Patents

Literature

37results about How to "Reduce remanufacturing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

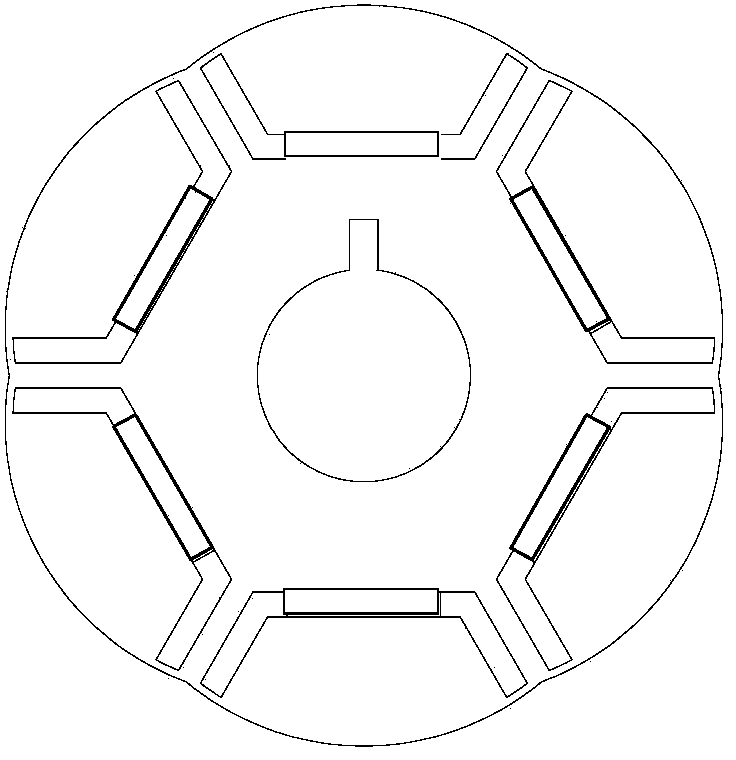

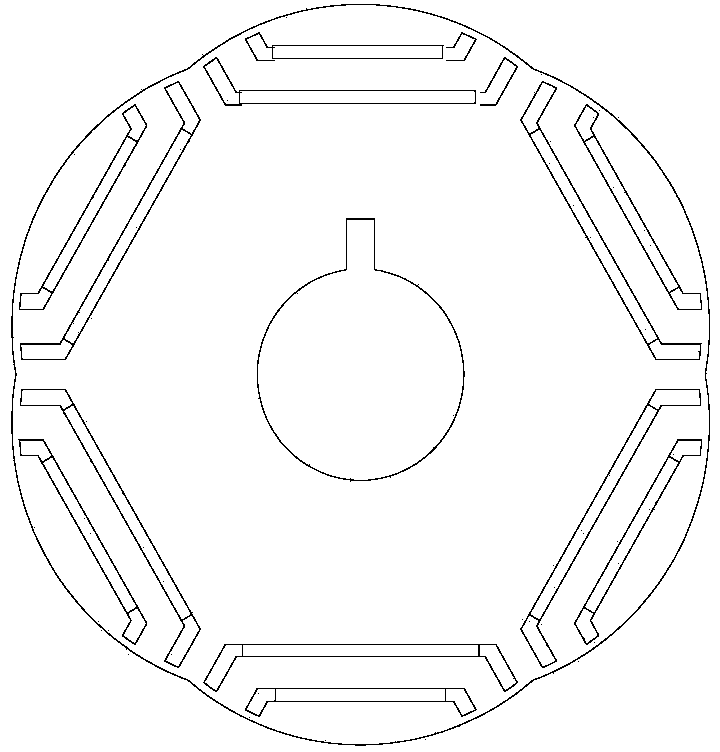

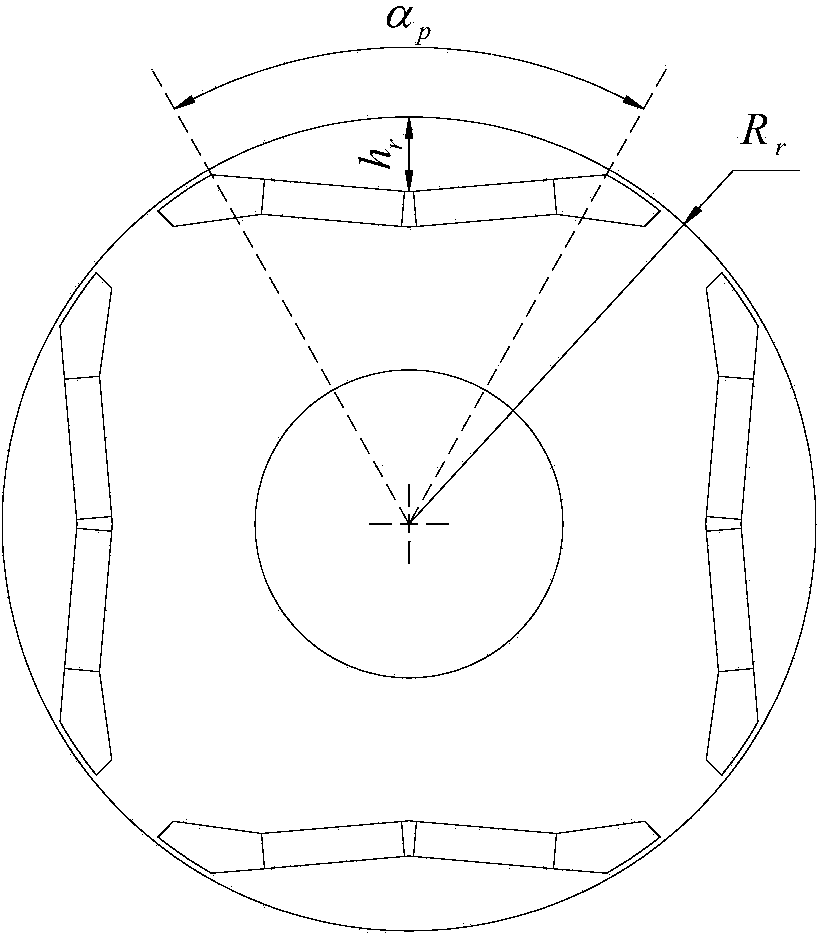

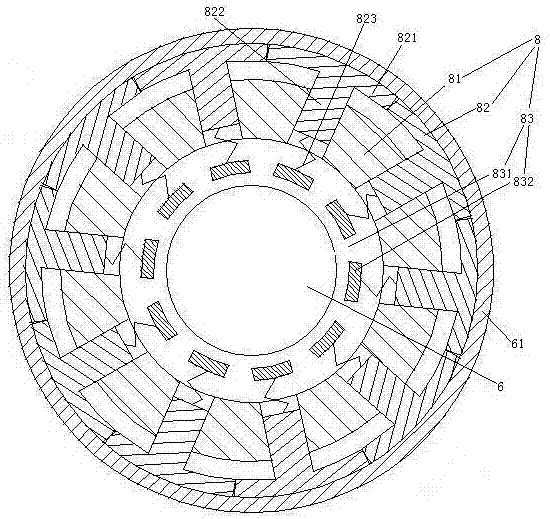

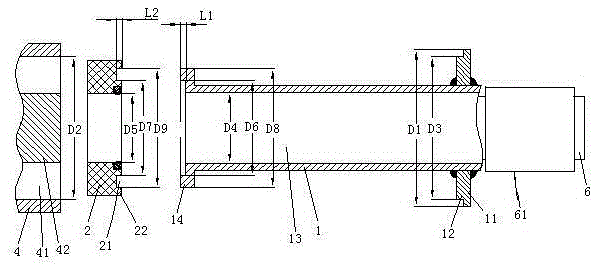

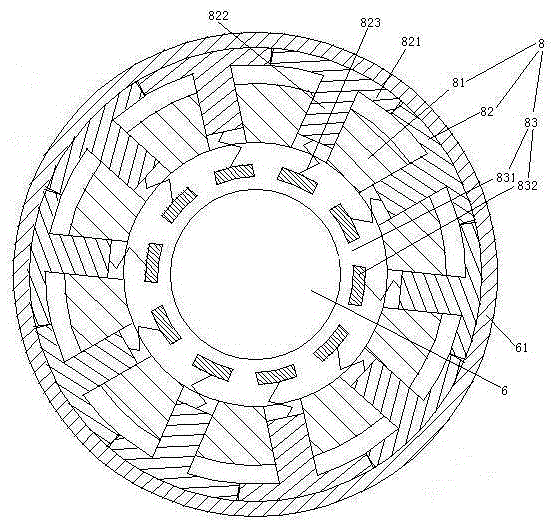

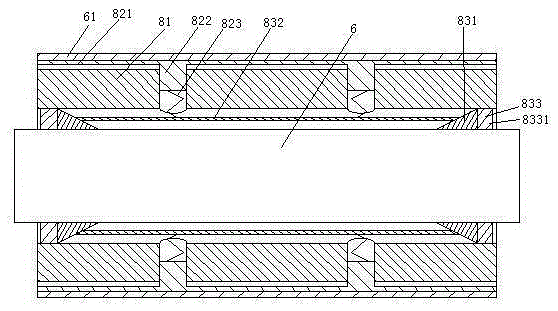

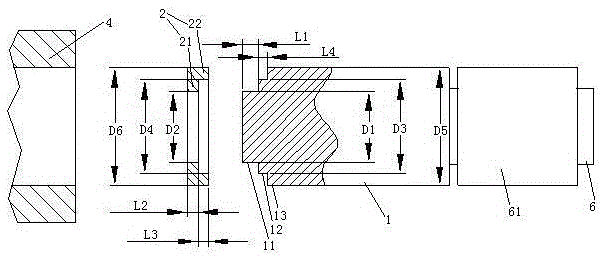

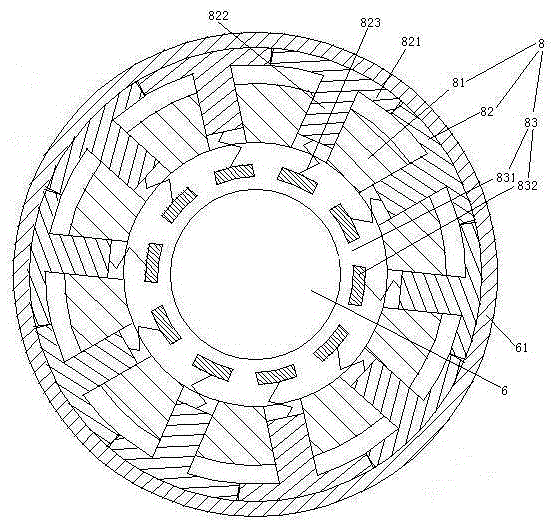

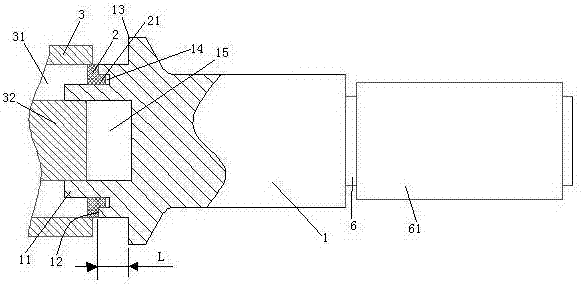

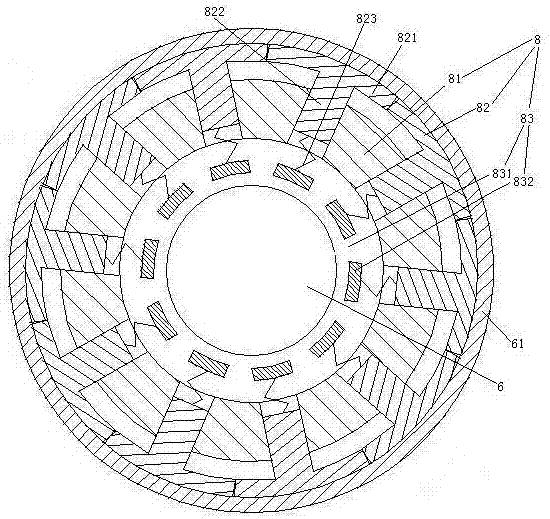

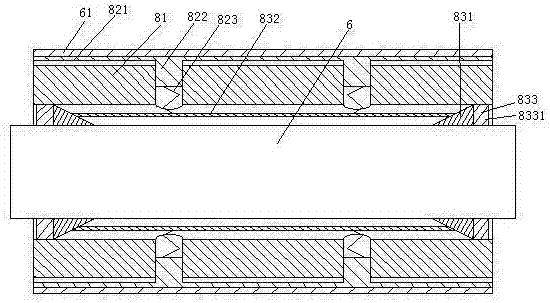

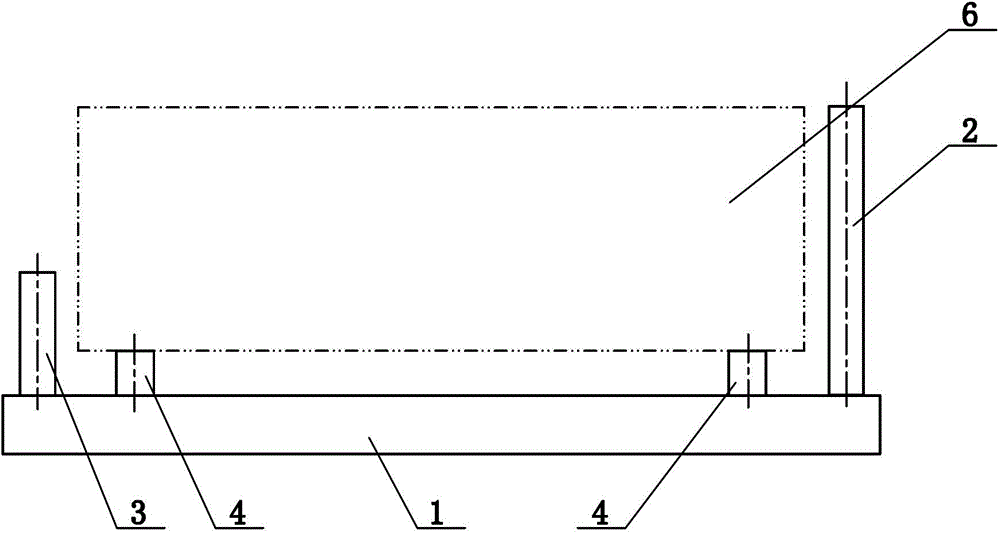

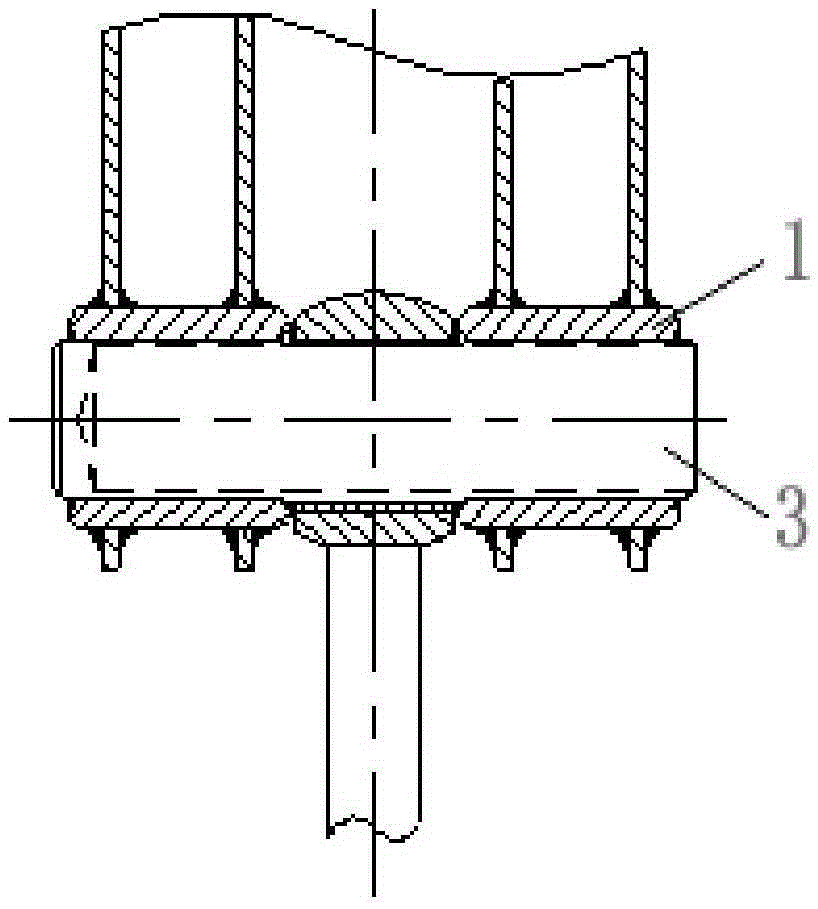

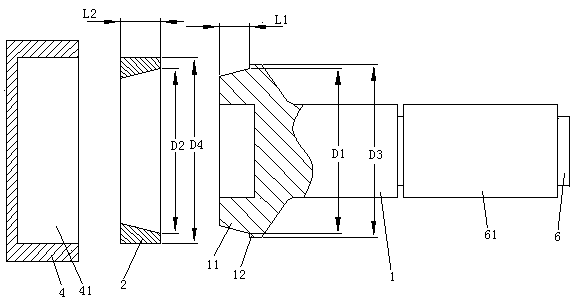

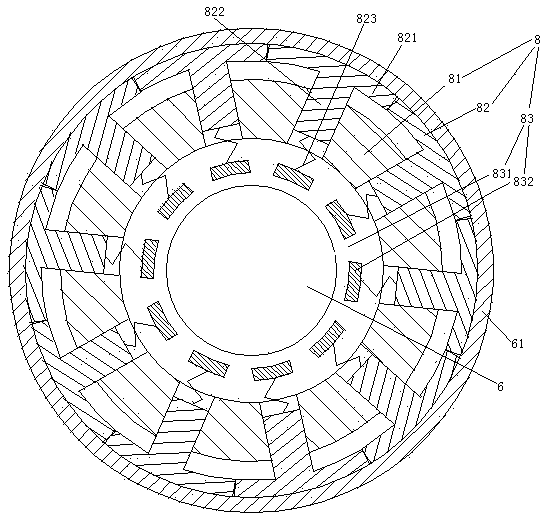

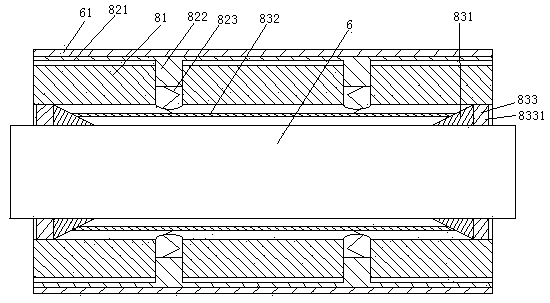

Remanufacturing method for inefficient three-phase asynchronous motor

InactiveCN103730994AImprove energy efficiencyEasy to controlManufacturing stator/rotor bodiesPermanent magnet rotorSynchronous motor

The invention relates to a remanufacturing method for an inefficient three-phase asynchronous motor and belongs to the field of motor efficiency enhancing. The remanufacturing method aims at solving the problem of low efficiency of prior three-phase asynchronous motor. According to the remanufacturing method, an asynchronous cage rotor of a prior inefficient three-phase asynchronous motor is replaced by a built-in permanent magnet rotor, that is, the inefficient three-phase asynchronous motor is changed into a built-in permanent-magnet synchronous motor, so that the remanufactured motor energy efficiency level reaches IE4, the remanufactured motor rated load rated load rate is larger than 1.5, and the remanufactured motor no-load opposite electro-dynamic potential total harmonic distortion is smaller than 7%, which is lower than low-speed and medium-high-speed sensorless control. The remanufacturing method is applicable to transformation of inefficient three-phase asynchronous motors.

