Continuous grinding method and continuous grinding production line for metal strip

A metal belt and production line technology, which is applied to the parts of grinding machine tools, abrasive belt grinders, metal processing equipment, etc., can solve the problems of fire accidents in grinding racks, increased load, and reduced productivity, and achieve the goal of preventing fire accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

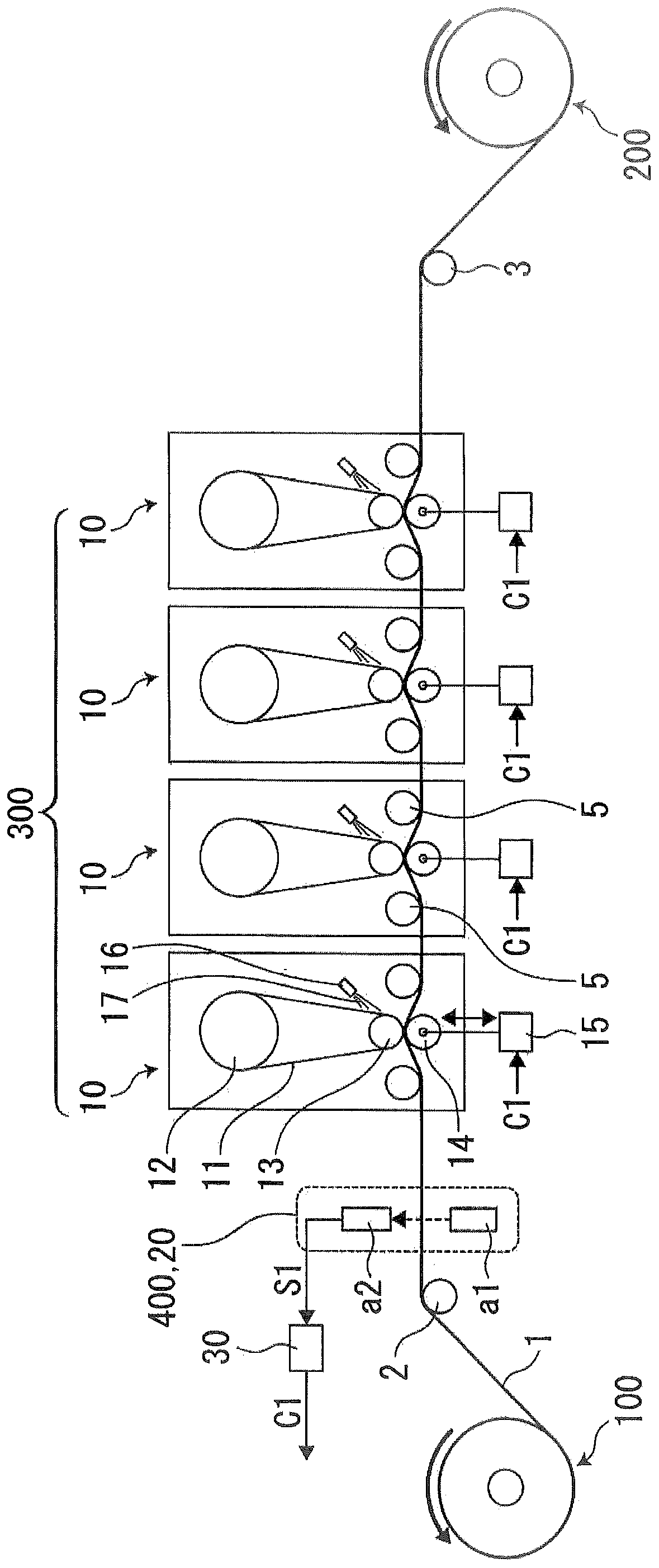

[0102] About 10,000 to 20,000 tons of ferritic stainless steel hot-rolled steel strips with a plate thickness of 1.5-13mm and a plate width of 700-1600mm per year Figure 6 In the continuous grinding production line of the company, the plate passing is carried out. In the past when the grinding operation was performed, the fire accidents associated with the occurrence of plate passing abnormalities (plate cracks or broken tails) were expressed in numbers relative to the number of times of plate passing abnormalities occurring 10 times. frequency occurs.

[0103] Therefore, according to the present invention, in figure 1 In the illustrated embodiment of the invention, the grinding operation is automatically stopped at the moment the sensor output signal S1 of the light sensor changes from "slab present" to "slab absent" during the grinding operation. As a result, the grinding operation was automatically stopped before the operator noticed the abnormality of the plate passage a...

