Rare earth oxide ceramic material with exchange bias reversal and preparation method of rare earth oxide ceramic material

A technology for rare earth oxides and ceramic materials, which is applied in the field of rare earth oxide ceramic materials and their preparation, can solve the problems of rare compounds and difficult practical application, and achieves a simple and easy preparation process, reduced energy consumption and fewer defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

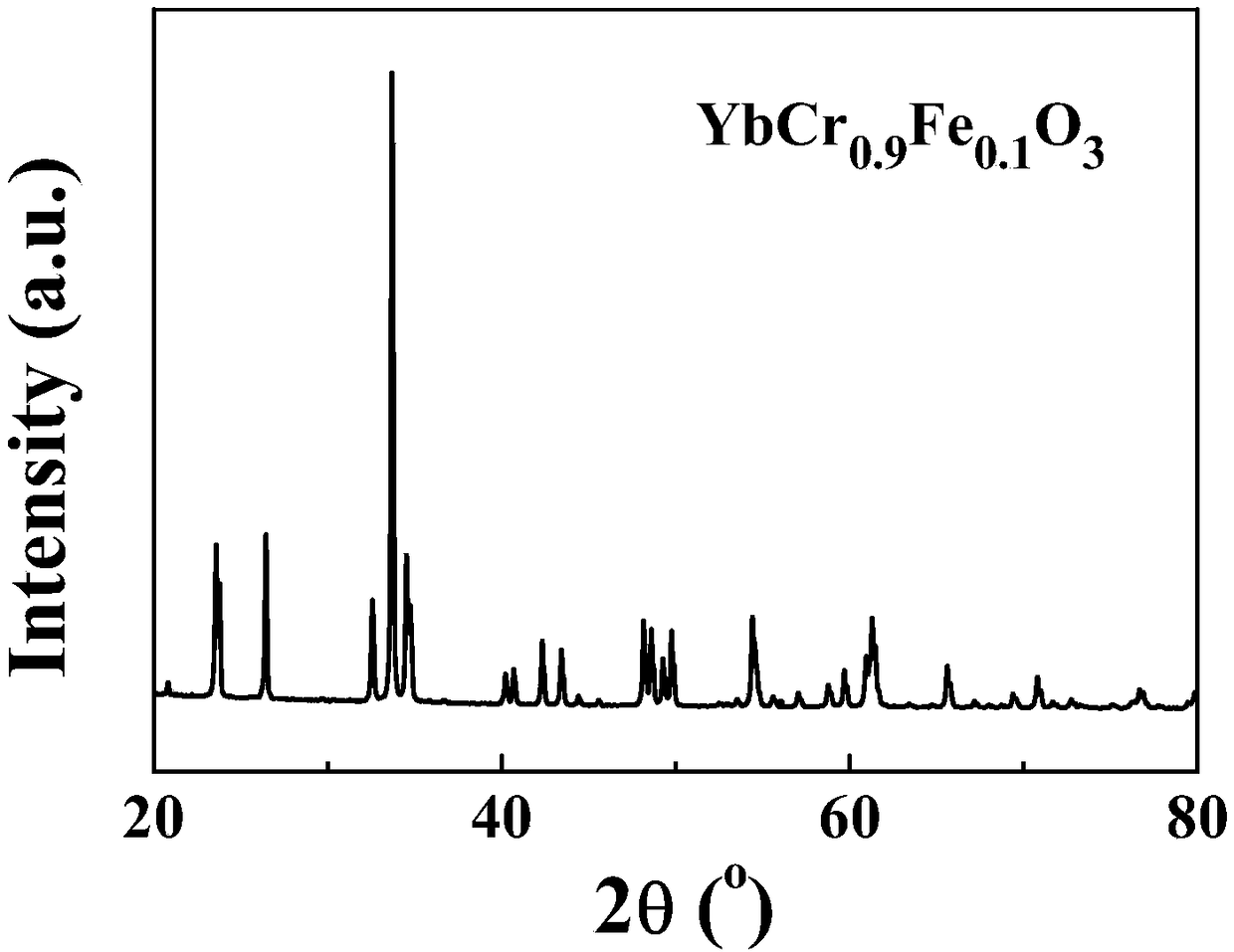

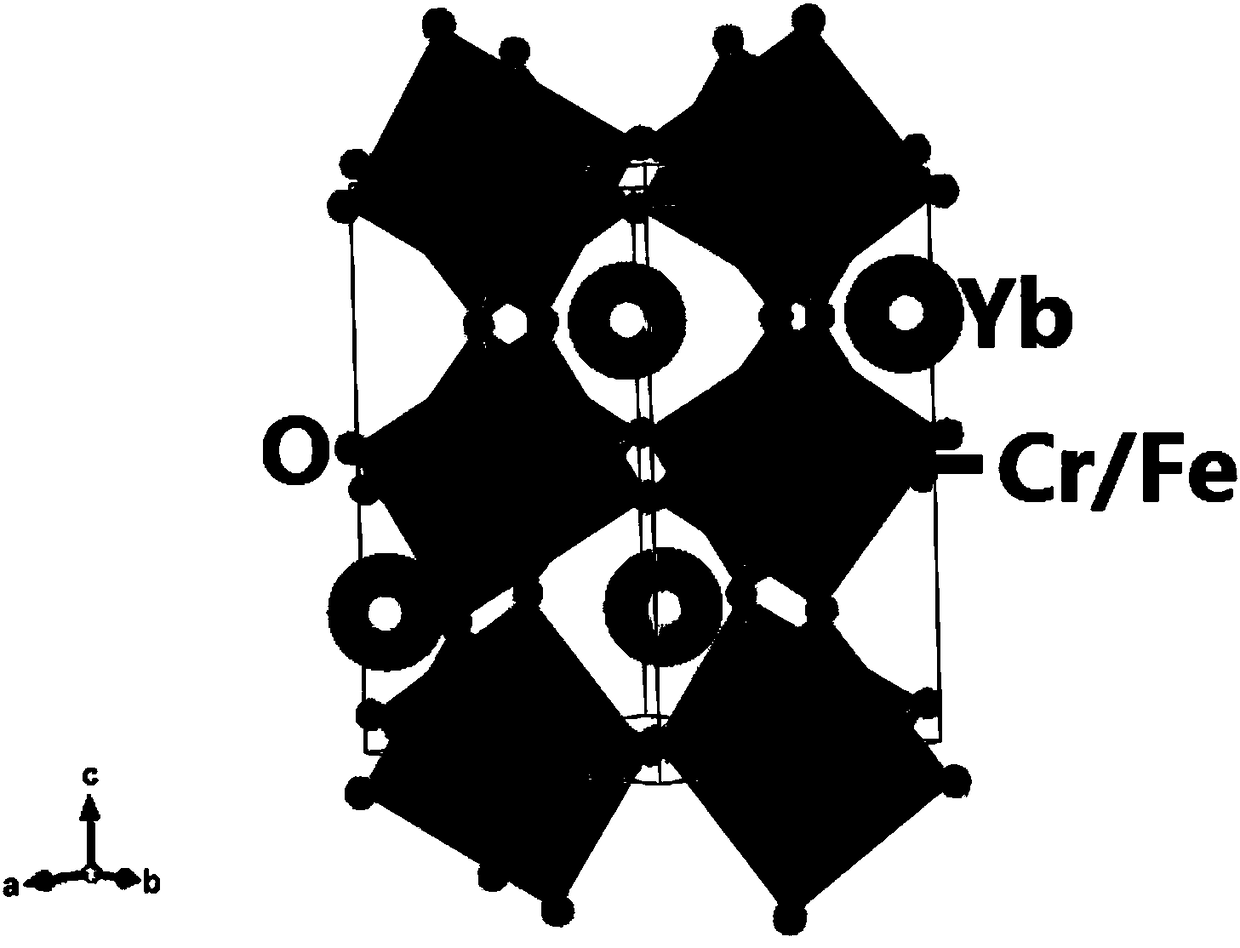

[0030] Step 1: ytterbium trioxide (Yb 2 o 3 ), chromium trioxide (Cr 2 o 3 ) and ferric oxide (Fe 2 o 3 ) powder with a particle size of 10 microns is used as a raw material, which is mixed according to the ratio of Yb:Cr:Fe=50:45:5 (atomic percentage), and mixed uniformly.

[0031] Step 2: Press the uniformly mixed powder in step 1 into a cylindrical sheet with a diameter of 12mm and a thickness of 2-3mm by using a cold pressing die, and the applied pressure is 18Mpa.

[0032] Step 3: put the cylindrical piece molded in step 2 into a box-type resistance furnace for sintering, firstly raise it from room temperature (25°C) to 450°C at 5°C / min, and keep it warm at 450°C for 1 hour, that is, pre-fire; Then rise to 1100°C at 5°C / min, then rise to 1350°C at 2°C / min, and keep at 1350°C for 48 hours, that is, high-temperature solid-phase sintering; then cool down to 500°C at 5°C / min, Then cool down to room temperature naturally with the furnace.

[0033] Step 4: Put the molded...

Embodiment 2

[0040] Step 1: Hydrated ytterbium carbonate (Yb 2 (CO 3 ) 3 ·nH 2 O), hydrated chromium carbonate (Cr 2 (CO 3 ) 3 ·nH 2 O) and hydrated iron carbonate (Fe 2 (CO 3 ) 3 ·nH 2 O) The powder with a particle size of 6 microns is used as the raw material, and the ingredients are mixed according to the ratio of Yb:Cr:Fe=50:45:5 (atomic percentage), and mixed evenly.

[0041] Step 2: Press the uniformly mixed powder in step 1 into a cylindrical sheet with a diameter of 12mm and a thickness of 2-3mm by using a cold pressing die, and the applied pressure is 6Mpa.

