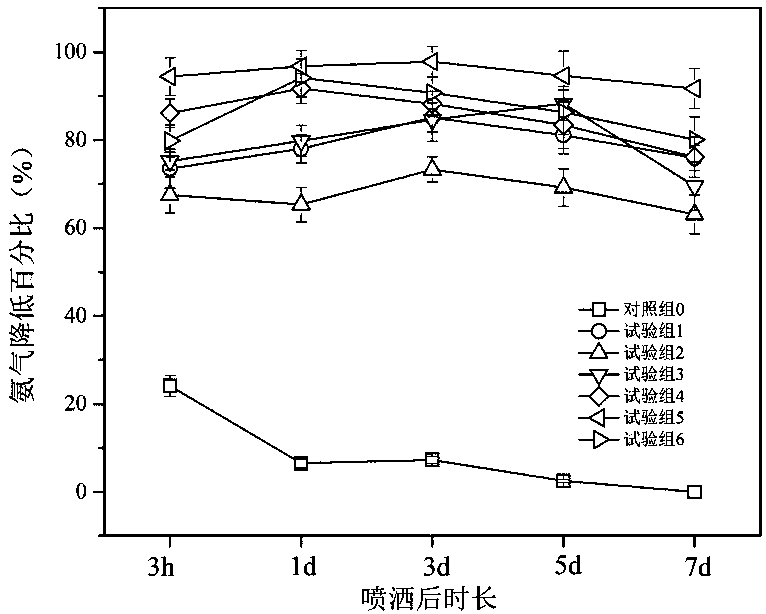

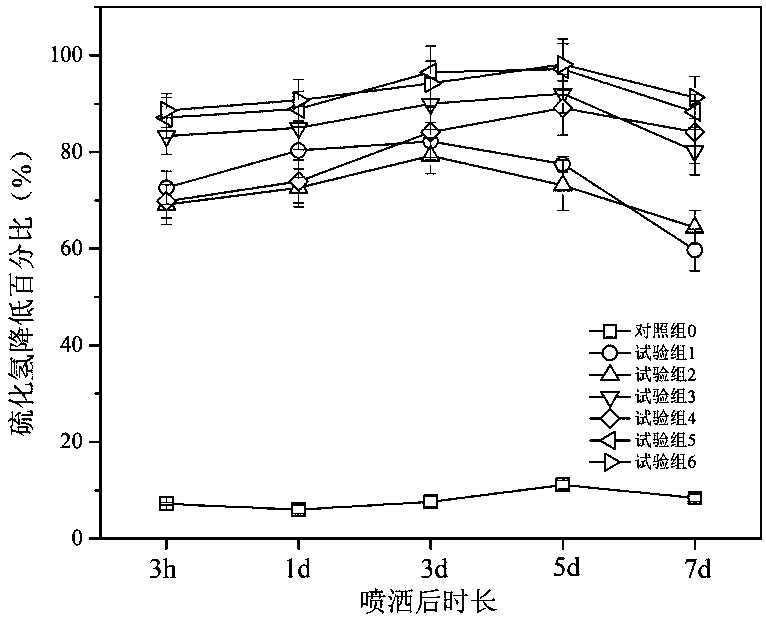

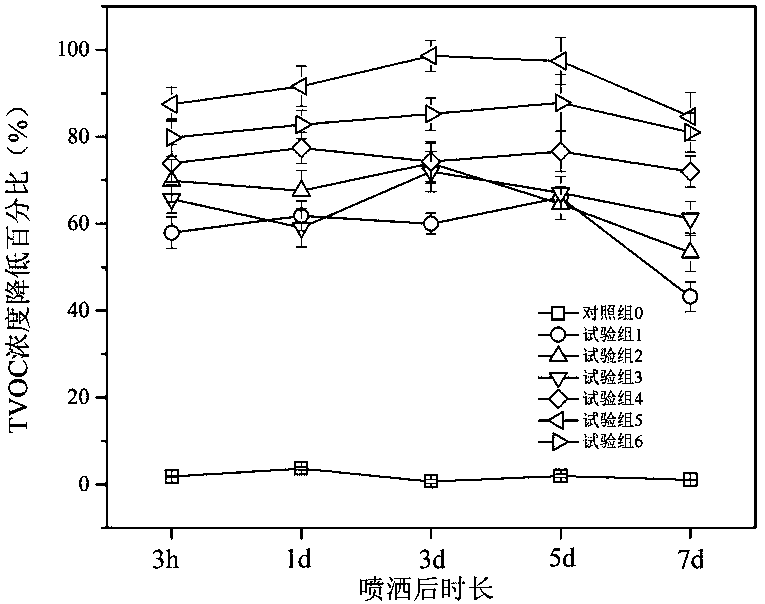

Preparation method and application of disinfection deodorant

ActiveCN111249879ANo side effectsReduce dosageBiocideDispersed particle separationBenzoic acidSodium phosphates

