Vibrating screen for feeding a color sorter

A vibrating screen and color sorter technology, applied in the direction of vibrating conveyor, filter screen, conveyor, etc., can solve the problem that the color sorter cannot perform color sorting to the maximum extent, the material is unevenly cut, and the working power of the color sorter is reduced. problems, to achieve the effect of improving the efficiency of color sorting, uniform sorting and blanking, and improving the ability of color sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

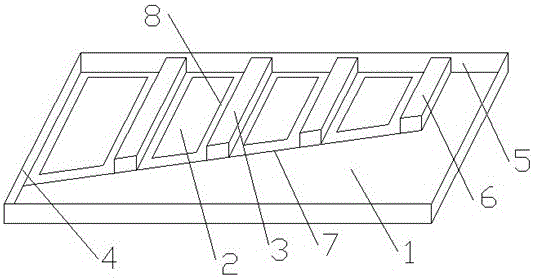

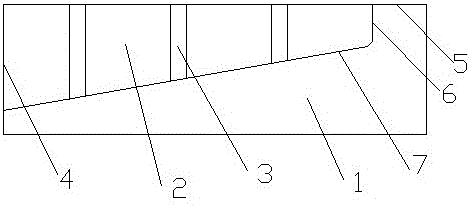

[0011] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

[0012] Such as figure 1 As shown, a color sorter feeding vibrating screen includes a vibrating screen body, a rectangular feeder is arranged in the vibrating screen body, and a dividing line 7 along the diagonal direction of the feeder is arranged in the vibrating screen body. One side of the line 7 is set as a material sorting channel 1, and the other side is set as a discharge channel 8, and the discharge channel 8 includes no less than two sub-feeding channels 2, and between the sub-feeding channels 2 Both are provided with partitions 3 .

[0013] One end of the separation line 7 is set on the narrower side 4 of the material channel, and the other end is connected to the longer side 2 5 adjacent to the side 1 4 .

[0014] A small baffle 6 perpendicular to the side 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com