[0042] Step 3: Put the cylindrical sheet molded in step 2 into a box-type resistance furnace for sintering. First, the temperature is raised from room temperature to 900°C at 5°C / min, and kept at 900°C for 3 hours, that is, pre-fired; / min to 1100°C, then raised to 1350°C at 2°C / min, and kept at 1350°C for 48 hours, that is, high-temperature solid phase sintering; then cooled to 500°C at 5°C / min, and then naturally...

Embodiment 3

[0046] Step 1: Hydrated ytterbium nitrate (Yb(NO 3 ) 3 ·nH 2 O), chromium nitrate hydrate (Cr(NO 3 ) 3 ·nH 2 O) and ferric nitrate hydrate (Fe(NO 3 ) 3 ·nH 2 O) The powder with a particle size of 3 microns is used as the raw material, and the ingredients are prepared according to the ratio of Yb:Cr:Fe=50:45:5 (atomic percentage), and mixed evenly.

[0047] Step 2, step 3, and step 4 are the same as in embodiment 1.

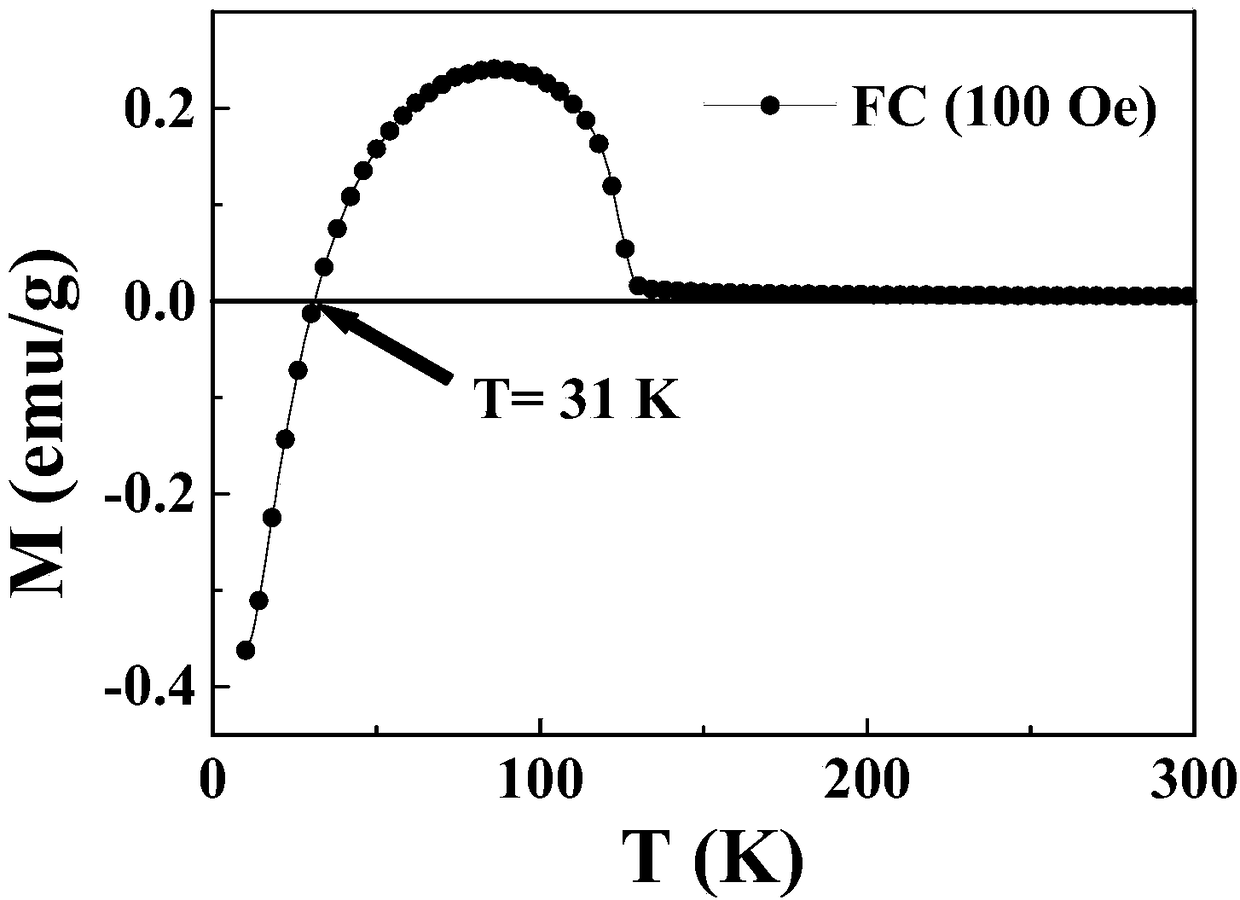

[0048] For the target product YbCr 0.9 Fe 0.1 o 3 The detailed characterization process of magnetic properties such as exchange bias reversal and magnetization reversal of the single-phase ceramic material is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com