Anti-wrinkle textile drying machine

A drying machine and anti-wrinkle technology, which is applied in textile processing machine accessories, textiles and papermaking, and textile material processing, etc., can solve the problem of dry and wet textile fabrics, reduce the drying efficiency of textile fabrics, and secondary dampness of textile fabrics And other problems, to achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

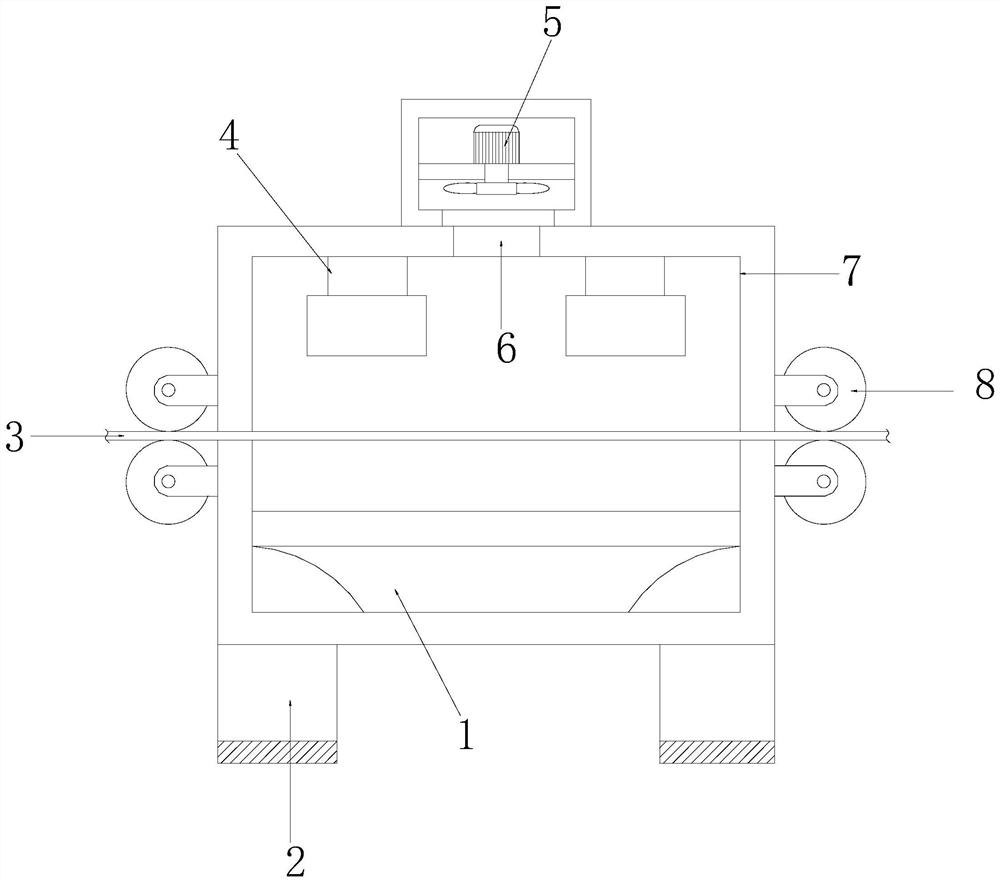

[0033] see figure 1 , the present invention provides a technical solution: a wrinkle-resistant textile dryer, the structure of which includes a dehumidification device 1, a bracket 2, a textile cloth 3, a dryer 4, a fan 5, an air outlet 6, a body 7, and a guide roller 8. The bracket 2 and the body 7 are matched by welding, the dehumidification device 1 is installed inside the body 7, the body 7 is provided with a dryer 4 and the two are connected by wires, and the body 7 is provided with There is an air outlet 6, and the air outlet 6 is arranged at the bottom of the fan 5, and the fan 5 is embedded and fixed on the body 7, and two guide rollers 8 connected thereto are arranged on both sides of the body 7, and the textile The cloth 3 runs through the machine body 7 and is connected to guide rollers 8 , and the two guide rollers 8 are in contact with the woven cloth 3 .

