Rare earth doped oxysulfide - HoCu2 ceramic-metal composite magnetic cold-storage material

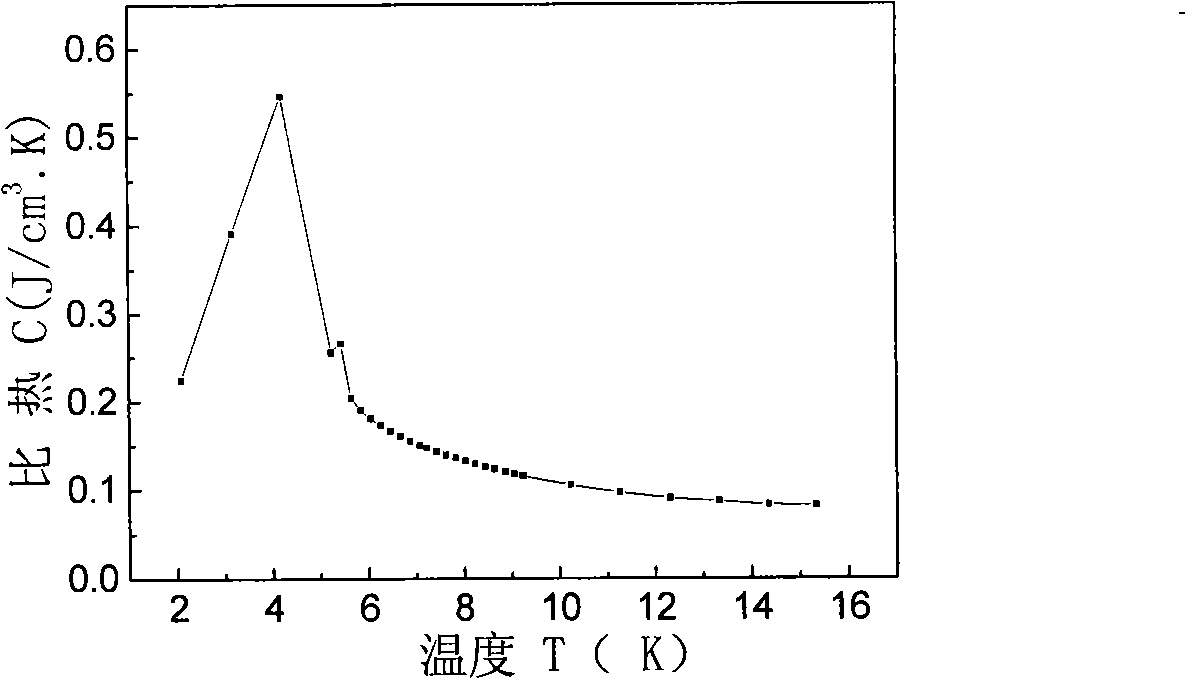

A technology of rare earth sulfur oxides and cold storage materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of narrow effective working temperature range, achieve widened temperature range, high specific heat peak value, and improved cold storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

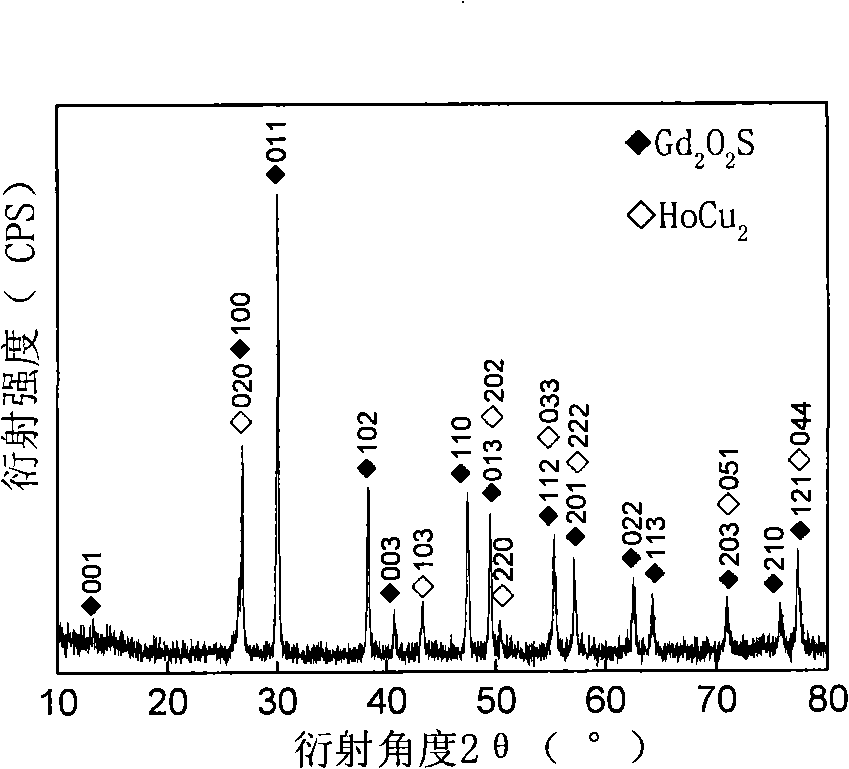

Embodiment 1

[0024] Will Gd 2 o2 S and HoCu2 are mixed in a ratio of 65wt%: 35wt%, stainless steel balls are used, and absolute ethanol is used as the ball milling medium. When the mass ratio of the ball to material is 12:1, the powder with an average particle size of 2.043um can be obtained by ball milling for 4 hours. After vacuum drying, Using spark plasma sintering, the sintering pressure is 40MPa, the sintering temperature is 1100℃, and the sintering time is 5min, the Gd can be obtained 2 o 2 S-HoCu 2 Ceramic-metal composite magnetic cold storage material.

Embodiment 2

[0026] Will Tb 2 o 2 S and HoCu 2 Mix at a ratio of 50wt%: 50wt%, use alumina ceramic balls, and use absolute ethanol as the ball milling medium. When the mass ratio of the ball to material is 8:1, the powder with an average particle size of 2.454um can be obtained by ball milling for 3 hours. After vacuum drying, use Spark plasma sintering, sintering pressure 40MPa, sintering temperature 1100°C, sintering time 5min, Tb can be obtained 2 o 2 S-HoCu 2 Ceramic-metal composite magnetic cold storage material.

Embodiment 3

[0028] Will Dy 2 o 2 S and HoCu 2 Mix at a ratio of 60wt%: 40wt%, use silicon nitride balls, and use absolute ethanol as the ball milling medium. When the mass ratio of the ball to the material is 9:1, the powder with an average particle size of 1.888um can be obtained by ball milling for 6 hours. After vacuum drying, use Spark plasma sintering, sintering pressure 40MPa, sintering temperature 1100 ℃, sintering time 5min, that is to get Dy 2 o 2 S-HoCu 2 Ceramic-metal composite magnetic cold storage material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com