Light-emitting diode

A technology of light-emitting diodes and electrodes, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced luminous efficiency, influence of component luminous efficiency, loss of light, etc., and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

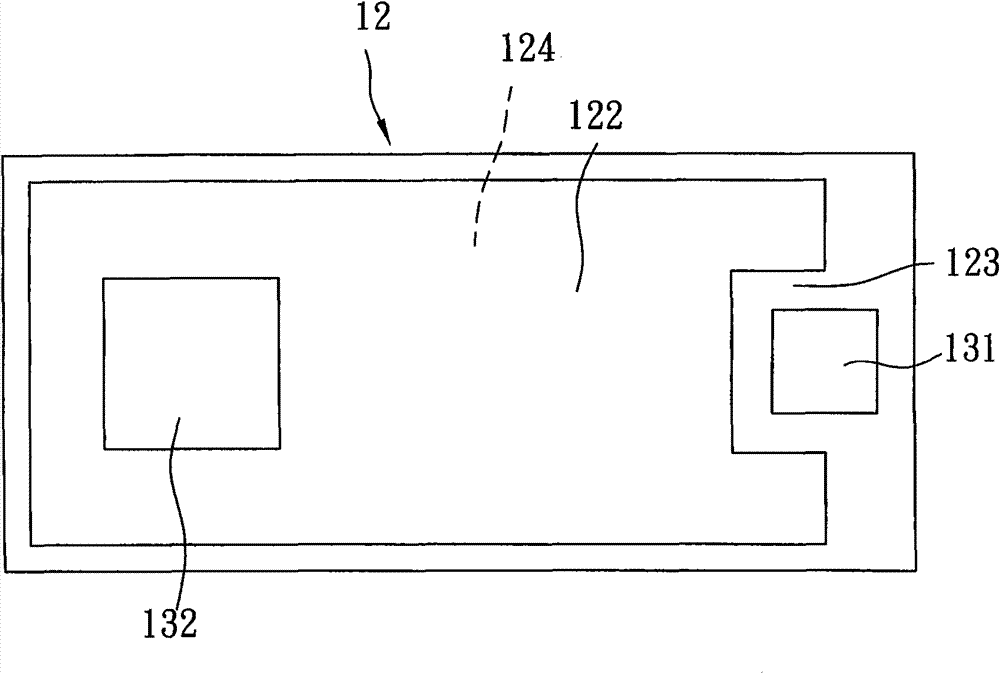

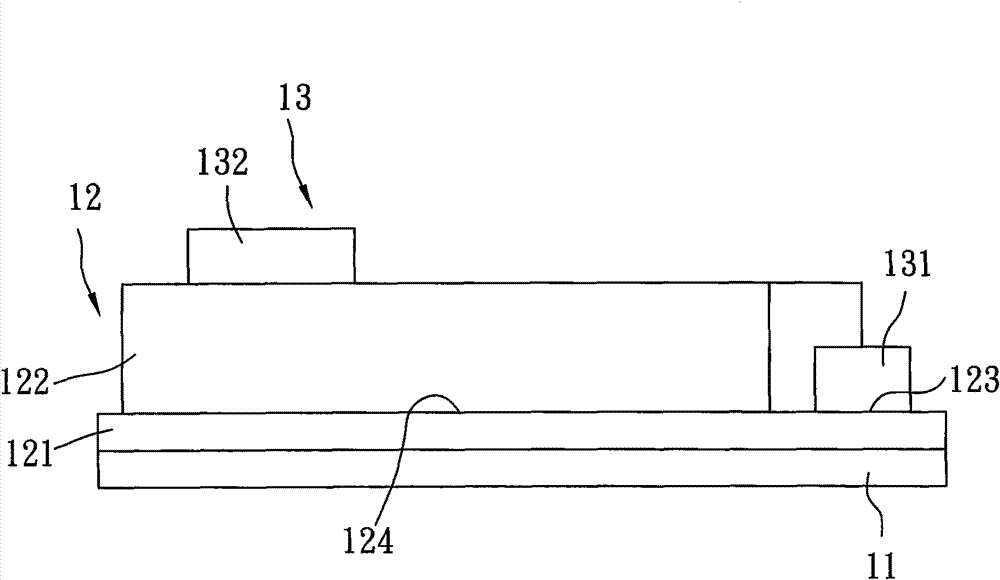

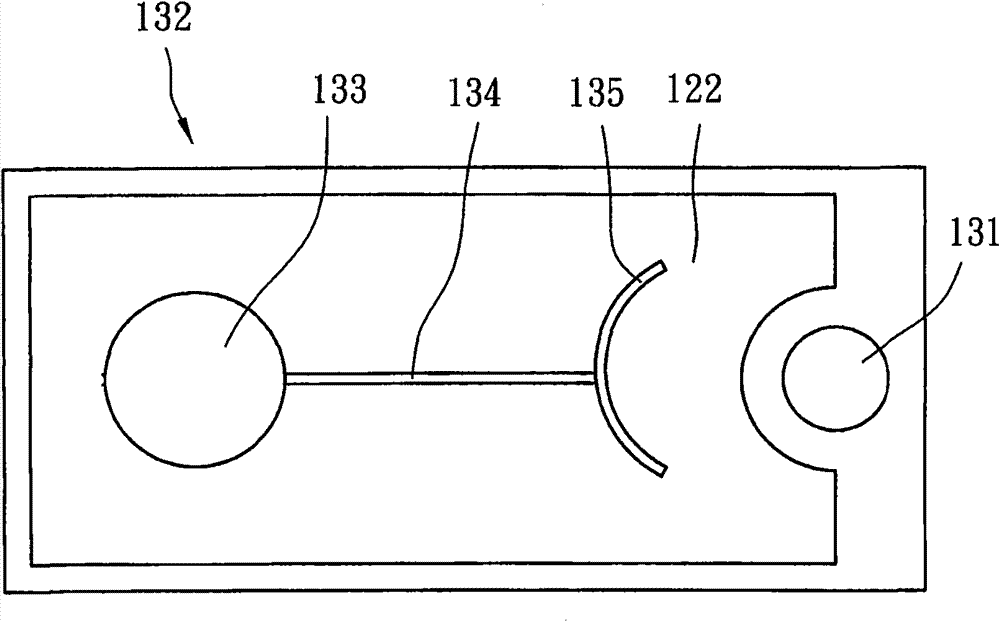

[0030] refer to Figure 7 , Figure 8 , Figure 8 is selected from Figure 7 In the cross-sectional view of line 8-8, a preferred embodiment of the high-brightness light-emitting diode of the present invention includes a substrate 2, an action film 3 formed on the substrate, and an electrode unit 4. The electrode unit 4 can cooperate to provide The electric energy is sent to the action film 3, and the action film 3 can convert the electric energy into light energy by the photoelectric effect after receiving the electric energy and then send it out.

[0031] The substrate 2 is made of an insulating material. Since the constituent materials of the substrate 2 are well known to those skilled in the art, no more details are given here. In this embodiment, the substrate 2 is rectangular and made of sapphire. constituted, and define a direction perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com