5xxx aluminum alloy board for automobile body and manufacturing method thereof

A technology of aluminum alloy sheet and automobile body, which is applied in the field of alloy materials, can solve problems such as low elongation, easy cracking, and failure to meet the requirements of automobile body, and achieve the effect of preventing β phase from overburning and improving yield strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

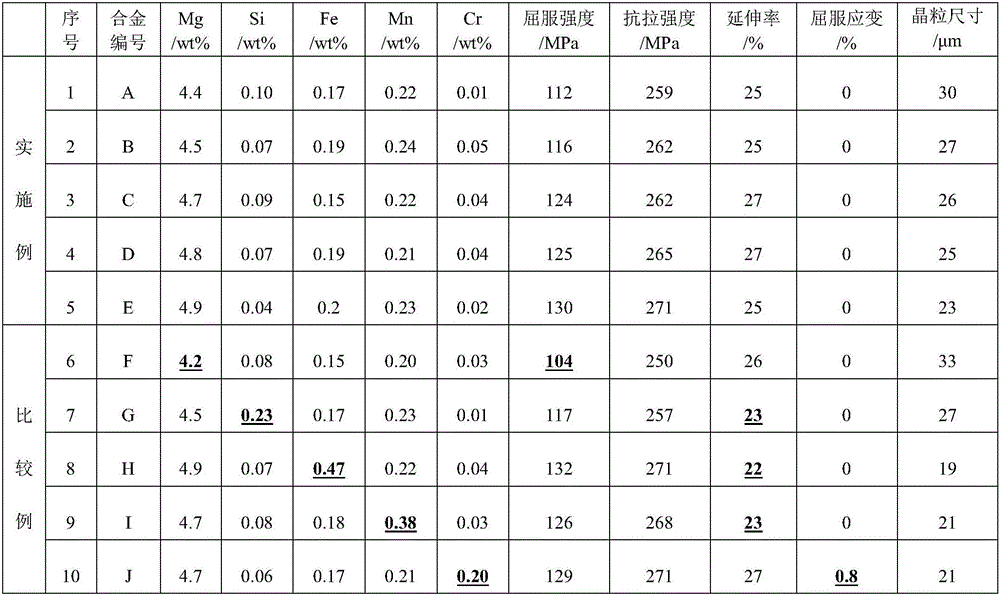

[0036]Table 1 shows the examples of aluminum alloy plates that meet the requirements prepared by the alloy composition of the present invention, and the properties of the aluminum alloy plates produced by using alloys other than the alloy composition of the present invention. The process of preparing aluminum alloy plates using the alloy components in the examples and comparative examples is: melting, casting, face milling and homogenization of the ingot, wherein the homogenization process adopts two-stage homogenization, and first heats up at 50°C / h Heat to 420°C, keep it warm for 2 hours, then raise the temperature to 540°C at 30°C / h, keep it warm for 8 hours, take it out and cool it in air. Hot rolling, cold rolling, intermediate annealing, and final cold rolling are performed on the homogenized ingot, followed by continuous annealing at 465°C to obtain a finished plate. Finally, according to the requirements of GB / T228, the mechanical performance evaluation experiment of t...

Embodiment 2

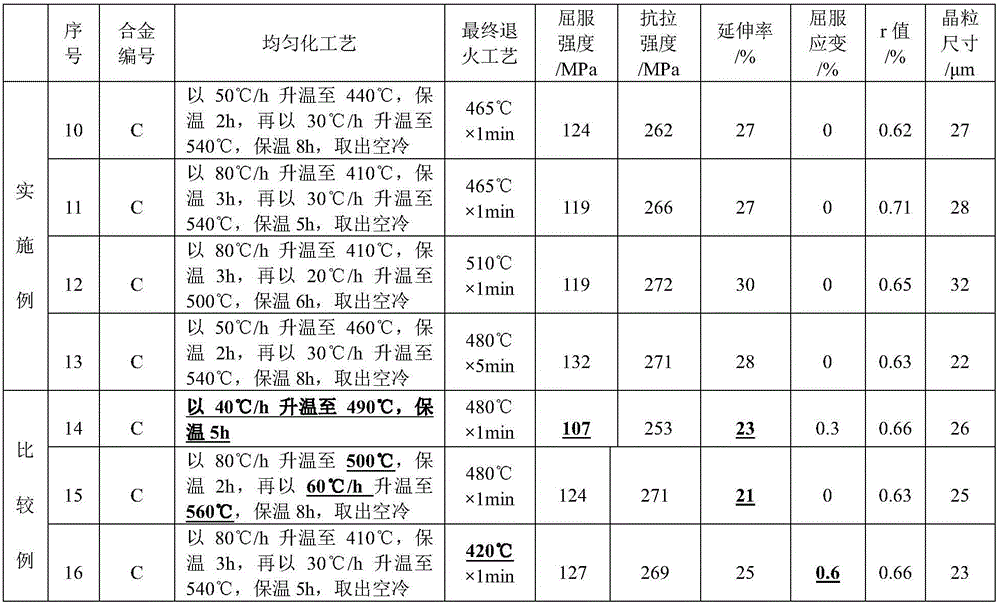

[0044] For alloy C in Table 1, the plates were prepared according to the process sequence of smelting→casting→face milling→homogenization→hot rolling→cold rolling→intermediate annealing→cold rolling→final annealing. Table 2 shows the influence of the preparation process on the properties of the alloy. In the test results, if the yield strength is not between 110 and 150 MPa, the elongation rate is less than 24%, the yield strain value is greater than 0, and the grain size is less than 20 microns, underline the value.

[0045] As shown in Table 2, Table 2 is the preparation process and performance of the examples and comparative examples. In the examples, the preparation process of serial numbers 10-13 meets the scope of the present invention, and the yield strength, elongation, and yield strain of the obtained aluminum alloy plate The value satisfies the requirements of the present invention. In comparative example, serial number 14-16 is because of not satisfying the technic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com