The invention relates to the field of livestock and poultry industry pollutant treatment. Based on malodorous gases and pathogenic microorganisms in livestock and poultry houses, the invention discloses a disinfection deodorant capable of simultaneously and efficiently removing malodorous gases and killing pathogenic microorganisms, wherein the main components of the disinfection deodorant consistof sodium percarbonate, calcium peroxide, sodium persulfate, peroxybenzoic acid, malic acid, hydroxypropyl methyl cellulose and sodium hexametaphosphate. The invention also provides a preparation method of the disinfection deodorant, wherein the disinfection deodorant prepared by the method has the advantages of uniform dispersion of all components, strong adhesion and good stability. According to the application of the disinfection deodorant, hydrogen peroxide, active oxygen (.O), hydroxyl free radicals (.OH) and sulfate free radicals (.SO4) can be rapidly generated, and can efficiently playdisinfection and deodorization roles, existing slow-release components can maintain the cleanness of the poultry house environment for a long time, and action products are clean and free of pollution. The disinfection deodorant has the advantages of simple use method and strong operability in the preparation process, and is suitable for large-batch and large-scale production.

Owner:湖南现代资源生物科技有限公司 +1

Anti-wrinkle textile drying machine

InactiveCN112760872AEffective absorption treatmentFast output processingLiquid/gas/vapor removalTextile treatment machine arrangementsFiberPolymer science

The invention discloses an anti-wrinkle textile drying machine. The anti-wrinkle textile drying machine structurally comprises a dehumidification device, a support, textile cloth, a dryer, a fan, an air outlet, a machine body and a guide roller. When the anti-wrinkle textile drying machine is used after improvement, hot air is evenly diffused on the textile cloth through an air cushion elastic film, water impacting on the air cushion elastic film can slide onto a separating and filtering layer to be filtered and removed, the filtered water drops onto fiber cotton from water guiding holes, absorbing paper makes contact with the fiber cotton to absorb the water, then a resin sheet is used for absorbing the water on the absorbing paper, after the resin sheet absorbs the water and expands, the water in the resin sheet can be separated from the resin sheet and drops onto a clamping block, the water flows to a water guide plate through water outlet holes using a transparent film, then the water guide plate guides the water to a sliding plate, the sliding plate guides the water to the interior of a drying cavity through a nano arc plate for adsorption treatment, the dried textile cloth is prevented from being affected with damp for the second time, and the drying effect of the textile cloth is improved.

Owner:李惠明

Magnesium alloy material smelting device

PendingCN114485157AAvoid turning upShorten the time of precipitationStirring devicesCharge supportsMolten slagMagnesium alloy

A magnesium alloy material smelting device comprises a smelting furnace and a disc type filling device, the disc type filling device comprises a stirring shaft, a filling basket and a disc type stirring head, the stirring shaft is connected with the filling basket, the bottom of the filling basket is connected with the disc type stirring head, the disc type stirring head comprises a plurality of stirring wings, and the stirring wings are connected with the filling basket and a stirring disc. The connecting ends of the stirring wings are mutually connected, the stirring ends extend to the edge part of the stirring disc, and a liquid through hole is formed in the side wall of the filler basket; in the process of preparing and processing the magnesium alloy, the disc type stirring head can accelerate diffusion, the disc type stirring head rotates to divide molten liquid into an upper layer and a lower layer, the molten liquid on the upper layer forms a solution vortex, and diffusion of intermediate alloy elements is accelerated; and the lower-layer melt is kept relatively static, so that the precipitated slag is prevented from turning upwards, the slag precipitation time is shortened, and the productivity is improved.

Owner:CITIC DICASTAL

Vertical parasitic type PNP triode and manufacture method

ActiveCN103066115BRaise the cutoff frequencyReduce areaTransistorSemiconductor/solid-state device manufacturingOxygenImpurity

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

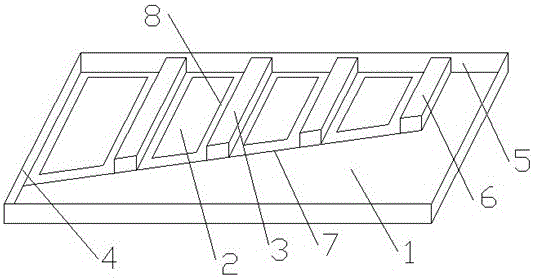

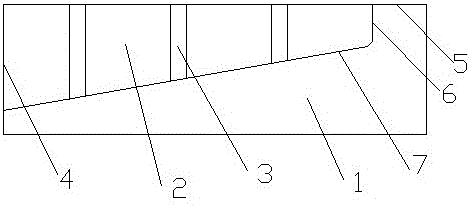

Vibrating screen for feeding a color sorter

ActiveCN103658058BImprove color sorting efficiencyDiffusion evenly distributedSievingScreeningDiagonalEngineering

