Double-filtration anti-blocking pulse bag dust collector

A technology of pulse cloth bag and dust collector, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low pressure of compressed air source and frequent start-up, so as to improve loading capacity, improve efficiency, The effect of normal dust removal time improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

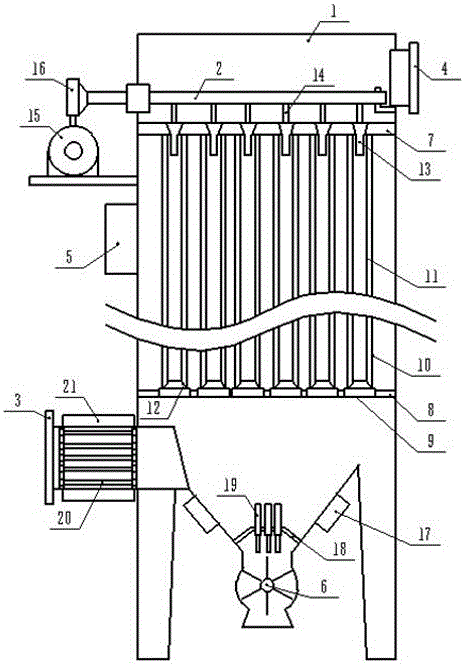

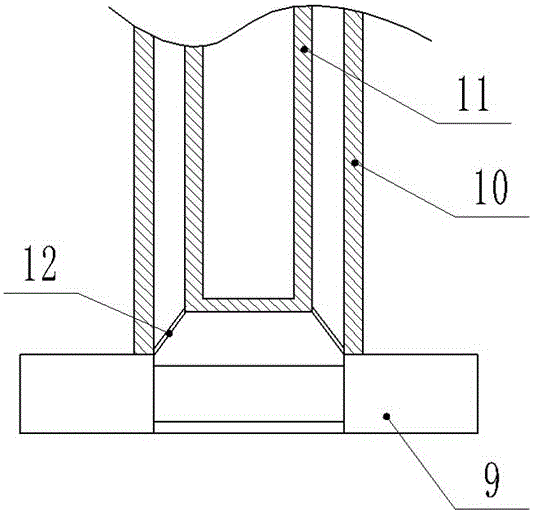

[0016] see figure 1 , a double-filter anti-blocking pulse bag filter, including a box body 1 and a blowing pipe 2, the lower end of the left side of the box body 1 is connected with an air inlet pipe 3, and the upper side of the right side of the box body 1 is connected with an air outlet pipe 4, and the box body 1 The left side wall is also fixedly connected with a control device 5. The lower part of the box body 1 is a funnel-shaped structure and a discharger 6 is installed. The control device 5 is a S7-300 programmable controller, which is convenient for controlling the opening and closing of the following electrical components. Complete automatic control, which is the conventional structure of the existing pulse dust collector, the box body 1 is fixedly connected with a flower plate 7 and a cage frame 8, and the cage frame 8 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com