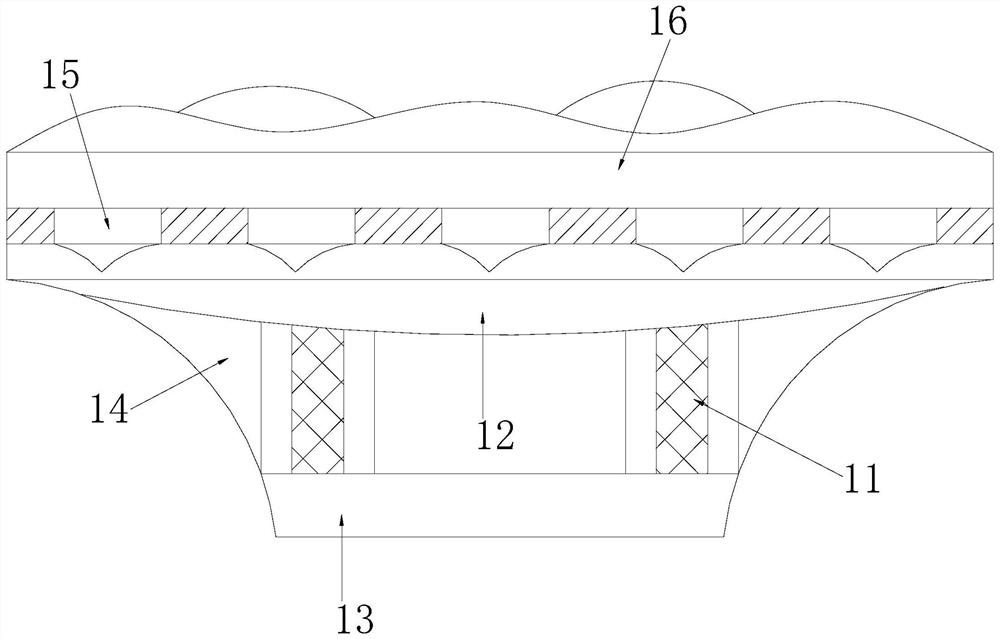

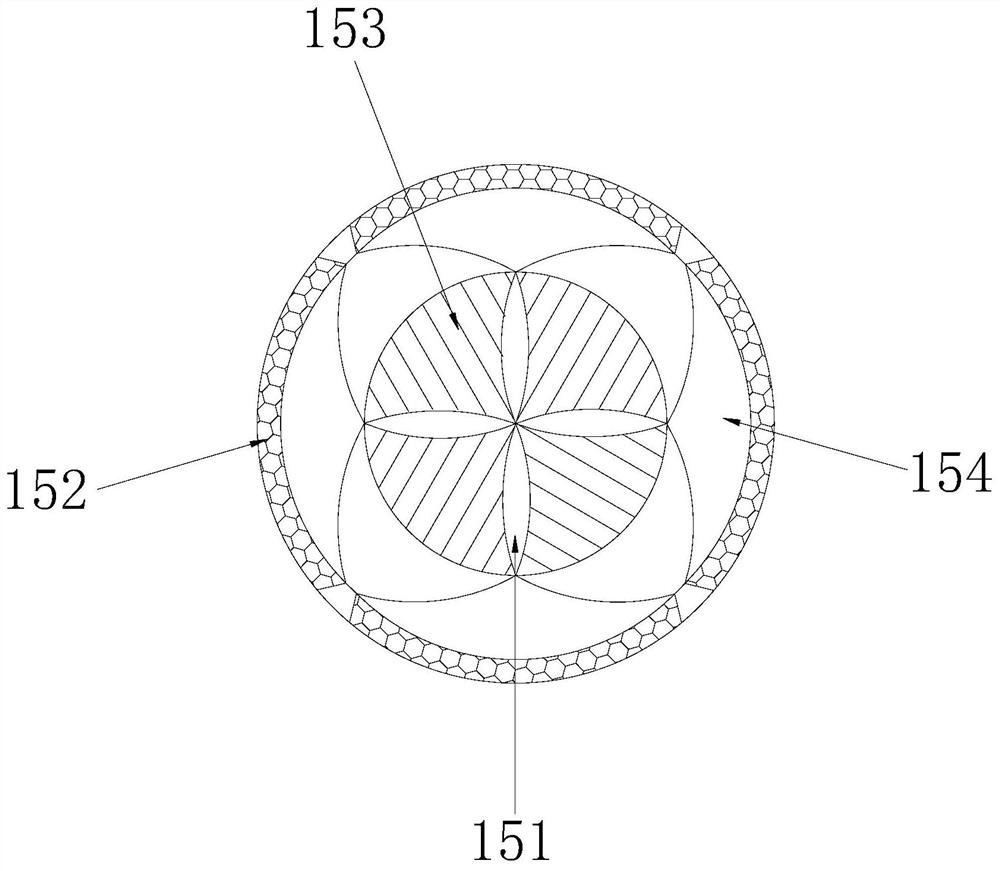

[0034] see figure 2 , the dehumidification device 1 includes a drying chamber 11, a nano-arc plate 12, a ...

Embodiment 2

[0045] see figure 1 , the present invention provides a technical solution: a wrinkle-resistant textile dryer, the structure of which includes a dehumidification device 1, a bracket 2, a textile cloth 3, a dryer 4, a fan 5, an air outlet 6, a body 7, and a guide roller 8. The bracket 2 and the body 7 are matched by welding, the dehumidification device 1 is installed inside the body 7, the body 7 is provided with a dryer 4 and the two are connected by wires, and the body 7 is provided with There is an air outlet 6, and the air outlet 6 is arranged at the bottom of the fan 5, and the fan 5 is embedded and fixed on the body 7, and two guide rollers 8 connected thereto are arranged on both sides of the body 7, and the textile The cloth 3 runs through the machine body 7 and is connected to guide rollers 8 , and the two guide rollers 8 are in contact with the woven cloth 3 .

[0046] see figure 2 , the dehumidification device 1 includes a drying chamber 11, a nano-arc plate 12, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com