Multi-parameter workpiece sorting machine capable of moving workpieces by push rods

A moving workpiece and multi-parameter technology, applied in sorting and other directions, can solve the problems of roller-to-roller bumps, inconvenient transfer of rollers, and no transfer platform, etc., to achieve the effects of convenient transfer, compact structure, and reduced bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

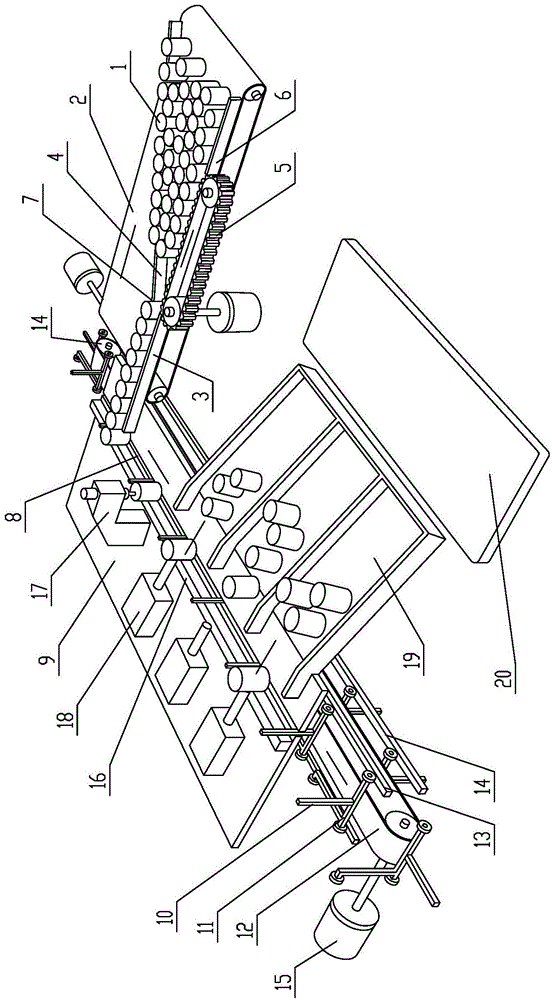

[0022] The present invention will be further described below in conjunction with specific examples.

