LED (light emitting diode) wafer with evenly distributed current

A technology of uniform current and wafer, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low light output efficiency, uneven light emission, small light output area, etc., to achieve uniform current diffusion, prolong service life, and improve light output efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

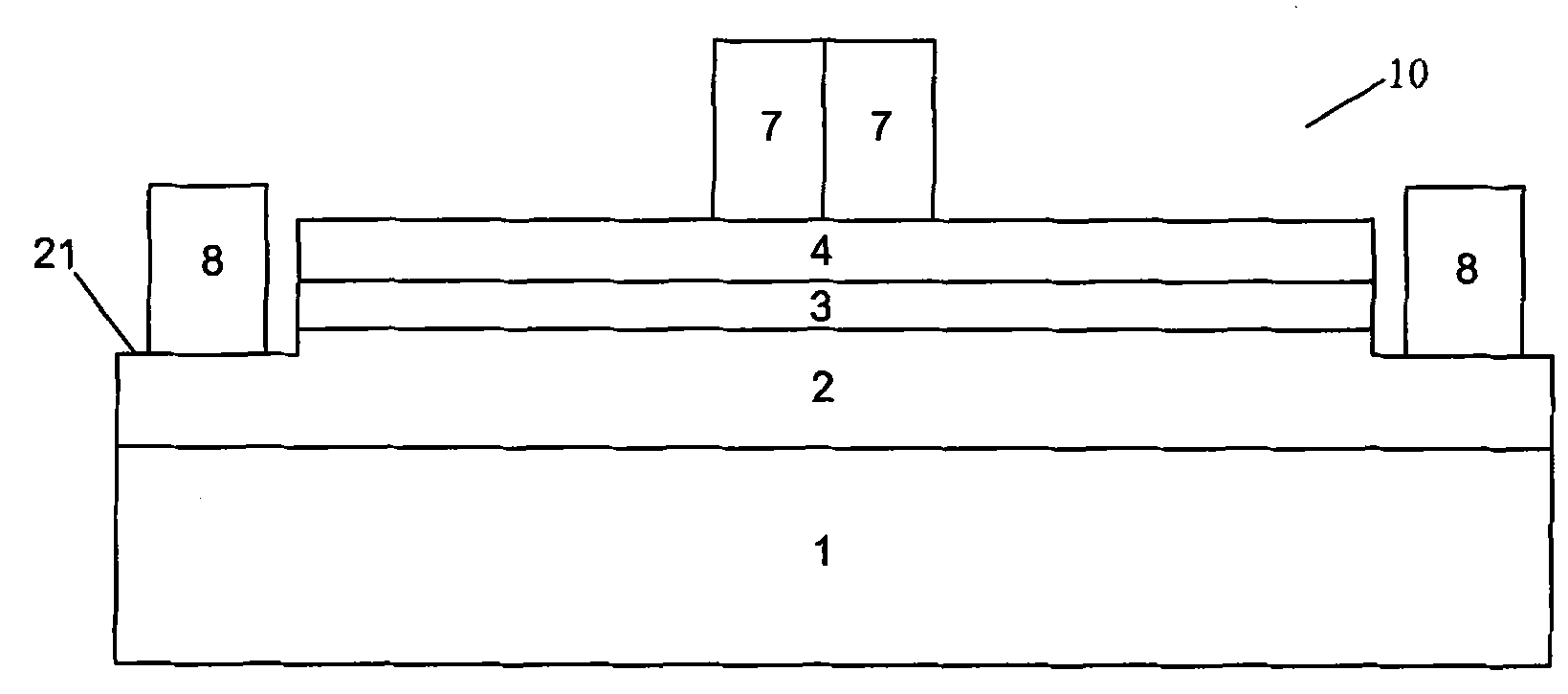

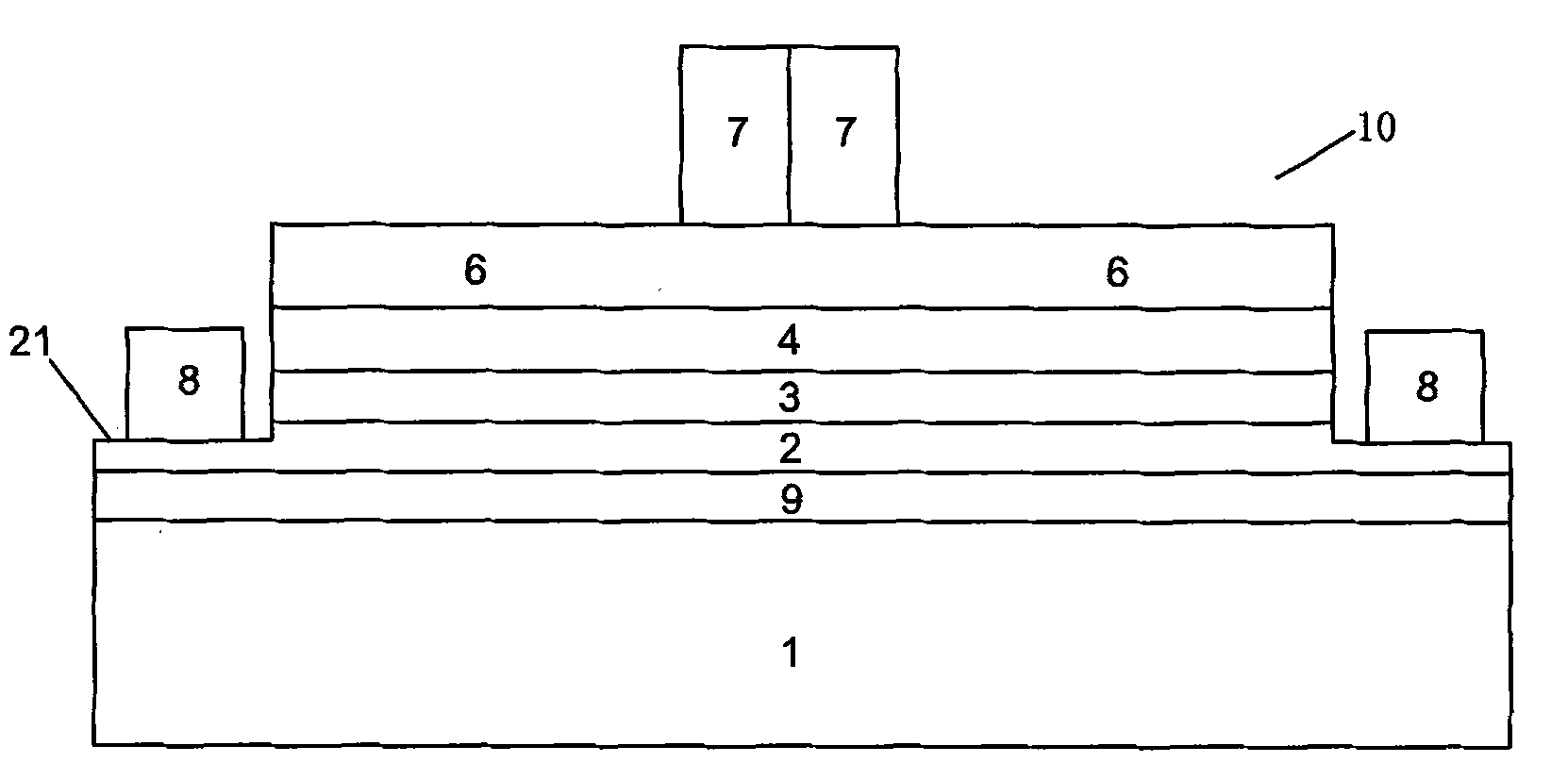

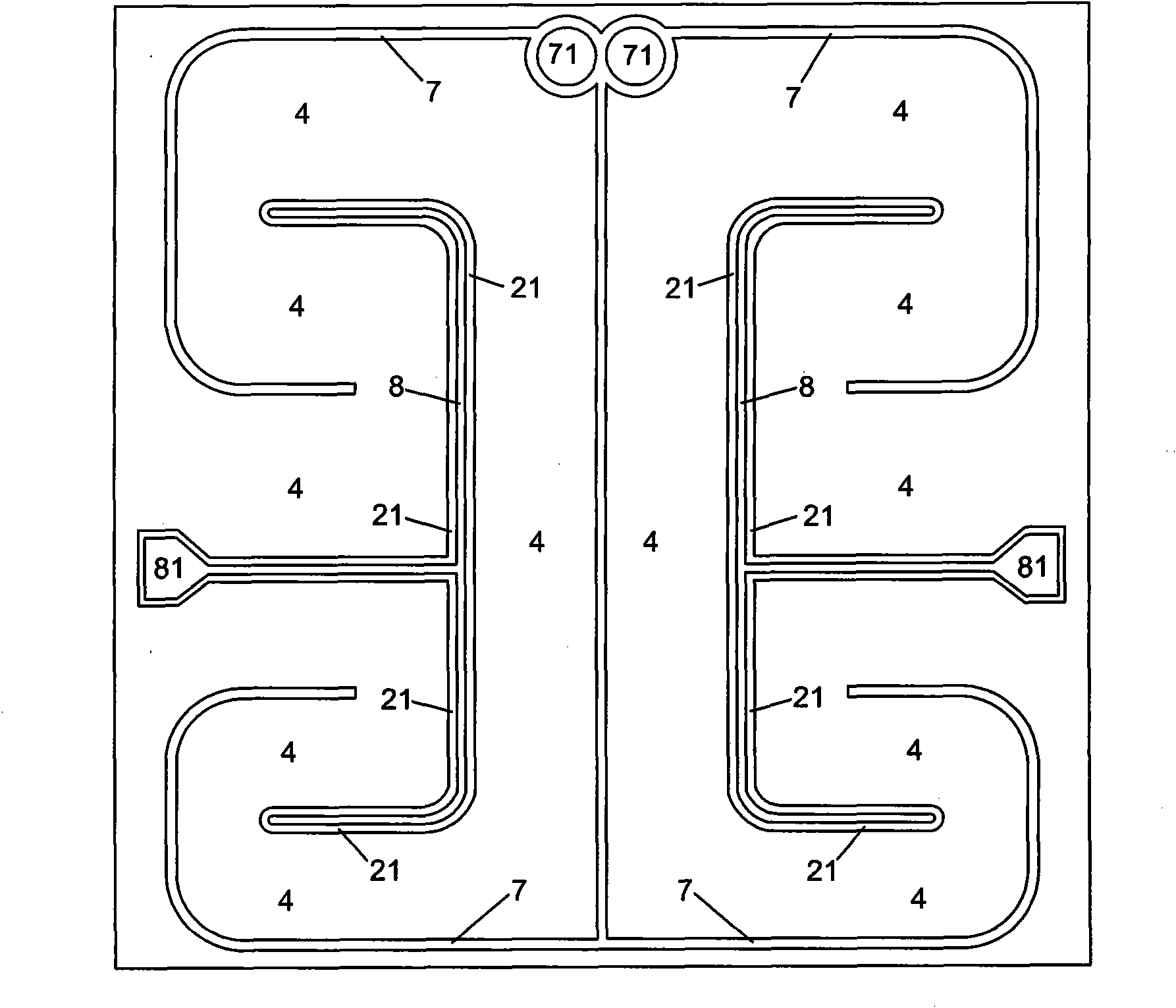

[0017] Refer to attached figure 1 , 2 , 3, and 4, the present invention includes an N-type semiconductor layer 2, a light-emitting layer 3 formed on the N-type semiconductor layer 2; a P-type semiconductor layer 4 formed on the light-emitting layer 3; the surface of the P-type semiconductor layer 4 is provided with A symmetrical "E"-shaped trench 21 connected to the N-type semiconductor layer 2; a negative electrode 8 formed in the symmetrical "E"-shaped trench 21 and a positive electrode 7 formed in the P-type semiconductor layer 4; symmetrical The "E"-shaped groove 21 is covered with the N-type semiconductor layer 2, and the negative electrode 8 is arranged on the symmetrical "E"-shaped groove 21 to form a symmetrical "E"-shaped negative electrode 8, and the positive electrode 7 surrounds the symmetrical Around the "E"-shaped negative electrode 8, a layer of metal is partially vapor-deposited on the positive electrode 7 to form a positive electrode bonding wire area 71 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com