Regeneration method for SCR (Selective Catalytic Reduction) denitration catalyst V2O5-WO3/TiO2

A V2O5-WO3, denitrification catalyst technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the degree of activity improvement is limited, cannot be fully satisfied, and the reaction temperature range cannot be widened, etc. problems, to achieve uniform distribution of active substances, improved denitrification efficiency, simple and easy-to-control regeneration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

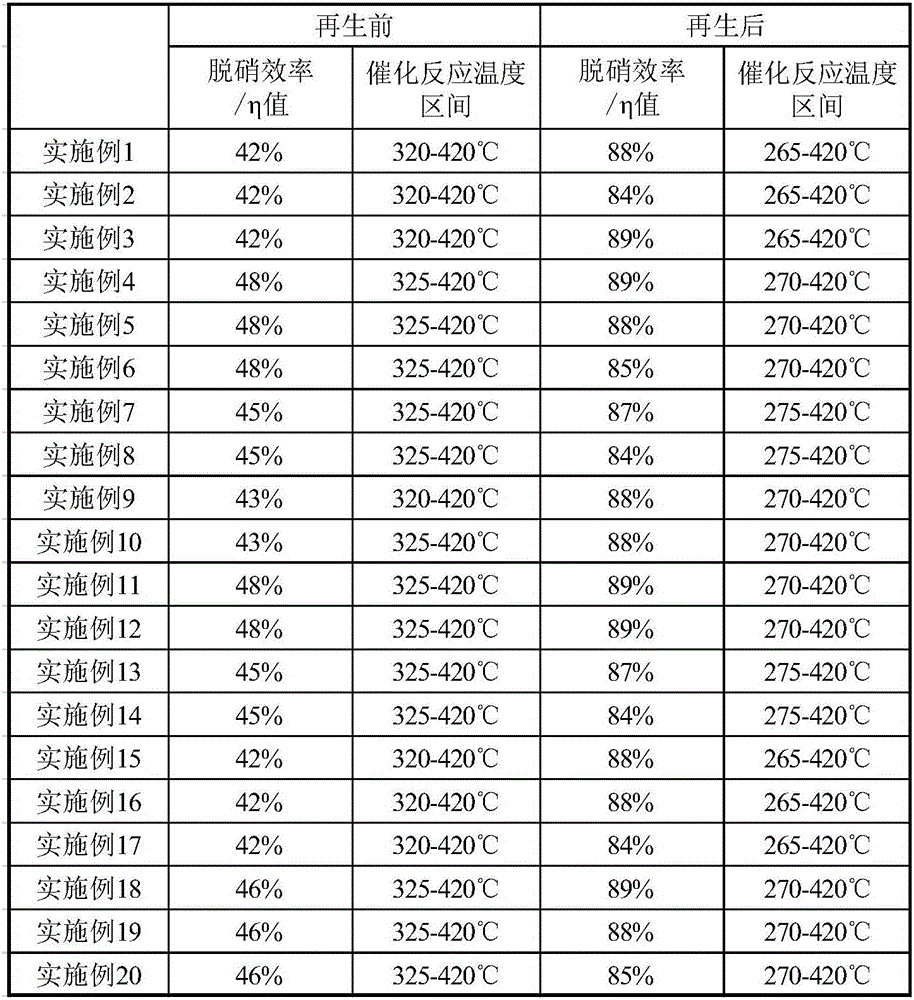

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

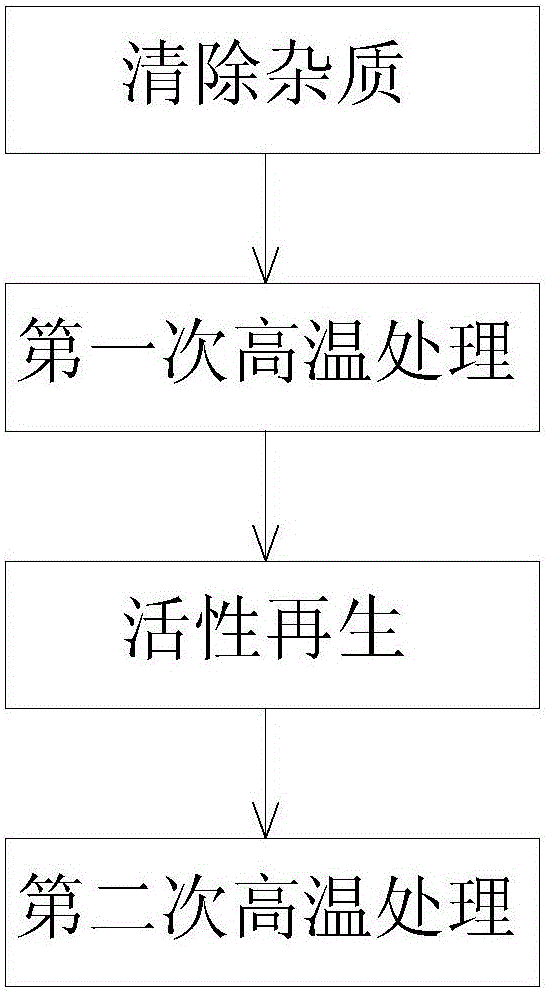

[0023] Such as figure 1 Shown, the SCR denitration catalyst V of the embodiment of the present invention 1-20 2 o 5 -WO 3 / TiO 2 The active regeneration includes the following steps:

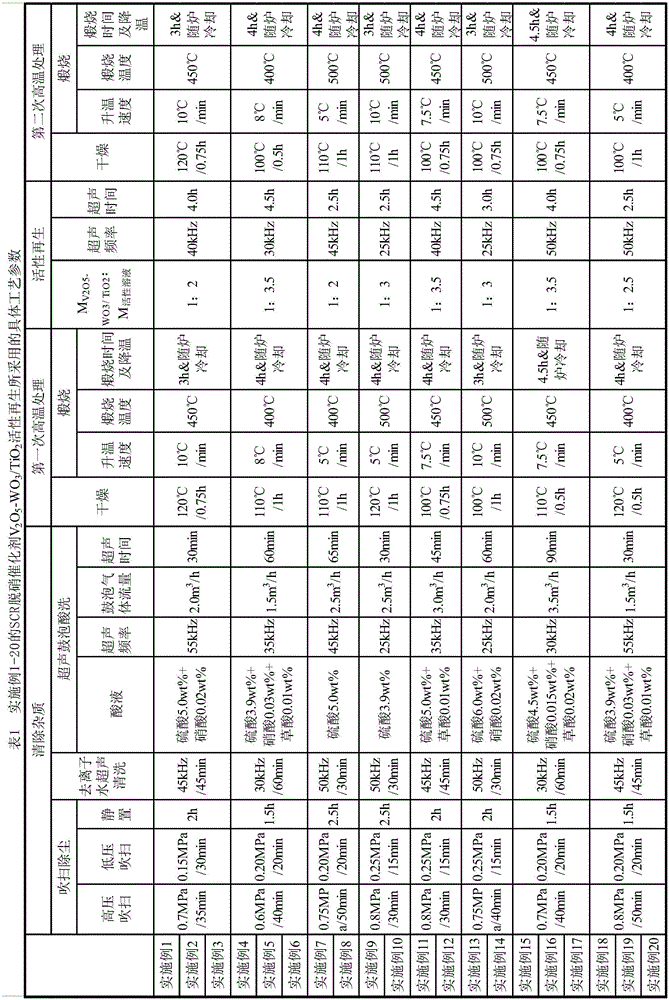

[0024] (1) Removal of impurities: remove the inclusions in the deactivated SCR denitration catalyst V by physical and chemical methods 2 o 5 -WO 3 / TiO 2 Various impurities such as dust and alkaline earth metals on the surface, specifically include the following three steps: ① Purging and dust removal treatment, the purging and dust removal treatment includes purging at a pressure of 0.6-0.8MPa for 30-50min, blowing at a pressure of 0.15-0.25MPa Three steps of sweeping for 15-35min and standing for 1.5-2.5h; ②Deionized water ultrasonic cleaning, the ultrasonic frequency and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com