A method of collecting dust

A technology for collecting dust and dust, applied in the field of dust collection, can solve the problems of many dust particles, pollute the environment, hidden safety hazards, etc., achieve high dust collection efficiency and avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

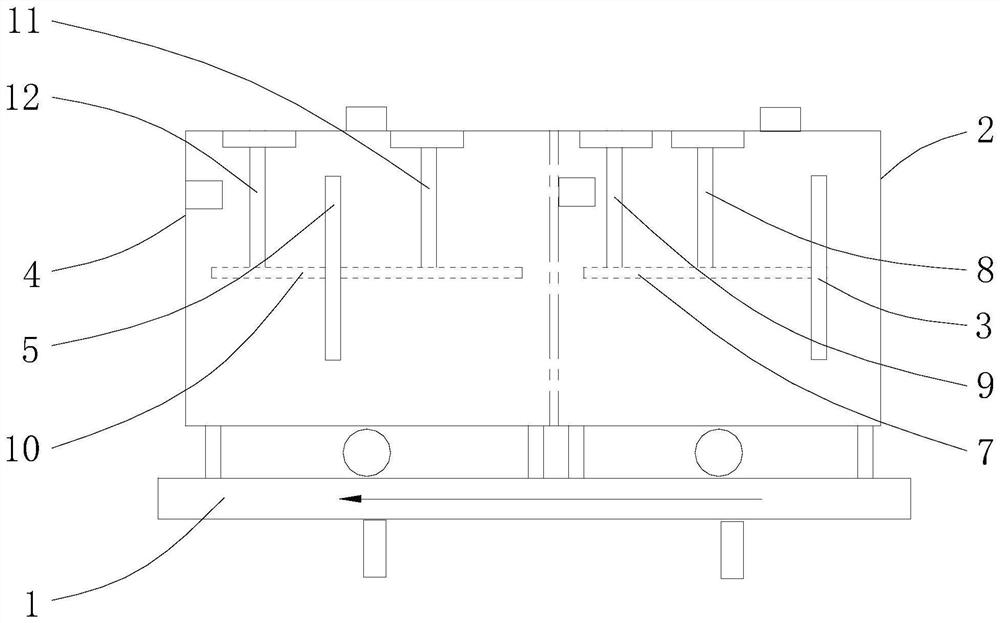

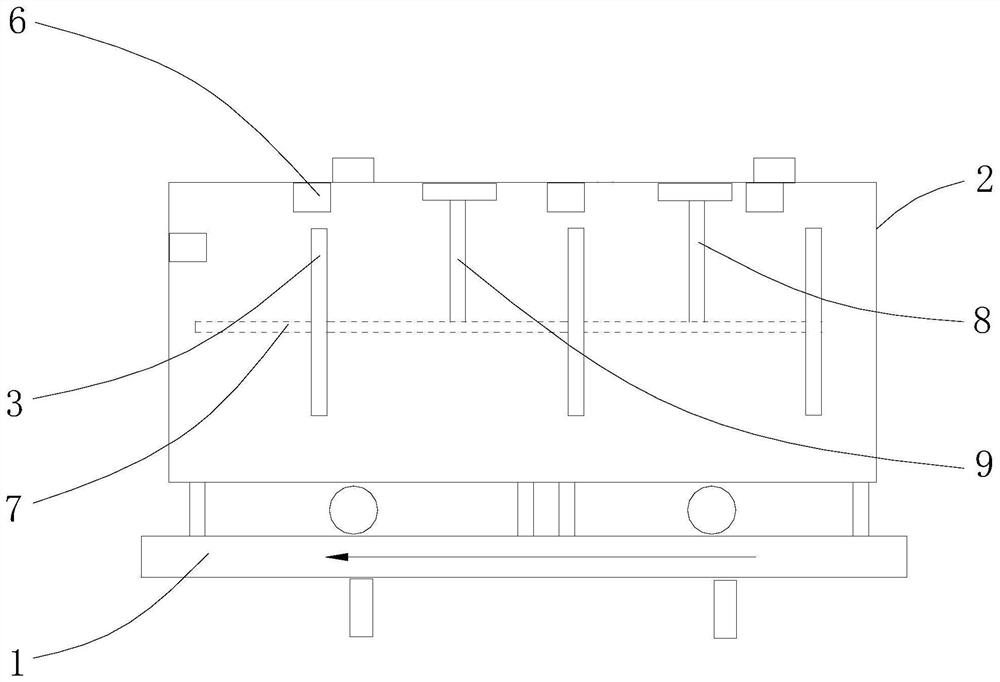

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] see Figure 1-2 Shown, above-mentioned a kind of dust collecting method is used for belt conveyor 1, comprises the following steps:

[0020] (1) Set the first housing 2 on the belt conveyor 1, and set the first electrode 3 in the first housing 2, connect the first electrode 3 through the first connecting shaft 7, and insulate the first electrode 3 through the first insulating porcelain bottle 8 Connect the first housing 2 and the first connection shaft 7, and electrically connect the first connection shaft 7 through the first terminal 9. Obviously, the first terminal 9 is insulated from the first housing 2, and the first connection shaft 7 is connected to the first connection shaft 7. The first electrode 3 is electrically connected; when working, the first electrode 3 is energized to form a first potential difference between the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com