Owner:HARBIN INST OF TECH

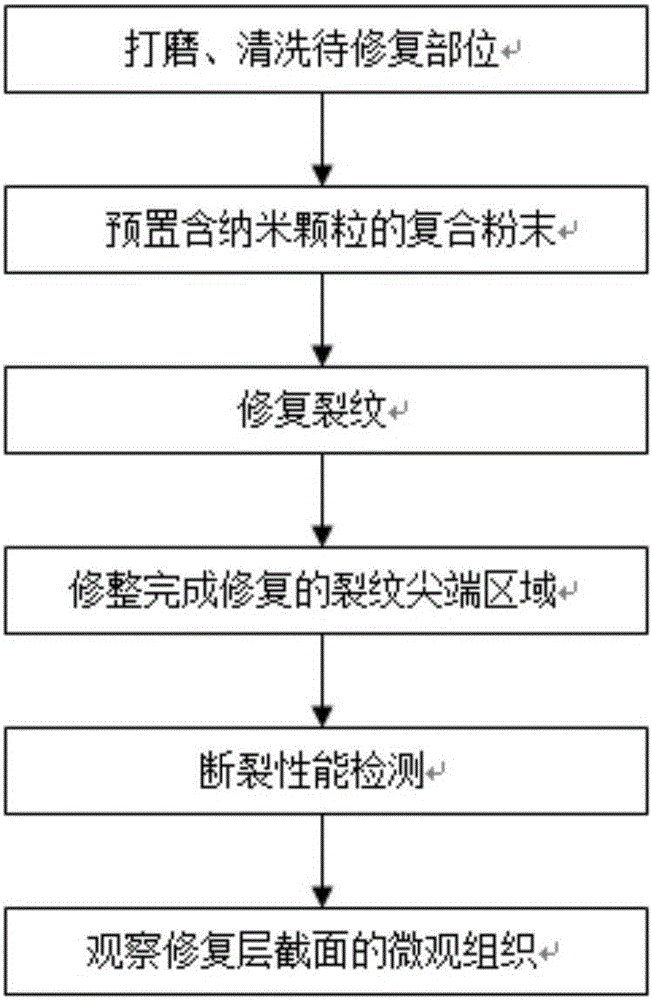

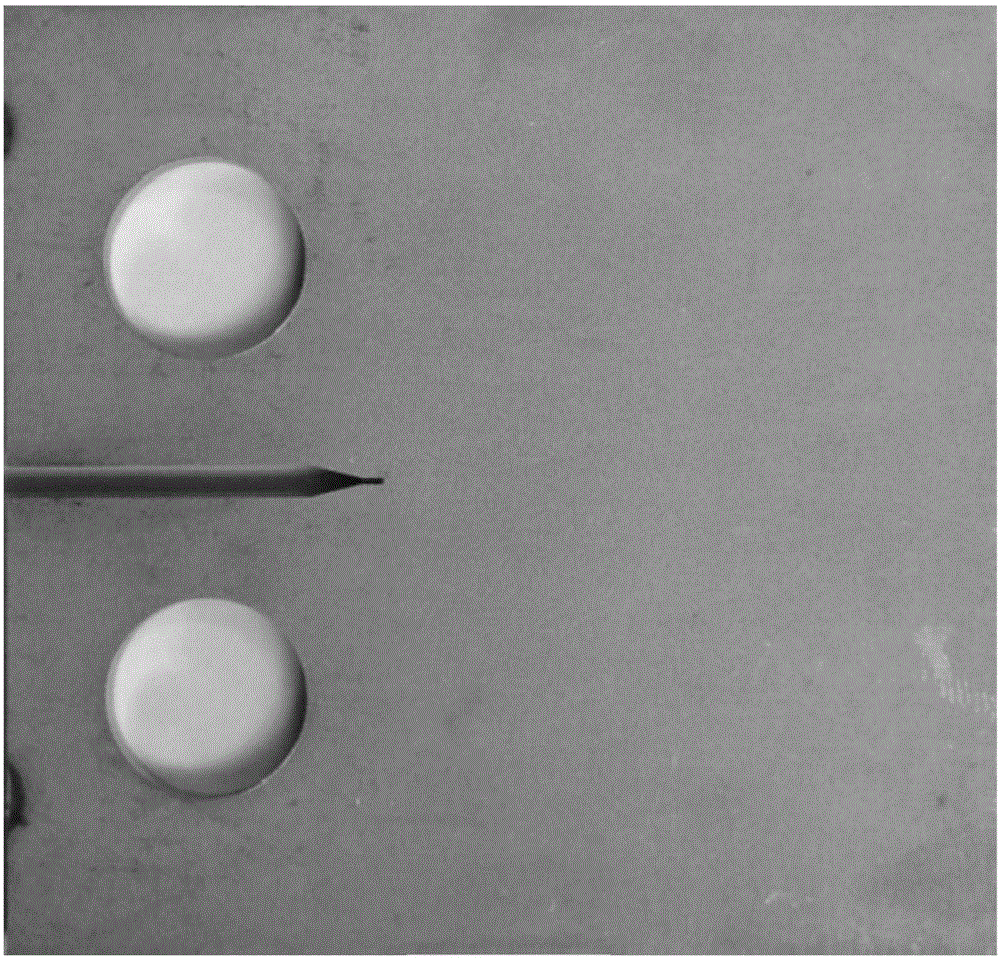

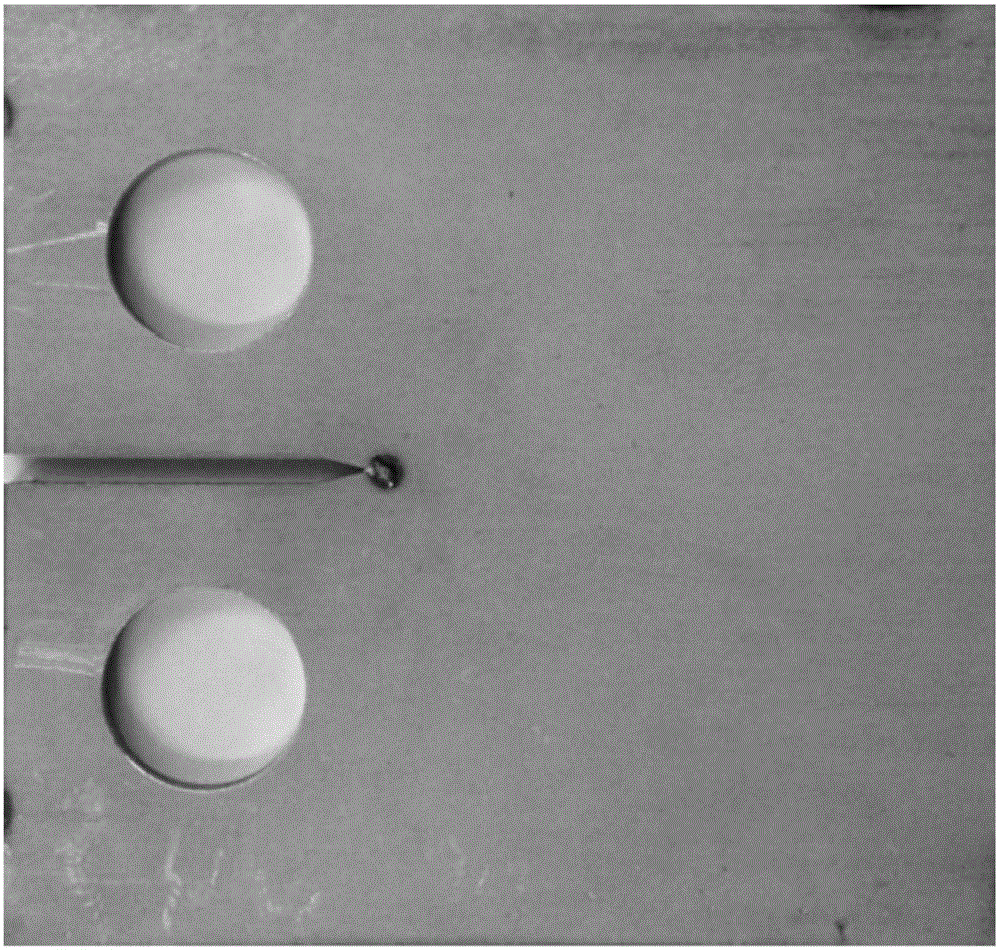

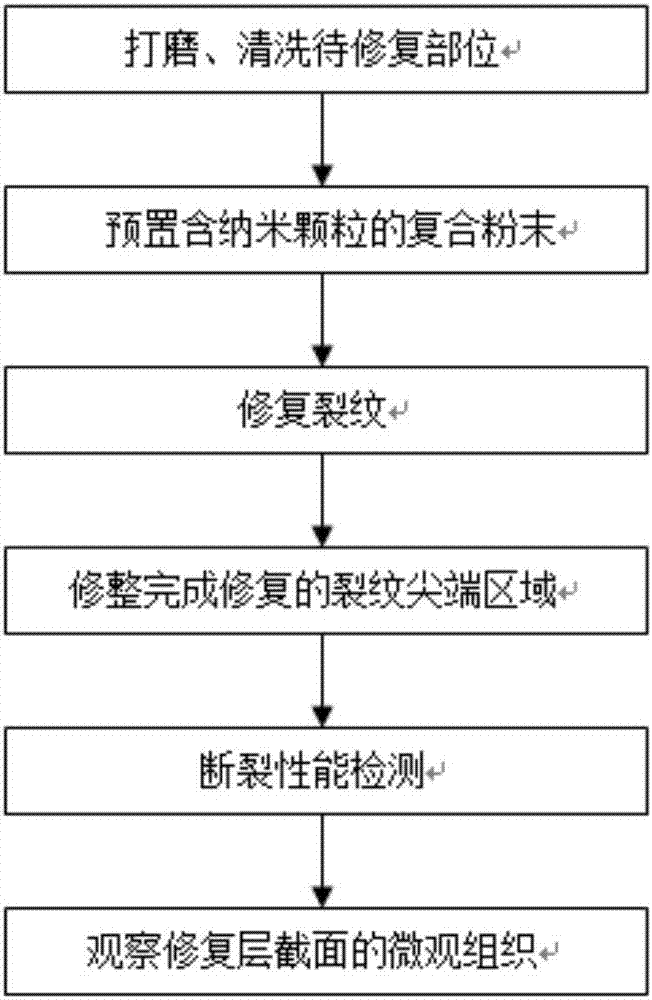

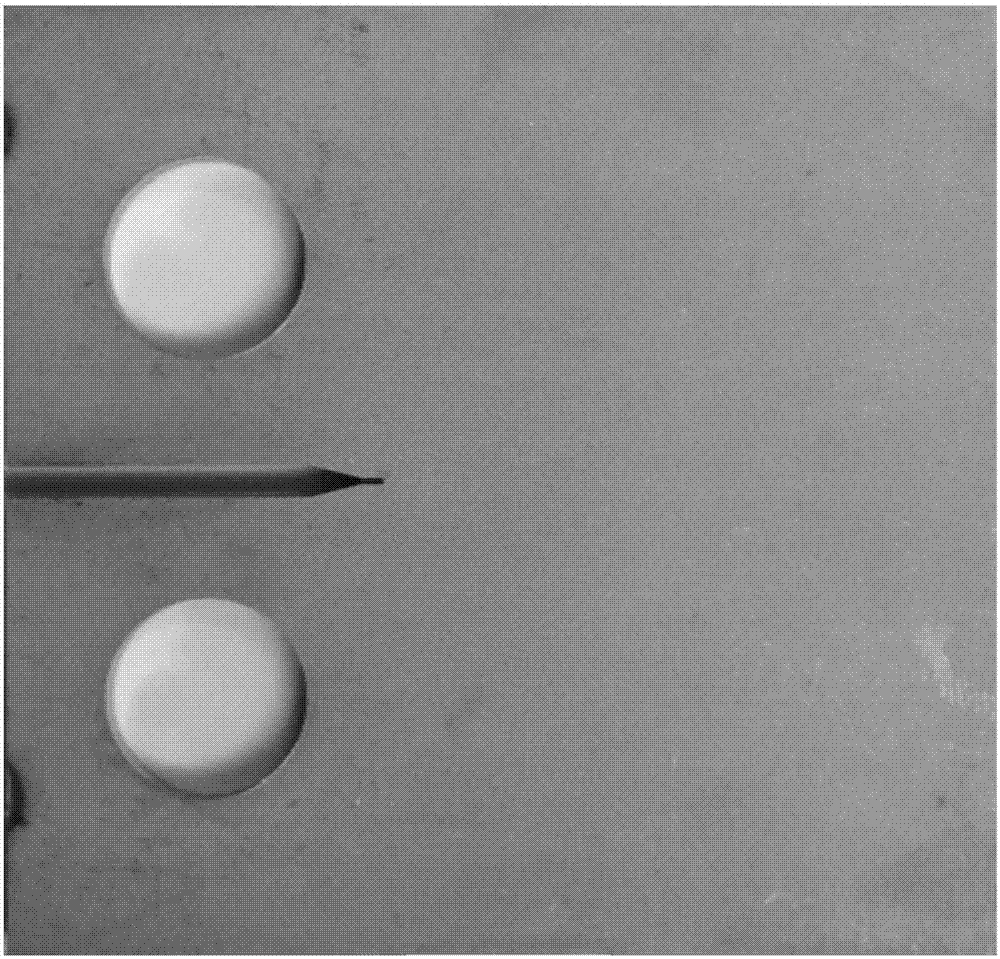

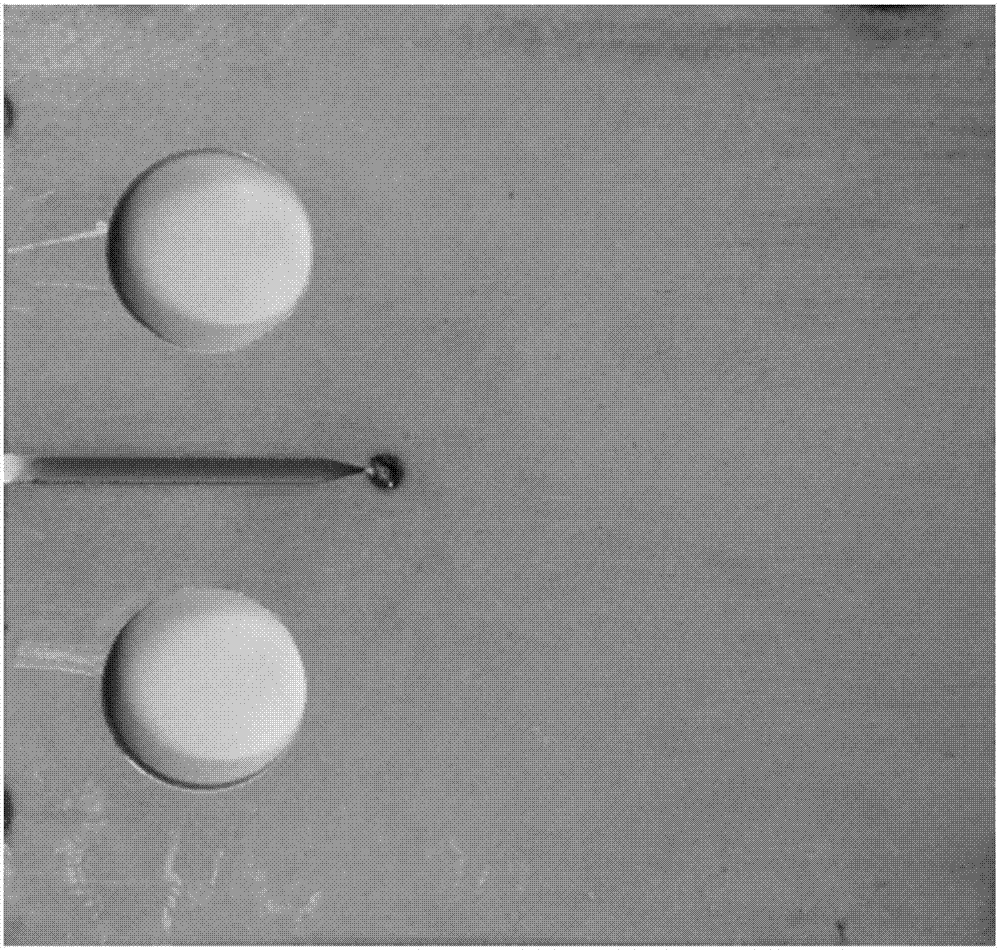

Method for repairing microcrack tip on stainless steel surface by means of nano-particles

ActiveCN105714286AImprove densification performanceExtended service lifeMetallic material coating processesHeat-affected zoneNanoparticle

The invention provides a method for repairing a microcrack tip on a stainless steel surface by means of nano-particles. The method is suitable for stainless steel with microcracks on the surface. The method comprises the steps that the to-be-repaired microcrack tip on the stainless steel surface is treated; composite powder containing the nano-particles is arranged on the microcrack tip in advance; the composite powder and a part of a matrix are fused by means of lasers; the repaired microcrack tip region is finished; and the fracture property of the stainless steel matrix obtained after repairing is detected, and the microstructure of the section of a repair layer is observed. The repairing method is high in flexibility, and repairing can be carried out many times; and meanwhile, the problems of large deformation, a large heat affected zone and the like in a conventional method are avoided in the repairing method. According to the repairing method, the microcrack tip is closed again, the matrix and the composite powder arranged on the microcrack tip in advance are in metallurgical bonding, and the defects of cracks, pores and the like do not exist in the bonding region; grains of the repair layer of the microcrack tip are refined, and the structural compactness is improved; and in addition, the fracture property generated after repairing is remarkably improved.

