Dysprosium-modified Cu-SAPO-34 molecular sieve denitration catalyst and preparation method thereof

A denitration catalyst, cu-sapo-34 technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of copper-based SAPO-34 catalyst poisoning, low catalytic activity, and complicated synthesis process. problems, to avoid structure damage, simplify synthesis steps, and achieve the effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

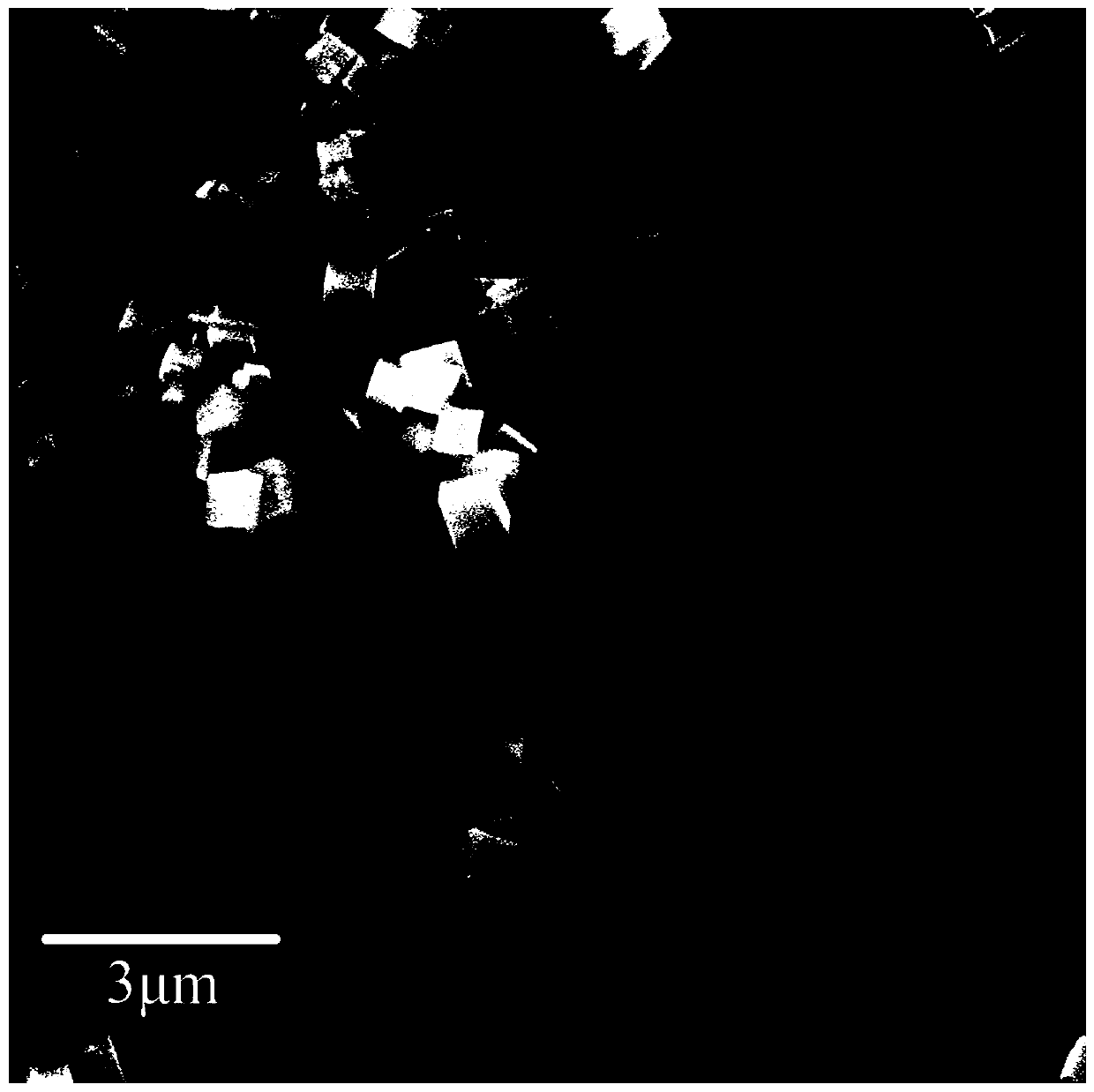

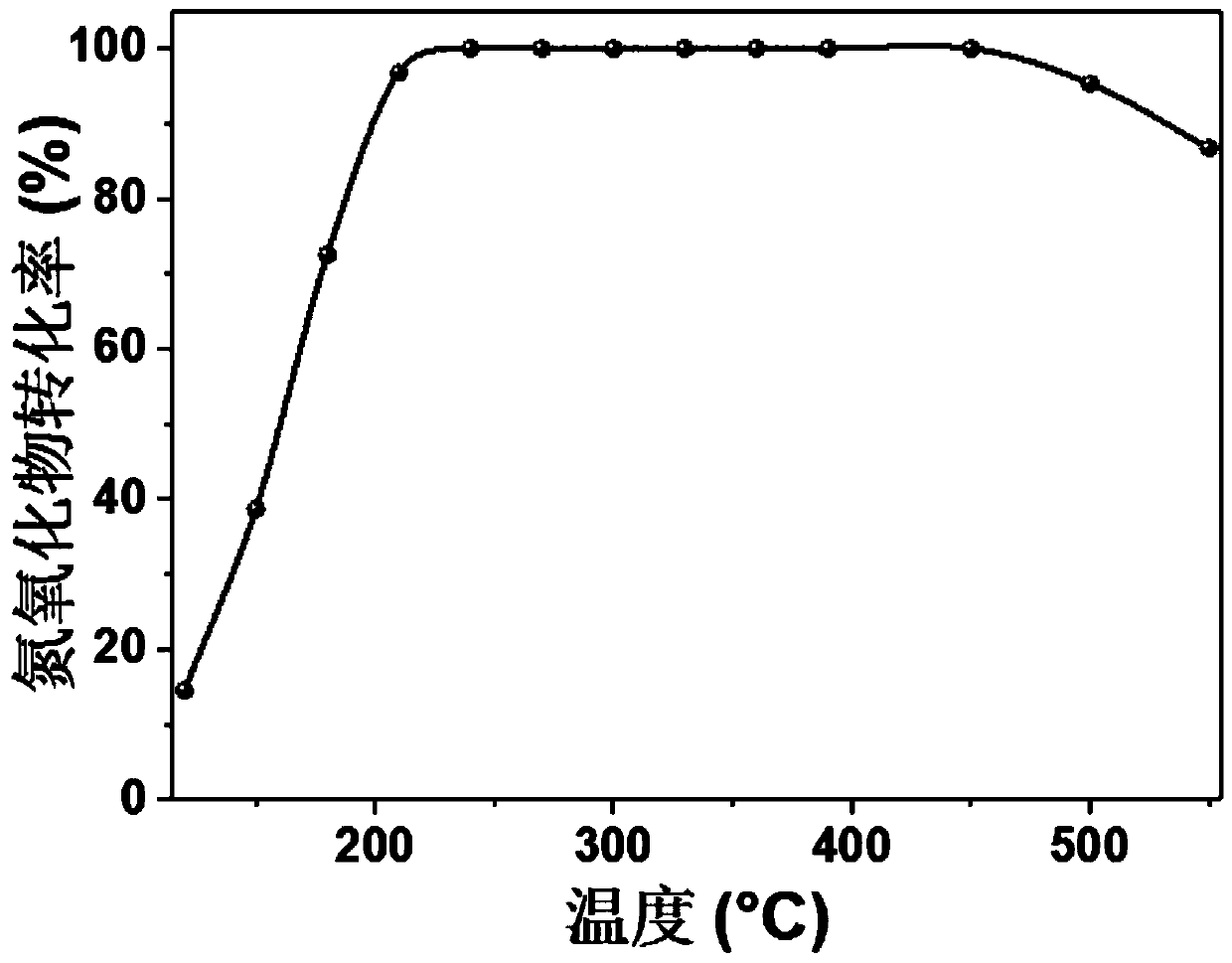

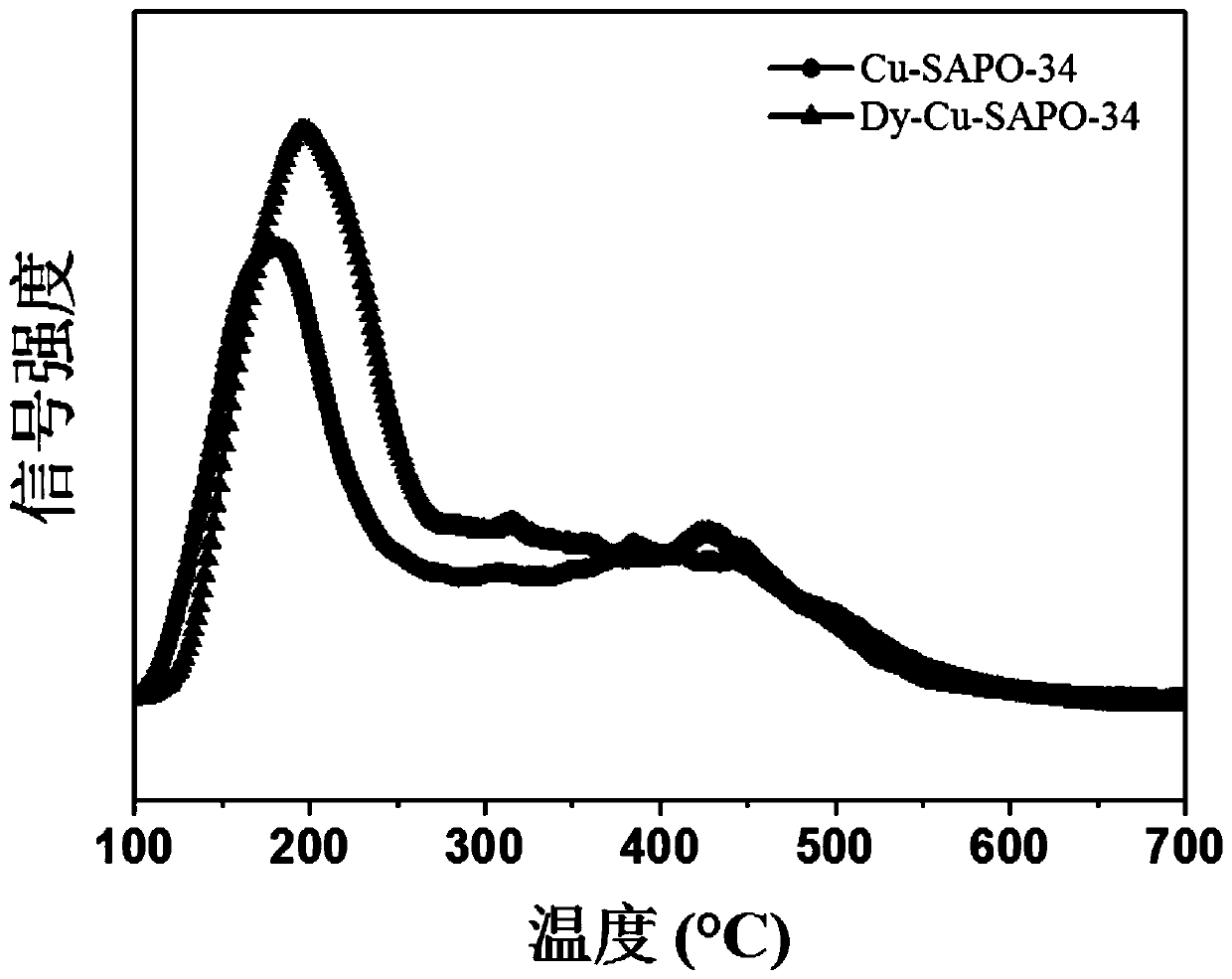

[0043] The preparation method of a kind of dysprosium modified Cu-SAPO-34 molecular sieve denitration catalyst of the present invention comprises the following steps:

[0044] Step 1, dissolve 0.5-0.55g of copper nitrate, 0.005-0.01g of dysprosium nitrate, and 3.4-5.3mL of tetraethylenepentamine in 20mL of deionized water at room temperature, and stir for 60min;

[0045] Step 2, add 2.0-2.5mL phosphoric acid and 2.7-3.5g aluminum hydroxide to the above solution, and continue to stir for 60min;

[0046] Step 3, add 2.0-3.0 mL of 30% aqueous silica solution to the above solution, and stir for 30 min;

