Method and system for increasing calsium and remelting flyash in boiler and high temperature desulfurizing in boiler

A fly ash and remelting technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as lack of sulfur dioxide monitoring systems, low desulfurization efficiency, and accidental shutdown of boilers, so as to avoid boiler fire-fighting accidents and high The effect of efficient flue gas desulfurization and high-efficiency boiler coal saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

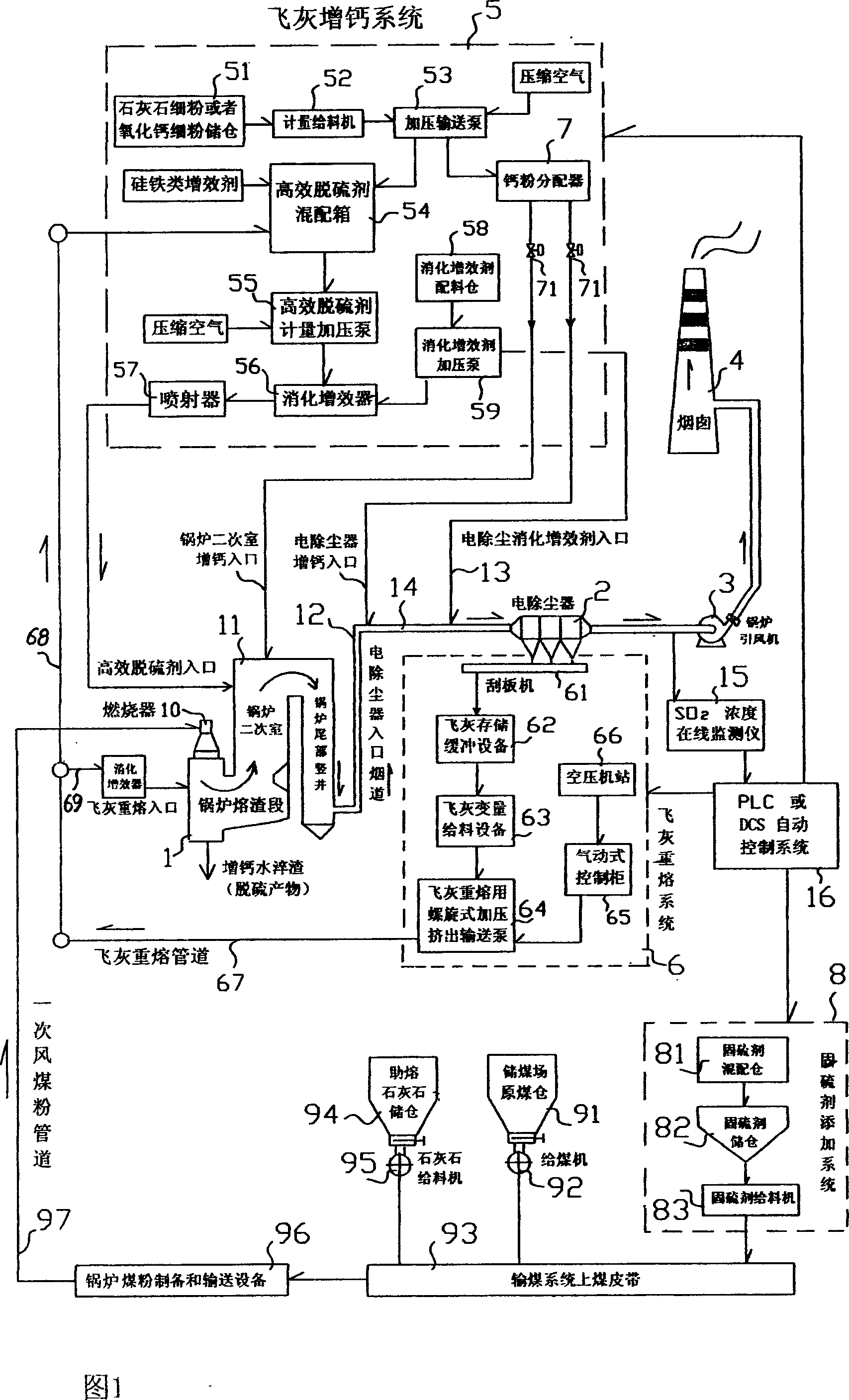

[0029] With reference to Fig. 1, the method for boiler fly ash of the present invention increasing calcium remelting-high temperature desulfurization in the furnace comprises the following steps:

[0030] (1) Collect, pressurize and distribute the fly ash discharged from the boiler through the fly ash remelting system;

[0031] (2) Calcium-increasing treatment is performed on the fly ash area that needs to be calcium-increased;

[0032] (3) Spray the calcium-increased fly ash into the furnace for secondary combustion, remelting and desulfurization.

[0033] In the above method, step (2) specifically includes the following steps:

[0034] (2.1) Feed limestone fine powder or calcium oxide fine powder, and transport it to the high-efficiency desulfurizer mixing box through pressurization;

[0035] (2.2) In the high-efficiency desulfurizer mixing box, add a ferrosilicon synergist, so that the fly ash that needs to be increased in calcium, the above-mentioned fine powder of calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com