Axial-flow type coupled filtering centrifuge

A centrifuge, axial flow technology, applied in centrifuges and other directions, can solve problems such as poor symmetry and increase the difficulty of centrifugation, and achieve the effects of improving the ability to separate fine particles, improving axial symmetry, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

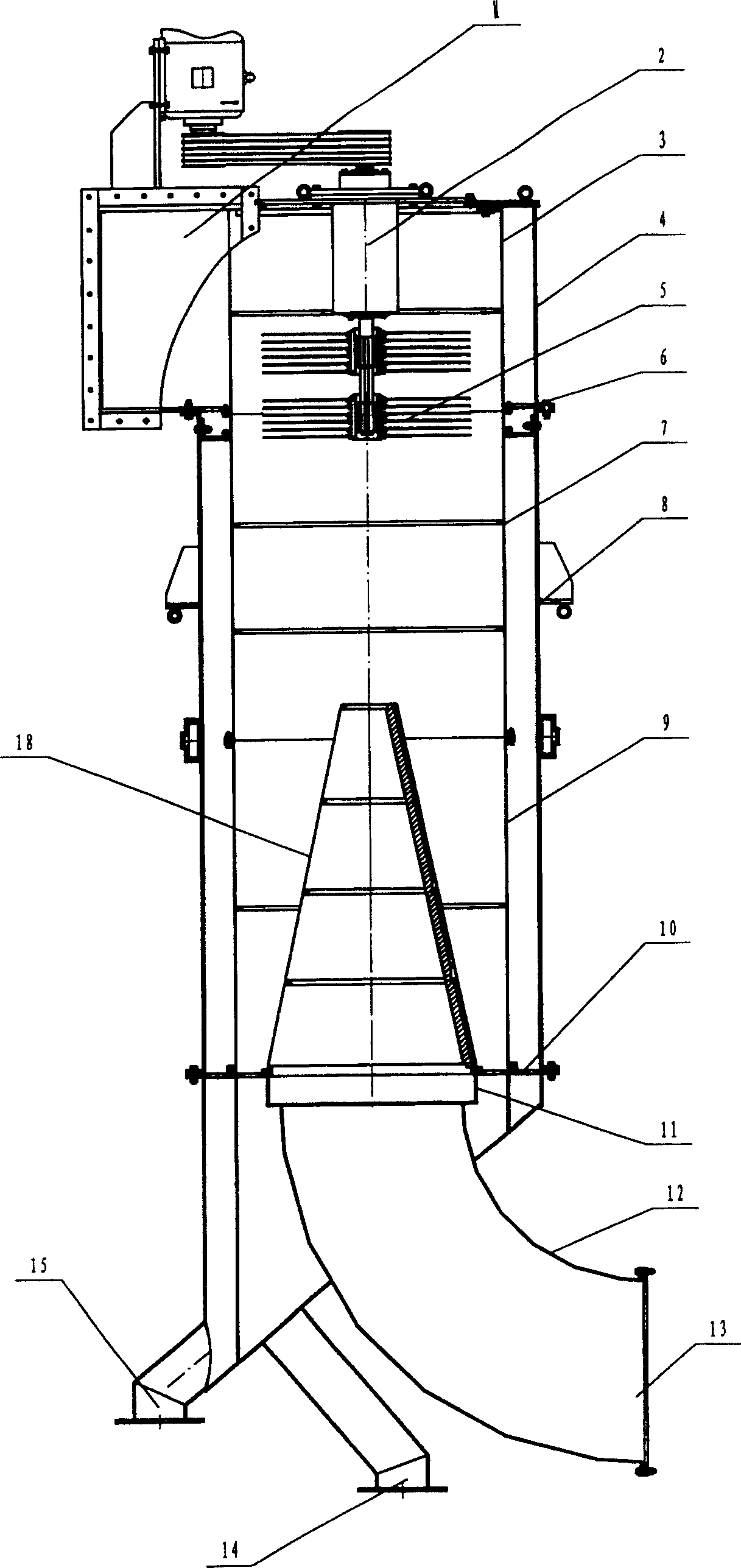

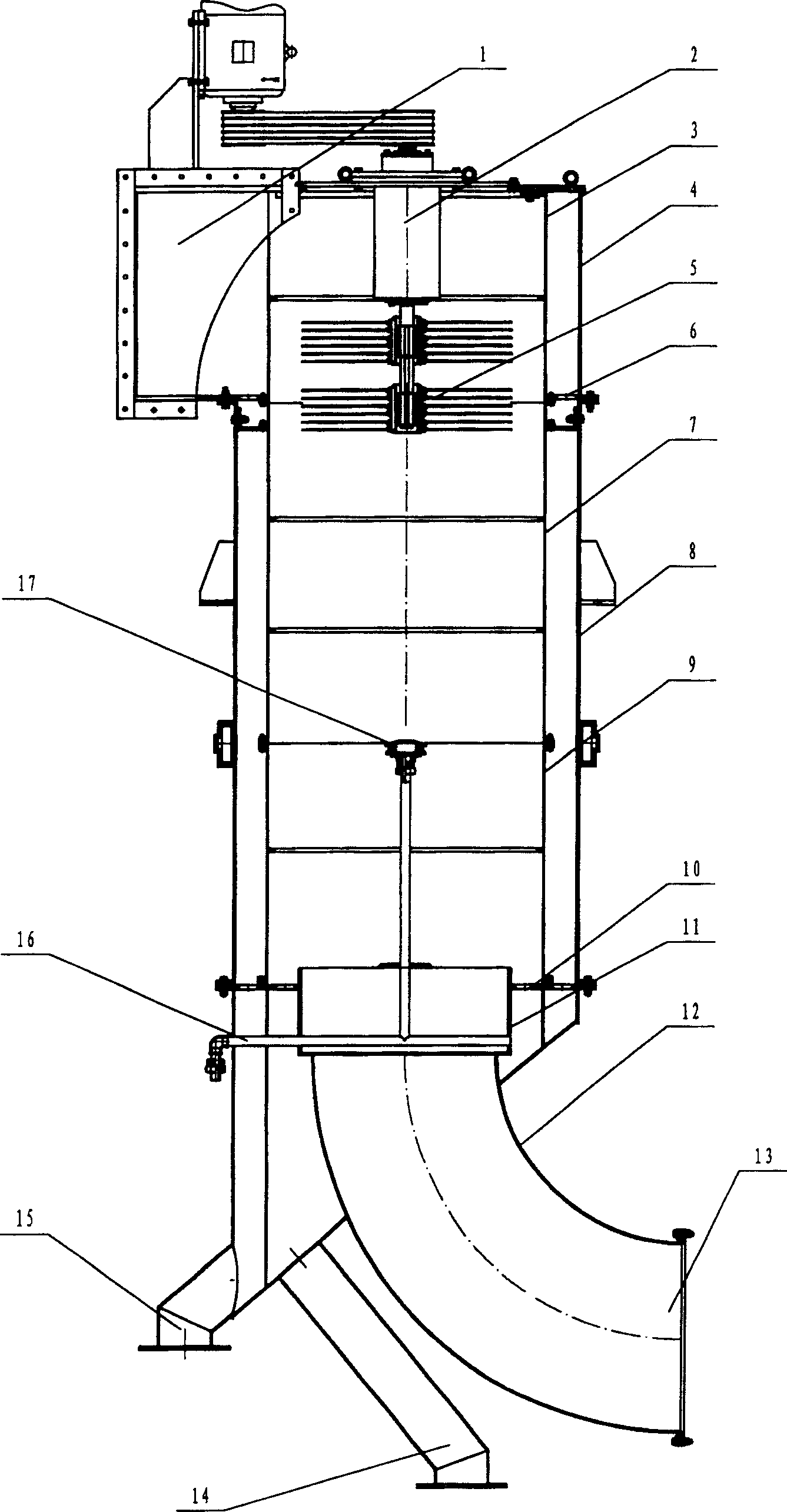

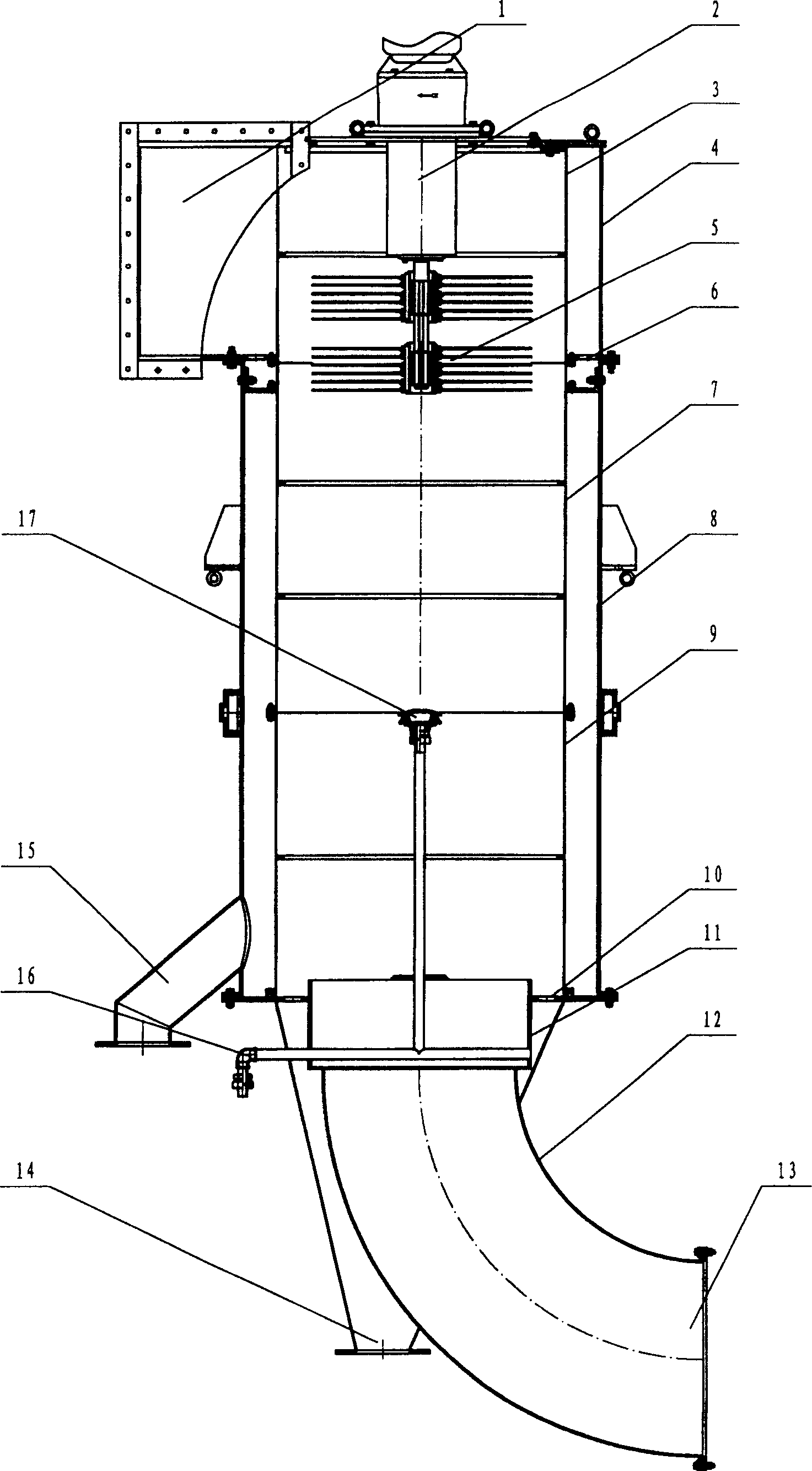

[0063] figure 1 As shown, it is a co-current settling dry-process axial-flow coupled filter centrifuge structure designed according to the technical solution 1 of the present invention. It is used for the separation of solid particles or liquid particles from gases.

[0064] The centrifuge is composed of a transmission device 2, a pin wheel 5, an air inlet chamber assembly, a filter device, a housing assembly 8 and a discharge assembly.

[0065] Transmission device 2 is made up of motor, bearing box, power transmission shaft, belt, belt pulley, motor support. The air intake cavity assembly is composed of an inlet flange, a coaming plate 4, an end cover, and a volute ring 6, and the volute ring 6 has holes. Housing assembly 8 is made up of upper and lower housing flanges, straight garden cylindrical housing, position-limiting lugs and the like. The discharge assembly consists of an air outlet 11, a flower plate 10 with a discharge hole, an obliquely cut cylindrical discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com