An intelligent environmental protection welding machine

A welding machine and environmental protection technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as excessive welding smoke and physical injury of operators, achieve reliable welding quality, reduce workload, and improve production The effect of manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

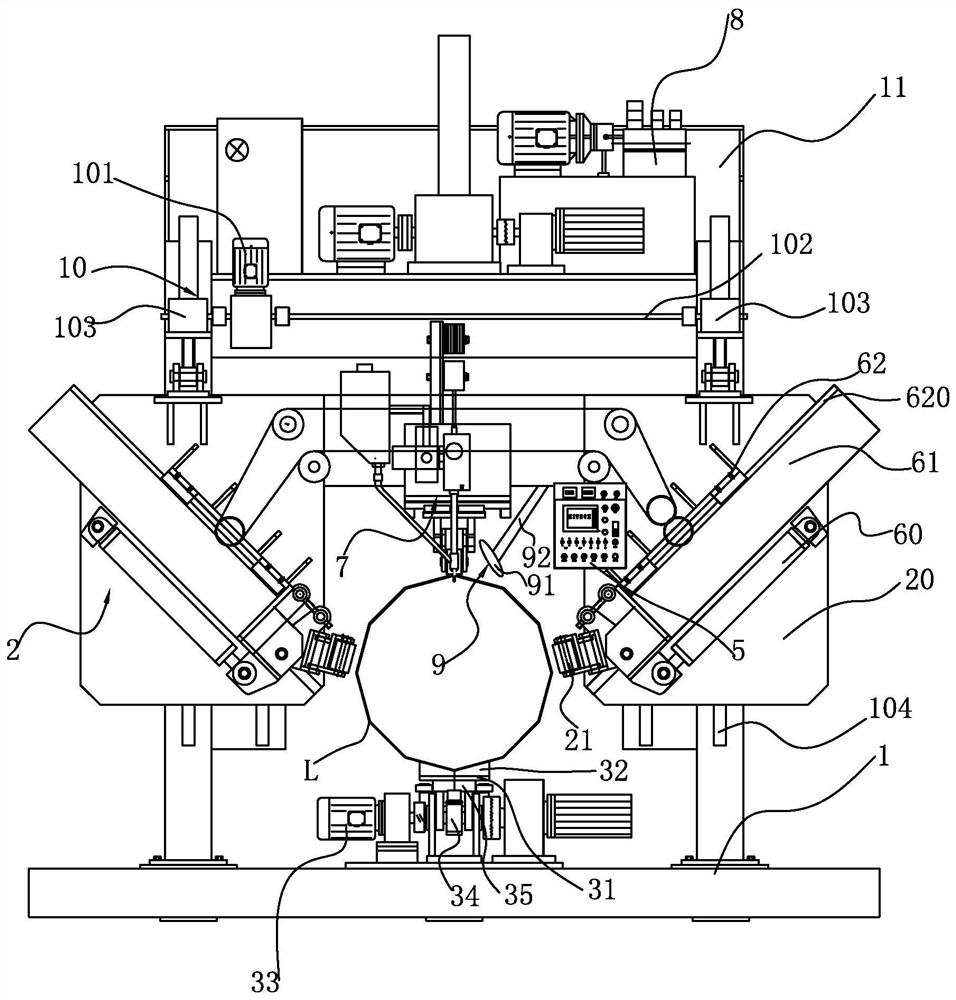

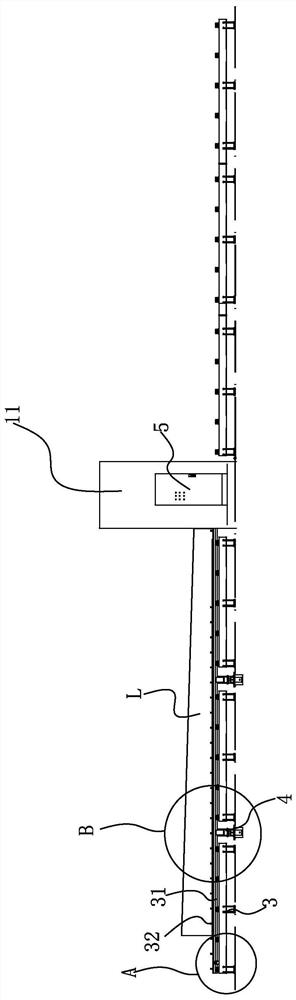

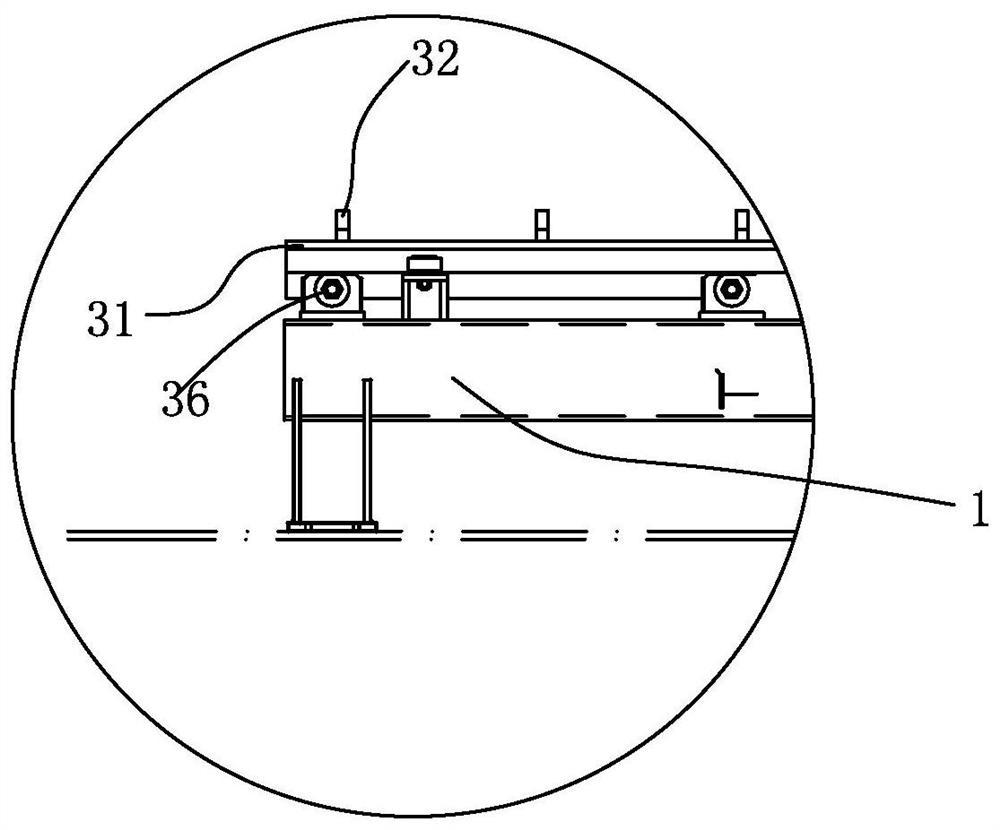

[0036] Intelligent environmental protection welding machine, the base of the frame 1 is provided with a conveying device 3 for transporting pyramidal steel pipes, the clamping device 2 for clamping the steel pipes is provided on the portal frame 11 of the frame 1, and a welding device 7 is provided above the conveying device 3 The power unit 8 that drives the above-mentioned clamping device 2 to clamp is installed on the gantry 11, and the power unit 8 is preferably set as a hydraulic station.

[0037] The clamping device 2 includes two sets of clamping components that are symmetrically arranged and act at the same time. In order to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com