Dual circulation-based power battery pack thermal management system

A power battery and management system technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as heating of water-cooled battery packs, and achieve the effect of widening the temperature range, reasonable structure design, and changing life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

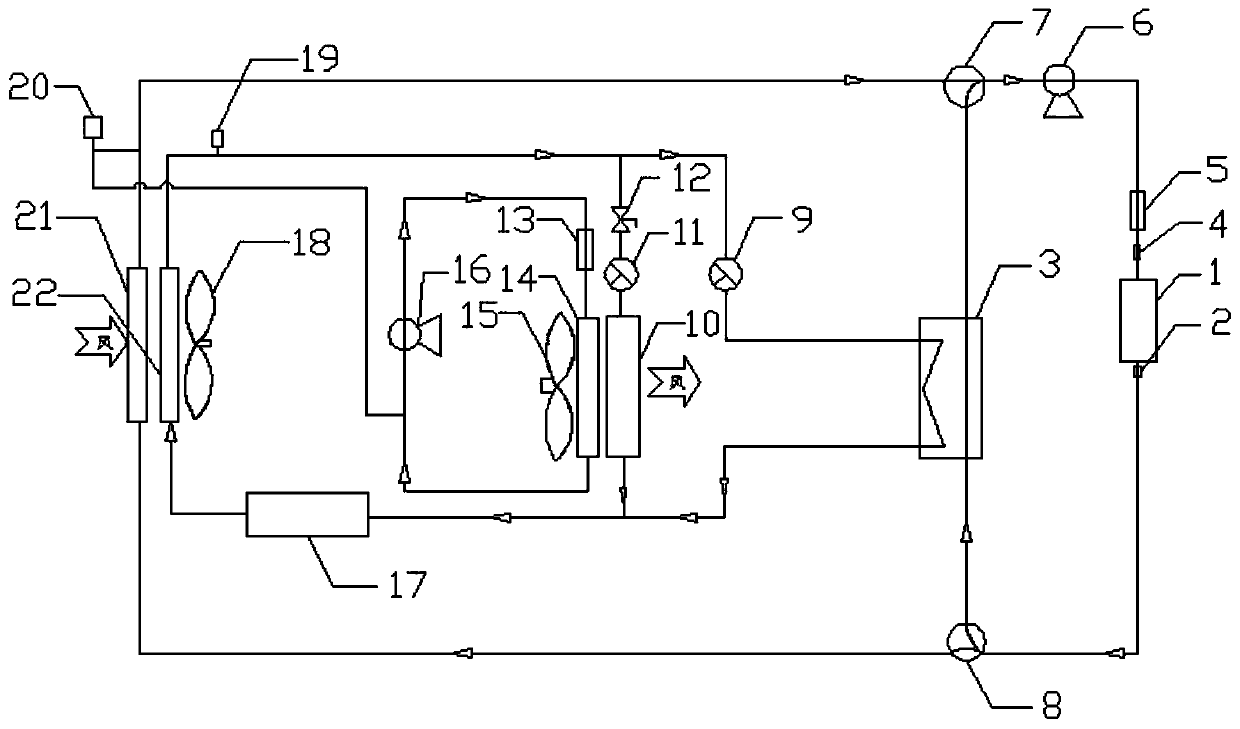

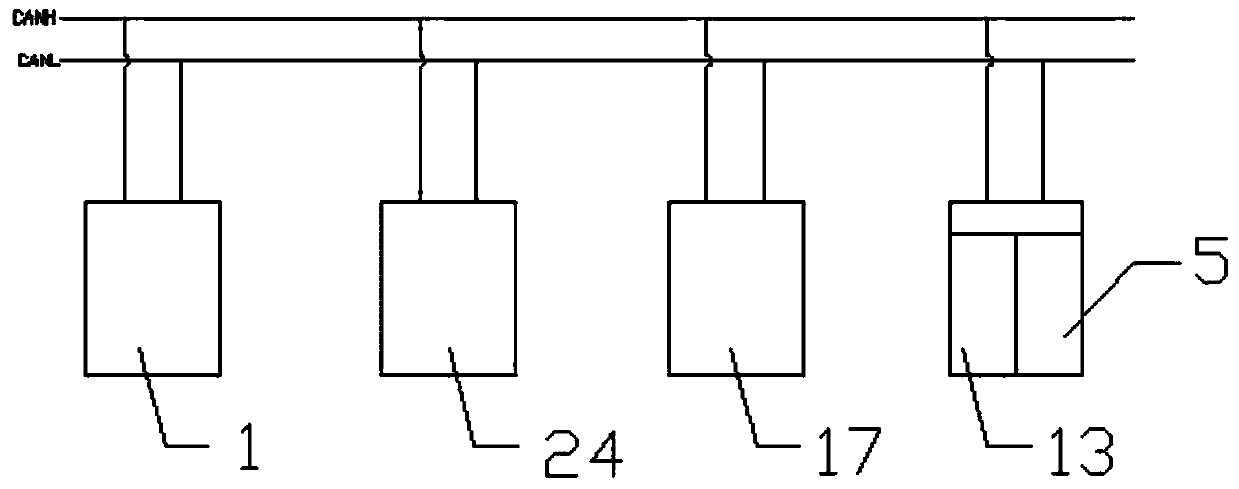

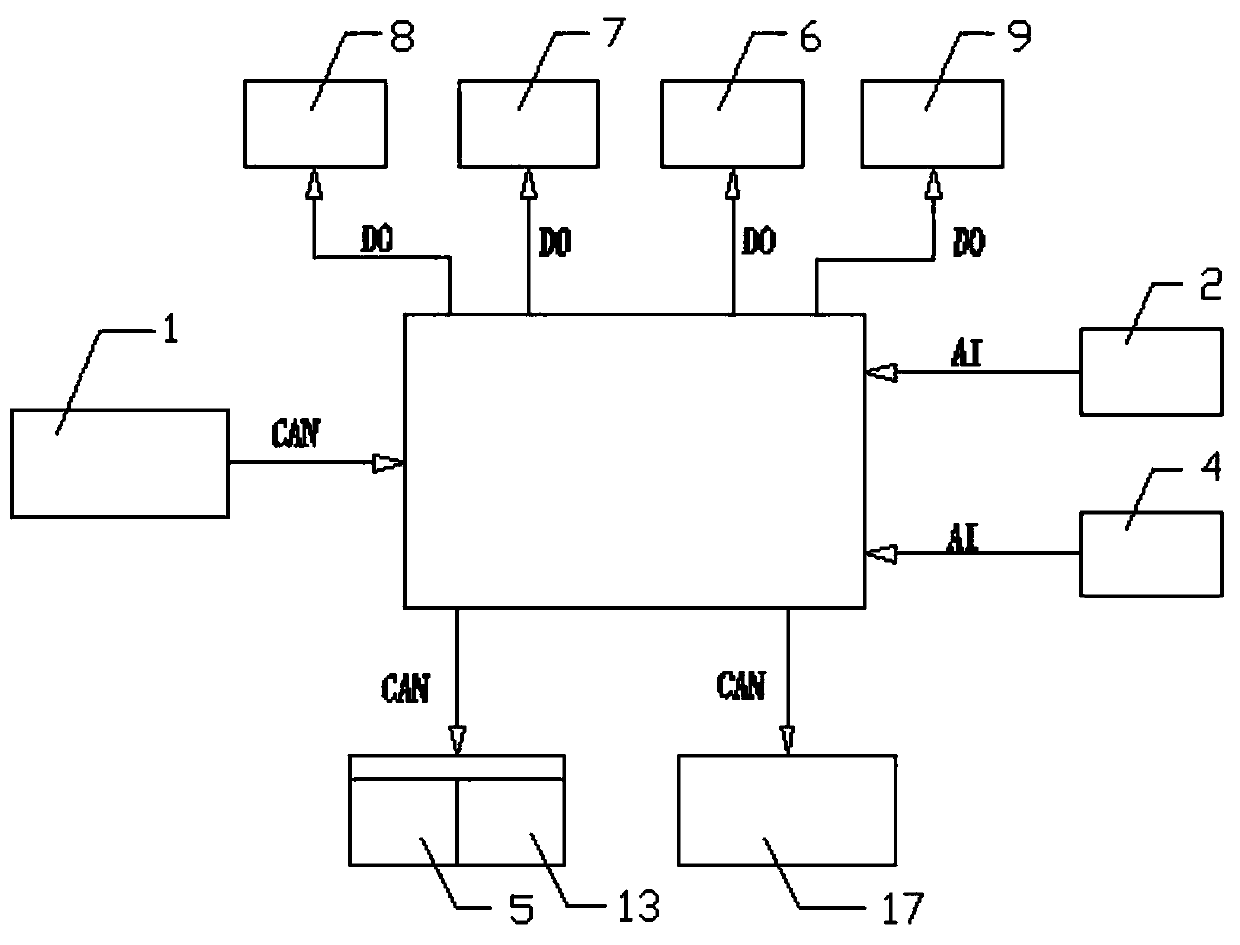

[0024] Example: such as Figure 1-5 As shown, it includes a battery pack BMS1, a thermal management controller 24, a compressor 17, a PTC heater A13, and a PTC heater B5. One end of the battery pack BMS1 is connected to a battery pack water inlet temperature sensor 2, and the other end is connected to a battery pack A water outlet temperature sensor 4, one side of the battery pack water inlet temperature sensor 2 is connected to a three-way reversing valve B7, one side of the three-way reversing valve A8 is connected to a cooler 3, and the other side is connected to a battery radiator 21, One side of the battery radiator 21 is connected to a compressor 17, one side of the compressor 17 is connected to an electric water pump A6, and the other side is connected to a cooler 3, one side of the electric water pump A6 is connected to a PTC heater B5, One side of the PTC heater B5 is connected to a battery pack water outlet temperature sensor 4, one side of the cooler 3 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com