Owner:DALIAN UNIV OF TECH

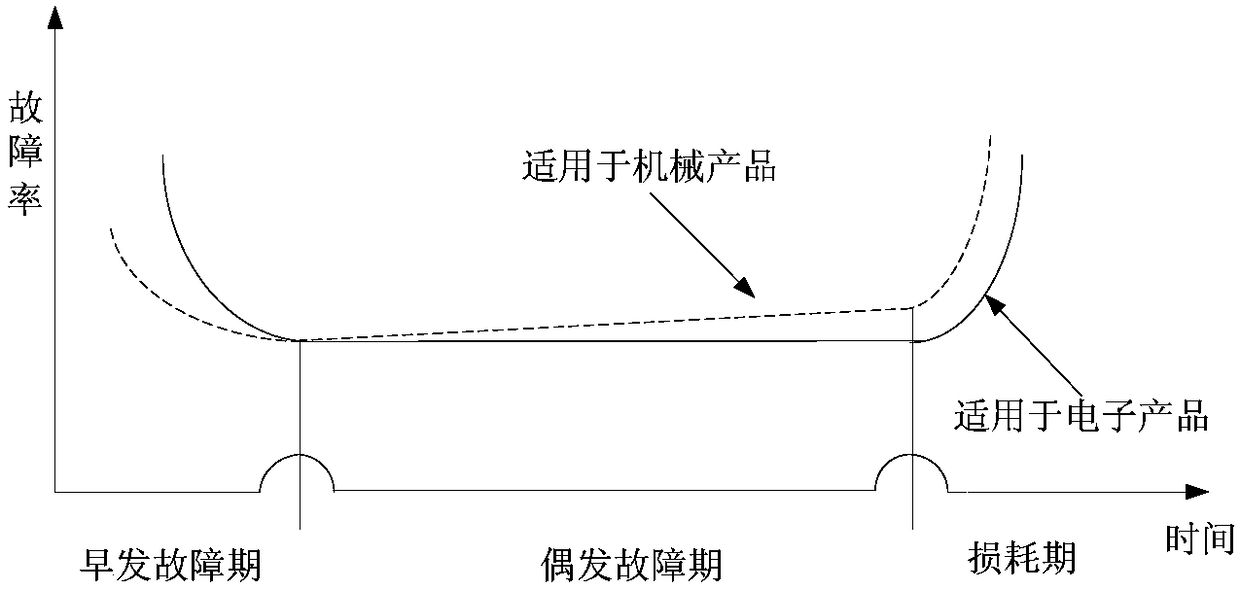

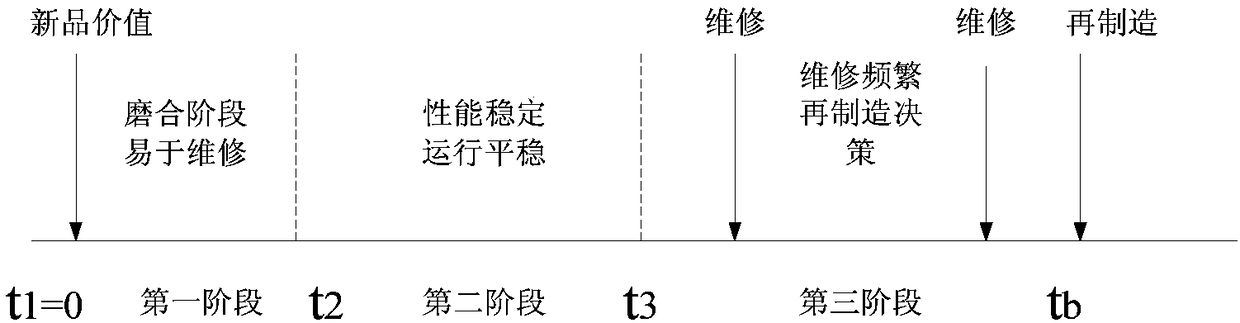

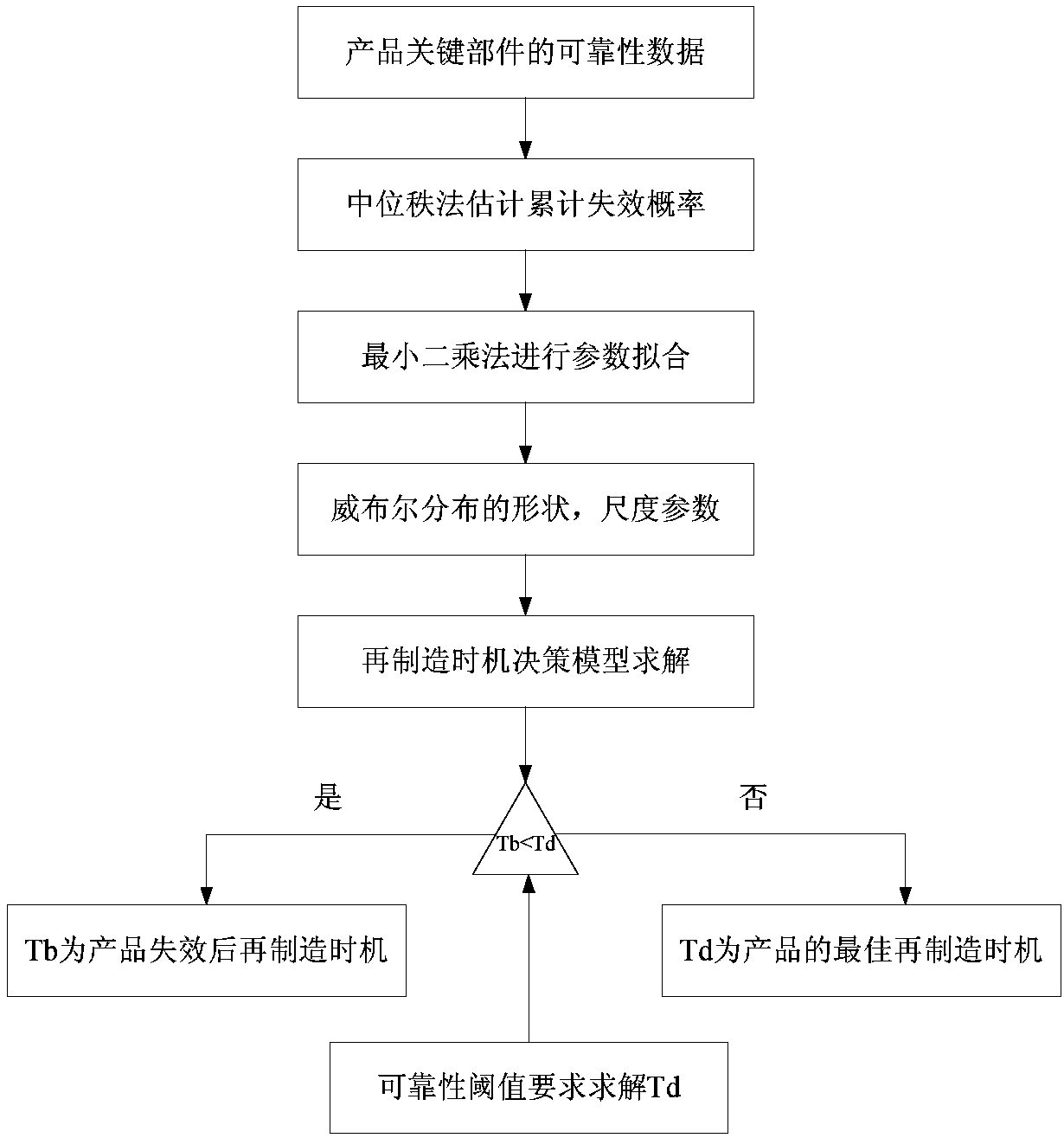

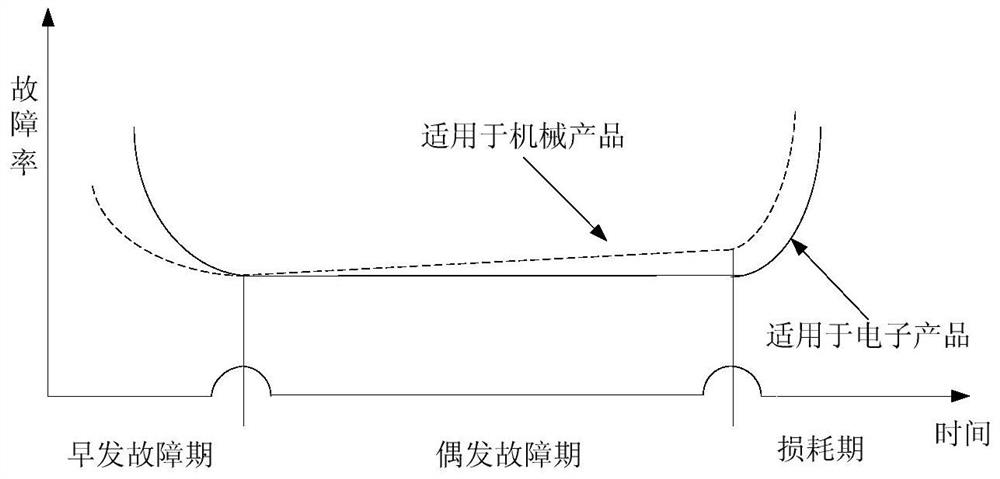

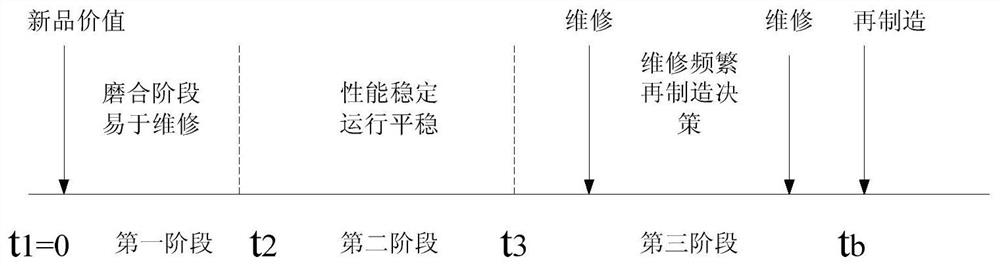

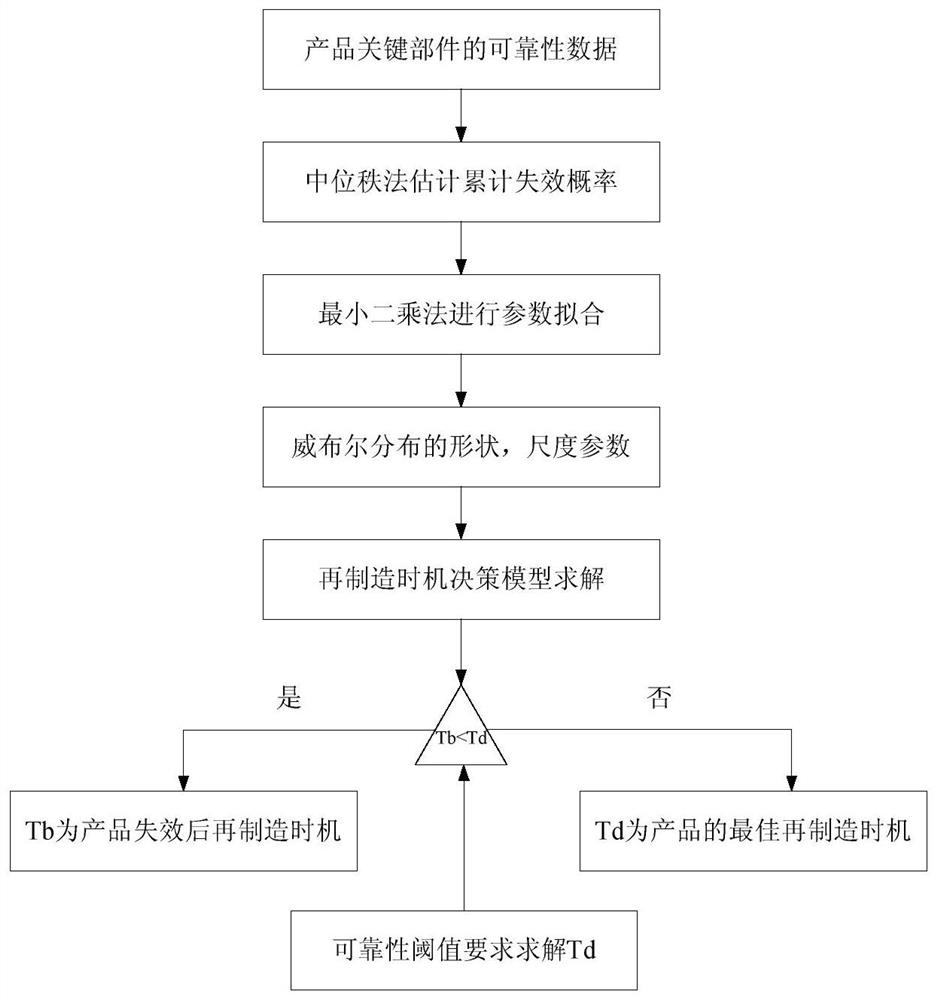

Method for predicting remanufacture timing of mechanical equipment

ActiveCN108241909ADegree of control failureEasy to remanufactureForecastingManufacturing computing systemsFailure rateDecision model

The invention relates to a method for predicting the remanufacture timing of mechanical equipment. The method includes the steps of first obtaining the failure time of several components in mechanicalequipment as sampling data, and using a median rank method to estimate the cumulative failure probability; fitting parameters by a least square method to obtain a relational expression of cumulativefailure probability and reliability; using the relational expression of cumulative failure probability and reliability and a reliability expression of two-parameter Weibull distribution to obtain a solution formula of a two-parameter Weibull failure rate h(t); using the solution formula of h(t) to solve N(t) according to the formula (as shown in the description); constructing a remanufacture timing decision-making model, substituting N(t) into the remanufacture timing decision-making model, and solving the theoretical remanufacture timing Td; and comparing the theoretical remanufacture timingTd with the recovery timing Tb after the mechanical equipment failure to determine the remanufacture timing of the mechanical equipment. The method of the invention can reliably predict the remanufacture timing, control the degree of waste failure, and save the remanufacture cost.

Owner:CHANGAN UNIV

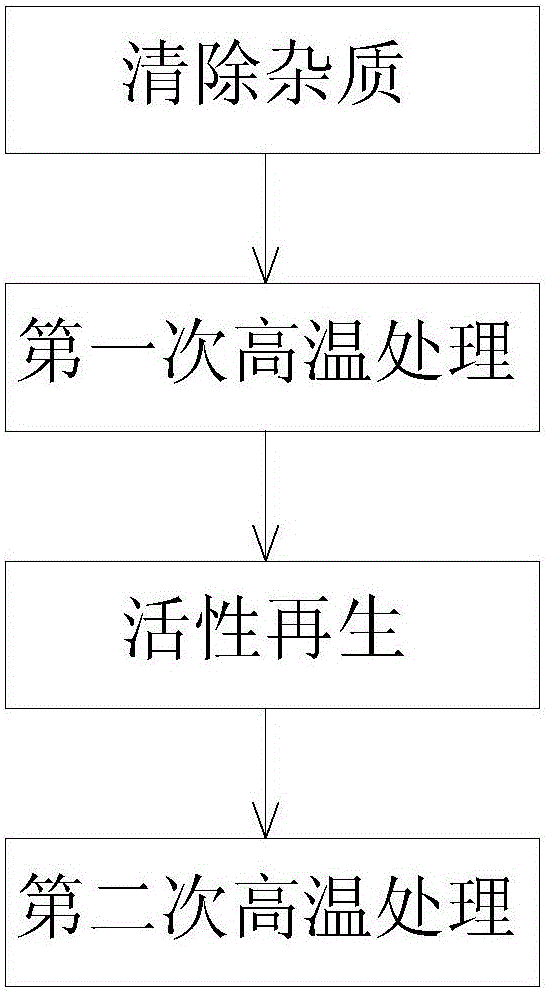

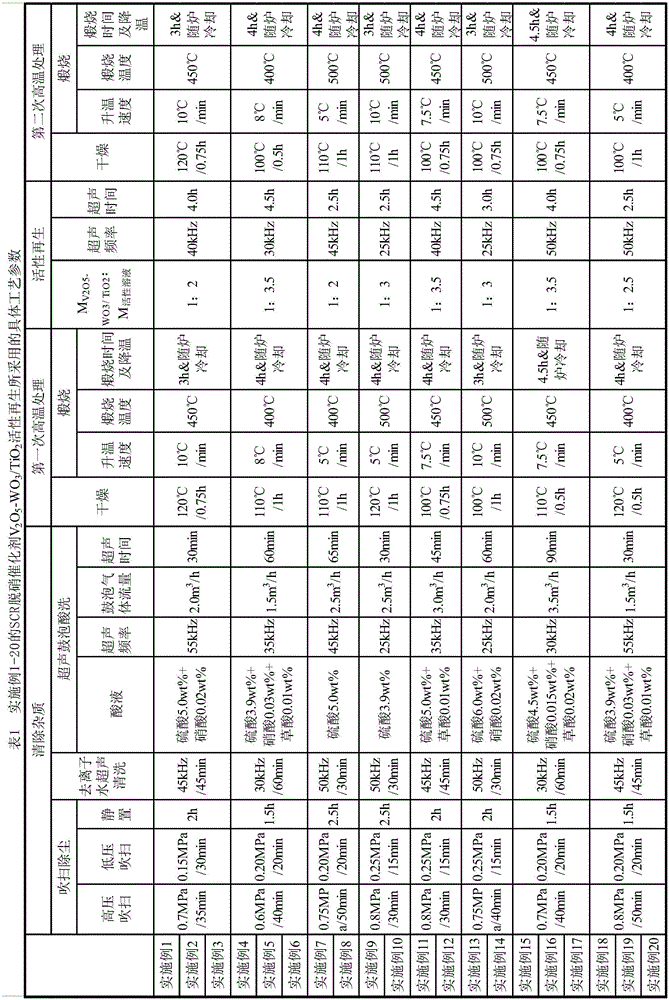

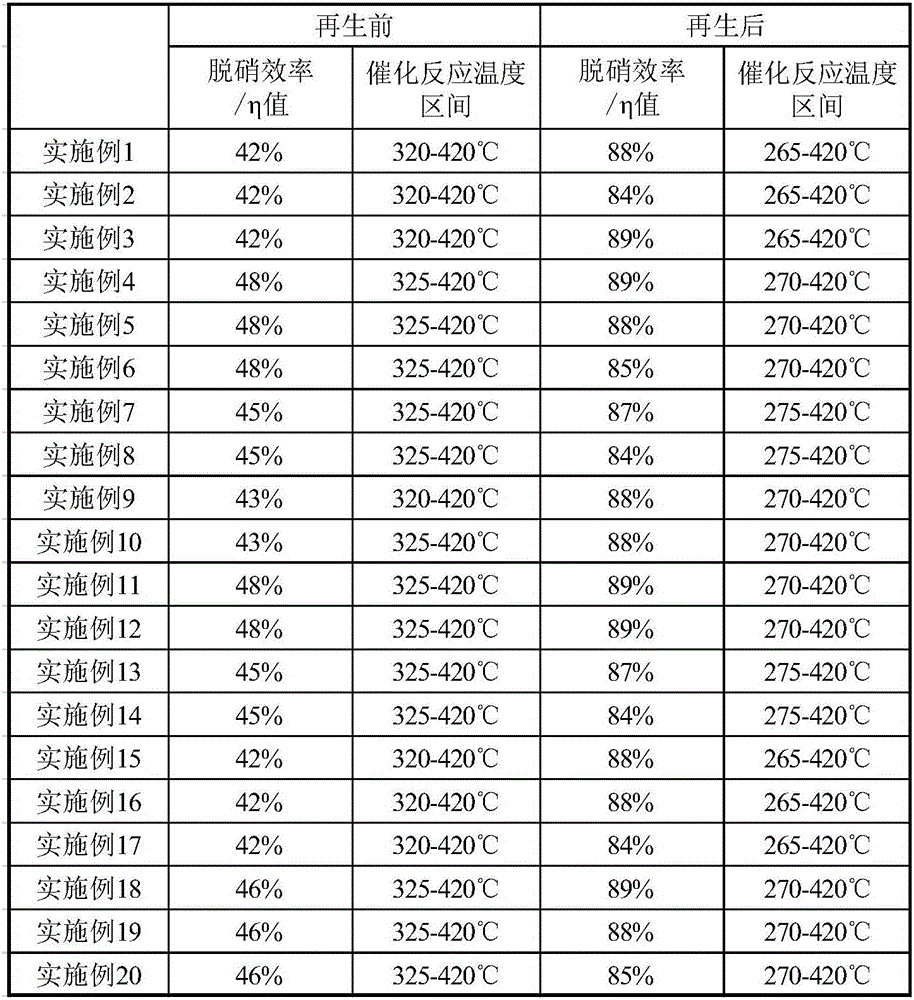

Regeneration method for SCR (Selective Catalytic Reduction) denitration catalyst V2O5-WO3/TiO2

InactiveCN105772028AWiden the temperature rangeRecovery of denitrification efficiencyCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATECerium nitrate hexahydrate

The invention discloses a regeneration method for an SCR (Selective Catalytic Reduction) denitration catalyst V2O5-WO3 / TiO2. The method comprises the following four steps: (1) carrying out impurity removal; (2) carrying out first-time high-temperature treatment; (3) carrying out activity regeneration; (4) carrying out second-time high-temperature treatment. According to the regeneration method, one or a mixture solution of more of a cerous nitrate solution, a cerous acetate solution, a manganous nitrate solution and a manganese acetate solution is adopted as an active solution, so that the denitration efficiency of the regenerated SCR denitration catalyst V2O5-WO3 / TiO2 is obviously increased, and the temperature range of a denitration reaction can be effectively widened; meanwhile, a template agent is added, so that the distribution of active substances is more uniform, and the activity recovery is facilitated. The regeneration method provided by the invention is simple and easy in control, and required equipment is readily available and cheap; compared with the existing regeneration methods, the regeneration method has greater technical and economic advantages, thereby having powerful market competitiveness.

Owner:WUHAN LONGKING ENVIRONMENTAL PROTECTION TECH

Deruster composition and method

InactiveUS20060094637A1Eliminate labor-intensive pH adjustmentsReduce remanufacturing costsOrganic detergent compounding agentsInorganic non-surface-active detergent compositionsMetal ChelantIon

The present invention relates to compositions comprising phosphonate metal chelants, chelating agents, and ferrous ions at a pH of about 5 to about 10, and methods of using the compositions.