Embodiment 2

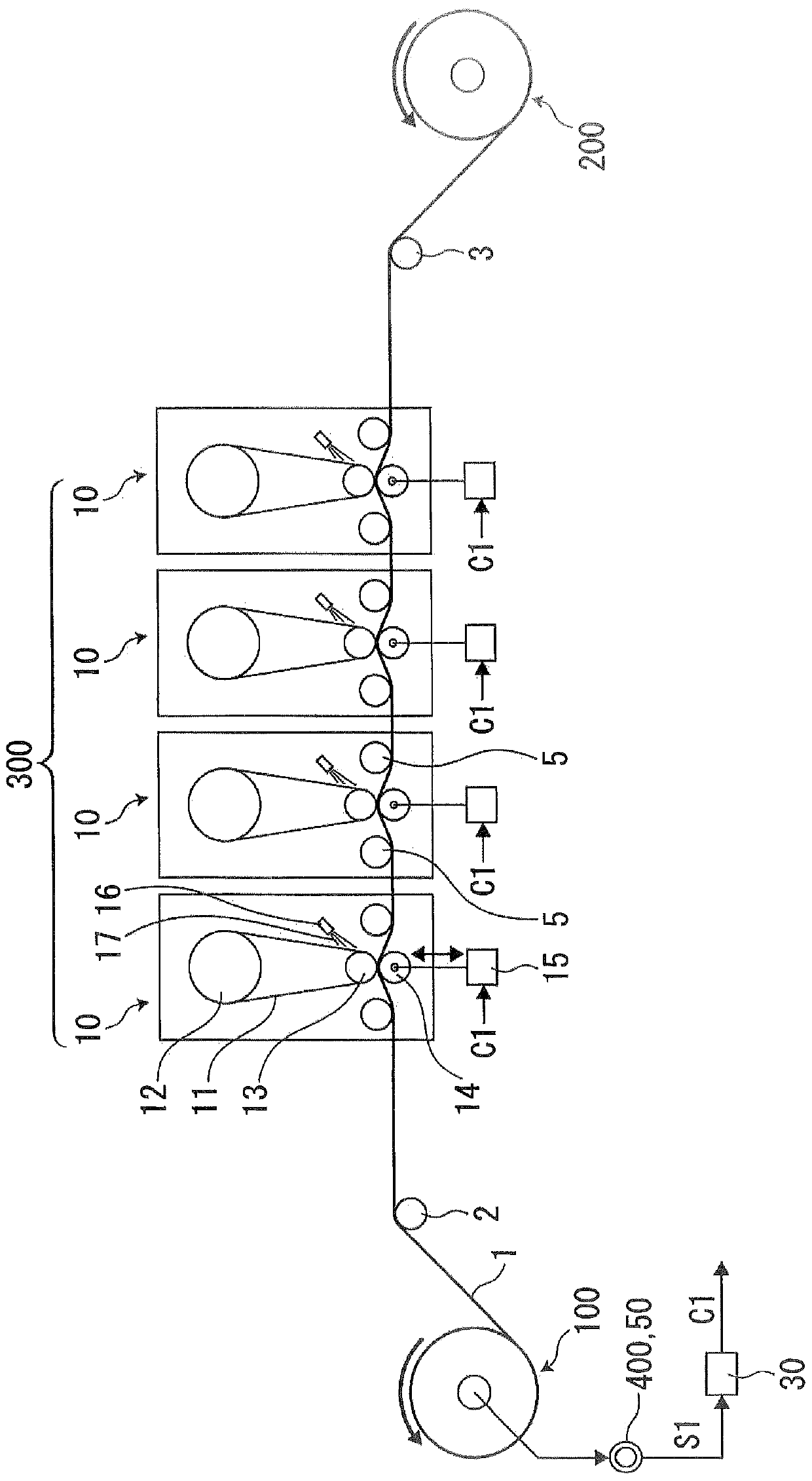

[0105] About 10,000 to 20,000 tons of hot-rolled ferritic stainless steel strips with a plate thickness of 1.5-13 mm and a plate width of 700-1600 mm are used with Figure 6 In the same continuous grinding production line different from Example 1, the plate passing is carried out. In the conventional situation of performing grinding work, the fire accident accompanying the occurrence of abnormal plate passing (plate cracking or broken tail) is relatively abnormal compared with the occurrence of abnormal plate passing. The number of times is 10 and it occurs at a frequency of several times.

[0106] Therefore, according to the present invention, in image 3 In the embodiment of the present invention shown, the threshold value of the POR speed is set to 50% of the POR speed during normal plate passing, and the grinding operation is automatically stopped when the POR speed is lower than the threshold value of the POR speed during the grinding operation . As a result, the grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com