White clay mixing device for grease decolorization

A mixing device and clay technology, which are applied in mixers, mixers with rotary stirring devices, mixing methods, etc., can solve the problems of easy agglomeration of clay, adhesion and clogging of pipelines, etc., and achieve low friction, prevent adhesion, and improve smoothness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

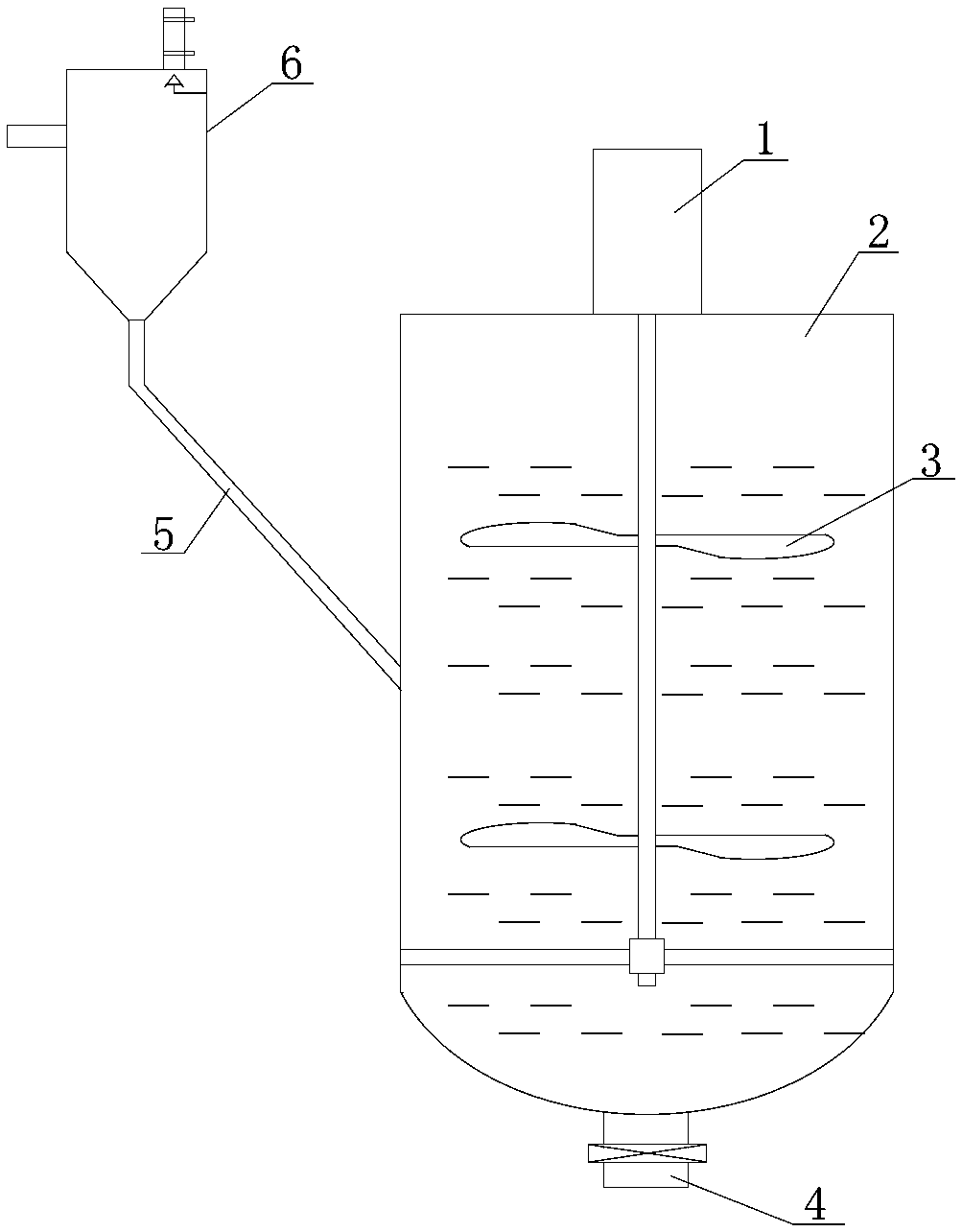

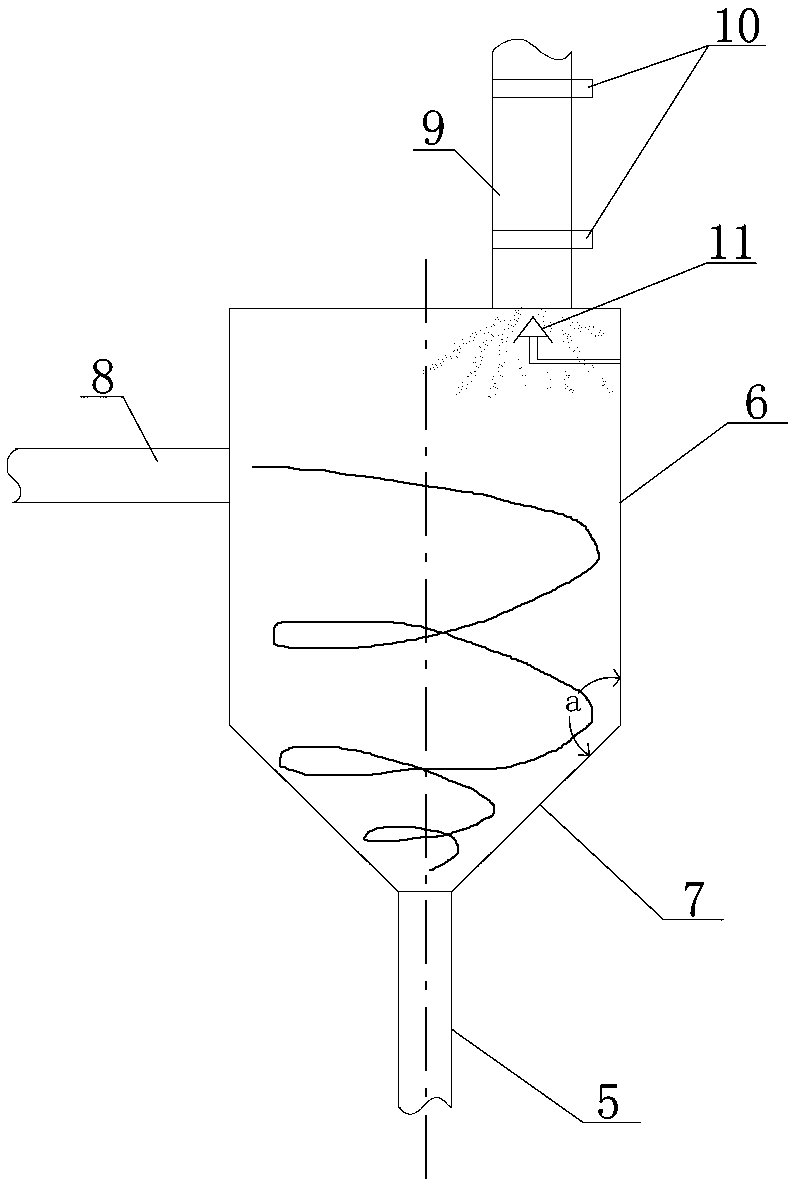

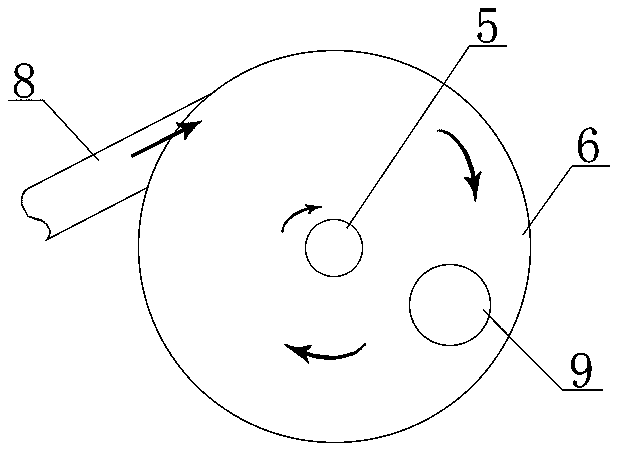

[0037] Refer to attached figure 1 to attach Figure 4 , the present invention includes a stirring tank 2; the bottom of the stirring tank 2 is provided with an oil outlet 4 with a gate valve, and the top of the stirring tank 2 is provided with an oil inlet 13; the top of the stirring tank 2 is provided with A stirring motor 1, and the stirring motor 1 is connected to the blade 3 arranged in the stirring tank 2 through a stirring shaft; one side of the stirring tank 2 is provided with a cylindrical premixing tank 6;

[0038] The top of the premix tank 6 is provided with a clay measuring cylinder 9; the top and the bottom of the clay measuring cylinder 9 communicate with the clay tank and the premix tank 6 respectively through a gate valve 10; the clay measuring cylinder 9 is connected to the The connection of the premix tank 6 is provided with a conical diffuser plate 11;

[0039] The bottom end of the premix tank 6 is provided with a conical hopper 7 coaxial with it, and the...

Embodiment 2

[0059] A kind of anti-blocking high-performance paint, it comprises the raw material preparation of following weight part:

[0060] 100 parts of epoxy resin, 20 parts of diethyl phthalate, 15 parts of nano-titanium dioxide, 12 parts of nano-graphite, 10 parts of kaolin, 5 parts of nano-talc powder, 8 parts of hexamethylcyclotrisiloxane, 1 part of emulsified silicone oil 2 parts, 2 parts of propylene glycol butyl ether, and 0.5 parts of polydimethylsiloxane.

[0061] The preparation method of above-mentioned coating is:

[0062] 1) Calcining kaolin at 650°C for 60 minutes, then cooling down to room temperature, grinding, and passing through a 200-mesh sieve to obtain calcined kaolin;

[0063] 2) Take epoxy resin (solid content is 40%), then add diethyl phthalate, stir magnetically at 300rpm for 5min, then add nano-titanium dioxide, nano-graphite, kaolin, nano-talcum powder, hexamethyl cyclothree Siloxane, magnetically stirred at 500rpm for 10min, then ultrasonically dispersed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com