Owner:HENKEL KGAA

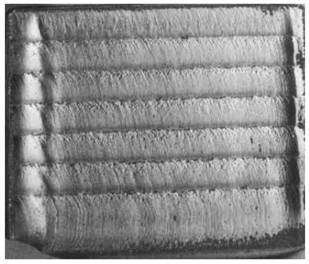

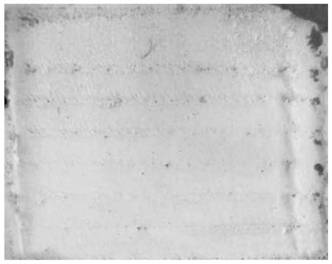

Rapid remanufacturing method of continuous casting machine roller

The invention provides a rapid remanufacturing method of a continuous casting machine roller. The method comprises steps as follows: the continuous casting machine roller is subjected to unilateral turning; submerged arc surfacing is performed; machining replication is performed; roller surface polishing and cleaning are performed; magnetic particle flaw detection and ultrasonic flaw detection areperformed; the continuous casting machine roller is coated with an oil film; the oil film is coated with alloy powder; an alloy powder coating is subjected to laser scanning, and a clad alloy layer is formed; surface dye penetrant inspection is executed; the qualified continuous casting machine roller after inspection is the remanufactured continuous casting machine roller. According to the method, the alloy powder is sprayed to the continuous casting machine roller, the alloy clad layer is formed on the surface of the roller with the laser cladding technology, so that remanufacturing of thecontinuous casting machine roller is realized, the service life of the roller can be prolonged, service efficiency can be improved, and cost of an iron and steel enterprise can be reduced; the methodhas the advantages of simple technology, high controllability, energy-saving and environment-friendly performance, low cost and the like.

Owner:天津北基新激光科技有限公司

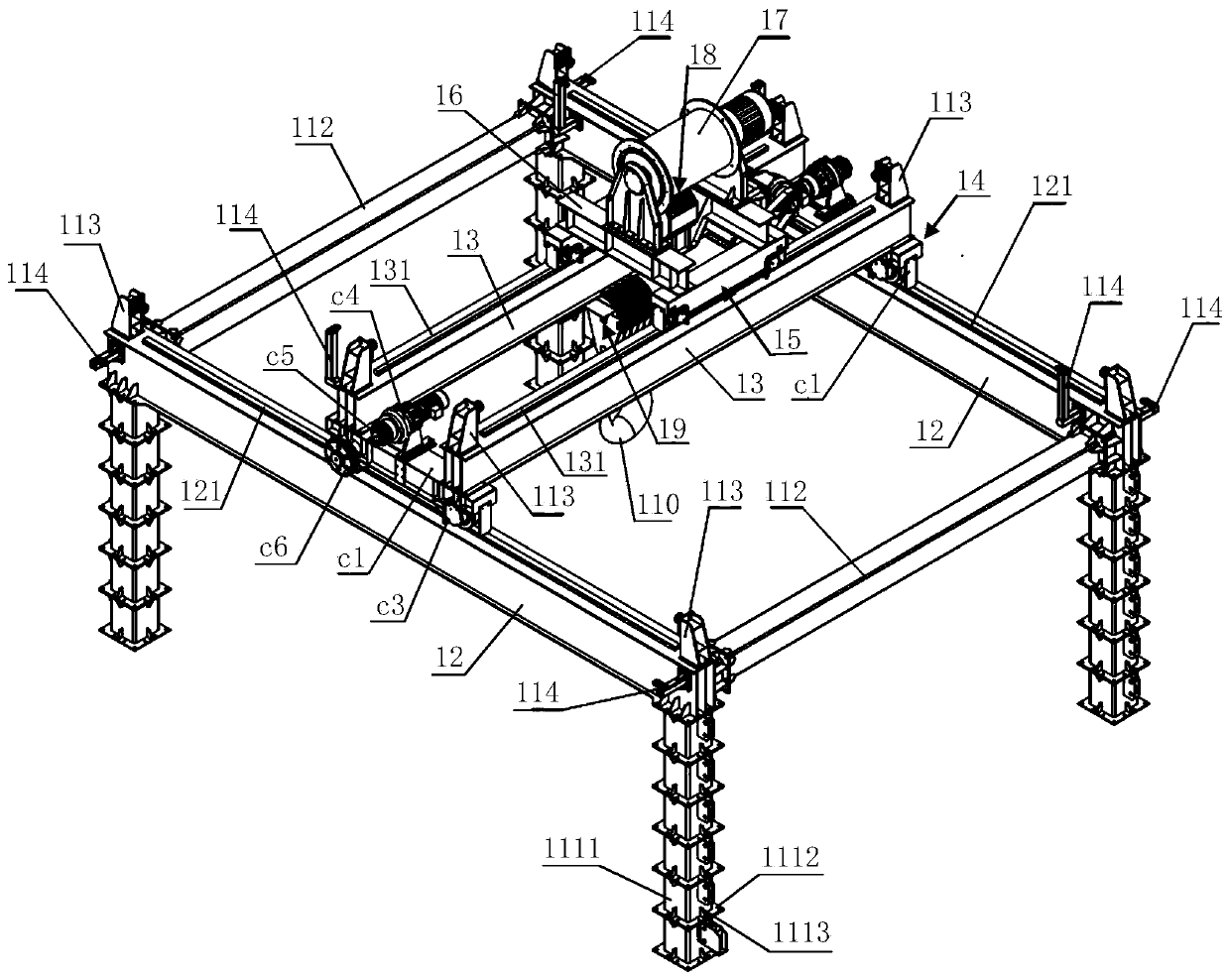

Receiving-free well pipe jacking machine and complete recycling method thereof

PendingCN108131160APromote recoveryReduce construction costsEarth drilling and miningUnderground transportEngineeringMechanical engineering

The invention relates to the technical field of pipe jacking construction and in particular relates to a receiving-free well pipe jacking machine and a complete recycling method thereof. A jacking direction of the pipe jacking machine is set to be a front side and a recycling direction of the pipe jacking machine is set to be a rear side; the pipe jacking machine is provided with a machine body ofthe pipe jacking machine and a supporting beam which is fixedly connected to the rear part of the machine body of the pipe jacking machine; the supporting beam is provided with a slippage oil cylinder; the slippage oil cylinder is provided with a slippage seat; the slippage seat moves in a front-rear direction along the supporting beam along the action of the slippage oil cylinder; the slippage seat is provided with a spreading shoe oil cylinder; the spreading boot supporting oil cylinder is provided with a spreading shoe; the spreading shoe is supported or gets far away from a pipeline underthe action of the spreading boot supporting oil cylinder. According to the receiving-free well pipe jacking machine and the complete recycling method thereof, provided by the invention, the pipe jacking machine can be completely recycled and the recycled pipe jacking machine can be used again; furthermore, when obstacles, which cannot be removed, are met at the front side in a pipe jacking and tunneling process, a vertical shaft does not need to be dug in front of the pipe jacking machine and the pipe jacking machine can be recycled firstly; after the obstacles at the front side are removed,jacking work is carried out again.

Owner:江苏格睿特管网工程有限公司

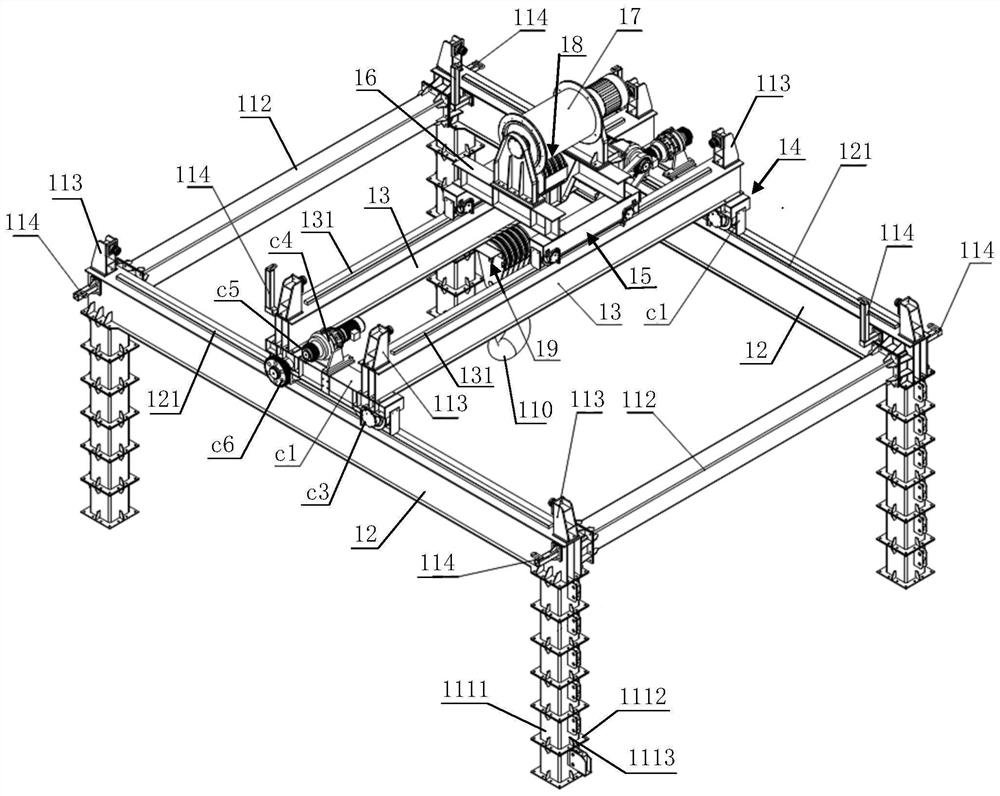

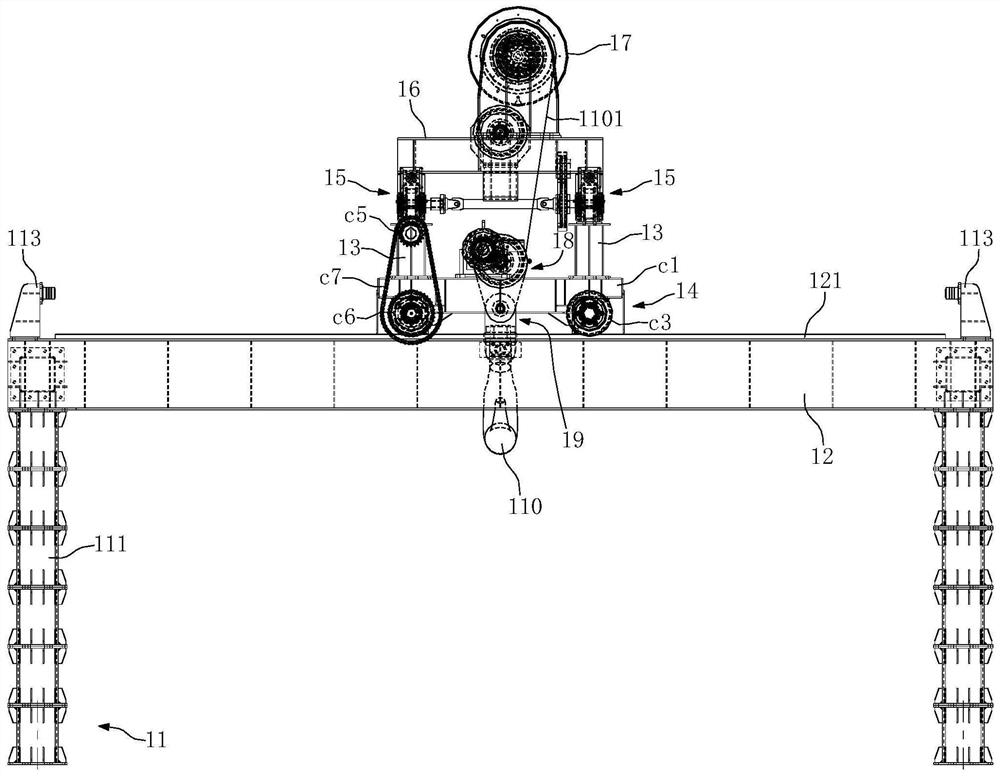

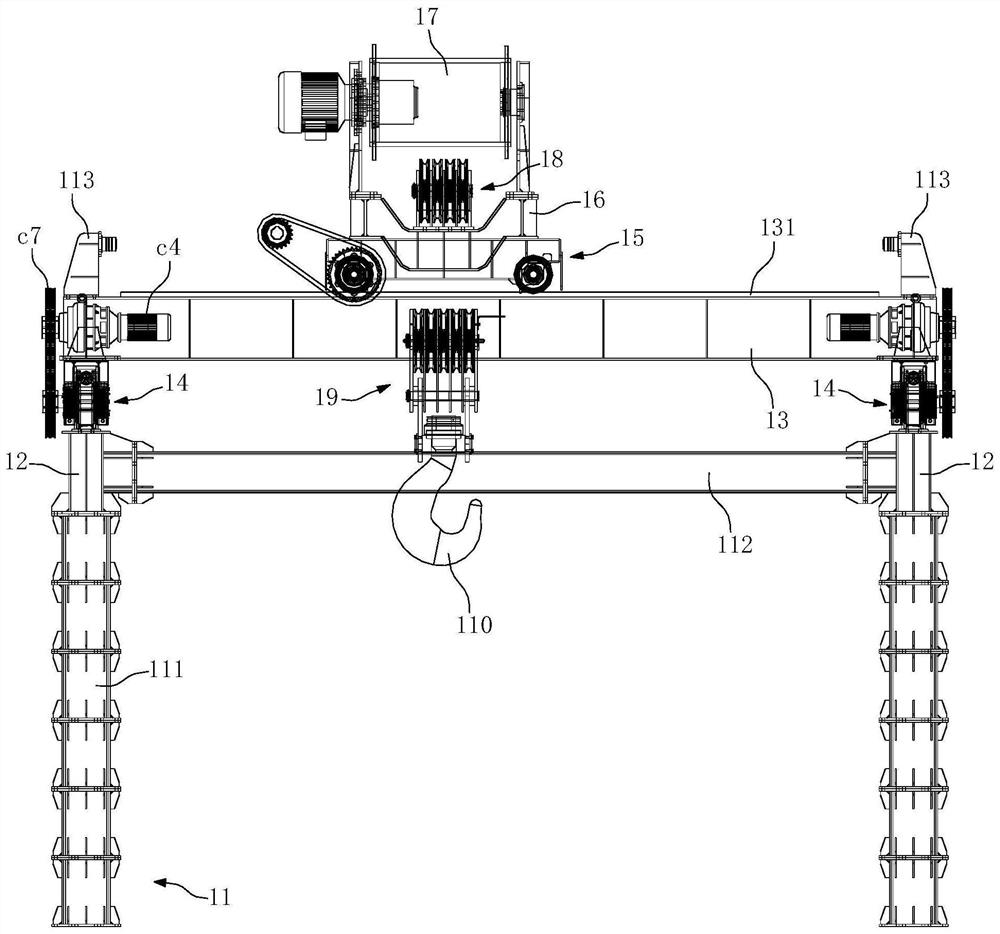

Modular disassembly construction method for shield tunneling machine in closed narrow space

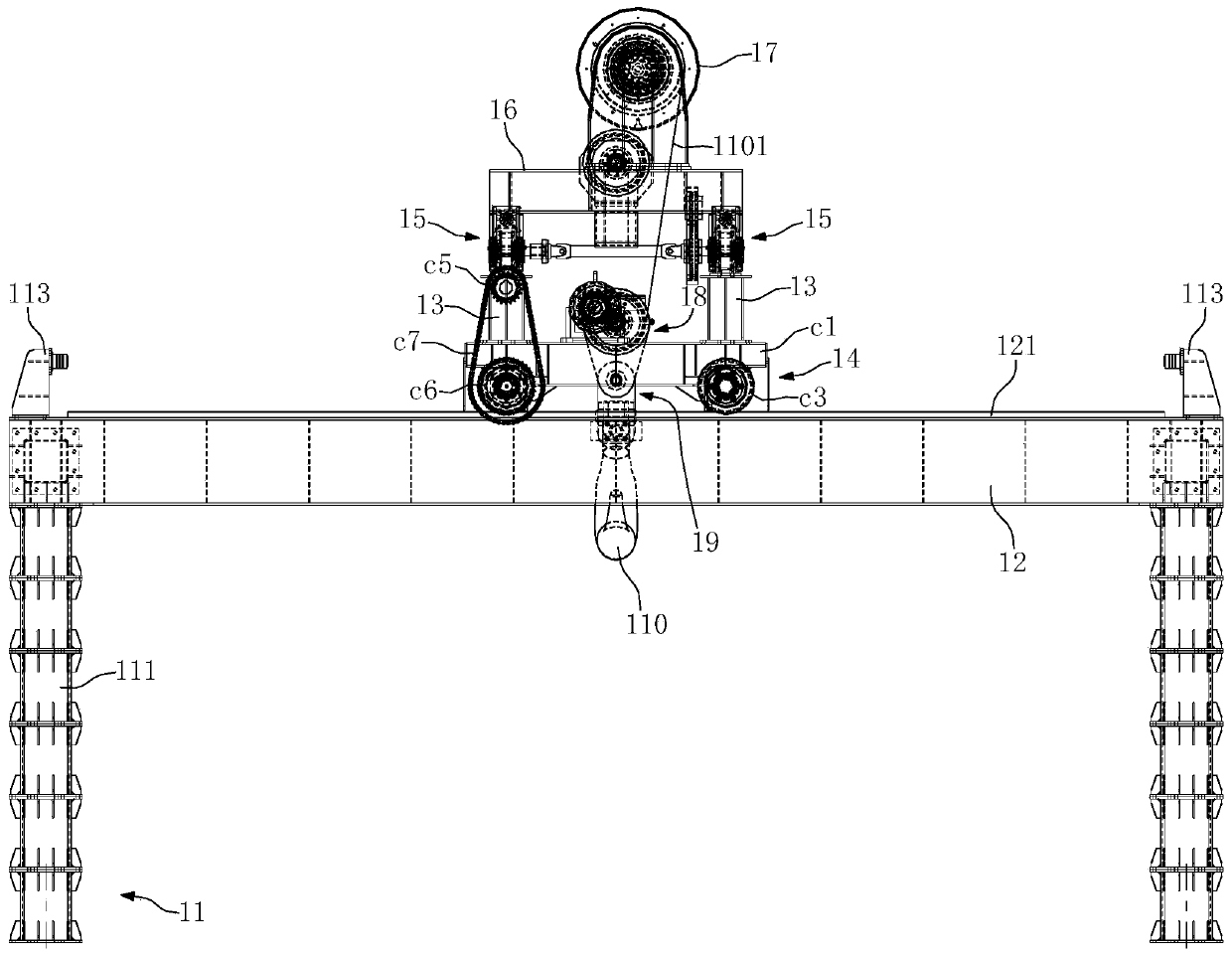

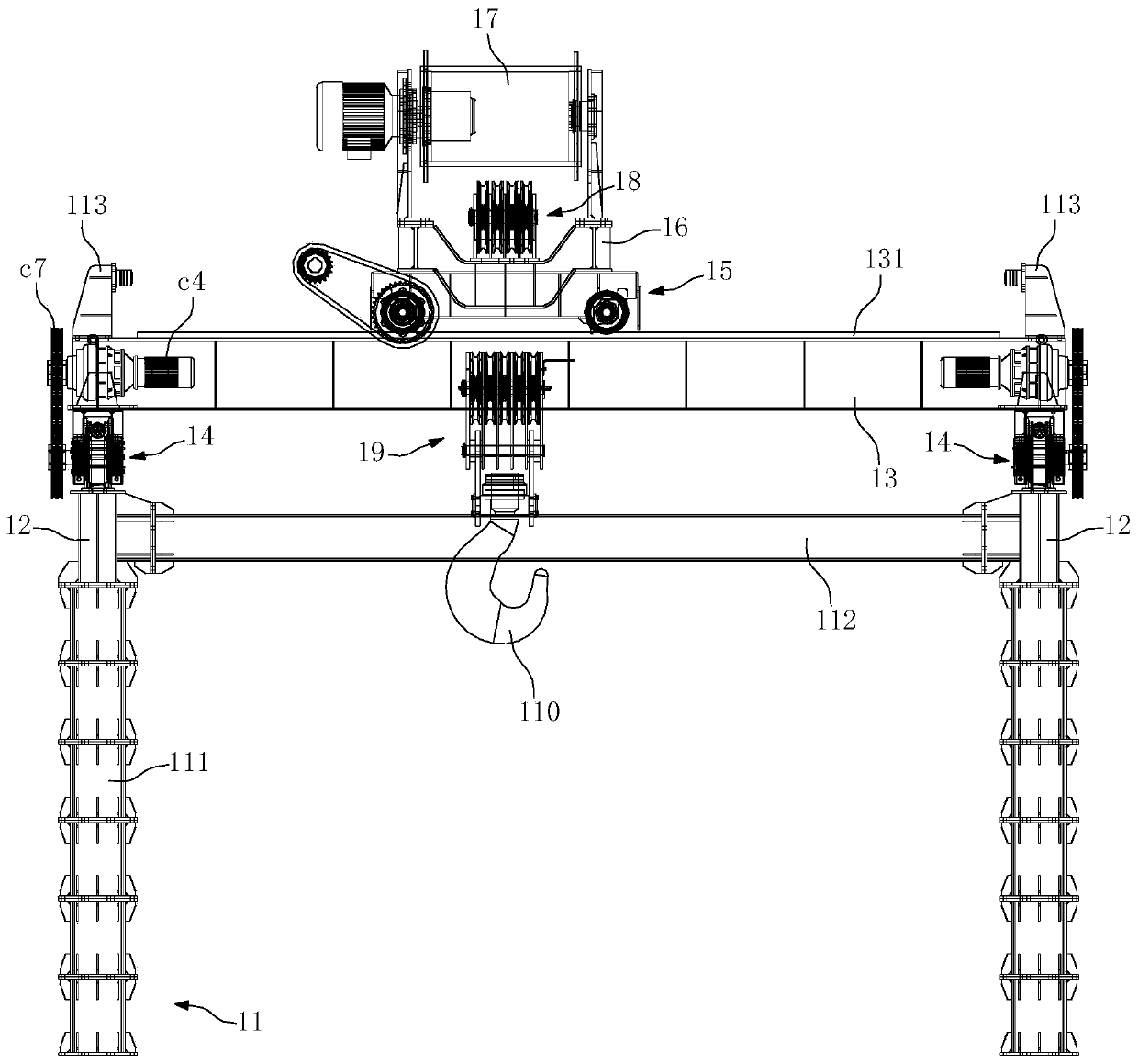

ActiveCN111255469AIntegrity guaranteedDisintegrates quicklyTunnelsUnderground transportSUSPENDING VEHICLEShield tunneling

