Lifting device for color sorter

A technology of color sorting machine and roller, which is applied in the direction of conveyor, transportation, packaging, sorting, etc., can solve the problems of food waste, time extension, and occupying a large space, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

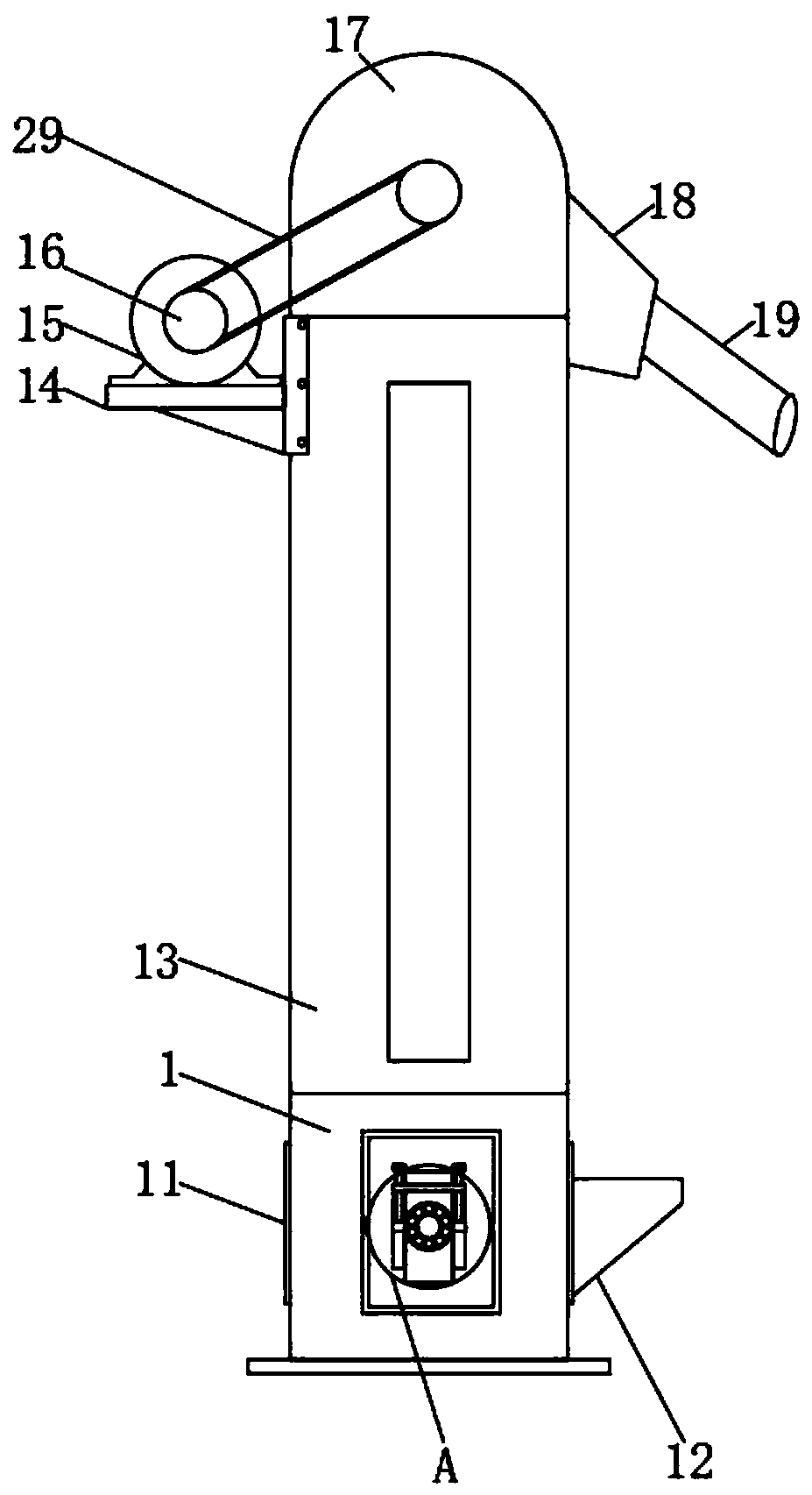

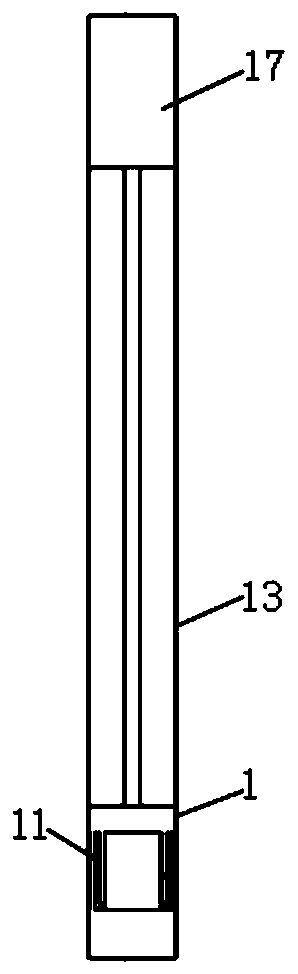

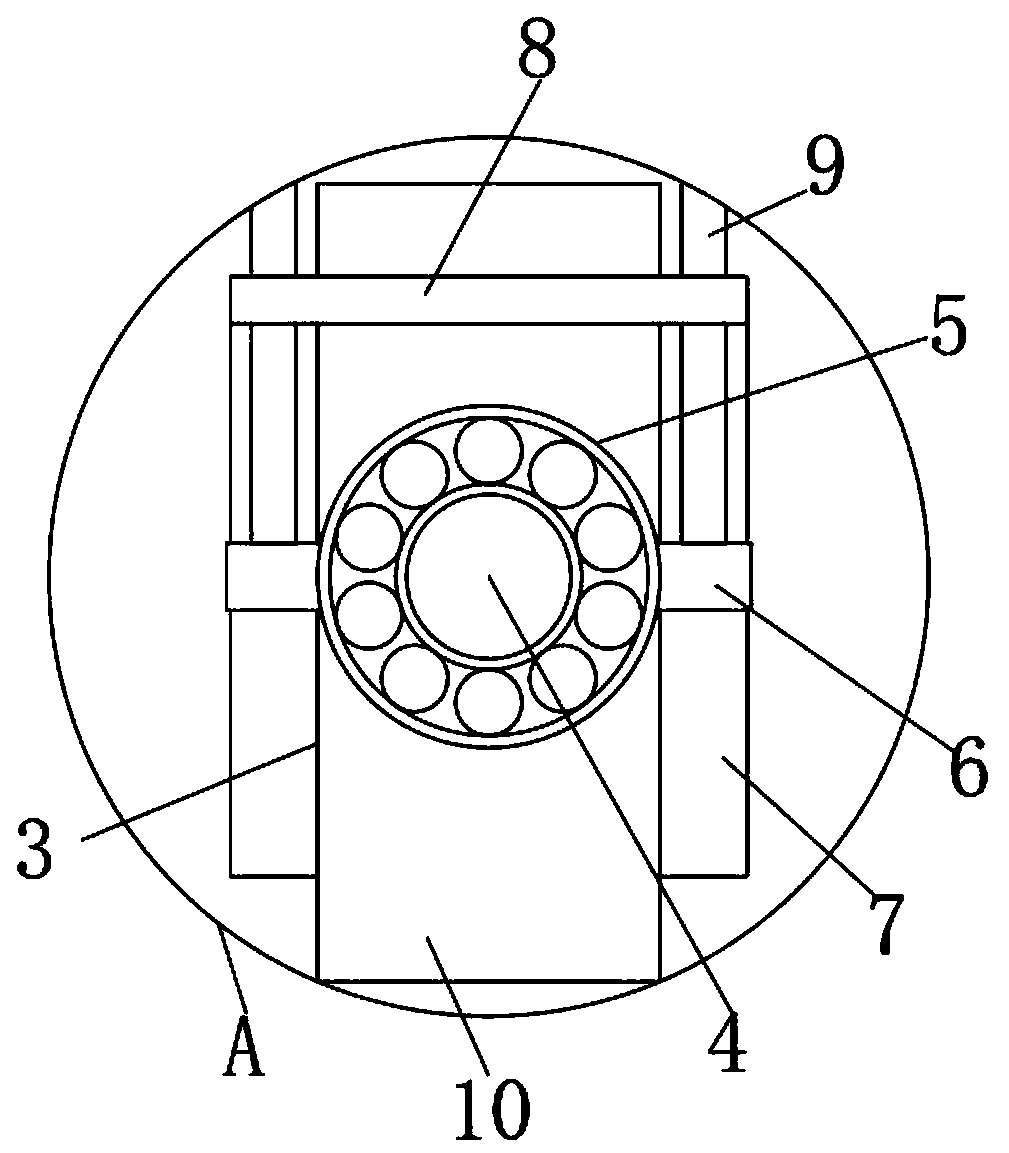

[0031] A lifting device for a color sorter, comprising a base 1, two transfer boxes 13, a material discharge cover 17, a material collection cover 18 and an outer discharge pipe 19, the base 1 is a hollow shell, and the vertical middle part of the inner cavity of the base 1 is set There is an isolation plate 2, the central part of the isolation plate 2 is provided with a movable groove 3, and a first roller 4 is longitudinally arranged in the movable groove 3, and the front and rear ends of the first roller 4 run through the front and rear sides of the inner wall of the base 1 and are provided with and extend to the outside respectively, the front and rear ends of the first roller 4 are sleeved with bearings 5, the left and right sides of the bearing 5 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com