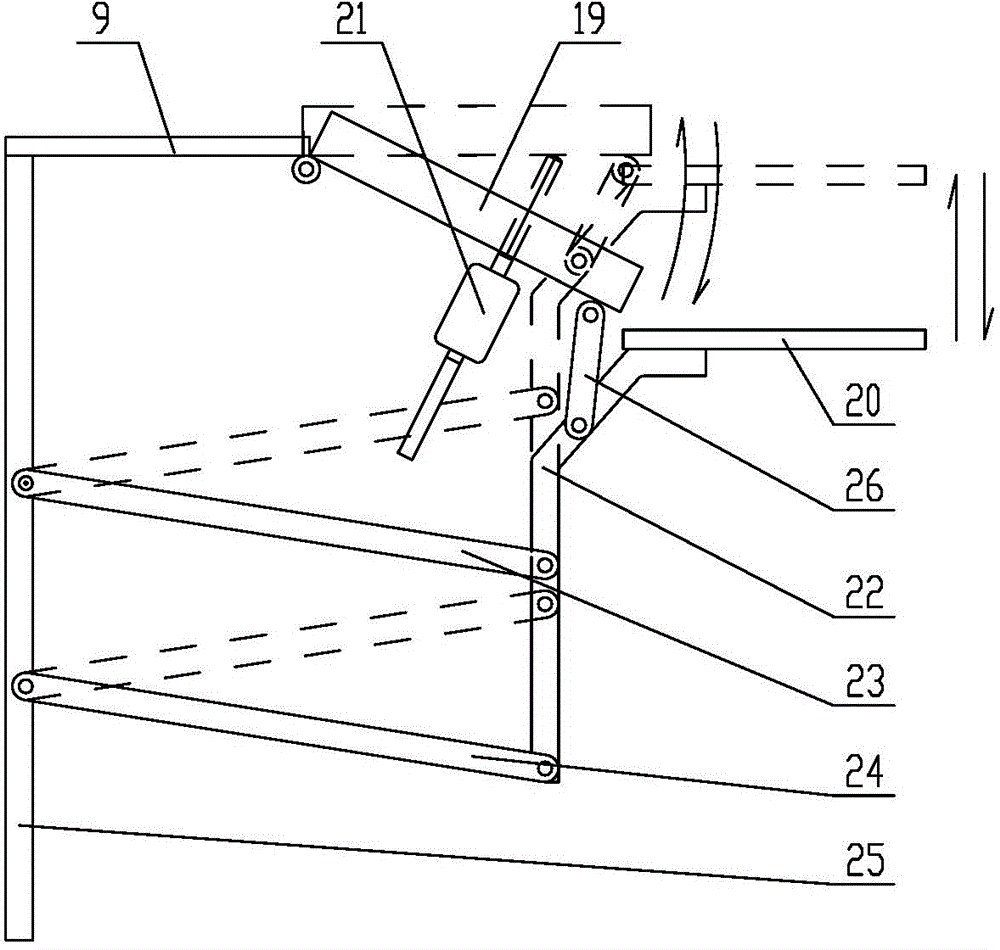

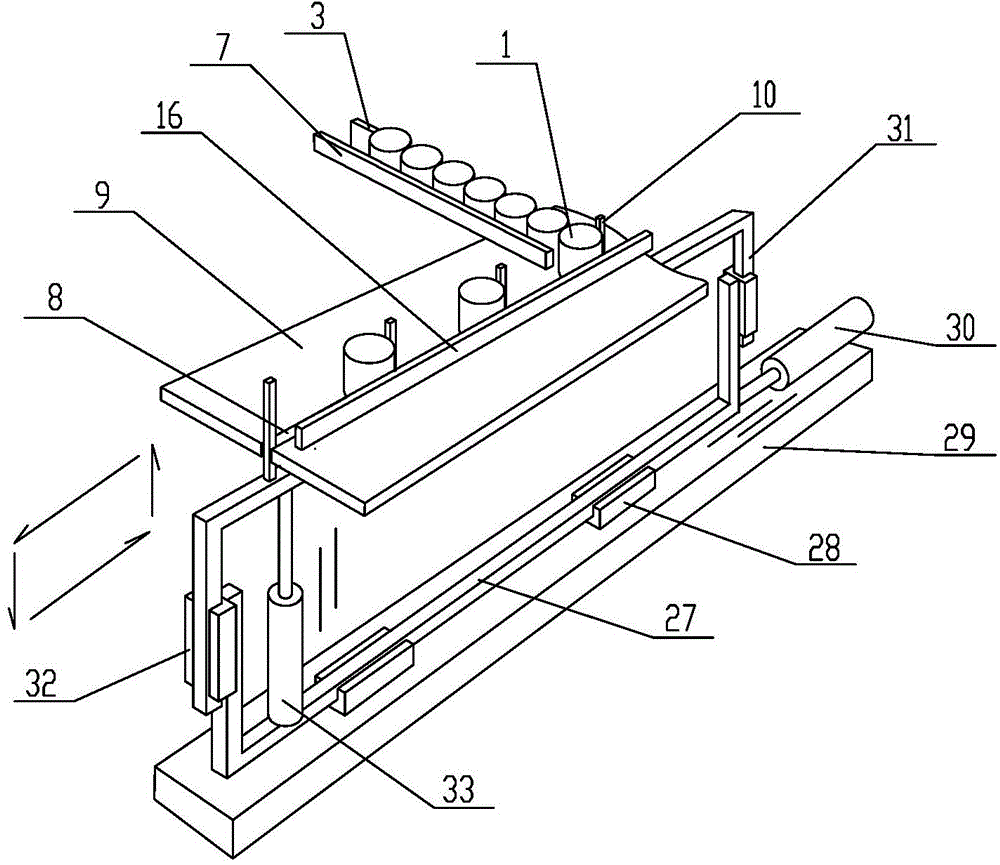

[0023] The workpiece multi-parameter sorting machine that moves the workpiece with a push rod includes a base frame 25, a support frame 22, a material trough 19 and a transfer platform 20, an upper arm 23 and a lower arm 24 are hinged on the base frame 25, and the other part of the upper arm 23 One end and the other end of the lower arm 24 are all hinged on the support frame 22, the support frame 22, the upper arm 23, the lower arm 24 and the base frame 25 form a parallelogram four-bar linkage, and the upper end of the base frame 25 is fixed with a panel 9, The feeding end of chute 19 is hinged on one side of panel 9, and connecting piece 26 is hinged at the discharge end of hopper 19, and the other end of connecting piece 26 is hinged on support frame 22, and is fixed on the upper end portion of support frame 22 There is a transfer platform 20, a pusher 18 and a sensor 17 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com