The invention discloses a modular disassembly construction method for a shield tunneling machine in a closed narrow space. The modular disassembly construction method comprises the steps that components of the shield tunneling machine are sequentially disassembled and placed on a tunnel transport vehicle, then the components are transported to a shield lower wellhead through the tunnel transport vehicle, and finally the components are hoisted out through a crane outside the shield lower wellhead. The modular disassembly construction method is suitable for the working condition that a reservedhoisting hole does not exist in the receiving end of a shield tunnel and the hoisting condition of the shield tunneling machine is not met, the disassembled components are placed on the tunnel transport vehicle, the tunnel transport vehicle drives the components of the shield tunneling machine to go back to the shield lower wellhead to be hoisted out, the technical problem and the safety problem of disassembly construction of the shield tunneling machine in the closed narrow space are solved, and the shield tunneling machine enters and exits from the same tunnel portal. The designed bending-moment-resistant guide beam movable type gantry crane for assisting in disassembly of the shield tunneling machine is used for assisting, a winch on the gantry crane can move within the range of transverse and longitudinal beams, the hoisting range is wide, and hoisting of the components of the shield tunneling machine can be met.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Main oil seal demounting tool provided with handle sleeve and used for remanufacturing of automatic transmission

The invention relates to the technical field of automatic transmissions. A main oil seal demounting tool provided with a handle sleeve and used for remanufacturing of an automatic transmission comprises a base, a handheld rod and two pull rods used for penetrating into two inner cavities in a one-to-one correspondence manner. The handheld rod and the base are connected together through a connecting rod. One end of each pull rod is rotationally connected to the base in a hooking manner, and the other end of each pull rod is provided with a hook head, wherein the length of the hook heads is smaller than that of an opening but larger than the width of the opening, and the width of the hook heads is smaller than that of the opening. The handheld rod is provided with the handle sleeve. A threaded hole penetrating the base in the extending direction of the pull rods is formed in the base. The connecting rod is in threaded connection into the threaded hole. The two pull rods are symmetrically distributed on the two sides of the connecting rod. The main oil seal demounting tool provided with the handle sleeve and used for remanufacturing of the automatic transmission can be used for completely demounting a main oil seal, and the problem that the main oil seal can be taken down only after being broken in the remanufacturing process of the automatic transmission, and consequently the main oil seal cannot be reused is solved.

Owner:TAIZHOU HAILING HYDRAULIC MACHINERY

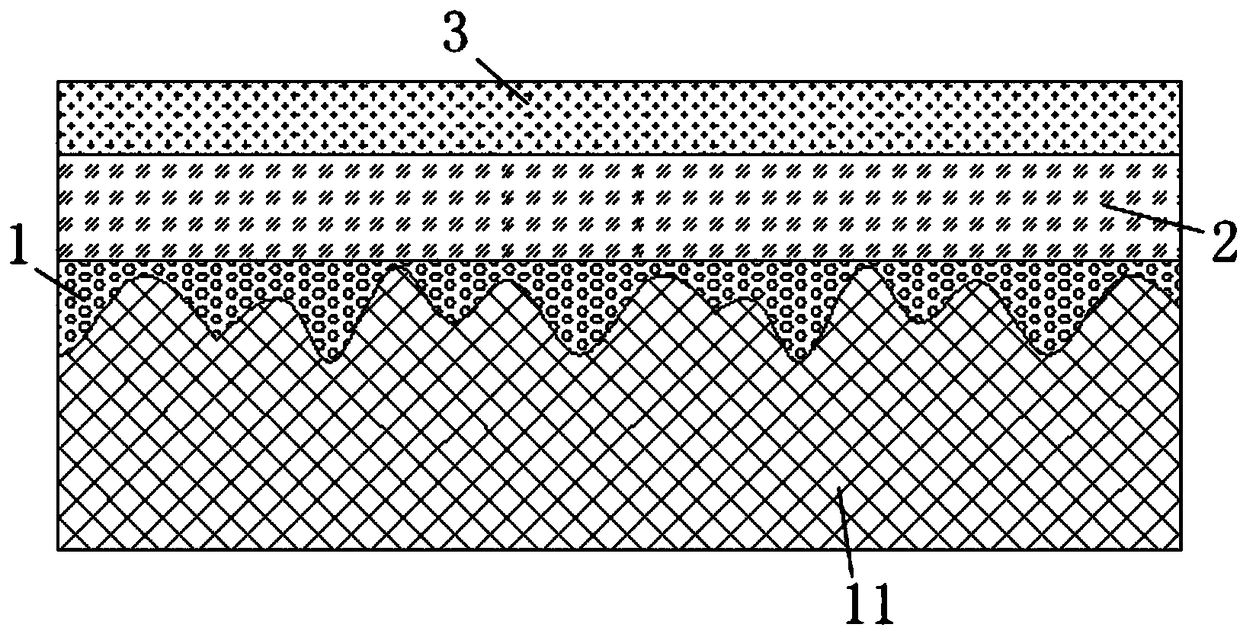

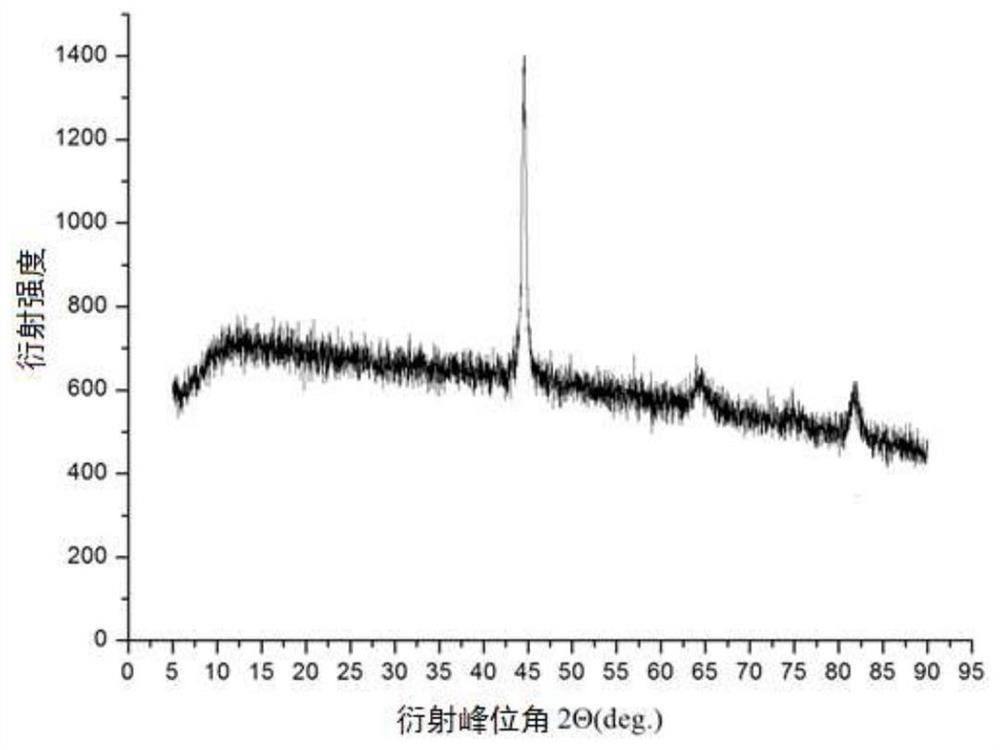

High-strength die steel remanufacturing method

ActiveCN107794527AQuality assuranceReduce remanufacturing costsSuperimposed coating processMicro nanoProtection layer

The invention relates to the technical field of die steel, in particular to high-strength die steel and a high-strength die steel remanufacturing method. The remanufacturing method comprises the following steps that a plurality of micro-nano grooves are formed in the surface of the high-strength die steel; metal nanoparticles are solidified into the multiple micro-nano grooves, and a transition bottom layer is formed on the surface of the high-strength die steel; iron-base alloy powder is fused on the transition bottom layer to form a fusion covering middle layer; and an outermost protection layer is arranged on the fusion covering middle layer, and at least one of silicon nitride and silicon carbide is contained in the outermost protection layer. According to the remanufacturing method, the high-strength die steel remanufacturing quality can be guaranteed, the high-strength die steel can be used in serious working environment, and the application scope of the high-strength die steel is enlarged; in addition, the remanufacturing cost of the high-strength die steel can be reduced, energy consumption is reduced, and the production efficiency is improved; and the corrosion resistancecan be improved, the material residual stress and brittleness are reduced, and the service life of the die steel under various working conditions is prolonged.

Owner:JIANGSU XIANGHE ELECTRONICS SCI & TECH

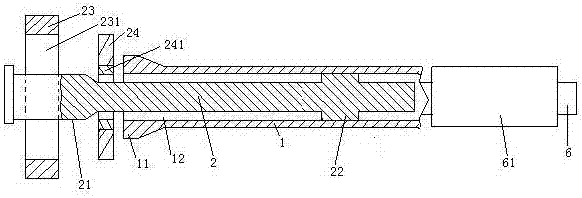

Portable Left Half Shaft Flange Bearing Installation Tool for Automatic Transmission Remanufacturing

ActiveCN105690064BEasy to installNot easy to damageMetal working apparatusLeft halfAutomatic transmission

The invention relates to the technical field of remanufacturing of automatic transmissions. A conveniently-held left half shaft flange bearing installation tool for remanufacturing of an automatic transmission is characterized by comprising a pushing rod; a knocking section is arranged at one end of the pushing rod, and the diameter of the knocking section is smaller than that of a shaft hole, used for installation of a bearing, of a flange; a receding hole which penetrates through the end surface of the knocking section, extends in the length direction of the pushing rod and allows a left half shaft to be inserted therein is arranged in the pushing rod, and the diameter of the receding hole is smaller than the outer diameter of an inner ring of the bearing; and a handheld rod is arranged at the other end of the pushing rod. By means of the conveniently-held left half shaft flange bearing installation tool for remanufacturing of the automatic transmission, the bearing can be conveniently installed between the left half shaft and the flange, and the problem that in the remanufacturing process of the automatic transmission, the bearing is inconvenient to install on the left half shaft to support the flange is solved.

Owner:苏州盛泽科技创业园发展有限公司

Re-manufacturing method for direct laser cladding of failed carburized quenching piece

The invention discloses a re-manufacturing method for direct laser cladding of a failed carburized quenching piece. The method comprises the following specific steps that (1), surface treatment is carried out, specifically, surface treatment is performed on the surface of a base body of the failed carburized quenching piece, so that the surface is kept clean and is free of an oxide layer; (2), laser cladding is carried out, specifically, according to a matrix material, a cladding material is selected, a cladding device is selected, process parameters during cladding are set, and laser claddingre-manufacturing repair is carried out on the surface of the treated failed carburized quenching piece; and (3), inspection is carried out, specifically, crack detection and hardness detection are carried out on the carburized quenching piece. When the laser cladding is carried out in the step (2), the used re-manufacturing repair material is a powder material and has a particle size of 150 meshes to 270 meshes; and the repair material comprises the following components of, in percentage by mass, 0.1 wt.%-0.17 wt.% of C, 15 wt.%-18.5 wt.% of Cr, 0.3 wt.%-1.00 wt.% of Mn, 1.0 wt.% -1.5 wt.% ofSi, 1.2 wt.%-2.0 wt.% of Mo, 0.8 wt.%-1.50 wt.% of B, 1.2 wt.%-2.0 wt.% of Ni, and the balance Fe. According to the re-manufacturing method, laser cladding can be carried out without removing a carburized layer, a cladding layer is free of cracks, the forming process is good, and meanwhile, the cladding layer has excellent wear resistance.

Owner:泰尔(安徽)工业科技服务有限公司

Main oil seal mounting tool with holding rod for remanufacturing of automatic gearbox

ActiveCN105619326AEasy to installAvoid breakingMetal-working hand toolsAutomatic transmissionPetroleum engineering

The invention relates to the technical field of remanufacturing of an automatic gearbox, in particular to a main oil seal mounting tool with a holding rod for remanufacturing of the automatic gearbox. The end face of a main oil seal is provided with an annular groove, and an outer sealing lip is formed on the outer side wall of the annular groove. The main oil seal mounting tool with the holding rod for remanufacturing of the automatic gearbox is characterized in that the tool comprises a push rod; a limiting ring is formed in the outer peripheral face of the push rod; the outer diameter of the limiting ring is larger than the outer diameter of the main oil seal; one end of the push rod is provided with a receding hole and a push ring; the diameter of the receding hole is larger than the inner diameter of the main oil seal; the inner diameter of the push ring is larger than the inner diameter of the annular groove; the diameter of the push ring is smaller than the outer diameter of the annular groove; and the holding rod is arranged at the other end of the push rod. The main oil seal mounting tool with the holding rod for remanufacturing of the automatic gearbox can mount the main oil seal conveniently and accurately, and the problem that the main oil seal is inconvenient to mount and not likely to be mounted in place accurately in the remanufacturing process of the automatic gearbox is solved.

Owner:HANGZHOU TENGHUA AUTOMOTIVE TRANSMISSION

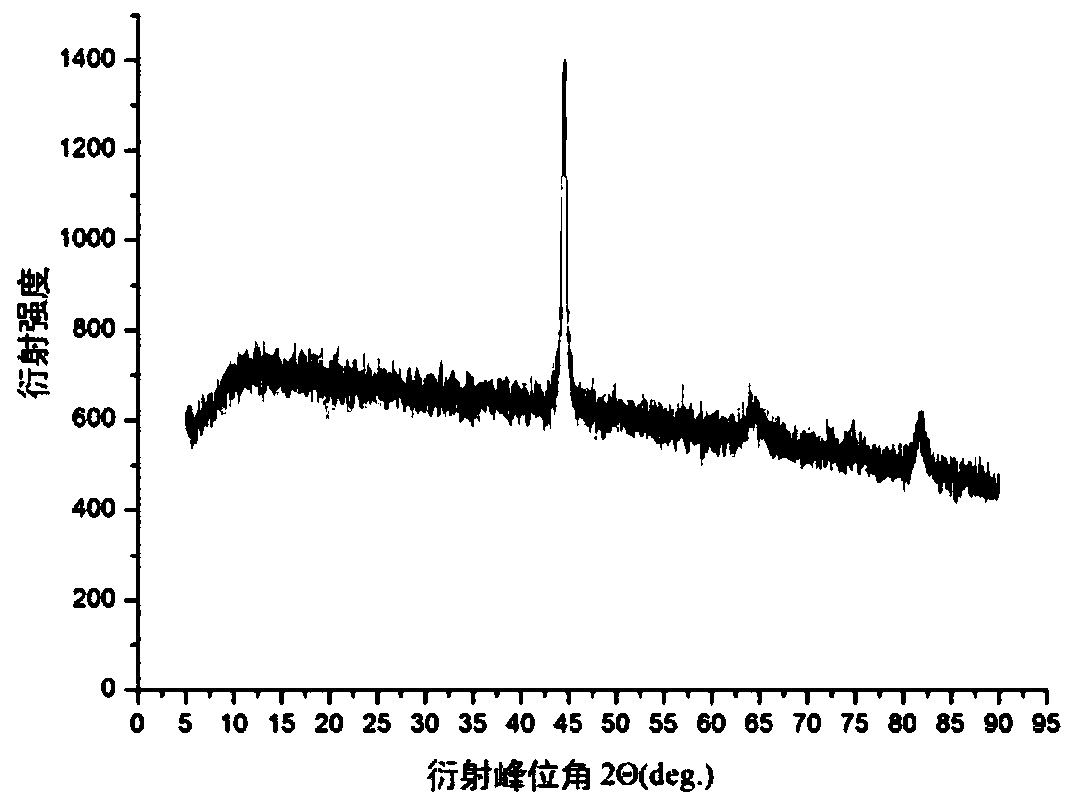

A method for repairing micro-crack tips on stainless steel surfaces using nanoparticles

ActiveCN105714286BImprove fracture performanceImprove reliabilityMetallic material coating processesHeat-affected zoneNanoparticle

The invention provides a method for repairing a microcrack tip on a stainless steel surface by means of nano-particles. The method is suitable for stainless steel with microcracks on the surface. The method comprises the steps that the to-be-repaired microcrack tip on the stainless steel surface is treated; composite powder containing the nano-particles is arranged on the microcrack tip in advance; the composite powder and a part of a matrix are fused by means of lasers; the repaired microcrack tip region is finished; and the fracture property of the stainless steel matrix obtained after repairing is detected, and the microstructure of the section of a repair layer is observed. The repairing method is high in flexibility, and repairing can be carried out many times; and meanwhile, the problems of large deformation, a large heat affected zone and the like in a conventional method are avoided in the repairing method. According to the repairing method, the microcrack tip is closed again, the matrix and the composite powder arranged on the microcrack tip in advance are in metallurgical bonding, and the defects of cracks, pores and the like do not exist in the bonding region; grains of the repair layer of the microcrack tip are refined, and the structural compactness is improved; and in addition, the fracture property generated after repairing is remarkably improved.

Owner:DALIAN UNIV OF TECH

Customized laser intelligent rapid deposition method for remanufacturing of railway train wheel pair

ActiveCN107190258AExtended service lifeLow costMetallic material coating processesNondestructive testingPart type

The invention provides a customized laser intelligent rapid deposition method for remanufacturing of a railway train wheel pair, and belongs to the train wheel pair repairing field so as to solve the problems that according to a current manner, the repairing effect is not ideal, the service life is short, and the railway transporting cost is high. The method comprises the steps that a damaged or failure wheel and axle component are subjected to damage situation checking, and the damage failure degree and generation factors are determined; according to the checking result, the part types and materials and the using requirement, the whole life cycle of the components is determined; according to the checking result, the part types and materials, the using requirement and the whole life cycle, alloy materials used for remanufacturing of the components are designed; a to-be-repaired part is thoroughly cleaned, a semiconductor laser machine and a single-arm robot are adopted for depositing the alloy materials to the to-be-repaired part; the single-arm robot guides laser beams to deposit the alloy materials with the speed of 480-800 mm / min; and the remanufactured components are recovered to the original designed and manufactured specification and dimension, nondestructive testing and hardness detection are conducted, and accordingly the technology standard requirement of the components is met.

