Parasitic transversal NPN component and manufacturing method

A lateral device technology, applied in the manufacture of parasitic lateral NPN devices, in the field of parasitic lateral NPN devices, can solve the problems of large area, weak current capability, small gain, etc., achieve uniform diffusion distribution, improve current capability, and improve Effect of Cutoff Frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

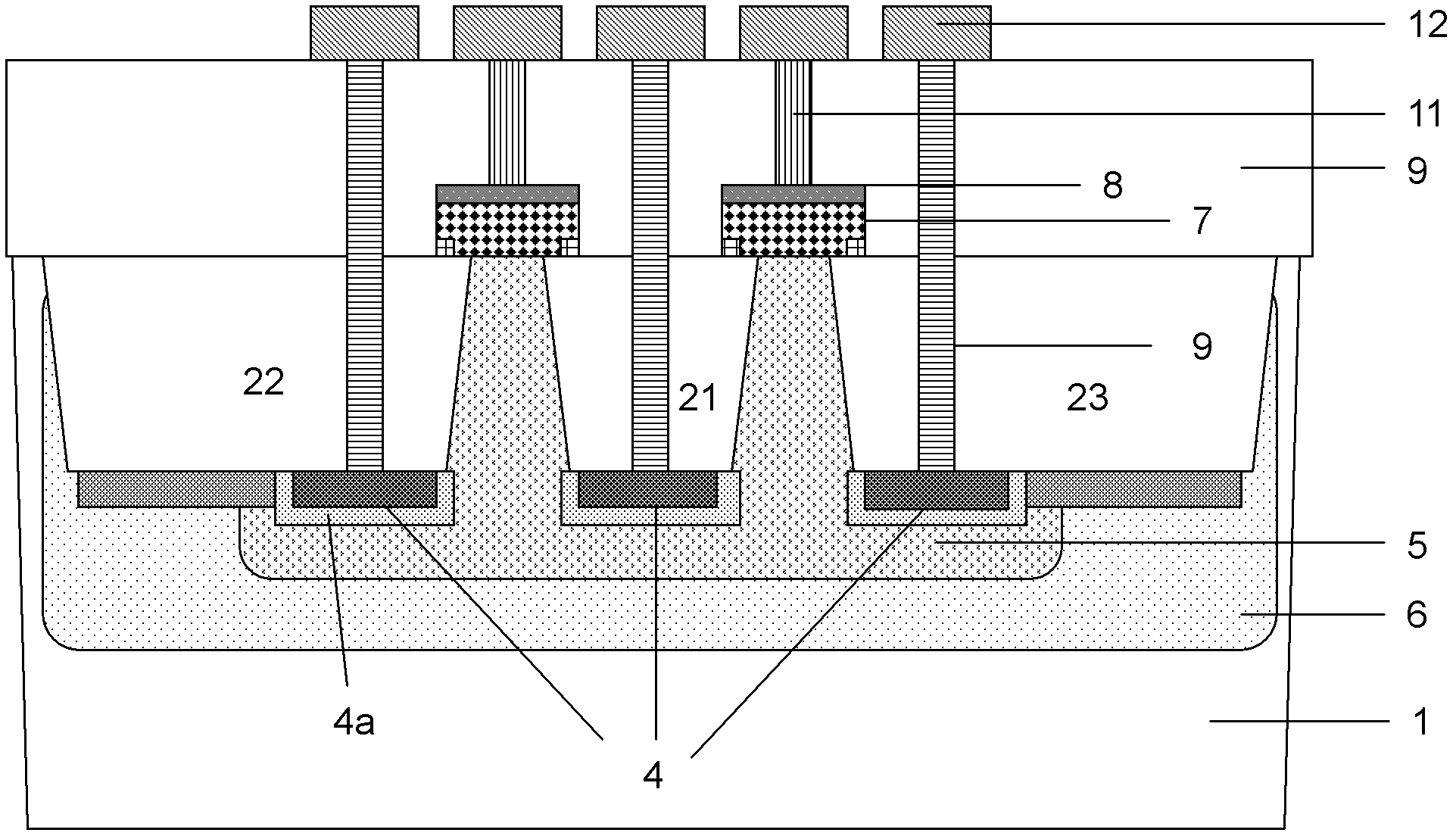

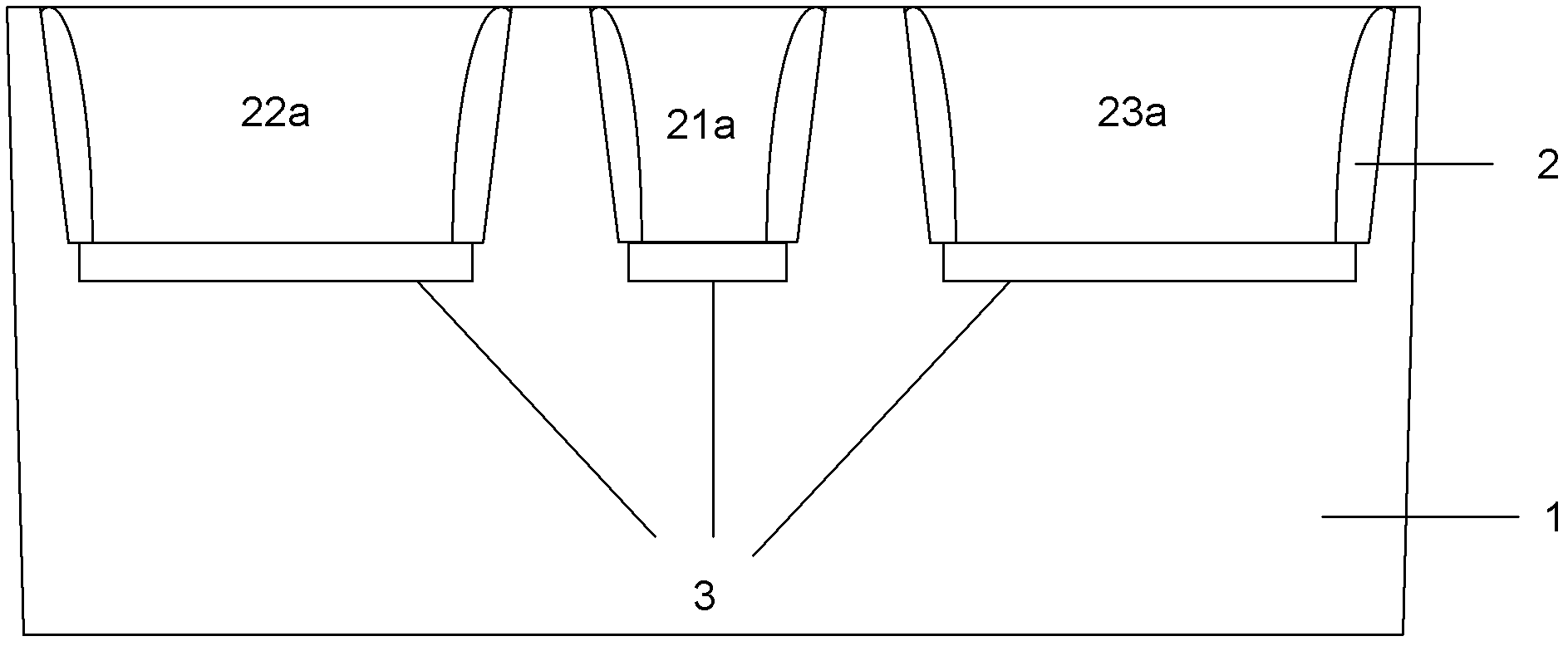