[0047] Step 4, then add 1.4-2.0 mL of morpholine and 20-100 mg of SAPO-34 seed crystals into the above solution, and stir for 2 hours;

[0048] Step 5, adding the uniformly stirred above-mentioned solution into a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and aging at a temperature of 160-200°C for 48-72 hours;

[0049] Step 6, the reaction product is tak...

Embodiment 1

[0057] The preparation method of a kind of dysprosium modified Cu-SAPO-34 molecular sieve denitration catalyst of the embodiment of the present invention 1 comprises the following steps:

[0058] (1) Dissolve 0.50g of copper nitrate, 0.0075g of dysprosium nitrate, and 4.30mL of tetraethylenepentamine in 20mL of deionized water at room temperature, and stir for 60min;

[0059] (2) Add 2.20mL phosphoric acid and 3.10g aluminum hydroxide to the above solution, and continue stirring for 60min;

[0060] (3) Add 2.60 mL of 30% silicon dioxide aqueous solution to the above solution, and stir for 30 min;

[0061] (4) Then add 1.75mL of morpholine and 100mg of SAPO-34 seed crystals into the above solution, and stir for 2h;

[0062] (5) The uniformly stirred solution was added into a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and aged at a temperature of 200°C for 60 hours.

[0063] (6) The reaction product was taken out from the polytetrafluoroethylene liner, ...

Embodiment 2

[0068] The preparation method of a kind of dysprosium modified Cu-SAPO-34 molecular sieve denitration catalyst of embodiment 2 of the present invention comprises the following steps:

[0069] (1) Dissolve 0.55g of copper nitrate, 0.0100g of dysprosium nitrate, and 4.60mL of tetraethylenepentamine in 20mL of deionized water at room temperature, and stir for 60min;

[0070] (2) Add 2.45mL phosphoric acid and 2.85g aluminum hydroxide to the above solution, and continue stirring for 60min;

[0071] (3) Add 2.60 mL of 30% silicon dioxide aqueous solution to the above solution, and stir for 30 min;

[0072] (4) Then add 1.90 mL of morpholine and 50 mg of SAPO-34 seed crystals into the above solution, and stir for 2 h;

[0073] (5) The uniformly stirred solution was added into a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and aged at a temperature of 180°C for 48 hours.

[0074] (6) The reaction product was taken out from the polytetrafluoroethylene liner, wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com