Owner:葫芦岛科大耐磨材料研究院有限公司

Torque converter turbine oil seal mounting tool with holding rod for remanufacturing of automatic gearbox

ActiveCN105619325AEasy to installAvoid breakingMetal-working hand toolsAutomatic transmissionTurbine

The invention relates to the technical field of remanufacturing of an automatic gearbox, in particular to a torque converter turbine oil seal mounting tool with a holding rod for remanufacturing of the automatic gearbox. The torque converter turbine oil seal mounting tool comprises a push rod; an oil seal comprises an oil seal body and an annular sealing lip arranged on the radial outer side of the end face of the oil seal body; a column head, a first convex ring and a second convex ring are sequentially arranged at one end of the push rod; the diameter of the column head is smaller than the inner diameter of the oil seal body; the length of the column head is larger than or equal to the axial length of the oil seal body; the outer diameter of the first convex ring is smaller than the inner diameter of the sealing lip; the axial length of the first convex ring is equal to the axial length of the sealing lip; the outer diameter of the second convex ring is larger than the inner diameter of the sealing lip and smaller than or equal to the outer diameter of the sealing lip; and the holding rod is arranged at the other end of the push rod. The torque converter turbine oil seal mounting tool with the holding rod for remanufacturing of the automatic gear box can mount the oil seal with the sealing lip into a hydraulic torque converter turbine conveniently and the problem that the oil seal of the hydraulic torque converter turbine is inconvenient to mount in the remanufacturing process of the automatic gearbox is solved.

Owner:苏州盛泽科技创业园发展有限公司

Remanufacturing method of high strength die steel

ActiveCN107794527BQuality assuranceReduce remanufacturing costsSuperimposed coating processMicro nanoProtection layer

The invention relates to the technical field of die steel, in particular to high-strength die steel and a high-strength die steel remanufacturing method. The remanufacturing method comprises the following steps that a plurality of micro-nano grooves are formed in the surface of the high-strength die steel; metal nanoparticles are solidified into the multiple micro-nano grooves, and a transition bottom layer is formed on the surface of the high-strength die steel; iron-base alloy powder is fused on the transition bottom layer to form a fusion covering middle layer; and an outermost protection layer is arranged on the fusion covering middle layer, and at least one of silicon nitride and silicon carbide is contained in the outermost protection layer. According to the remanufacturing method, the high-strength die steel remanufacturing quality can be guaranteed, the high-strength die steel can be used in serious working environment, and the application scope of the high-strength die steel is enlarged; in addition, the remanufacturing cost of the high-strength die steel can be reduced, energy consumption is reduced, and the production efficiency is improved; and the corrosion resistancecan be improved, the material residual stress and brittleness are reduced, and the service life of the die steel under various working conditions is prolonged.

Owner:JIANGSU XIANGHE ELECTRONICS SCI & TECH

A method for predicting the timing of mechanical equipment remanufacturing

ActiveCN108241909BDegree of control failureEasy to remanufactureForecastingManufacturing computing systemsFailure rateDecision model