The invention belongs to the field of blanking of color sorters, and particularly relates to a blanking vibrating screen of a color sorter. The blanking vibrating screen of the color sorter comprises a vibrating screen body, wherein a rectangular material channel is arranged in the vibrating screen body, a separation line along a diagonal of the material channel is arranged in the material channel, a material sorting channel is arranged on one side of the separation line, a blanking channel on arranged on the other side, the blanking channel comprises at least two sub blanking channels, and a baffle is arranged between every two sub blanking channels. According to the vibrating screen, the diagonally arranged separation line of the sorting channel and the blanking channel is adopted, so that the chance that materials pass through each sub blanking channel in the blanking channel is equal, the blanking vibrating screen is even in sorting and blanking, the color sorting working efficiency of the color sorter can be effectively improved, and the color sorting capacity can be improved.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Parasitic transversal NPN component and manufacturing method

ActiveCN103137663AMultiple choiceIncreased current capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceOxygen

The invention discloses a parasitic transversal NPN component. A base region is formed by P-shaped injection layers formed in two adjacent active areas, an emitter region is formed by N-shaped mixed polycrystalline silicon buried layers formed on the bottom of shallow groove oxygen between the two active regions of the base region, and a current collection region is formed by the N-shaped mixed polycrystalline silicon buried layers formed on the bottom of the shallow groove oxygen on two sides of the two active regions of the base region. The structure of the component is C-B-E-B-C. The structure can enable a current path in the base region of the component to change into a linear shape, improve current capacity of the component, and enable current gain and frequency characteristic of the component to be improved greatly, reduce area of the component and provide current density. The polycrystalline silicon buried layers can reduce connecting resistance of an emitter and a collector, enable the resistance to be uniform, and greatly improve cut-off frequency of the component. The invention further discloses a manufacturing method of the parasitic transversal NPN component.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Light-emitting diode

InactiveCN101944559BDiffusion evenly distributedImprove luminous efficiencySemiconductor devicesEngineeringLight-emitting diode

Owner:UBILUX OPTOELECTRONICS CORP

Parasitic transversal NPN component and manufacturing method

ActiveCN103137663BMultiple choiceIncreased current capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesPower flowOxygen

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

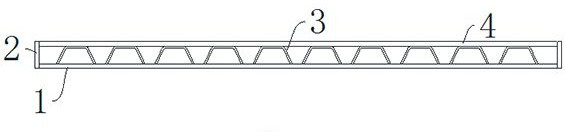

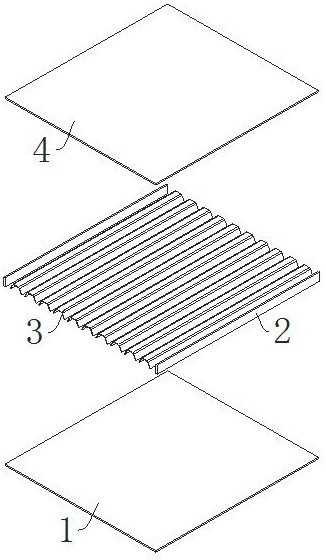

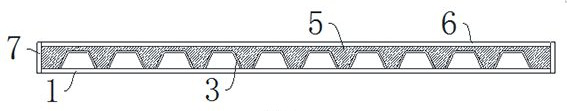

Novel U rib web assembly type floor system structure system

PendingCN113653236ASimple construction processShorten the construction periodFloorsProtective buildings/sheltersArchitectural engineeringLong span

The invention relates to the technical field of floor assembly, in particular to a novel U rib web assembly type floor structure system. The system comprises a lower rib plate and a plurality of U rib plates, the plurality of U rib plates are arranged at the top of the lower rib plate in a linear array, and the bottoms of the plurality of U rib plates and the lower rib plate are welded. According to the system, a tooth-shaped partition plate, a reinforcing mesh and a strip-shaped partition plate are additionally arranged in each scheme, so that different industrial requirements are met, the four U rib web plate structure schemes are provided, the strict requirements for the clearance of floors, the construction technology, the economical efficiency of the structure schemes and the construction period in modern infrastructure construction are met, the construction progress is accelerated, meanwhile, the engineering quality can be better guaranteed, and the system is suitable for being applied to floors in large-span, large-column-grid and large-bay structures.

Owner:江西博筑工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com