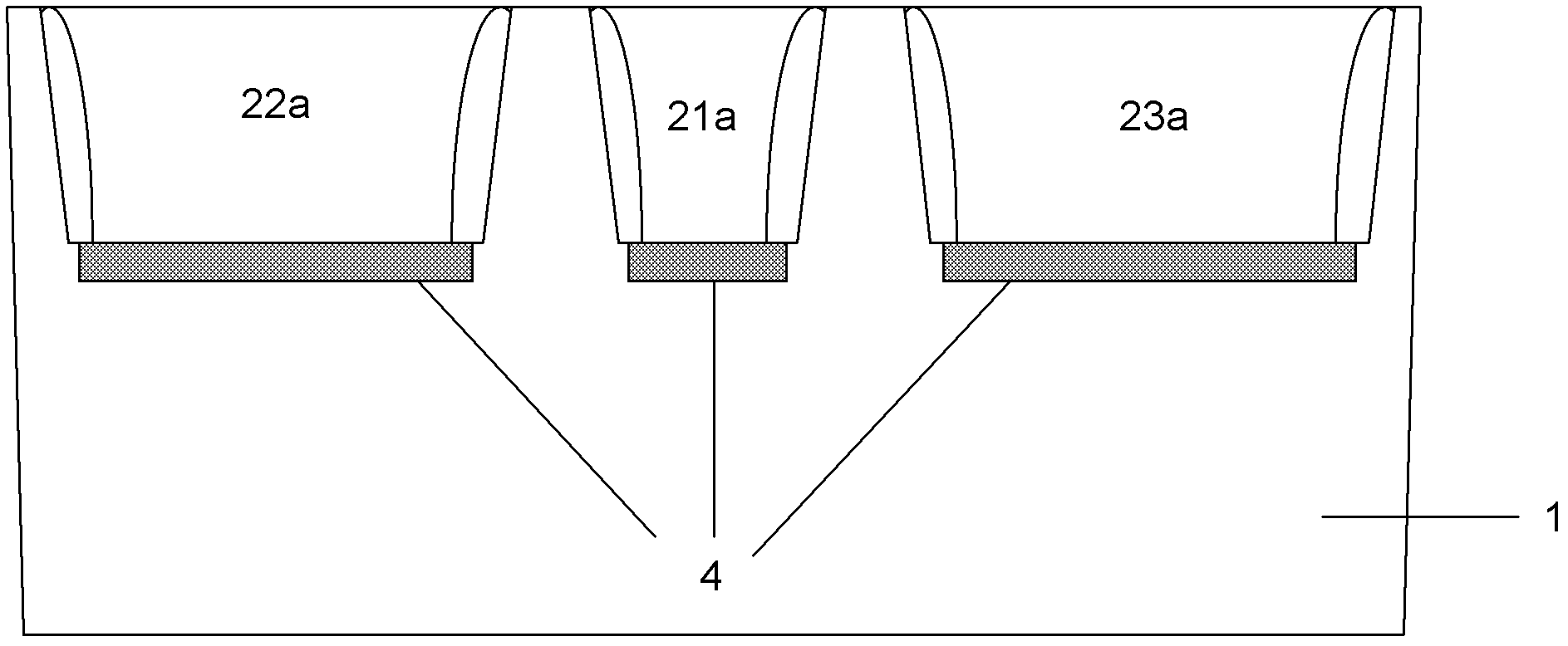

[0040] Such as figure 2 Shown is a schematic diagram of the structure of a parasitic lateral NPN device according to an embodiment of the present invention. In the embodiment of the present invention, a parasitic lateral NPN device is formed on a P-type silicon substrate 1, and the active region is isolated by shallow trench field oxygen, that is, the isolation structure of the active region is shallow trench isolation (STI), and the shallow trench field oxygen The depth is 0.3 micron to 0.5 micron. Parasitic lateral NPN devices include:

[0041] A base region 5 is composed of P-type injection layers formed in two adjacent first active regions and second active regions. The P-type injection layer can share the P- injection layer in the vertical PNP (VPNP) in the bipolar device (Bipolar) process, or share the P-type well process in the BiCMOS process. The implant dose of the P-type ion implantation of the P-type implant layer is 1e12cm -2 ~5e13cm -2 , the implantation ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com