Owner:CHANGAN UNIV

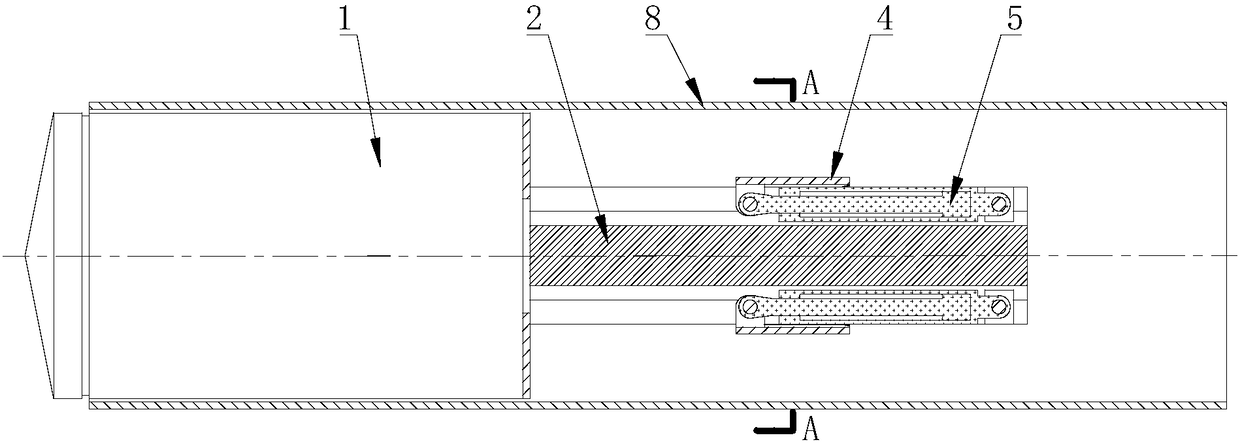

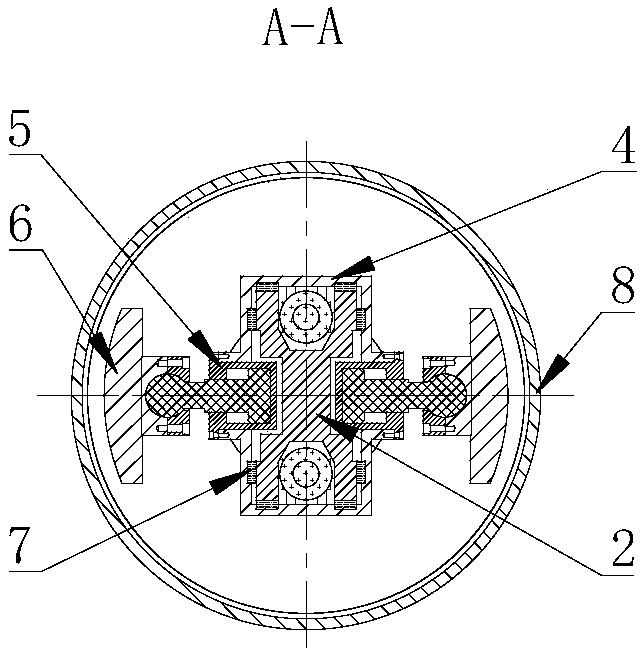

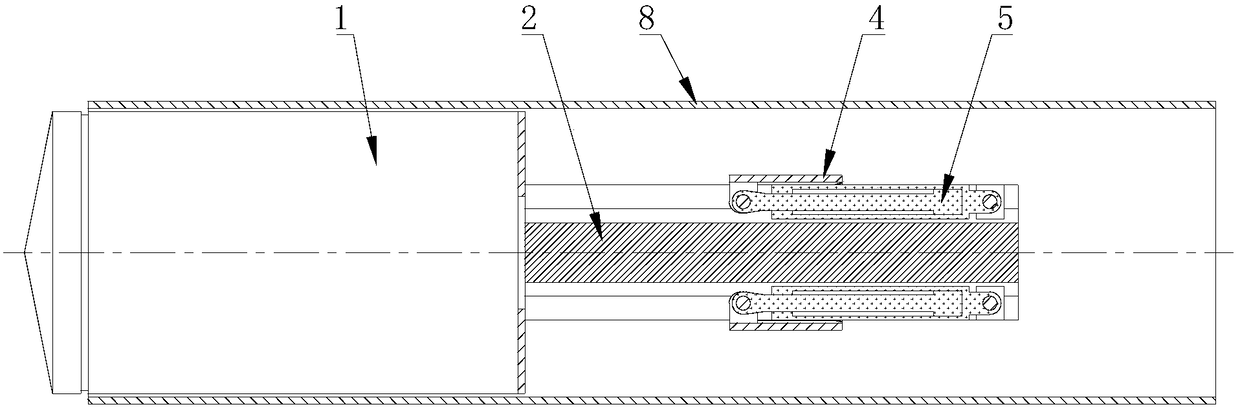

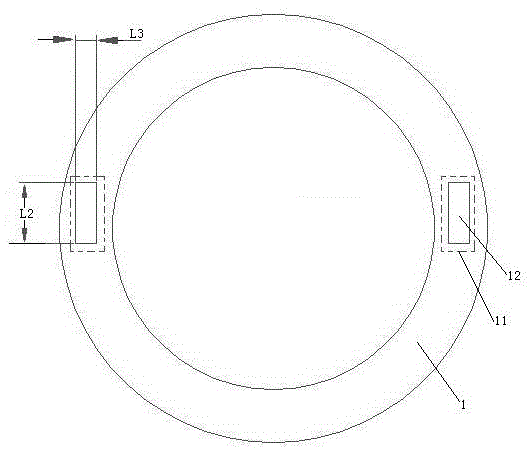

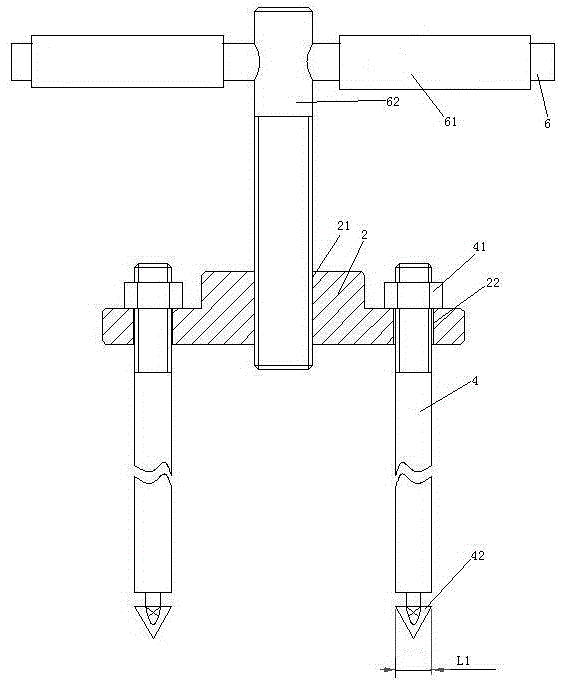

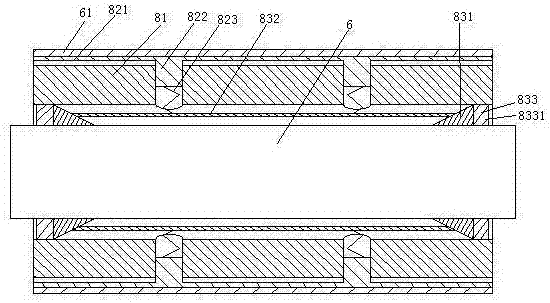

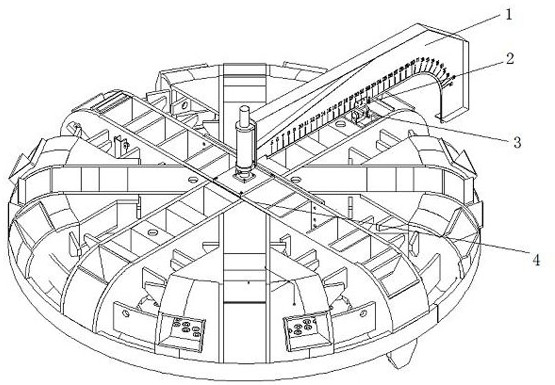

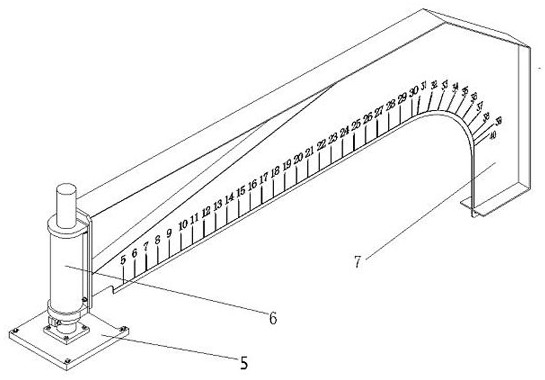

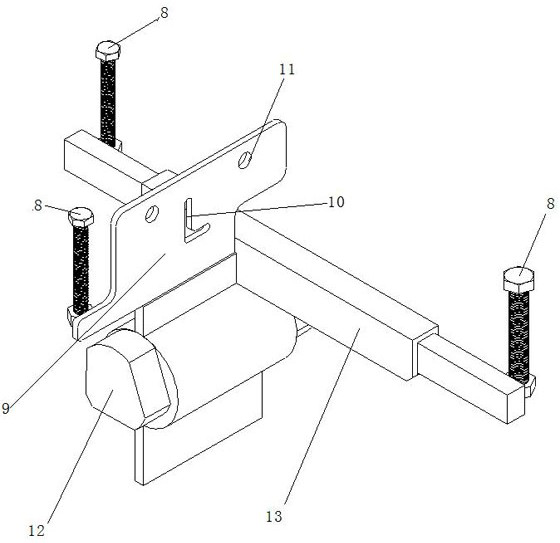

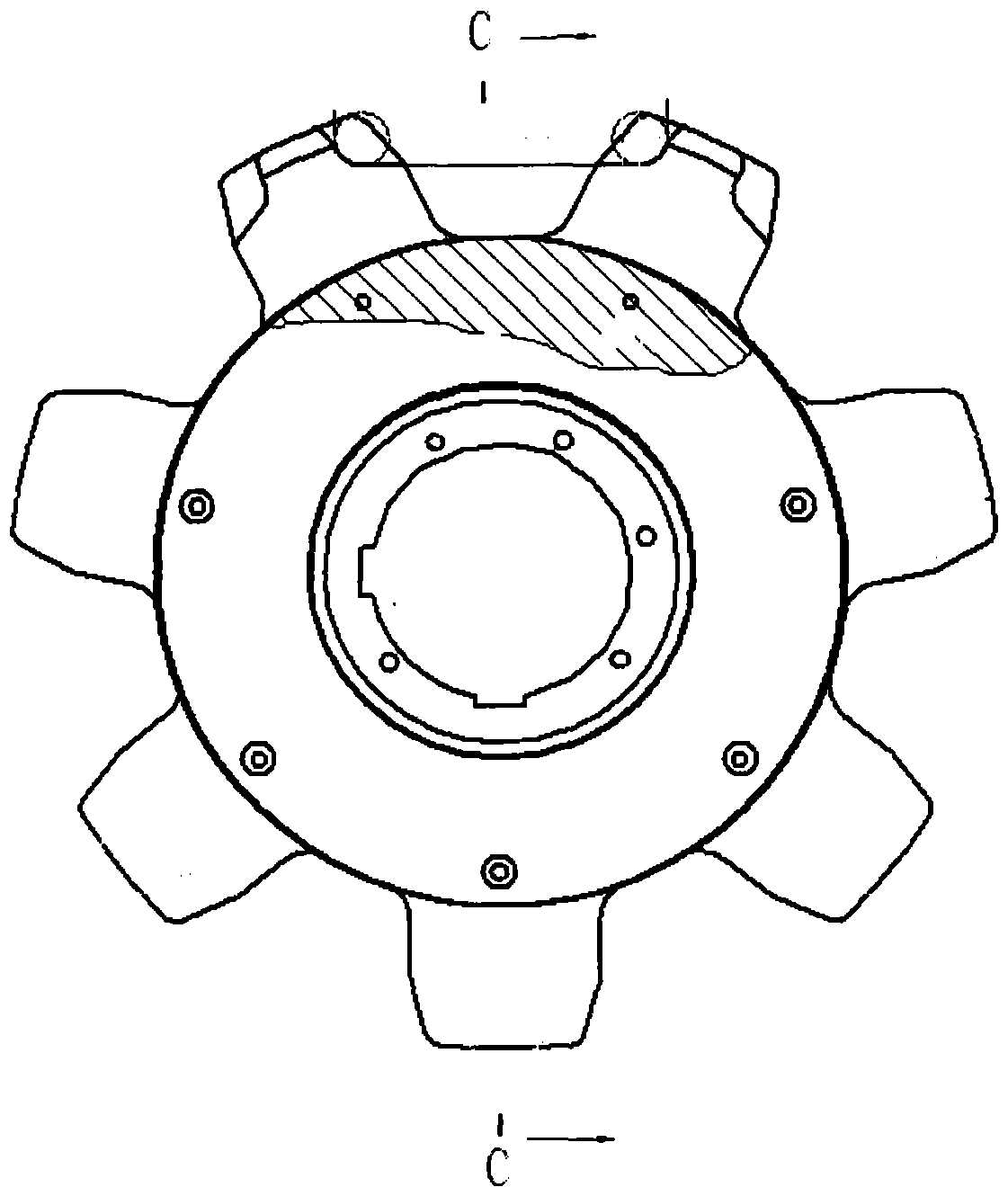

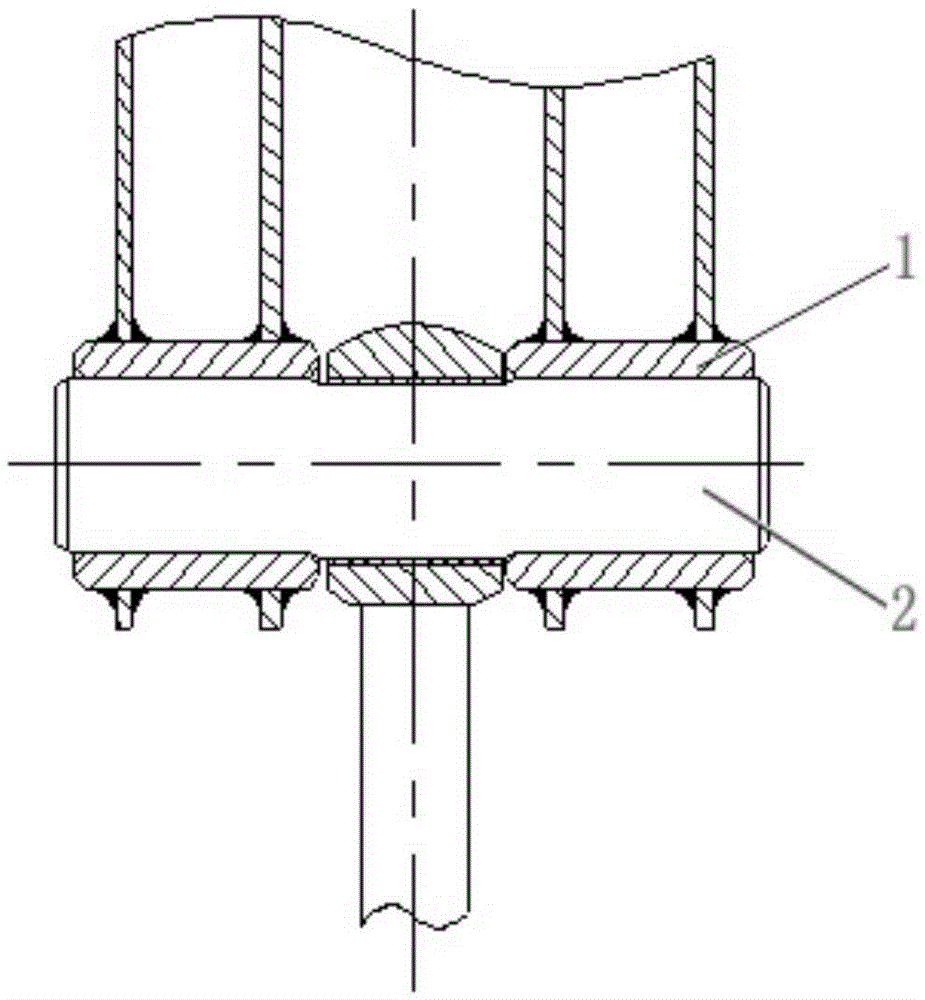

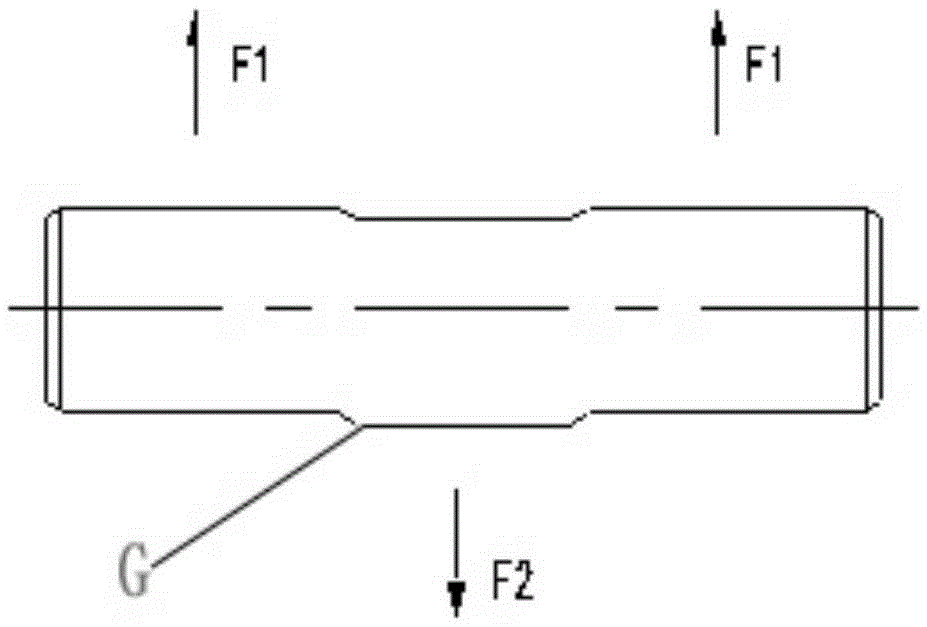

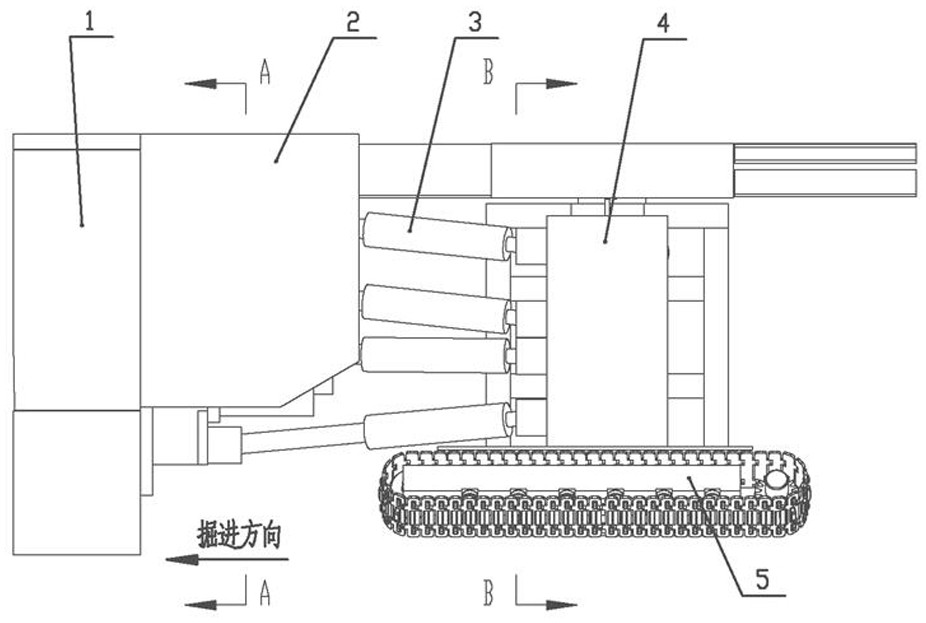

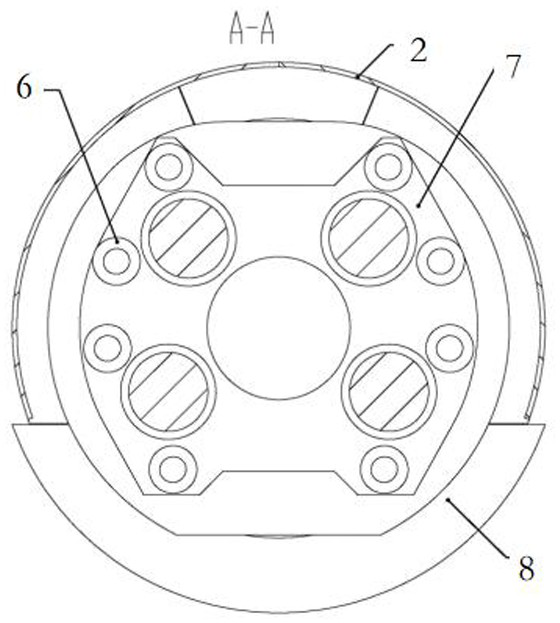

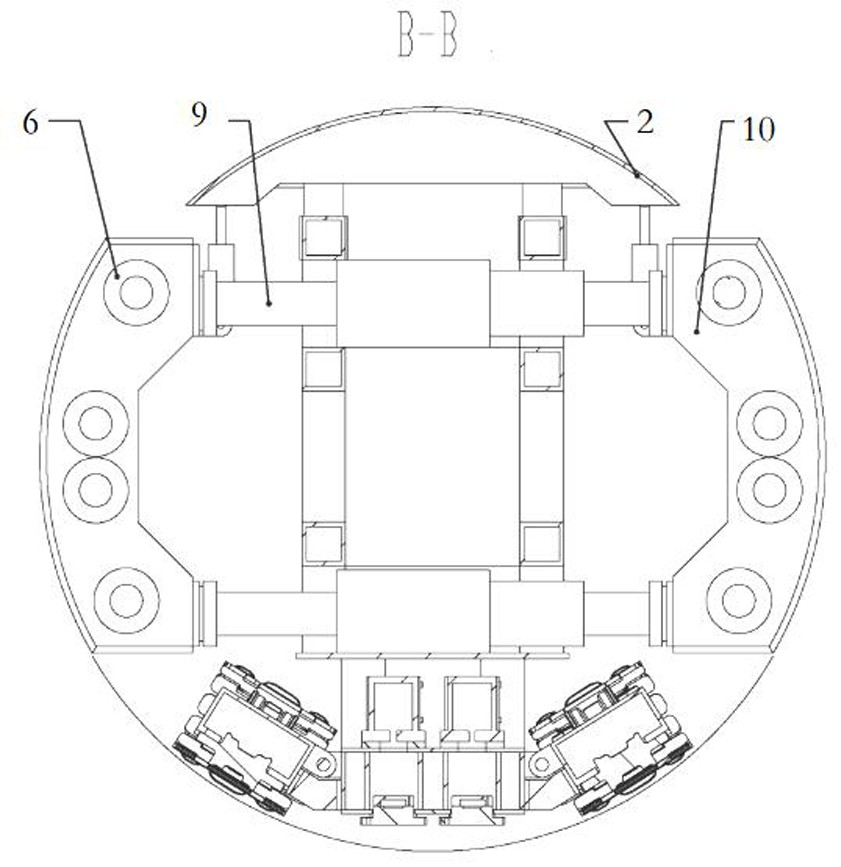

A tbm cutter head hob cutter seat replacement positioning detection device

ActiveCN110625554BReduce remanufacturing costsSimple structureWelding/cutting auxillary devicesWork holdersRotational axisHobbing

The invention belongs to the technical field of remanufacturing of a tunnel boring machine (TBM), and relates to a positioning and detecting device for replacement of a cutter bed of a hobbing cutteron a cutter head of the tunnel boring machine. The provided positioning and detecting device for replacement of the cutter bed of the hobbing cutter on the cutter head of the tunnel boring machine hasa rotating shaft arranged at the center of the cutter head; a horizontal rule is connected to the rotating shaft; a vertical scale line for the standard cutter space of the hobbing cutter on the cutter head of the tunnel boring machine, and a horizontal scale line are marked on the horizontal rule; the positioning and detecting device is also provided with a fake cutter tool for being placed in asquare hole of a cutter box on the cutter head; the two ends of a fake cutter shaft of the fake cutter tool are respectively supported on a left base and a right base; a perforated faceplate is welded on the fake cutter shaft; the lower end of the perforated faceplate is welded at the middle part of the upper end surface of a cutter shaft; a slot is formed in the left lower end of the upper end surface of the perforated faceplate; an ejection lead screw parallel to the left base is welded in the slot; and an L-shaped through hole is formed in the perforated faceplate. The positioning and detecting device ensures the installation accuracy, improves the replacement efficiency of a new cutter bed, and reduces the remanufacturing cost of the cutter head of the TBM.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Lipped oil seal installation tool with grip bar for automatic transmission remanufacturing

ActiveCN105619324BEasy to installAvoid breakingMetal-working hand toolsAutomatic transmissionEngineering

The invention relates to the technical field of remanufacturing of an automatic gearbox, in particular to a mounting tool with a holding rod for an oil seal with a lip side for remanufacturing of the automatic gearbox. The mounting tool comprises a push rod; one end of the push rod is sequentially provided with a column head, a first convex ring and a second convex ring; the diameter of the column head is smaller than the inner diameter of the oil seal; the outer diameter of the first convex ring is smaller than or equal to the outer diameter of the oil seal; an annular groove containing the lip side is formed in the end face of the first convex ring; the outer diameter of the second convex ring is larger than the outer diameter of the oil seal; the distance between the first convex ring and the second convex ring is equal to the depth that the oil seal needs to be mounted inside a part for mounting the oil seal of the gearbox; the other end of the push rod is provided with the holding rod, and a receding hole for containing a shaft head in a hole of the part for mounting the oil seal of the gearbox is formed in the end face of the column head. The mounting tool with the holding rod for the oil seal with the lip side for remanufacturing of the automatic gearbox can mount the oil seal with the lip side conveniently, and the problem that the oil seal with the lip side is inconvenient to mount in the remanufacturing process of the automatic gearbox is solved.

Owner:HANGZHOU TENGHUA AUTOMOTIVE TRANSMISSION

Remanufacturing Method of Main Bearing Hole of Engine Cylinder Block Assembly

ActiveCN103447903BAchieve remanufacturingSimple processHoning machinesPlane surface grinding machinesCrankcaseEngineering

The invention discloses a reproducing method of a main bearing hole of an engine cylinder block assembly, belongs to the field of engine reproducing technologies, and is characterized in that a combination surface of a main bearing seat of a cylinder block is taken as a reference, an amount of finish of 0.02-0.10 mm is eliminated from the combination surface of the main bearing seat of the cylinder block, and requirements of a form and location tolerance of the main bearing seat of the cylinder block are ensured; a combination surface of a main bearing seat of a crankcase is taken as a reference, an amount of finish of 0.02-0.10 mm is eliminated from the combination surface of the main bearing seat of the crankcase; the cylinder block and the crankcase are assembled together through a main bearing bolt so as to form a cylinder block assembly; each main bearing hole of the engine cylinder block assembly is honed, and honing of the main bearing holes needs to be synchronously carried out so as to ensure each technological requirement of the main bearing holes of the engine cylinder block assembly. The reproducting method has the advantages of simple process, no potential hidden trouble of a brush plating manner, and capability of realizing reproduction of the engine cylinder block assembly with the problem of the size out-of-tolerance of the main bearing holes.

Owner:WEICHAI POWER CO LTD

Modular dismantling construction method of shield machine in confined and narrow space

ActiveCN111255469BSolve technical problemsFix security issuesTunnelsUnderground transportStringerShield tunneling

The invention discloses a modular disintegration construction method in a confined and narrow space of a shield machine. The components of the shield machine are sequentially removed, placed on a tunnel transport vehicle, and then transported to the shield tunnel by the tunnel transport vehicle. At the wellhead, it is finally hoisted out by a crane outside the wellhead under the shield. The invention is applicable to the working condition that there is no hoisting hole reserved at the receiving end of the shield tunnel and the conditions for hoisting the shield machine are not available. By placing the disassembled components on the tunnel transport vehicle, the tunnel transport vehicle carries the shield The various components of the tunneling machine go back and forth and go back to the lower wellhead of the shield machine to be hoisted out, which solves the technical and safety problems of the shield machine dismantling and constructing in a confined and narrow space, and realizes the shield machine entering and exiting at the same tunnel entrance . The designed auxiliary anti-moment guide beam movable door crane assists the dismantling of the shield machine, and the hoist on it can move within the range of the transverse and longitudinal beams, and the lifting range is wide, which can meet the lifting and transportation of the components of the shield machine.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

