Cigarette lighter with electric heating unit easy to replace

A technology of electric heating and cigarette lighter, applied in lighting and heating equipment, combustion ignition, incandescent ignition, etc., can solve problems such as difficult observation, unstable installation of electric heating wire ignition head, poor contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

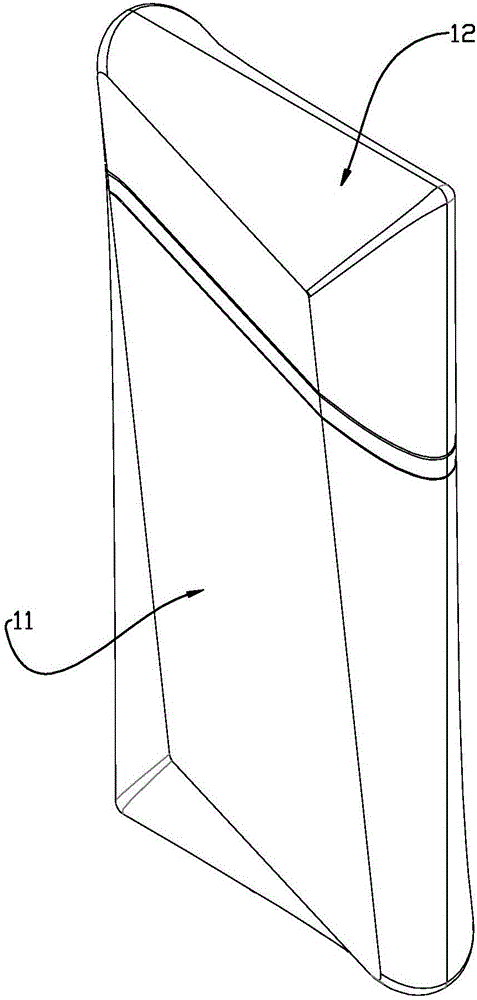

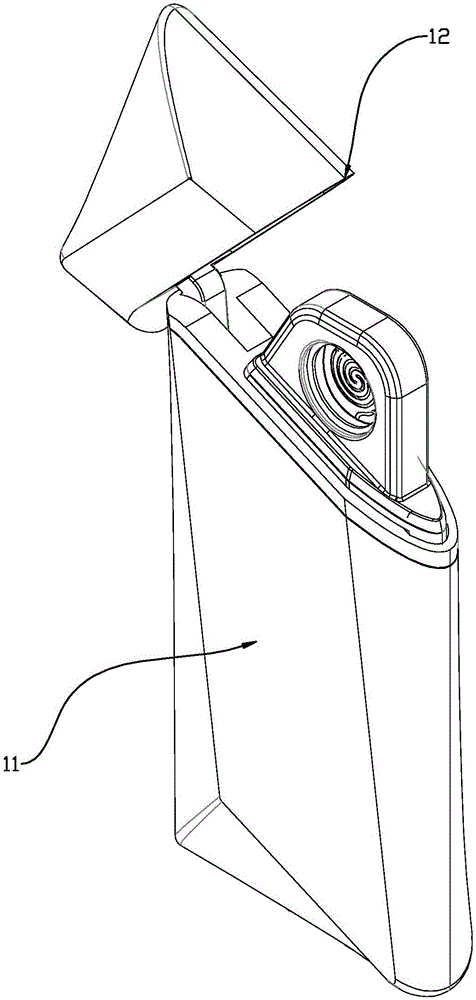

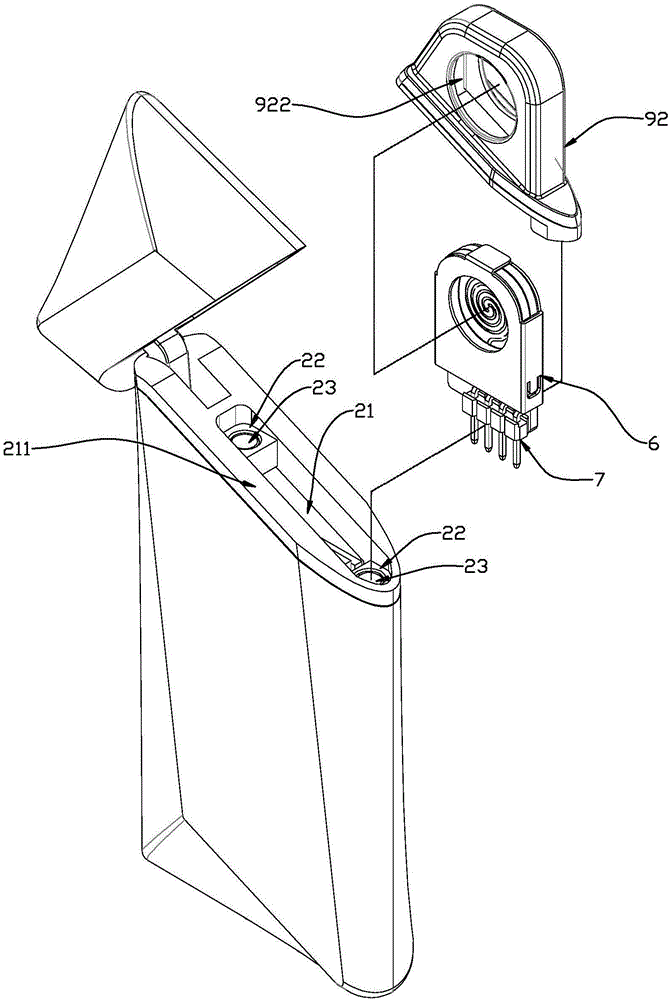

[0037] Specific embodiments of the present invention such as Figure 1-9 Shown is a cigarette lighter with an easily replaceable electric heating unit 6, including a casing 11 and a cover 12, and a middle frame 2, a circuit board 3, a battery 4, a switch 5, and an electric heating unit 6 are also installed in the casing 11 and the cover 12 , the electric heating unit cover 92, the middle frame 2 is provided with the socket 21 that can be inserted into the power supply heating unit 6, the electric heating unit 6 includes an electric heating element 61, an electric heating circuit board 62 electrically connected with the electric heating element 61, an insulating sheet 8. The outer cover 91, the insulating sheet 8, the electric heating element 61, and the electric heating circuit board 62 are sequentially installed in the outer cover 91 in a sandwich structure to form an overall structure. The position corresponding to the installation position of the electric heating element 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com