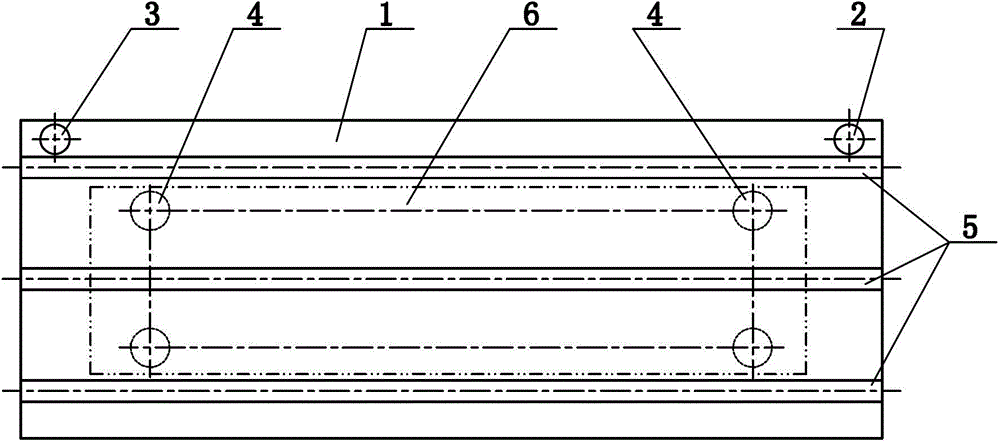

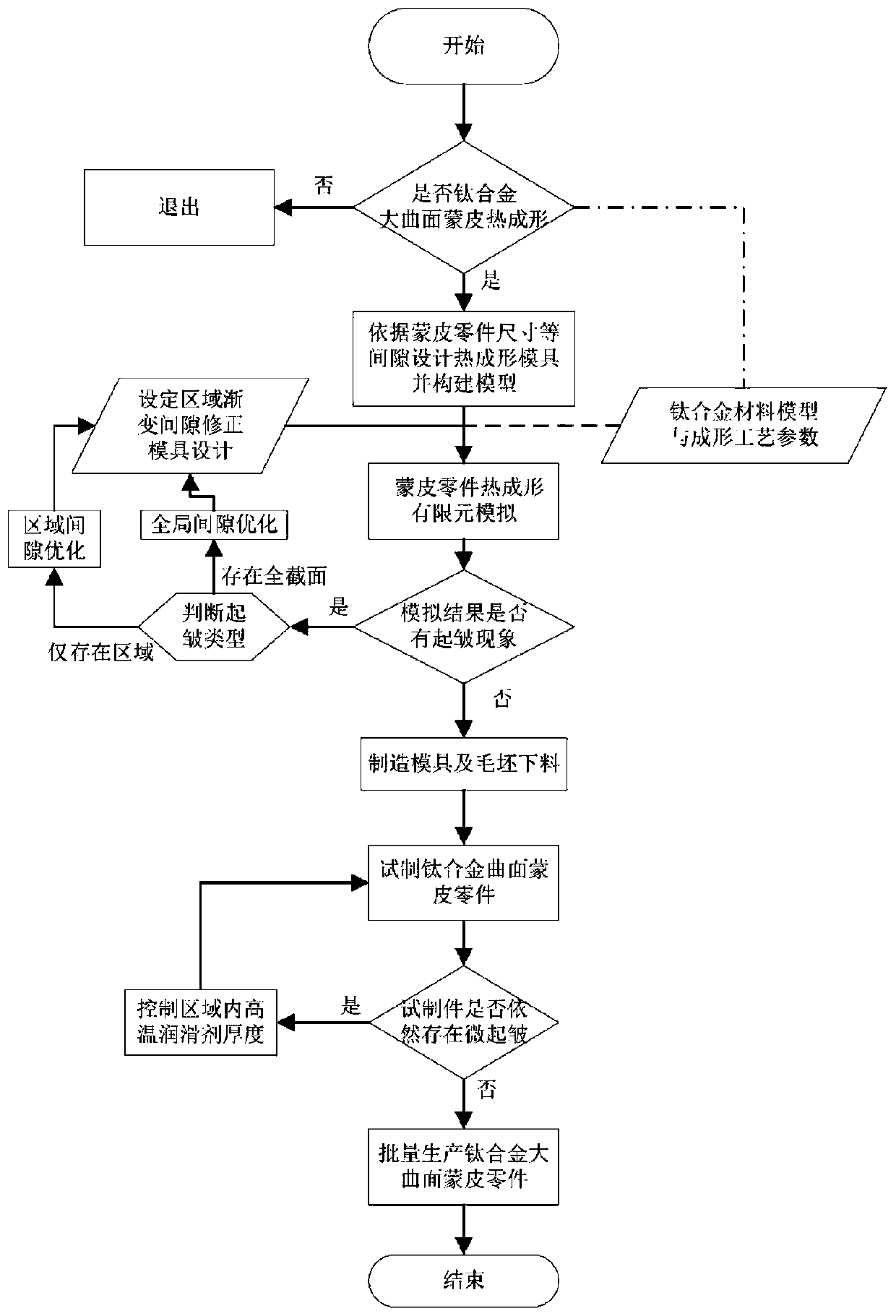

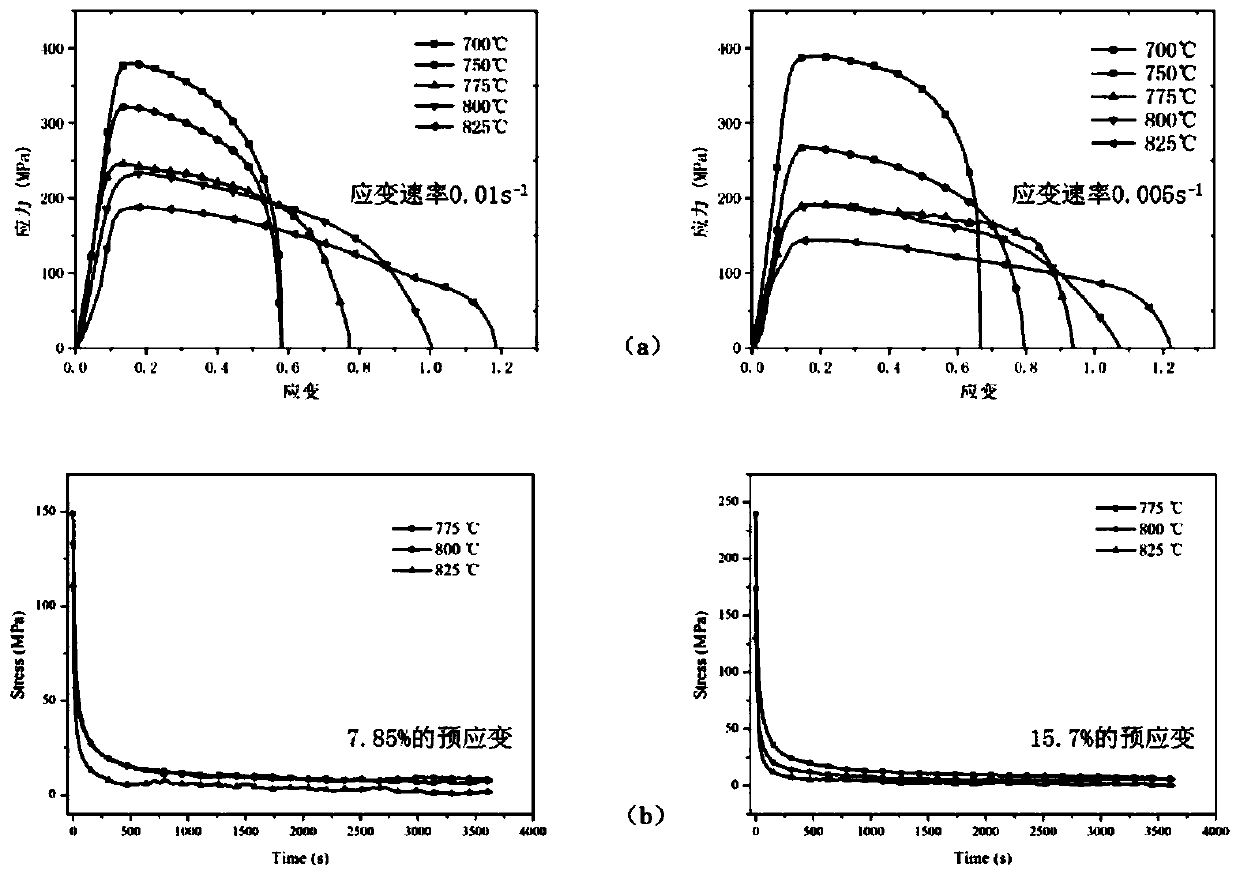

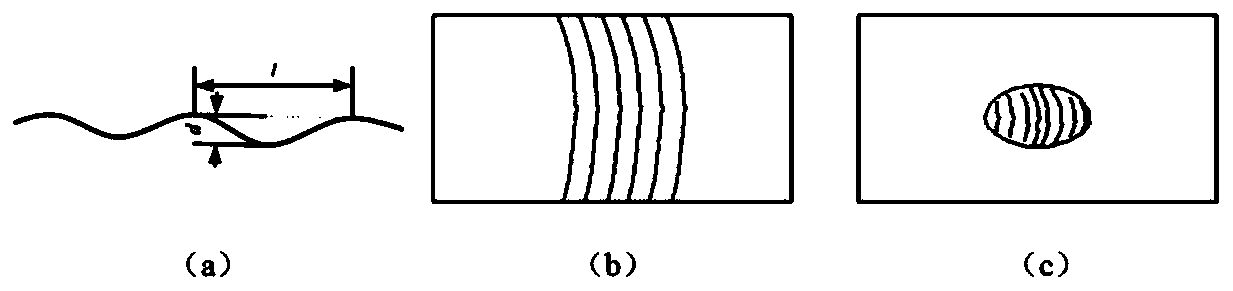

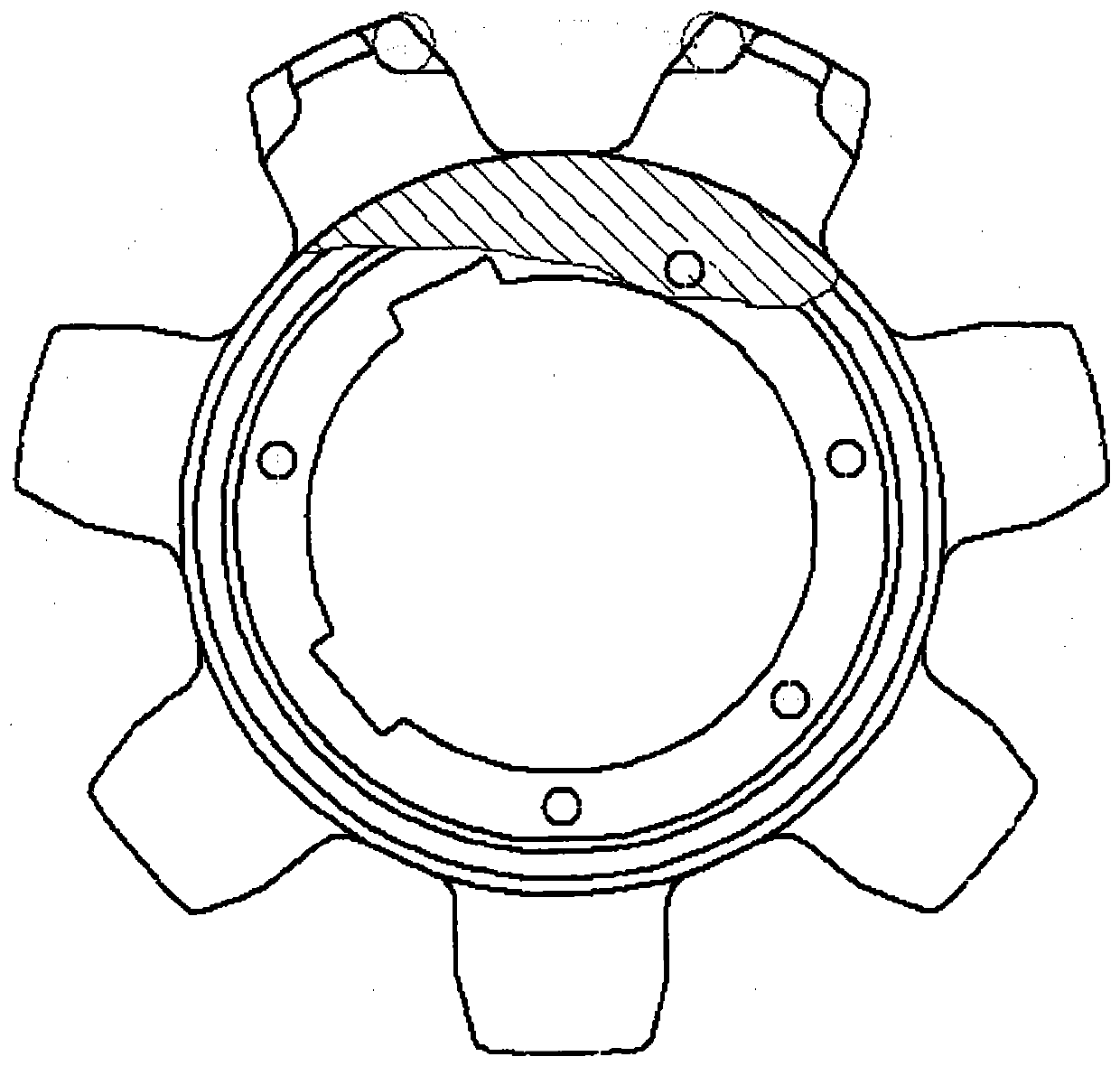

A Method of Eliminating Wrinkling of Large Curved Surface Based on Gradient Gap Die

The invention discloses a method of eliminating skin wrinkles of a large surface based on a gradient gap die and belongs to the field of techniques of removing skin formation wrinkles. Batch production of high-quality skin can be implemented herein by optimally designing die gaps and manufacturing; the method herein is applicable to the formation of skin parts of various high-intensity materials,particularly manufacturing of titanium alloy skin parts; pressure-pressure stress state is a main cause to wrinkling; gaps are reasonably designed, gradient frictional resistance is utilized to form acontrollable resistance field, and therefore, mobility during plate forming process is limited, the pressure-pressure stress state in plates is reduced, wrinkle removal is achieved, and high-qualityparts with corrugation meeting technical requirements are met. The method herein may be used as a new method to eliminate wrinkles in thermal formation of titanium alloy large-surface skin so as to obtain high-quality parts.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

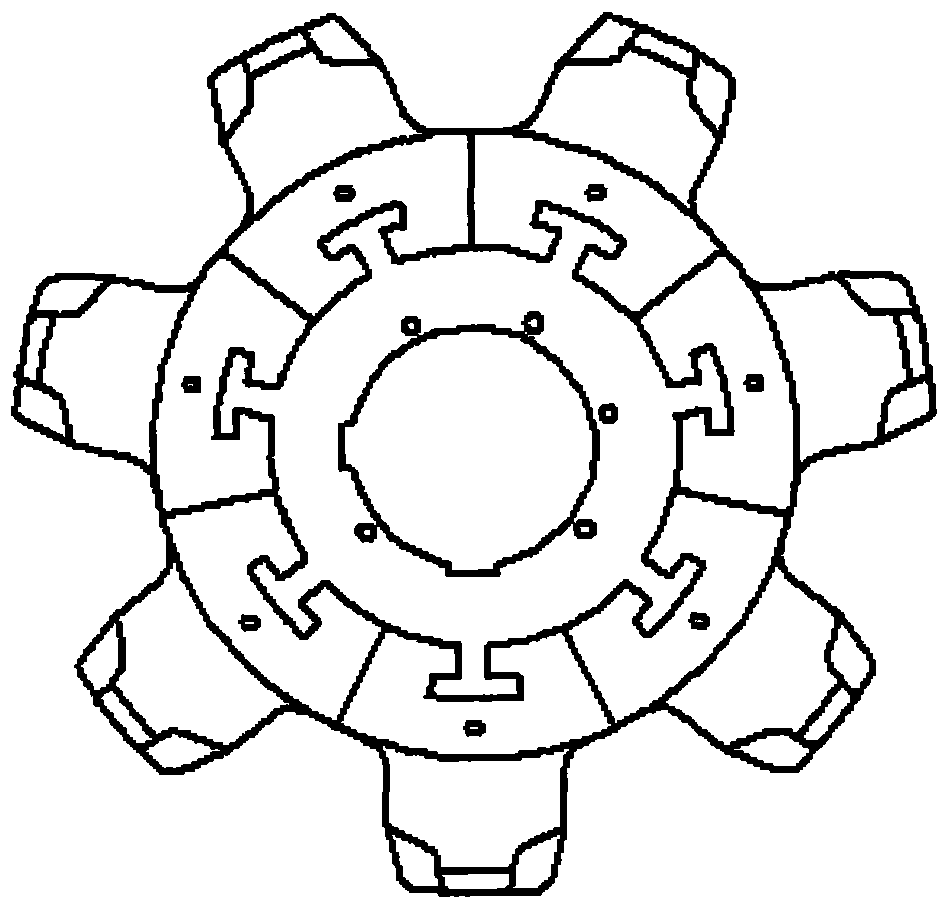

Manufacturing process of combined sprocket for scraper conveyor in coal mine

The invention relates to a coal mine scraper conveyor sprocket and a manufacturing process, in particular to a coal mine scraper conveyor combined sprocket and a manufacturing process. At present, the sprockets of scraper conveyors used in coal mines all have an overall structure of two or three rows of teeth. It is suitable for mass production, especially in the installation and use, when a certain tooth of the sprocket is broken or worn abnormally, the entire sprocket must be replaced, resulting in another waste of materials. The coal mine combined sprocket of the present invention is composed of a left end cover, a right end cover, a sprocket tooth block, a shaft sleeve, a positioning bolt, and a nut, and each component is consistent with the overall sprocket structure after production and assembly. In the present invention, the integral sprocket is improved into a combined type, and the tooth-shaped block of the sprocket is changed from the original machining to direct forging, which simplifies the process, improves the utilization rate of raw materials and reduces the remanufacturing cost.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

A dismantling process for deformed pin shaft of remanufactured concrete pump truck

ActiveCN103495833BRealize reuse valueReduce remanufacturing costsVehicle componentsMetal working apparatusEngineeringConcrete pump

The invention discloses a disassembly technology for remanufacturing a deformation hinge pin of a concrete pump truck. The disassembly technology comprises the following steps that (1) a hole is drilled in the axial center position of the deformation hinge pin and the diameter of the drilled hole is smaller than that of the hinge pin; (2) the method that a jack or a hammer is used for knocking the hinge pin wall after the hole is drilled is adopted, so that the deformation hinge pin is disassembled. When the diameter of the hinge pin is large, the hole is bored after being drilled, so that the hinge pin wall has a soft elastic structure after the hole is drilled. Under the condition that a shaft sleeve and a component body are not damaged, the reuse value of the shaft sleeve is achieved, the remanufacturing cost is effectively reduced, the procedures that the shaft sleeve is installed and welded again, a line is drawn, a shaft sleeve hole is machined are not needed, the production bottleneck is overcome, and the production efficiency is greatly improved.

Owner:HUNAN UNIV OF SCI & TECH

Portable tapered roller bearing race installation tool for automatic transmission remanufacturing

ActiveCN105710831BEasy to installAvoid breakingMetal-working hand toolsAutomatic transmissionEngineering

The invention relates to the technical field of automatic transmission reproducing. A portable tapered roller bearing race mounting tool for reproducing an automatic transmission is characterized by comprising a push rod, wherein one end of the push rod is provided with a tapered shaft head; the taper of the tapered shaft head is equal to that of a tapered roller bearing race; the root part of the tapered shaft head is provided with a pressing ring extending in a circumferential direction of the tapered shaft head; the diameter of the root part of the tapered shaft head is not larger than the internal diameter of the large diameter end of the tapered roller bearing race; and the other end of the push rod is provided with a holding rod. The invention provides the portable tapered roller bearing race mounting tool for reproducing the automatic transmission, which can conveniently mount the tapered roller bearing race; and a problem that the tapered roller bearing race is inconvenient to mount in the automatic transmission reproducing process is solved.

Owner:全椒康盛机电有限公司

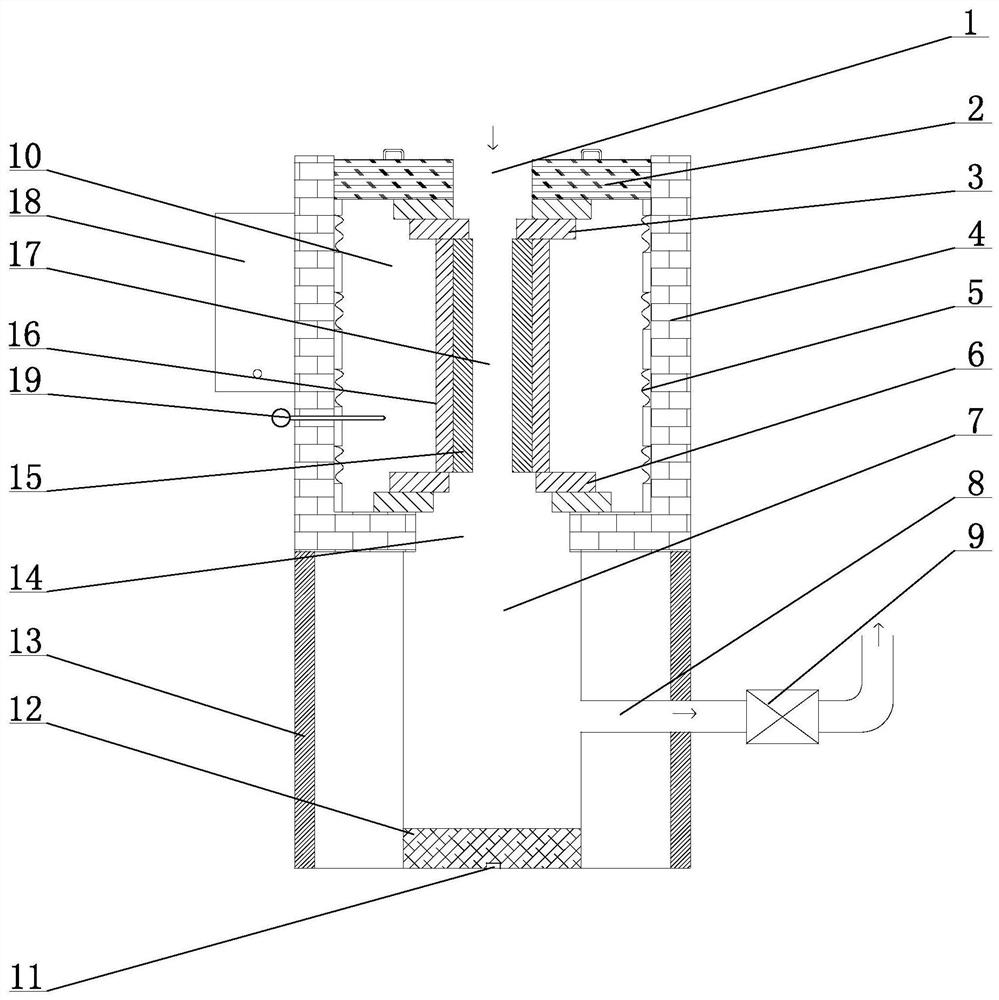

Interference fit composite cylinder sleeve disassembling furnace

PendingCN112235888ANot easy to damageReasonable structural designOhmic-resistance waterproof/air-tight sealsHeater elementsInterference fitBrick

The invention belongs to the field of remanufacturing disassembling equipment, and relates to an interference fit composite cylinder sleeve disassembling furnace which is used for disassembling a workpiece outer sleeve and a workpiece inner container and comprises a furnace lining, a furnace cover is arranged at the top of the furnace lining, a hearth is defined by the furnace cover and the furnace lining, and the workpiece outer sleeve and the workpiece inner container are arranged in the hearth; a heating element is arranged on the inner wall of the furnace lining, an upper reducing brick and a lower reducing brick are arranged in the hearth, the upper reducing brick is arranged between the workpiece outer sleeve and the furnace cover, the lower reducing brick is arranged below the workpiece outer sleeve, and the inner diameter of the lower reducing brick is larger than the outer diameter of the workpiece inner container; the furnace cover is provided with an air inlet, and the lowerwall of the furnace lining is provided with an air outlet; the air inlet and the air outlet are right opposite to an inner cavity of the workpiece inner container, and a ventilation mechanism is arranged below the furnace lining and comprises a draught fan. The workpiece outer sleeve is heated to expand by a heating method, the workpiece inner container naturally falls off, the workpiece is not easy to damage and can be reused, the remanufacturing cost is reduced, and the safety is high.

Owner:SHANDONG JIATENG IND CO LTD

Field remanufacturing method for upper seam allowance of cylinder body of marine diesel engine

The invention discloses a field remanufacturing method for an upper seam allowance of a cylinder body of a marine diesel engine. The field remanufacturing method includes the following steps that end face milling and rough machining are conducted; oil removing and rust removing are conducted; coating of a strengthening layer is conducted; end face milling and finish machining are conducted; end face grinding is conducted; and quality inspecting is conducted. An adopted coating method includes one-step method flame spray welding or induction melt coating. According to the field remanufacturing method for the upper seam allowance of the cylinder body of the marine diesel engine, the problem that difficulty and cost are high when the marine diesel engine is moved out of a cabin is solved, corrosion of the upper seam allowance of the cylinder body of the marine diesel engine is successfully repaired, the size of the upper seam allowance is recovered, the problem of water leakage between the cylinder body and a cylinder sleeve is solved, the remanufacturing cost is obviously reduced, the remanufacturing and maintaining period is greatly shortened, and obvious economic benefits are achieved.

Owner:河南汉工机械再制造技术有限公司

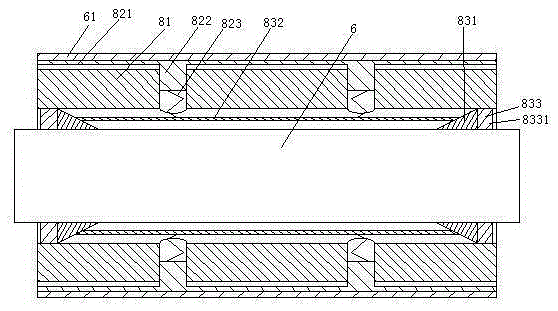

Propelling device for self-propelled tunnel boring machine

The invention relates to a propelling device for a self-propelled tunnel boring machine. The propelling device comprises a self-propelled base plate body, and an upper supporting shoe oil cylinder unit and a lower supporting shoe oil cylinder unit in parallel with the upper supporting shoe oil cylinder unit are installed on the self-propelled base plate body. Supporting shoes are installed on theupper supporting shoe oil cylinder unit and the lower supporting shoe oil cylinder unit, and the supporting shoes on the two sides are symmetrically arranged along the self-propelled base plate body.A telescopic shield and a front shield are sequentially installed on the front part of the self-propelled base plate body, a driving system is installed on the telescopic shield, and a propelling unitis installed between the driving system and supporting shoes on the two sides of the self-propelled base plate body. The propelling device for the self-propelled tunnel boring machine has the advantages that the high tunneling speed can be achieved, an operator is safe away from a working face, the propelling device for the self-propelled tunnel boring machine can adapt to various geologies, thethrust of n oil cylinder is large, and the requirement for low-cost safe and rapid transition can be met through small-range disassembly.

Owner:中船重工(青岛)轨道交通装备有限公司

Remanufacturing Method of Direct Laser Cladding of Failed Carburized and Quenched Parts

The invention discloses a remanufacturing method for direct laser cladding of failed carburized and quenched parts. The specific steps are: ① surface treatment: surface treatment is performed on the surface of the base body of the failed carburized and quenched parts to keep the surface clean and free of oxide layers; ② Laser cladding: According to the base material, select the cladding material, select the cladding equipment, set the process parameters during cladding, and remanufacture and repair the surface of the treated invalid carburized and quenched parts by laser cladding; ③ Inspection: Crack detection and hardness testing of carburized and quenched parts. Step ② During laser cladding, the remanufactured repair material used is a powder material with a particle size of 150 mesh to 270 mesh; the mass fraction percentage of the components is as follows: C: 0.1~0.17wt.%; Cr: 15~18.5wt .%Mn: 0.3~1.00wt.%; Si: 1.0~1.5wt.%; Mo: 1.2~2.0wt.%; B: 0.8~1.50wt.%; Ni: 1.2~2.0, the balance being Fe. The remanufacturing method of the invention can carry out laser cladding without removing the carburized layer, has no cracks in the cladding layer, and has good forming manufacturability. At the same time, the cladding layer has excellent wear resistance.

Owner:泰尔(安徽)工业科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com